ASTM B47-95a(2001)

(Specification)Standard Specification for Copper Trolley Wire

Standard Specification for Copper Trolley Wire

SCOPE

1.1 This specification covers round and grooved hard-drawn copper and silver-bearing copper trolley wire.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 47 – 95a (Reapproved 2001)

Standard Specification for

Copper Trolley Wire

ThisstandardisissuedunderthefixeddesignationB47;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

TABLE 1 Tensile Requirements (See Explanatory Note 2)

1. Scope

Tensile Strength, min. psi

1.1 Thisspecificationcoversroundandgroovedhard-drawn

Elongation

Diameter, Area,

25 troy oz.

copper and silver-bearing copper trolley wire.

in 10 in.,

No silver

in. cmils

min./short

min, %

1.2 The values stated in inch-pound units are to be regarded added

ton added

as the standard. The values given in parentheses are for

0.5477 300 000 46 400 48 500 4.50

information only.

0.4600 211 600 49 000 51 500 3.75

0.4096 167 800 51 000 53 000 3.25

2. Referenced Documents 0.3648 133 100 52 800 54 000 2.80

0.3249 105 600 54 500 55 000 2.40

2.1 ASTM Standards:

B 49 Specification for Copper Redraw Rod for Electrical

Purposes

4.2 Copper redraw rod of special qualities, forms, or types,

B 193 Test Method for Resistivity of Electrical Conductor

as may be agreed upon between the manufacturer and the

Materials

purchaser,andthatwillconformtotherequirementsprescribed

in this specification may also be used.

3. Ordering Information

4.3 Either oxygen-free or tough pitch copper may be sup-

3.1 Orders for material under this specification shall include

plied. Tests for oxygen content of the copper are not a

the following information:

requirement of this specification.

3.1.1 Quantity of each size and section,

ROUND WIRE

3.1.2 Wire size: diameter in inches (see 6.1 and Table 1) or

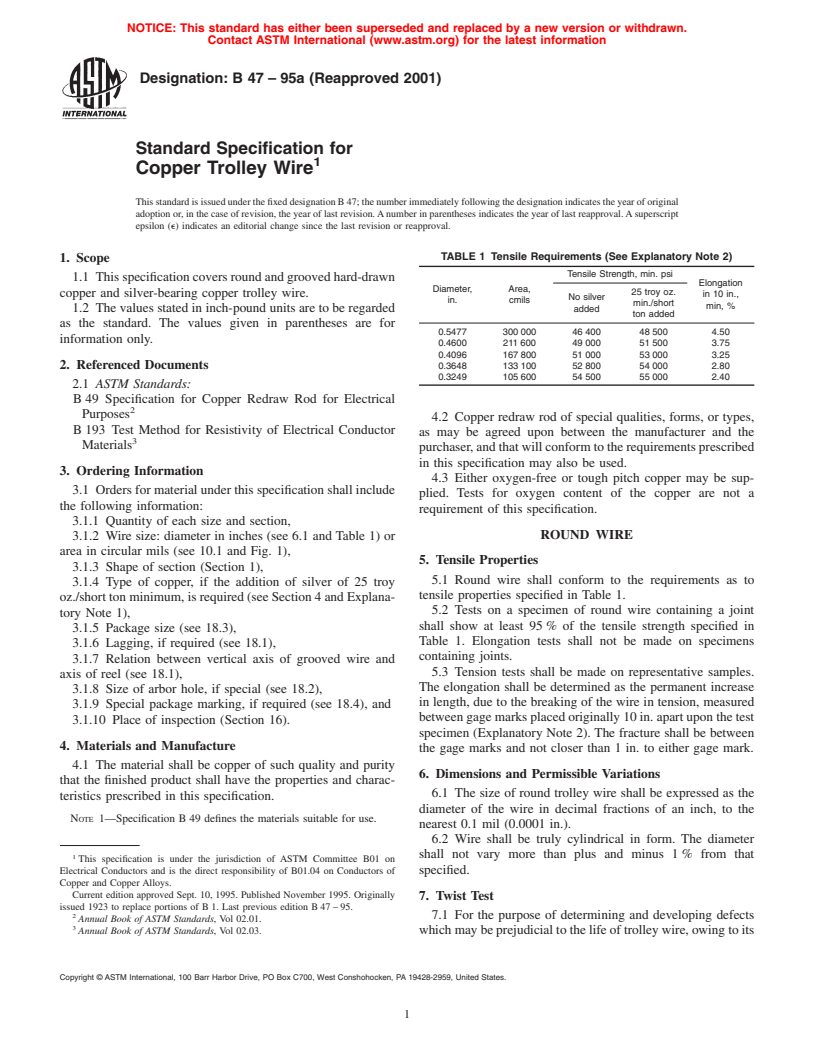

area in circular mils (see 10.1 and Fig. 1),

5. Tensile Properties

3.1.3 Shape of section (Section 1),

5.1 Round wire shall conform to the requirements as to

3.1.4 Type of copper, if the addition of silver of 25 troy

tensile properties specified in Table 1.

oz./short ton minimum, is required (see Section 4 and Explana-

5.2 Tests on a specimen of round wire containing a joint

tory Note 1),

shall show at least 95 % of the tensile strength specified in

3.1.5 Package size (see 18.3),

Table 1. Elongation tests shall not be made on specimens

3.1.6 Lagging, if required (see 18.1),

containing joints.

3.1.7 Relation between vertical axis of grooved wire and

5.3 Tension tests shall be made on representative samples.

axis of reel (see 18.1),

The elongation shall be determined as the permanent increase

3.1.8 Size of arbor hole, if special (see 18.2),

in length, due to the breaking of the wire in tension, measured

3.1.9 Special package marking, if required (see 18.4), and

between gage marks placed originally 10 in. apart upon the test

3.1.10 Place of inspection (Section 16).

specimen (Explanatory Note 2). The fracture shall be between

4. Materials and Manufacture

the gage marks and not closer than 1 in. to either gage mark.

4.1 The material shall be copper of such quality and purity

6. Dimensions and Permissible Variations

that the finished product shall have the properties and charac-

6.1 The size of round trolley wire shall be expressed as the

teristics prescribed in this specification.

diameter of the wire in decimal fractions of an inch, to the

NOTE 1—Specification B 49 defines the materials suitable for use.

nearest 0.1 mil (0.0001 in.).

6.2 Wire shall be truly cylindrical in form. The diameter

1 shall not vary more than plus and minus 1 % from that

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of B01.04 on Conductors of specified.

Copper and Copper Alloys.

Current edition approved Sept. 10, 1995. Published November 1995. Originally

7. Twist Test

issued 1923 to replace portions of B 1. Last previous edition B 47 – 95.

7.1 For the purpose of determining and developing defects

Annual Book of ASTM Standards, Vol 02.01.

Annual Book of ASTM Standards, Vol 02.03. whichmaybeprejudicialtothelifeoftrolleywire,owingtoits

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B47

Nominal size, cmils 133 100 167 800 211 600 300 000 350 000

Area, in. (Explanatory Note 6) 0 .1083 0 .1314 0 .1665 0 .2355 0 .2758

Area, cmils (Explanatory Note 6) 137 900 167 300 212 000 299 800 351 200

Weight, lb/mile (Explanatory Note 6) 2205 2674 3389 4792 5612

Dimensions for Inspection, in.

A 0.388 + 0.006 0.429 + 0.006 0.482 + 0.006 0.574 + 0.010 0.620 + 0.010

− 0.012 − 0.012 − 0.012 − 0.020 − 0.020

B 0.392 6 0.007 0.430 6 0.008 0.482 6 0.009 0.574 6 0.011 0.620 6 0.012

C 0.318 6 0.007 0.340 6 0.007 0.376 6 0.007 0.376 6 0.007 0.376 6 0.007

Dimensions for Reference, in.

D—radius 0.196 0.215 0.241 0.287 0.310

E 0.217 + 0.005 0.237 + 0.005 0.267 6 0.010 0.267 6 0.010 0.267 6 0.010

− 0.010 − 0.010

F 0.200 0.220 0.250 0.250 0.250

G 0.031 0.047 0.063 0.127 0.156

H 0.005 0.005 0.005 0.005 0.005

J27 6 2° 27 6 2° 27 6 2° 27 6 2° 27 6 2°

K51 6 2° 51 6 2° 51 6 2° 51 6 2° 51 6 2°

L 78° 78° 78° 78° 78°

M—radius 0.015 + 0.010 0.015 + 0.010 0.015 + 0.010 0.015 + 0.010 0.015 + 0.010

− 0.005 −0.005 − 0.005 − 0.005 − 0.005

NOTE—Dimension H is defined by two center lines, of which the upper is the center line of the radius of the groove and the lower is the center line

of the groove.

FIG. 1 Standard Sections Grooved Trolley Wire

peculiar service as compared to that of wire for other purposes, GROOVED WIRE

round wire shall be subjected to the twist test described in 7.2.

Round wire that does not withstand at least 9 twists without

8. Tensile Properties

breaking shall not be considered satisfactory.

8.1 Grooved wire shall conform to the requirements as to

7.2 Three twist tests shall be made on specimens 10 in. (254

tensile properties specified in Table 2.

mm) in length between the holders of the testing machine. The

8.2 Tests on a specimen of grooved wire containing a joint

twisting machine shall be so constructed that there is a linear

shall show at least 95 % of the tensile strength specified in

motion of the tail stock with respect to the head.The twist shall

Table 2. Elongation tests shall not be made on specimens

be applied not faster than 10 turns/min. All three specimens

containing joints.

shall be twisted to destruction and shall not reveal under test

8.3 The tension and elongation tests for grooved wire shall

any seams, pits, slivers, or surface imperfections of sufficient

be made in the same manner as those on round wire as

magnitude to indicate inherent defects or imperfections in the

described in 5.3.

wire. At the time of fracture, the wire shall twist with

reasonable uniformity.

B47

TABLE 2 Tensile Requirements (See Explanatory Note 2)

10. Dimensions and Permissible Variations

Tensile Strength, min. psi

Nominal Elongation

10.1 The size of grooved trolley wire shall be expressed as

Area, in 10 in.,

No silver 25 troy oz min./

the nominal area of cross section in circular mils, the standard

cmils min, %

added short ton added

sizes being as specified in Fig. 1.

350 000 42 800 44 600 4.50

10.2 The weight in pounds per mile of grooved trolley wire

300 000 44 200 48 000 4.50

211 600 46 600 51 300 3.75 calculated from the weight of a specimen not less than 18 in. in

167 800 48 500 52 700 3.25

length shall not vary more than plus and minus 4 % from that

133 100 50 200 53 000 2.80

specified in Fig. 1.

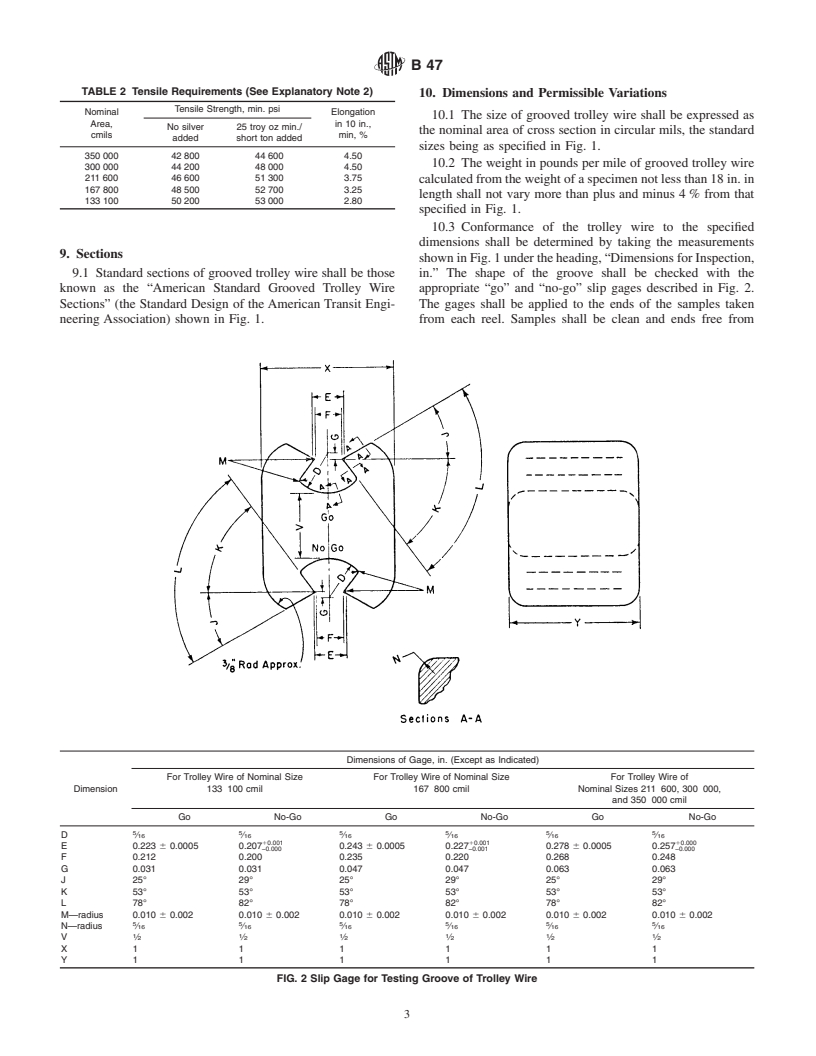

10.3 Conformance of the trolley wire to the specified

dimensions shall be determined by taking the measurements

9. Sections

showninFig.1undertheheading,“DimensionsforInspection,

9.1 Standard sections of grooved trolley wire shall be those in.” The shape of the groove shall be checked with the

known as the “American Standard Grooved Trolley Wire appropriate “go” and “no-go” slip gages described in Fig. 2.

Sections” (the Standard Design of the American Transit Engi- The gages shall be applied to the ends of the samples taken

neering Association) shown in Fig. 1. from each reel. Samples shall be clean and ends free from

Dimensions of Gage, in. (Except as Indicated)

For Trolley Wire of Nominal Size For Trolley Wire of Nominal Size For Trolley Wire of

Dimension 133 100 cmil 167 800 cmil Nominal Sizes 211 600, 300 000,

and 350 000 cmil

Go No-Go Go No-Go Go No-Go

5 5 5 5 5 5

D ⁄16 ⁄16 ⁄16 ⁄16 ⁄16 ⁄16

10.001 10.001 10.000

E 0.223 6 0.0005 0.207 0.243 6 0.0005 0.227 0.278 6 0.0005 0.257

–0.000 –0.001 –0.000

F 0.212 0.200

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.