ASTM D2272-11

(Test Method)Standard Test Method for Oxidation Stability of Steam Turbine Oils by Rotating Pressure Vessel

Standard Test Method for Oxidation Stability of Steam Turbine Oils by Rotating Pressure Vessel

SIGNIFICANCE AND USE

The estimate of oxidation stability is useful in controlling the continuity of this property for batch acceptance of production lots having the same operation. It is not intended that this test method be a substitute for Test Method D943 or be used to compare the service lives of new oils of different compositions.

This test method is also used to assess the remaining oxidation test life of in-service oils.

SCOPE

1.1 This test method utilizes an oxygen-pressured vessel to evaluate the oxidation stability of new and in-service turbine oils having the same composition (base stock and additives) in the presence of water and a copper catalyst coil at 150°C.

1.2 Appendix X1 describes a new optional turbine oil (unused) sample nitrogen purge pretreatment procedure for determining the percent residual ratio of RPVOT value for the pretreated sample divided by RPVOT value of the new (untreated) oil, sometimes referred to as a “% RPVOT Retention.” This nitrogen purge pretreatment approach was designed to detect volatile antioxidant inhibitors that are not desirable for use in high temperature gas turbines.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 Exception—Other units are provided in parentheses (psi, grams, and inches), because they are either the industry accepted standard or the apparatus is built according the figures in this standard, or both.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 6.2, 6.4, 6.5, 6.6, and 6.10.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2272 − 11

StandardTest Method for

Oxidation Stability of Steam Turbine Oils by Rotating

1

Pressure Vessel

This standard is issued under the fixed designation D2272; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2. Referenced Documents

3

2

2.1 ASTM Standards:

1.1 This test method utilizes an oxygen-pressured vessel to

B1 Specification for Hard-Drawn Copper Wire

evaluate the oxidation stability of new and in-service turbine

D943 Test Method for Oxidation Characteristics of Inhibited

oils having the same composition (base stock and additives) in

Mineral Oils

the presence of water and a copper catalyst coil at 150°C.

D1193 Specification for Reagent Water

1.2 Appendix X1 describes a new optional turbine oil

D4057 Practice for Manual Sampling of Petroleum and

(unused) sample nitrogen purge pretreatment procedure for

Petroleum Products

determining the percent residual ratio of RPVOT value for the

D4742 Test Method for Oxidation Stability of Gasoline

pretreated sample divided by RPVOT value of the new

Automotive Engine Oils by Thin-Film Oxygen Uptake

(untreated) oil, sometimes referred to as a “% RPVOT Reten-

(TFOUT)

tion.”This nitrogen purge pretreatment approach was designed

D6299 Practice for Applying Statistical Quality Assurance

to detect volatile antioxidant inhibitors that are not desirable

and Control Charting Techniques to Evaluate Analytical

for use in high temperature gas turbines.

Measurement System Performance

4

2.2 Energy Institute Standard:

1.3 The values stated in SI units are to be regarded as

IP 229 Determination of the relative oxidation stability by

standard. No other units of measurement are included in this

rotating bomb of mineral turbine oil

standard.

1.3.1 Exception—Other units are provided in parentheses

3. Summary of Test Method

(psi, grams, and inches), because they are either the industry

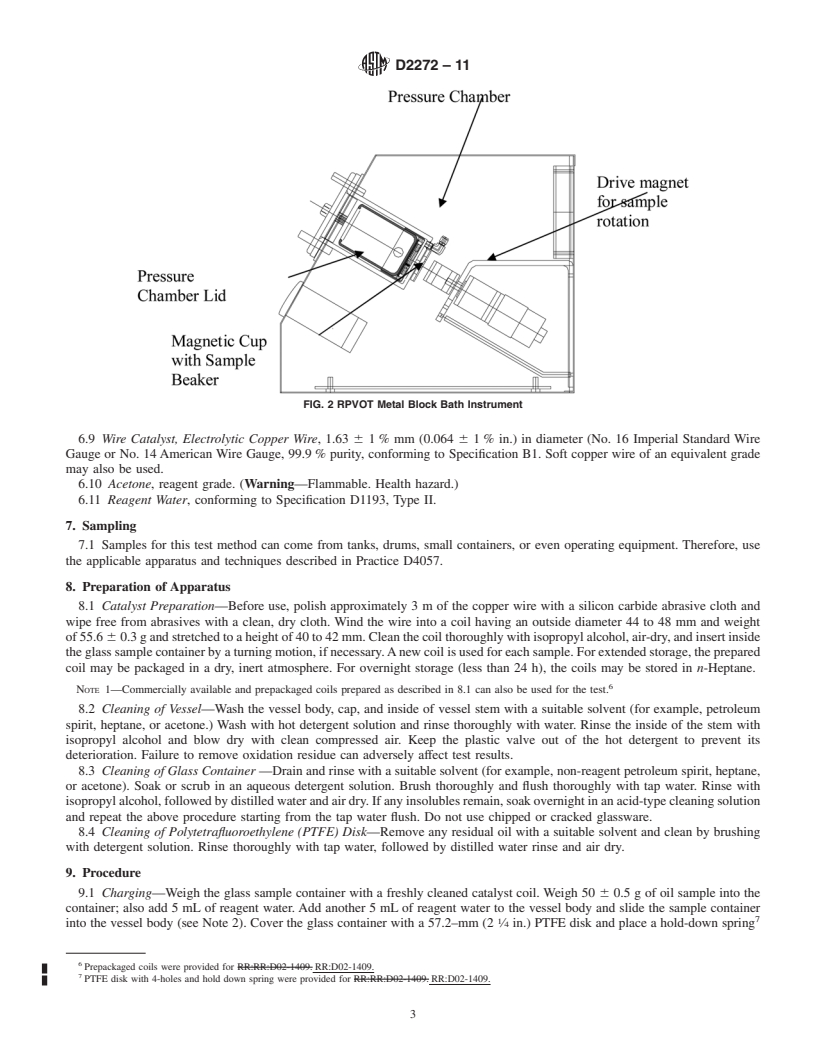

3.1 The test oil, water, and copper catalyst coil, contained in

acceptedstandardortheapparatusisbuiltaccordingthefigures

a covered glass container, are placed in a vessel equipped with

in this standard, or both.

a pressure gauge.The vessel is charged with oxygen to a gauge

1.4 This standard does not purport to address all of the pressure of 620 kPa (90 psi, 6.2 bar) (see Eq 1), placed in a

constant-temperatureoilbathsetat150°Cordryblocktakento

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 150°C (Fig. 1 and Fig. 2), and rotated axially at 100 rpm at an

angle of 30° from the horizontal.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific

3.2 The number of minutes required to reach a specific drop

warning statements, see 6.2, 6.4, 6.5, 6.6, and 6.10.

in gauge pressure is the oxidation stability of the test sample.

100 kPa 5 1.00 bar 5 14.5 psi (1)

4. Significance and Use

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

4.1 The estimate of oxidation stability is useful in control-

D02.09.0C on Oxidation of Turbine Oils.

ling the continuity of this property for batch acceptance of

Current edition approved May 1, 2011. Published May 2011. Originally

approved in 1964. Last previous edition approved in 2009 as D2272–09. DOI:

3

10.1520/D2272-11. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

2

von Fuchs, G. H., Claridge, E. L., and Zuidema, H. H., “The Rotary Bomb contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Oxidation Test for Inhibited Turbine Oils,” Materials Research and Standards, Standards volume information, refer to the standard’s Document Summary page on

MTRSA (formerly ASTM Bulletin), No. 186, December 1952, pp. 43-46; von the ASTM website.

4

Fuchs, G. H., “Rotary Bomb OxidationTest,” Lubrication Engineering,Vol 16, No. Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

1, January 1960, pp. 22-31. U.K., http://www.energyinst.org.uk.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2272 − 11

FIG. 1 Schematic Drawing of the Rotary Vessel Test Apparatus

FIG. 2 RPVOT Metal Block Bath Instrument

production lots having the same operation. It is not intended Down Spring, Catalyst-Coil, Pr

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D2272–09 Designation: D2272 – 11

Standard Test Method for

Oxidation Stability of Steam Turbine Oils by Rotating

1

Pressure Vessel

This standard is issued under the fixed designation D2272; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

2

1.1 This test method utilizes an oxygen-pressured vessel to evaluate the oxidation stability of new and in-service turbine oils

having the same composition (base stock and additives) in the presence of water and a copper catalyst coil at 150°C.

1.2The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1

1.2 Appendix X1 describes a new optional turbine oil (unused) sample nitrogen purge pretreatment procedure for determining

thepercentresidualratioofRPVOTvalueforthepretreatedsampledividedbyRPVOTvalueofthenew(untreated)oil,sometimes

referred to as a “% RPVOT Retention.” This nitrogen purge pretreatment approach was designed to detect volatile antioxidant

inhibitors that are not desirable for use in high temperature gas turbines.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 Exception—Other units are provided in parentheses (psi, grams, and inches), because they are either the industry accepted

standard or the apparatus is built according the figures in this standard, or both.

1.3

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific warning statements, see 6.2, 6.4, 6.5, 6.6, and 6.10.

2. Referenced Documents

3

2.1 ASTM Standards:

B1 Specification for Hard-Drawn Copper Wire

D943 Test Method for Oxidation Characteristics of Inhibited Mineral Oils

D1193 Specification for Reagent Water

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4742 Test Method for Oxidation Stability of Gasoline Automotive Engine Oils by Thin-Film Oxygen Uptake (TFOUT)

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical

Measurement System Performance

4

2.2 Energy Institute Standard:

IP 229 Determination of the relative oxidation stability by rotating bomb of mineral turbine oil

3. Summary of Test Method

3.1 The test oil, water, and copper catalyst coil, contained in a covered glass container, are placed in a vessel equipped with a

pressure gauge. The vessel is charged with oxygen to a gauge pressure of 620 kPa (90 psi, 6.2 bar) (see Eq 1), placed in a

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.09.0C

on Oxidation of Turbine Oils.

Current edition approved June 15, 2009. Published September 2009. Originally approved in 1964. Last previous edition approved in 2002 as D2272–02. DOI:

10.1520/D2272-09.

Current edition approved May 1, 2011. Published May 2011. Originally approved in 1964. Last previous edition approved in 2009 as D2272–09. DOI: 10.1520/D2272-11.

2

von Fuchs, G. H., Claridge, E. L., and Zuidema, H. H., “The Rotary Bomb Oxidation Test for Inhibited Turbine Oils,” Materials Research and Standards, MTRSA

(formerlyASTM Bulletin), No. 186, December 1952, pp. 43-46; von Fuchs, G. H., “Rotary Bomb Oxidation Test,” Lubrication Engineering, Vol 16, No. 1, January 1960,

pp. 22-31.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR, U.K., http://www.energyinst.org.uk.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2272 – 11

constant-temperature oil bath set at 150°C or dry block taken

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.