ASTM E1730-99

(Specification)Standard Specification for Rigid Foam for Use in Structural Sandwich Panel Cores

Standard Specification for Rigid Foam for Use in Structural Sandwich Panel Cores

SCOPE

1.1 This specification covers rigid, closed cell, polyurethane and polyisocyanurate thermal insulation for sandwich panels used in shelter construction for exposure to ambient temperatures of -25° to 160°F (-32° to 71°C). Painted surfaces of shelters in actual field use reach temperatures of 200°F (93°C). The materials in this specification must be capable of withstanding processing, (laminating) temperatures of 110°C (230°F).

1.2 The values stated in either inch-pound or SI units are to be regarded separately as the standard. The values given in parentheses are for information only.

1.3 The following precautionary caveat pertains only to the test method portion, Section 12, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1730 – 99 An American National Standard

Standard Specification for

Rigid Foam for Use in Structural Sandwich Panel Cores

This standard is issued under the fixed designation E 1730; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C 550 Practice for Measuring Trueness and Squareness of

Rigid Block Thermal Insulation

1.1 This specification covers rigid, closed cell, polyurethane

D 883 Terminology Relating to Plastics

and polyisocyanurate thermal insulation for sandwich panels

D 1621 Test Method for Compressive Properties of Rigid

used in shelter construction for exposure to ambient tempera-

Cellular Plastics

tures of −25° to 160°F (−32° to 71°C). Painted surfaces of

D 1622 Test Method for Apparent Density of Rigid Cellular

shelters in actual field use reach temperatures of 200°F (93°C).

Plastics

The materials in this specification must be capable of with-

D 1623 Test Method for Tensile and Tensile Adhesion

standing processing, (laminating) temperatures of 110°C

Properties of Rigid Cellular Plastics

(230°F).

D 2126 Test Method for Response of Rigid Cellular Plastics

1.2 The values stated in either inch-pound or SI units are to

to Thermal and Humid Aging

be regarded separately as the standard. The values given in

D 2856 Test Method for Open Cell Content of Rigid Cel-

parentheses are for information only.

lular Plastics by the Air Pycnometer

1.3 The following precautionary caveat pertains only to the

E 864 Practice for Surface Preparation of Aluminum Alloys

test method portion, Section 12, of this specification: This

to Be Adhesively Bonded in Honeycomb Shelter Panels

standard does not purport to address all of the safety concerns,

F 501 Test Method for Aerospace Materials Response to

if any, associated with its use. It is the responsibility of the user

Flame with Vertical Test Specimen (for Aerospace Vehicles

of this standard to establish appropriate safety and health

Standard Conditions)

practices and determine the applicability of regulatory limita-

2.2 Code of Federal Regulations Aeronautics and Space:

tions prior to use.

14 CFR 25.853 (Federal Air Regulation 25.853) Compart-

2. Referenced Documents

ment Interior (Amend. 25-72)

2.3 Federal Standard:

2.1 ASTM Standards:

QQ-A-25011 Aluminum Alloy 6061-T6 Plate and Sheet

C 165 Test Method for Measuring Compressive Properties

QQ-A-260/11 Aluminum Alloy 6081, Plate and Sheet

of Thermal Insulations

2.4 Military Standards:

C 168 Terminology Relating to Thermal Insulating Materi-

MIL STD 105 Sampling Procedures and Tables for Inspec-

als

tion by Attributes

C 177 Test Method for Steady-State Heat Flux Measure-

ments and Thermal Transmission Properties by Means of

3. Terminology

the Guarded Hot Plate Apparatus

3.1 Definitions—The terms used in this specification are

C 273 Test Method for Shear Properties in Flatwise Plane of

defined in Terminologies C 168 and D 883.

Flat Sandwich Constructions or Sandwich Cores

C 366 Test Methods for Measurement of Thickness of

4. Classification

Sandwich Cores

4.1 The unfaced foam thermal insulation boards covered by

C 390 Criteria for Sampling and Acceptance of Preformed

2 this specification are classified as follows:

Thermal Insulation Lots

3 3

4.1.1 Type 1—Nominal density: 32 kg/m (2.0 lb/ft ).

C 518 Test Method for Steady-State Heat Flux Measure-

3 3

4.1.2 Type 2—Nominal density: 48 kg/m (3.0 lb/ft ).

ments and Thermal Transmission Properties by Means of

3 3

2 4.1.3 Type 3—Nominal density: 64 kg/m (4.0 lb/ft ).

the Heat Flow Meter Apparatus

Annual Book of ASTM Standards, Vol 08.01.

This specification is under the jurisdiction of ASTM Committee E-6 on

Annual Book of ASTM Standards, Vol 08.02.

Performance of Buildings and is under the direct responsibility of Subcommittee

Annual Book of ASTM Standards, Vol 04.11.

E06.53 on Materials and Processes for Durable Rigidwall Relocatable Structures. Discontinued: see 1998 Annual Book of ASTM Standards, Vol 04.07.

Current edition approved Oct. 10, 1999. Published November 1999. Originally Available from Superintendent of Documents, U.S. Government Printing

published as E 1730–95. Last previous edition E 1730–95. Office, Washington, DC 20402.

2 9

Annual Book of ASTM Standards, Vol 04.06. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 15.03. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1730

3 3

4.1.4 Type 4—Nominal density: 192 kg/m (12.0 lb/ft ).

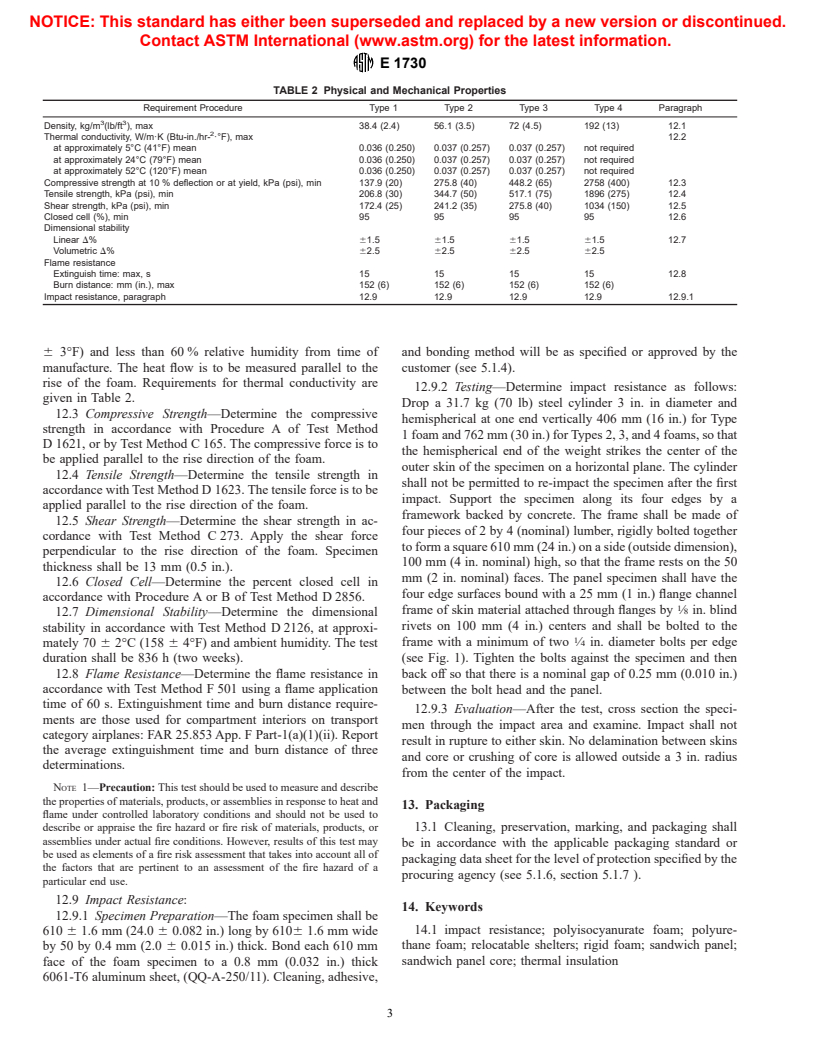

Property Requirement Method

Density Table 2 12.1

5. Ordering Information

Compressive strength Table 2 12.3

5.1 Orders for materials purchased under this specification

Shear strength Table 2 12.5

Flame resistance Table 2 12.8

shall include the following:

5.1.1 Designation of this specification,

9.3 Sampling for Acceptance (Examination):

5.1.2 Product name and type, or both,

9.3.1 Samples for quality conformance examination shall be

5.1.3 Dimensions and tolerances,

selected in accordance with Inspection Level II of MIL STD

5.1.4 Impact resistance test specimen preparation,

105.

5.1.5 Material marking requirements, and

9.3.2 When the conditions for reduced inspection specified

5.1.6 Packaging requirements.

in MIL-STD-105 have been complied with, a reduced sam-

pling in lieu of full sampling shall be instituted. Sampling for

6. Foam

reduced inspection shall be in accordance with Criteria C 390

6.1 The morphology of the insulation shall consist of a

(Inspection Level S-2 of MIL STD 105).

multitude of individual cells of uniform size and dimension,

9.4 Examination:

essentially closed off from each other, homogeneous through-

9.4.1 Samples selected in accordance with 9.3 shall be

out, free of voids, accumulations of unexpanded material,

examined for characteristics listed in Table 1.

foreign inclusions, or seams (see Table 1).

9.4.2 Visual examination shall consist of scanning for sur-

face characteristics.

7. Dimensions and Tolerances

9.4.3 Dimensional measurements shall be made with cali-

7.1 The dimensions, squareness, and tolerances shall be

pers, rules, and tape rules as appropriate to the specified

specified by the purchaser.

tolerances. In cases of dispute or when specifically invoked by

the purchaser, the methodology and procedures of Method

8. Qualification

C 336 or Practice C 550 shall be utilized.

8.1 When required by the purchaser, materials supplied

9.4.4 The Acceptable Quality Level (AQL) for major char-

under this specification must be tested for and meet the

acteristics shall be 1.0 % and for minor characteristics shall be

properties listed in Table 2. Having a qualified product does not

2.5 %.

obviate the supplier from continued, on-going product compli-

9.4.5 Seams (see Table 1) are defined as: a plane of

ance with all requirements to this specification.

undermixed material, or a fold which developed within the

8.2 In addition to meeting the requirements of the tests

rising foam mass that reduces the tensile strength of the foam.

stipulated in Table 2 as manufactured, the compressive, tensile,

When viewed normal to a cut sheet, a seam appears as a line on

and shear properties must also meet these requirements after

the foam surface. This condition must be differentiated from

having been preconditioned for4hat110°C (230°F), and

simple discoloration (arising from the same causes but not as

allowed to equilibrate in accordance with 11.2.

pronounced) that have no appreciable effect on foam strength.

8.3 Unless otherwise specified by the purchaser, qualified

This condition shall be evaluated by taking a sample, (not to

materials remain qualified as long as there are no changes in

exceed 51 mm (2 in.) thick from the sheet and bending it over

product formulation, critical raw materials, that is, isocyanates

a 305 mm (12 in.) cylinder to failure. If the failure plane

and polyols, basic methods of manufacture, or plant location.

follows the discontinuity then the discontinuity shall be con-

sidered a seam.

9. Acceptance

9.1 Lot Size for Acceptance Testing—For the purpose of

10. Physical Property Requirements

acceptan

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.