ASTM C1239-06a

(Practice)Standard Practice for Reporting Uniaxial Strength Data and Estimating Weibull Distribution Parameters for Advanced Ceramics

Standard Practice for Reporting Uniaxial Strength Data and Estimating Weibull Distribution Parameters for Advanced Ceramics

SCOPE

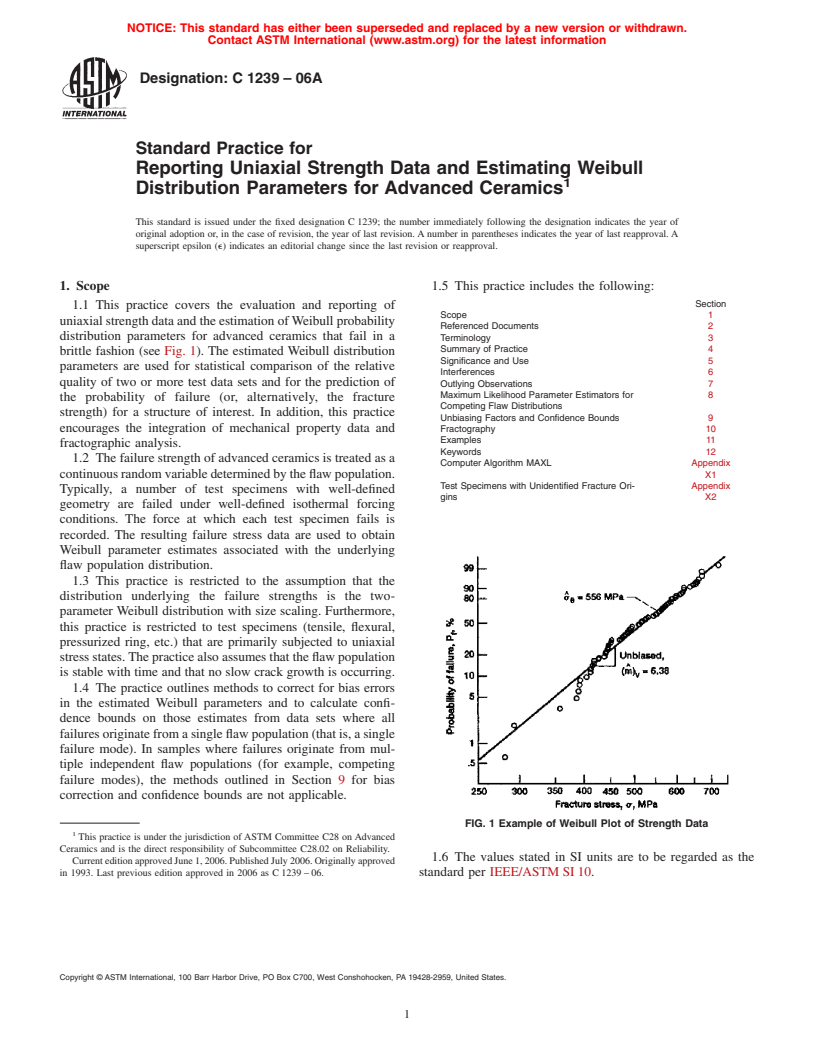

1.1 This practice covers the evaluation and reporting of uniaxial strength data and the estimation of Weibull probability distribution parameters for advanced ceramics that fail in a brittle fashion (see ). The estimated Weibull distribution parameters are used for statistical comparison of the relative quality of two or more test data sets and for the prediction of the probability of failure (or, alternatively, the fracture strength) for a structure of interest. In addition, this practice encourages the integration of mechanical property data and fractographic analysis.

1.2 The failure strength of advanced ceramics is treated as a continuous random variable determined by the flaw population. Typically, a number of test specimens with well-defined geometry are failed under well-defined isothermal forcing conditions. The force at which each test specimen fails is recorded. The resulting failure stress data are used to obtain Weibull parameter estimates associated with the underlying flaw population distribution.

1.3 This practice is restricted to the assumption that the distribution underlying the failure strengths is the two-parameter Weibull distribution with size scaling. Furthermore, this practice is restricted to test specimens (tensile, flexural, pressurized ring, etc.) that are primarily subjected to uniaxial stress states. The practice also assumes that the flaw population is stable with time and that no slow crack growth is occurring.

1.4 The practice outlines methods to correct for bias errors in the estimated Weibull parameters and to calculate confidence bounds on those estimates from data sets where all failures originate from a single flaw population (that is, a single failure mode). In samples where failures originate from multiple independent flaw populations (for example, competing failure modes), the methods outlined in Section for bias correction and confidence bounds are not applicable.

1.5 This practice includes the following:

1.6 The values stated in SI units are to be regarded as the standard per IEEE/ASTM SI 10.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1239 – 06A

Standard Practice for

Reporting Uniaxial Strength Data and Estimating Weibull

1

Distribution Parameters for Advanced Ceramics

This standard is issued under the fixed designation C1239; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This practice includes the following:

Section

1.1 This practice covers the evaluation and reporting of

Scope 1

uniaxialstrengthdataandtheestimationofWeibullprobability

Referenced Documents 2

distribution parameters for advanced ceramics that fail in a

Terminology 3

Summary of Practice 4

brittle fashion (see Fig. 1). The estimated Weibull distribution

Significance and Use 5

parameters are used for statistical comparison of the relative

Interferences 6

quality of two or more test data sets and for the prediction of Outlying Observations 7

Maximum Likelihood Parameter Estimators for 8

the probability of failure (or, alternatively, the fracture

Competing Flaw Distributions

strength) for a structure of interest. In addition, this practice

Unbiasing Factors and Confidence Bounds 9

encourages the integration of mechanical property data and

Fractography 10

Examples 11

fractographic analysis.

Keywords 12

1.2 Thefailurestrengthofadvancedceramicsistreatedasa

ComputerAlgorithm MAXL Appendix

continuousrandomvariabledeterminedbytheflawpopulation. X1

Test Specimens with Unidentified Fracture Ori- Appendix

Typically, a number of test specimens with well-defined

gins X2

geometry are failed under well-defined isothermal forcing

conditions. The force at which each test specimen fails is

recorded. The resulting failure stress data are used to obtain

Weibull parameter estimates associated with the underlying

flaw population distribution.

1.3 This practice is restricted to the assumption that the

distribution underlying the failure strengths is the two-

parameter Weibull distribution with size scaling. Furthermore,

this practice is restricted to test specimens (tensile, flexural,

pressurized ring, etc.) that are primarily subjected to uniaxial

stressstates.Thepracticealsoassumesthattheflawpopulation

is stable with time and that no slow crack growth is occurring.

1.4 The practice outlines methods to correct for bias errors

in the estimated Weibull parameters and to calculate confi-

dence bounds on those estimates from data sets where all

failuresoriginatefromasingleflawpopulation(thatis,asingle

failure mode). In samples where failures originate from mul-

tiple independent flaw populations (for example, competing

failure modes), the methods outlined in Section 9 for bias

correction and confidence bounds are not applicable.

FIG. 1 Example of Weibull Plot of Strength Data

1

This practice is under the jurisdiction ofASTM Committee C28 onAdvanced

Ceramics and is the direct responsibility of Subcommittee C28.02 on Reliability.

1.6 The values stated in SI units are to be regarded as the

CurrenteditionapprovedJune1,2006.PublishedJuly2006.Originallyapproved

in 1993. Last previous edition approved in 2006 as C1239–06. standard per IEEE/ASTMSI10.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C 1239 – 06A

2. Referenced Documents exclusive. A simple example is where every test specimen

2

containstheflawdistribution A,whilesomefractionofthetest

2.1 ASTM Standards:

specimensalsocontainsasecondindependentflawdistribution

C1145 Terminology of Advanced Ceramics

B.

C1322 Practice for Fractography and Characterization of

3.2.3 concurrent flaw distributions—type of multiple flaw

Fracture Origins in Advanced Ceramics

distribution in a homogeneous material where every test

E6 Terminology Relating to Methods of Mechanical Test-

specimen of that material contains representative flaws from

ing

each independent flaw population. Within a given test speci-

E178 Practice for Dealing With Outlying Observations

men,allflawpopulationsarethenpresentconcurrentlyandare

E456 Terminology Relating to Quality and Statistics

competing with each other to cause failure. This term is

IEEE/ASTMSI10 American National Standard for Use of

synonymous with “competing flaw distributions.”

the International System of Units (SI): The Modern Metric

3.2.4 effective gage section—that portion of the test speci-

System

men geometry that has been included within the limits of

3. Terminology

integration (volume, area, or edge length) of the Weibull

3.1 Proper use of the following terms and equations will distribution function. In tensile test specimens, the integration

may be restricted to the uniformly stress

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.