ASTM F1701-96(2001)

(Specification)Standard Specification for Unused Polypropylene Rope with Special Electrical Properties

Standard Specification for Unused Polypropylene Rope with Special Electrical Properties

SCOPE

1.1 This specification covers the requirements, sizes, construction, tests, and procedures for unused polypropylene ropes for use by electrical utilities and related industries on energized lines operating at voltages higher than 1 kV.

1.2 This specification covers the minimum electrical, mechanical, and physical properties guaranteed by the manufacturer and the detailed procedures by which such properties are to be determined. The purchaser has the option to perform or have performed any of these tests in order to verify the guarantee. Claims for failure to meet the specification are subject to verification by the manufacturer.

1.3 The rope to which this specification applies is designed to be used in a clean and dry condition, on or near energized lines.

1.4 A margin of safety shall be allowed between the maximum voltage and working distances on which it is used and the test voltage and lengths at which it is tested.

1.5 It is common practice for the user of this type of equipment to prepare complete instructions and regulations to govern in detail the correct and safe use of such equipment.

1.6 The use and maintenance of this equipment is beyond the scope of this specification.

1.7 The values stated in SI units are to be regarded as the standard.

1.8 The following safety hazards caveat pertains only to the test method portion, Section 13, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1701 – 96 (Reapproved 2001)

Standard Specification for

Unused Polypropylene Rope with Special Electrical

Properties

This standard is issued under the fixed designation F 1701; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 4268 Test Methods for Testing Fiber Ropes

E 4 Practices for Force Verification of Testing Machines

1.1 This specification covers the requirements, sizes, con-

E 380 Practice for Use of the International System of Units

struction, tests, and procedures for unused polypropylene ropes

(SI) (the Modernized Metric System)

for use by electrical utilities and related industries on energized

F 711 Specification for Fiberglass-Reinforced Plastic (FRP)

lines operating at voltages higher than 1 kV.

Rod and Tube Used in Live Line Tools

1.2 This specification covers the minimum electrical, me-

2.2 IEEE Standards:

chanical, and physical properties guaranteed by the manufac-

IEEE Std 4 StandardTechniques for HighVoltageTesting

turer and the detailed procedures by which such properties are

IEEE Paper Field and Test Experience With Insulating

to be determined. The purchaser has the option to perform or

Rope at BPA (July 1991)

have performed any of these tests in order to verify the

2.3 ISO Standard:

guarantee. Claims for failure to meet the specification are

ISO 2307 Ropes —Determination of Certain Physical and

subject to verification by the manufacturer.

Mechanical Properties

1.3 The rope to which this specification applies is designed

2.4 Other Standard:

to be used in a clean and dry condition, on or near energized

Cordage Institute CIA-3 Standard test methods fibre rope

lines.

including standard terminations for hollow braided rope

1.4 A margin of safety shall be allowed between the

and double braided rope (June 1980)

maximum voltage and working distances on which it is used

and the test voltage and lengths at which it is tested.

3. Terminology

1.5 It is common practice for the user of this type of

3.1 General—The terms used in this specification are com-

equipment to prepare complete instructions and regulations to

mon to and well known by the industries that will be using

govern in detail the correct and safe use of such equipment.

them.

1.6 The use and maintenance of this equipment is beyond

the scope of this specification.

4. Ordering Information

1.7 The values stated in SI units are to be regarded as the

4.1 Orders for rope under this specification should include

standard.

the following information:

1.8 The following safety hazards caveat pertains only to the

4.2 Manufacturer’s designation of the rope.

test method portion, Section 13, of this specification: This

4.3 Length of Coil or Reel:

standarddoesnotpurporttoaddressallofthesafetyconcerns,

4.3.1 Lengths—Unless otherwise specified, rope shall be

ifany,associatedwithitsuse.Itistheresponsibilityoftheuser

furnishedinlengthsdescribedforsizeinTable1.Eachpackage

of this standard to establish appropriate safety and health

shall be continuous throughout without splices or knots. Ends

practices and determine the applicability of regulatory limita-

shall be taped, heat sealed, or served to prevent ravelling.

tions prior to use.

4.3.2 Special Lengths—Lengths other than listed in Table 1

2. Referenced Documents to be negotiated with the vendor.

2.1 ASTM Standards:

D 1125 Test Methods for Electrical Conductivity and Re-

sistivity of Water

Annual Book of ASTM Standards, Vol 07.02.

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 10.03.

1 7

This specification is under the jurisdiction of ASTM Committee F18 on Available from the Institute of Electrical and Electronics Engineers, Inc., 345

Electrical Protective Equipment for Workers and is the direct responsibility of E. 47th St., New York, NY 10017.

Subcommittee F18.35 on Tools and Equipment. Available from the American National Standards Institute, 11 West 42nd St.,

Current edition approved April 10, 1996. Published August 1996. 13th Floor, New York, NY 10036.

2 9

Annual Book of ASTM Standards, Vol 11.01. Available from Cordage Institute.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1701

TABLE 1 Dimensions, Mass, and Permissible Variations

6.2 Circumference—The nominal circumference and diam-

Nominal Nominal Standard eter sizes are listed in Table 1.

Minimum Nominal Weight,

Diameter, Circumference, Length,

6.3 Hardness—Refer to 13.5.

Breaking Test, lb lb/100 ft

in. in. ft

6.4 Lay, Diameter, and Gage Length—Refer to 13.5.

1 3

⁄4 ⁄4 1300 1.65 1200

6.5 Melt Point—Refer to 13.5.

3 1

⁄8 1 ⁄8 2950 4.0 1200

7 1

⁄16 1 ⁄4 3750 4.6 1200

1 1 7. Mechanical Properties

⁄2 1 ⁄2 4850 6.0 1200

9 3

⁄16 1 ⁄4 5750 7.2 1200

7.1 Theprimarymechanicalpropertyofropeisthebreaking

⁄8 2 7000 9.9 1200

3 1

strength.The minimum breaking strengths for the various sizes

⁄4 2 ⁄4 9450 13.1 1200

7 3

⁄8 2 ⁄4 12 600 17.0 1200

of rope are listed in Table 1.

1 3 15 300 20.7 1200

1 1

1 ⁄8 3 ⁄2 19 350 28.0 1200

8. Dimensions, Mass and Permissible Variations

8.1 Thedimensions,mass,andapplicablepermissiblevaria-

tions are found in Table 1.

4.3.3 Rope should be shipped in reels.

4.4 Weight—The weight per 100 ft of rope shall be as

9. Workmanship, Finish, and Appearance

specified in Table 1. Rope weight more than 5 % in excess for

9.1 All sizes of rope shall be evenly laid and well balanced

size as billed by the vendor shall be reduced by such excess

in accordance with best rope making workmanship. Rope and

weight. The weight shall be determined in accordance with

strandsshallbefreefromkinks,strandknots,anddartingyarns

Cordage Institute Standard test methods.

or loose ends (inside yarns which project through cover yarns

4.4.1 Rope is billed by weight. If rope is supplied by the

of strand at intervals along the rope).

vendor that weighs more than 5 % in excess for the size, the

total weight will be reduced to the maximum weight allowed

10. Sampling and Number of Tests or Retests

for billing purposes.

10.1 Composition of Batch to be Sampled—Samples shall

NOTE 1—For example, (1) ⁄8 in. rope maximum weight 17.0 lb/100 ft; be taken from a homogeneous batch consisting of ropes of the

(2) 5 % excess weight allows 17.85 lb/100 ft; (3) 100 ft of rope is

samesizeandsamedimensionsandwhichhavebeensubjectto

delivered that weighs 18.0 lb. The billable weight would be reduced to

the same series of manufacturing operations and the same

17.85 lb.

checking procedure.

4.5 Test Facility—The test facility for the electrical and

10.2 Selecting the Samples—Unless otherwise agreed upon

mechanical tests will be agreed to by the manufacturer/seller

between the purchaser and manufacturer, take at random from

and the buyer.

the batch the number of samples, S, obtained from the

4.6 Standard Atmospheric Conditions—The atmospheric following equation:

condition shall be substantially at a temperature of 22 6 5°C

S 5 0.4 N

=

(72 6 9°F) and relative humidity of 35 % minimum and

where N = number of coils making up the batch.

negligible air movement.

Where the calculated value of S is not a whole number, the

5. Materials and Manufacture numberobtainedshallberoundedtothenearestwholenumber.

For example, 27.5 and 30.35 shall be rounded to 28 and 30,

5.1 Materials—The rope filaments used shall be 100 %

respectively. Where S < 1, take one sample length.

orientedpolypropylenehavingaminimumtenacityof5.0gper

10.3 Specimen Selection Location—For coils, specimens

denier strength. The fiber shall be fortified to stabilize and

shall be selected from each end. For rope made and shipped in

retard degradation due to oxidation and ultraviolet decay. The

reel lengths, one specimen shall be selected from the outside

use of undrawn fiber is prohibited (inside yarns may be clean

end and one from the inside (drum) end.

and unfortified).

1 10.3.1 Thisrequirementwillrequireare-reelingoftherope.

5.2 Manufacture—Rope shall be 3-strand; sizes ⁄4through

⁄2 in. diameter ropes shall be from single ply yarns or 3 ply

11. Specimen Preparation

yarns of approximately 12 000 to 22 000 denier as a maximum

11.1 Specimen preparation is included as a part of each test

for singles and 15 000 denier as a maximum for the component

method. The ends of each rope specimen shall be heat scaled.

of the ply. Rope sizes ⁄16 in. diameter and larger shall be

constructed from 3-ply yarns; the subyarn (component) shall

12. Recommended Working Load

contain a maximum of 15 000 denier. The lay for all rope shall

12.1 Manufacturers furnishing rope under this specification

be right hand or “Z” lay. Rope shall be “F” (firm) lay to

shall specify a recommended maximum working load.

maintain best dimensional stability under load.

5.2.1 See Table 1 for values.

NOTE 2—A minimum breaking load is specified in Table 1.

6. Physical Properties 13. Test Methods and Performance Requirements

6.1 Color—The color of the rope shall be orange. A 13.1 The polypropylene ropes complying with these speci-

maximum of two outside tracers for customer or manufacturer fications shall undergo two different tests, electrical and

identification, or both, may be used. Tracers shall be 100 % mechanical/physical, and are to be termed “nonconductive”

polypropylene. rope. Samples of rope selected in accordance with Section 10

F 1701

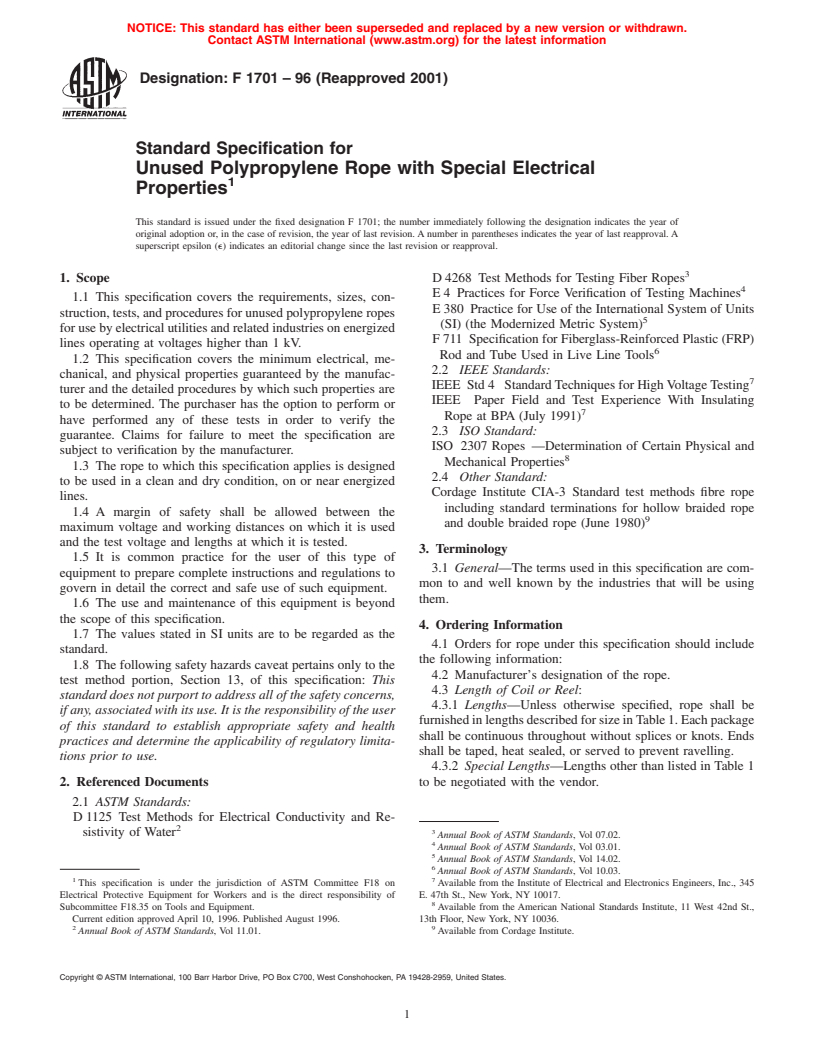

FIG. 1 Polypropylene Rope With Special Electrical Properties

from every lot (single finished production length) shall be gage solid copper wire twisted tightly and pigtailed to ensure

testedandeachreelidentifiedbylot(see4.3).Ifsingle-finished all filaments are in contact. See Fig. 2.

production length is greater than 1828 m (6000 ft) then tests

13.3.4 Wetting of Specimen:

shall be conducted at the beginning and end of the finished

13.3.4.1 A clean nonmetallic tank or trough shall be rinsed

production length.

with the same type water to be used during the wetting.

13.1.1 The test sequence is (1) visual; (2) electrical; (3)

13.3.4.2 The entire rope specimen shall be kept submerged

mechanical/physical.

horizontally in test water at a depth of 305 mm (1 ft) using

13.2 Caution—It is recommended that the test apparatus be

non-metallicdevice(s)foraperiodof15min.Thereshallbeno

designed to afford the operator full protection in performance

bends in this specimen.

of his duties. Reliable means of deenergizing and grounding

13.3.5 Water for Wetting—The electrical resistivity of the

the high-voltage circuit shall be provided.

water used for wetting shall meet the requirements of IEEE

13.3 Electrical Test Procedure—Wet Test—–This is a rou-

Standard 4, that is 100 V m at ambient temperature 6 15°C.

tine production test.

The resistivity may be measured by using the test methods as

13.3.1 Specimen for Test—The test specimen shall be at described in Test Methods D 1125.

least 2.4 m (8 ft) long so that when the rope is held in a vertical

13.3.6 Drying of Specimen—Within 1 min after removing

position, there will be 1.5 m (5 ft) of rope free of knots, eyes,

specimen from wetting tank, the specimen shall be hung in a

or splices.

vertical position with an unrestrained weight of 4.5 kg (10 lb)

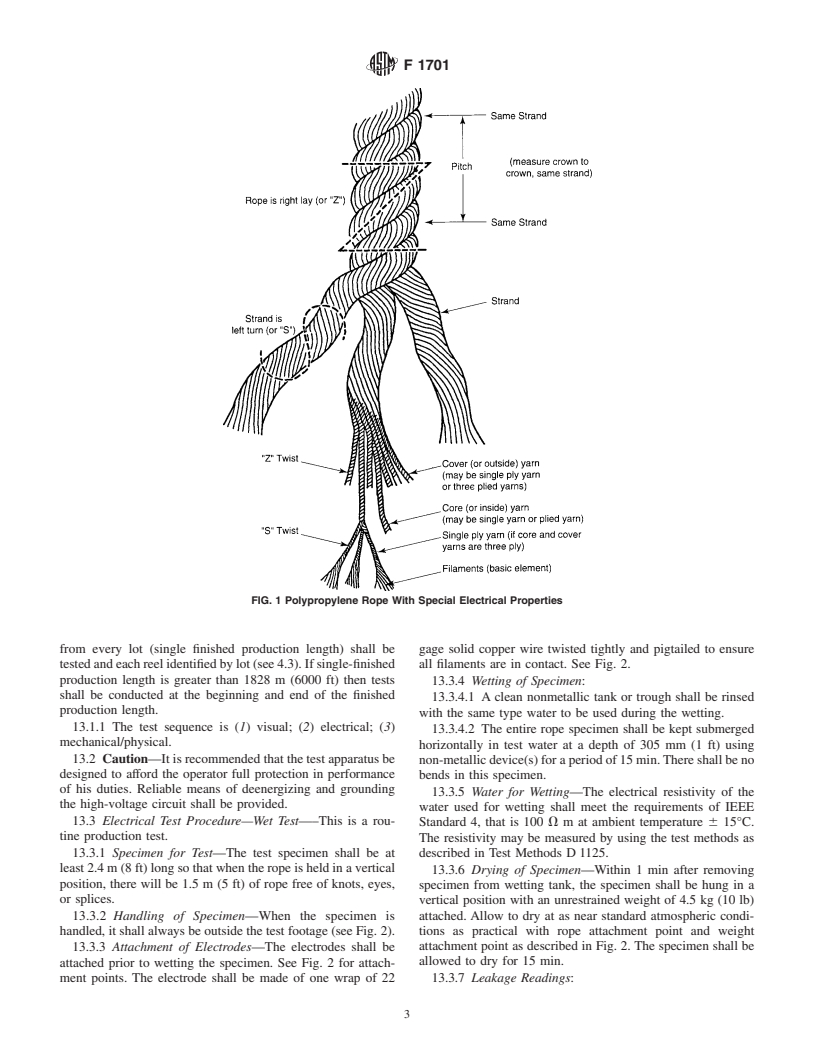

13.3.2 Handling of Specimen—When the specimen is attached. Allow to dry at as near standard atmospheric condi-

handled, it shall always be outside the test footage (see Fig. 2). tions as practical with rope attachment point and weight

attachment point as described in Fig. 2. The specimen shall be

13.3.3 Attachment of Electrodes—The electrodes shall be

allowed to dry for 15 min.

attached prior to wetting the specimen. See Fig. 2 for attach-

ment points. The electrode shall be made of one wrap of 22 13.3.7 Leakage Readings:

F 1701

Legend:

Faraday Box—a shielded container (continuous copper screen, with a suitable

mounting frame) enclosing and guarding the dropping resistorR1, and M (VM).

Both the screen, and shield of the measuring lead, by-pass R1 and M, by pro-

viding a path for stray capacitive currents to ground.

R1—100 V, 50 W wire wound noninductive resistor. A minimum 50 W resistor

is recommended because a hazardous condition would exist if the resistor

should burn open.

M—battery operated, true RMS, solid state voltmeter. Read drop acrossR1

and

E

calculate currentI= ⁄R

FIG. 3 Electrical Test Circuit

rope. The electrodes shall be mounted in a suitable frame to

allow the suspension of the 305 mm (12 in.) test section

between the electrodes. A4.5 kg (10 lb) weight shall be

attached to the rope to maintain good electrical contact. See

Fig. 4. For alternative electrode design, see Fig. 5.

13.4.4 Dry Test Leakage Readings—The 60 Hz voltage

shallberaisedfrom0to100kVrmsinnotlessthan5normore

than 15 s. The voltage shall be held at 100 kV rms for 5 min.

If at the end of 5 min the current is stable and has not exceeded

FIG. 2 Test Configuration for Electrical Routine Production Test

100 µA or flashed over, the specimen has passed the test. If at

the end of 5 min the current is not stable and does not exceed

100µA,orflashover,thetestshallcontinueforanadditional25

13.3.7.1 The 60 Hz voltage shall be applied immediately

min. If at the end of that time the rope has not flashed over and

after the 15-min drying period and shall be raised from 0 to 30

the current has stabilized at less than 100 µA, the specimen has

kV in not less than 5 nor more than 15 s. The voltage shall be

passed.

held at 30 kV for 30 s. The leakage current obtained over the

2 ft test section shall not exceed 50 µAfrom the time of initial NOTE 3—The acceptance tests may be performed at the option of the

purchaser to verify that the product meets the criteria of 13.4. The cost of

application of voltage until the end of the test. If the current

these tests is negotiable between the purchaser and the manufacturer.

exceeds 50 µA, the lot will be rejected. Refer to Fig. 3 for test

circuit. 13.5 Wet Acceptance Test:

13.3.7.2 The wet test in 13.3.1 is a discriminatory test used 13.5.1 Specimen for Test—The test specimen shall be at

as a method of determining the rope quality, not as a method of least 2.4 m (8 ft) long so that when the rope is held in a vertical

determining the rope’s ability to operate properly under wet position,therewillbe1.5m(5ft)ofropefreefromknots,eyes,

conditions in the field. or splices (see Fig. 2).

13.4 Electrical Test Procedure—Acceptance Test—This is a 13.5.2 Handling of Specimen—When the rope is handled, it

dry specimen acceptance test. shall always be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.