ASTM F1236-96(2001)

(Guide)Standard Guide for Visual Inspection of Electrical Protective Rubber Products

Standard Guide for Visual Inspection of Electrical Protective Rubber Products

SCOPE

1.1 The purpose of this guide is to present methods and techniques for the visual inspection of electrical protective rubber products. This guide also includes descriptions and photographs of irregularities found in these products.

Note—It is not the purpose of this guide to establish the acceptance level of any irregularity described herein. That shall be established by the standard for each product.

1.2 The values stated in inch-pound units are to be regarded as standard. The SI units in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1236 – 96 (Reapproved 2001)

Standard Guide for

Visual Inspection of Electrical Protective Rubber Products

This standard is issued under the fixed designation F 1236; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 The purpose of this guide is to present methods and

techniques for the visual inspection of electrical protective

rubber products. This guide also includes descriptions and

photographs of irregularities found in these products.

NOTE 1—It is not the purpose of this guide to establish the acceptance

level of any irregularity described herein. That shall be established by the

standard for each product.

1.2 The values stated in inch-pound units are to be regarded

as standard. The SI units in parentheses are for information

only.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

FIG. 1 Abrasion

2. Referenced Documents

3.1.3 breakdown—the electrical discharge or arc occurring

2.1 ASTM Standards:

between the electrodes and through the equipment being tested

F 496 Specification for In-Service Care of Insulating

(see Fig. 4).

Gloves and Sleeves

F 819 Definitions of Terms Relating to Electrical Protective

Equipment for Workers

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 abrasions and scratches—surface damage that nor-

mally occurs when a product makes contact with an abrasive

surface. Scuff-like damage can also occur from a brush contact

with a hot object such as a soldering iron. This can sometimes

look like the graining on leather (see Fig. 1 and Fig. 2).

3.1.2 age cracks—surface cracks that may look like the

crazing of glazed ceramics and become progressively worse

with time. It is normally a slow oxidation process caused by

exposure to sunlight and ozone in the atmosphere and starts in

areas of the rubber that are under stress (see Fig. 3).

This guide is under the jurisdiction of ASTM Committee F18 on Electrical

Protective Equipment for Workers and is the direct responsibility of Subcommittee

F18.60 on Terminology.

Current edition approved March 10, 1996. Published August 1996. Originally

published as F 1236 – 89. Last previous edition F 1236 – 89.

Annual Book of ASTM Standards, Vol 10.03. FIG. 2 Scratches

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1236 – 96 (2001)

FIG. 3 Age Cracks

FIG. 5 Chemical Bloom

FIG. 4 Breakdown (Dielectric Failure)

3.1.4 chemical bloom—a white or yellowish discoloration

on the surface of a rubber product caused by the migration to

the surface of chemical additives used in the manufacture of

the finished product (see Fig. 5).

3.1.5 color splash—a spot or blotch on the surface of a

rubber product that occurred during the manufacturing process

when a contrasting colored particle of unvulcanized rubber

became embedded into the finished product (see Fig. 6).

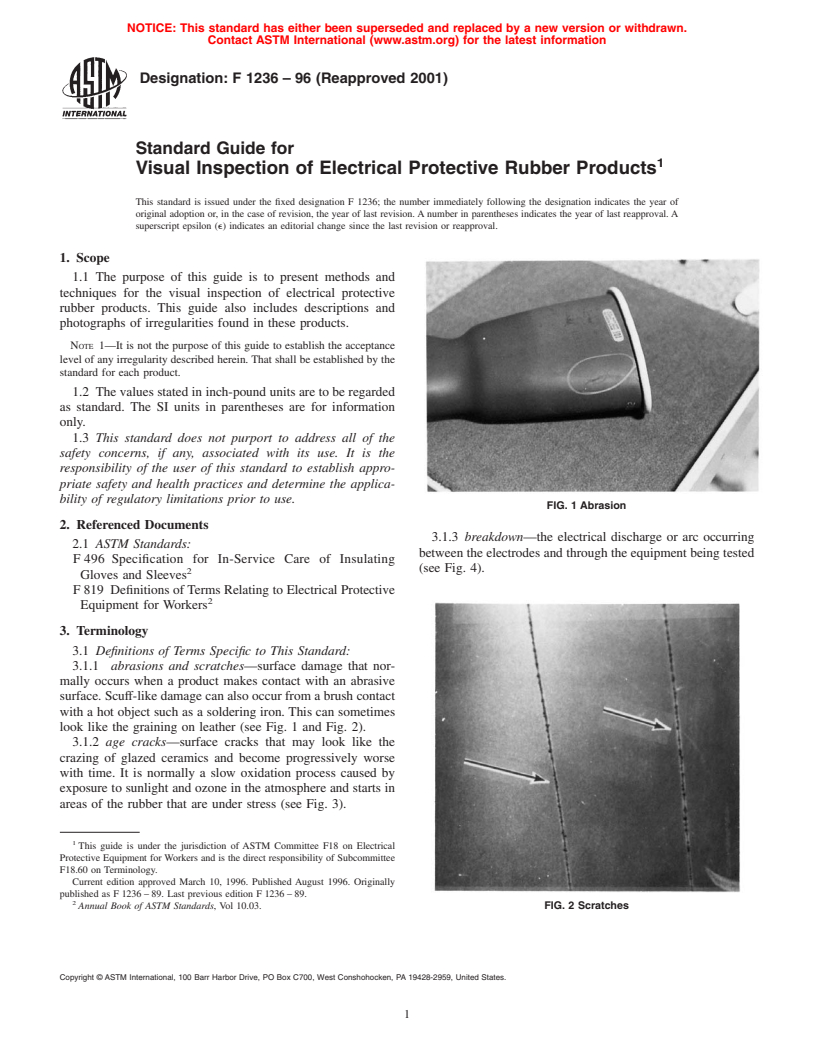

3.1.6 cuts— smooth incisions in the surface of the rubber

that are usually caused by a sharp-edged object that can

increase in size when they are placed under strain (see Fig. 7).

3.1.7 depressions or indentations—a shallow recess in the

surface of the rubber that exhibits a thinner rubber thickness at

the bottom of the depression than in the surrounding areas (see

FIG. 6 Color Splash

Fig. 8).

3.1.8 detergent cracks—cracks that appear on the inside

surface of a glove or sleeve that encircle the outline of a spot 3.1.9 embedded foreign matter—a particle of non-rubber

of detergent residue that was not removed during the cleaning material that has been molded into the finished product and

and rinsing of the form prior to the dipping process. mayappearasabumpwhentherubberisstretched(seeFig.9).

F 1236 – 96 (2001)

FIG. 7 Cuts

FIG. 10 Hard Spot

FIG. 8 Depressions or Indentations

FIG. 11 Hard Spot

3.1.12 mold marks—a raised or indented section on the

surface of the rubber that was caused by an irregularity in the

mold (see Figs. 14 and 15).

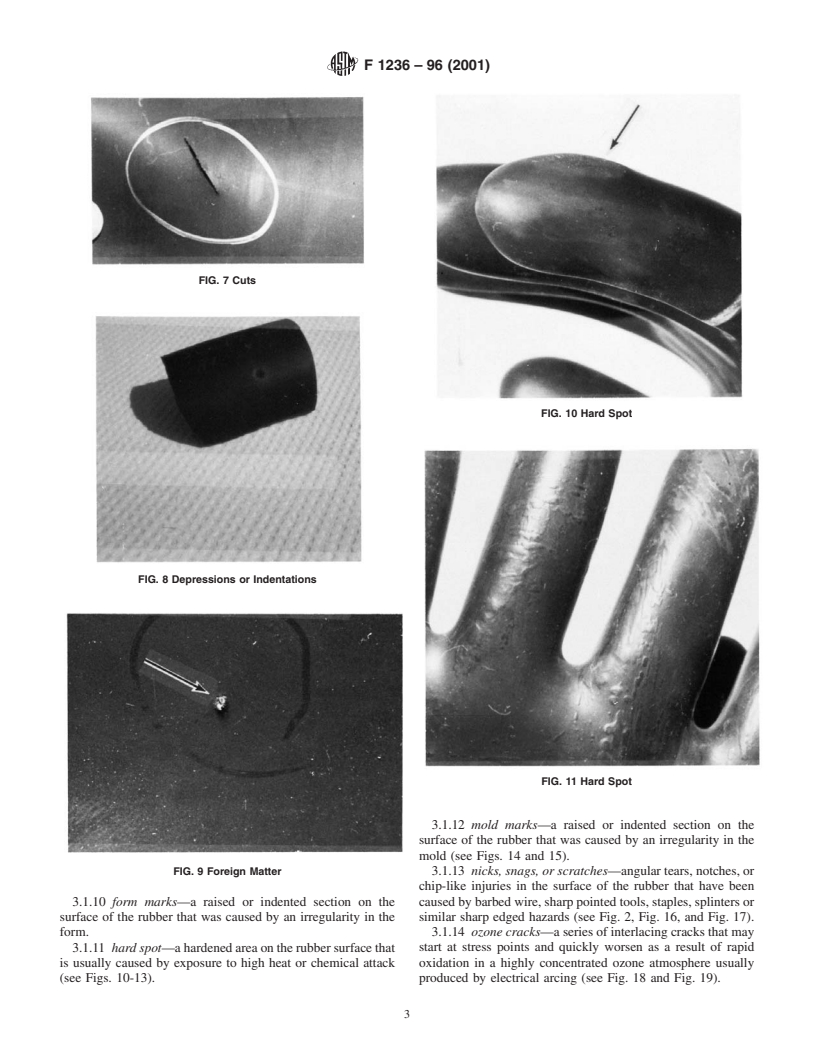

FIG. 9 Foreign Matter

3.1.13 nicks, snags, or scratches—angular tears, notches, or

chip-like injuries in the surface of the rubber that have been

3.1.10 form marks—a raised or indented section on the caused by barbed wire, sharp pointed tools, staples, splinters or

surface of the rubber that was caused by an irregularity in the similar sharp edged hazards (see Fig. 2, Fig. 16, and Fig. 17).

form. 3.1.14 ozone cracks—a series of interlacing cracks that may

3.1.11 hard spot—ahardenedareaontherubbersurfacethat start at stress points and quickly worsen as a result of rapid

is usually caused by exposure to high heat or chemical attack oxidation in a highly concentrated ozone atmosphere usually

(see Figs. 10-13). produced by electrical arcing (see Fig. 18 and Fig. 19).

F 1236 – 96 (2001)

FIG. 13 Hard Spot

FIG. 12 Hard Spot

3.1.15 parting line or flash line—a ridge of rubber left on

finished products occurring at mold joints during the manufac-

turing process.

3.1.16 pitting—a pit-like depression in the surface of the

rubber that may have been created by the rupturing of an air

bubble at or near the surface of the rubber during the

manufacturing process (see Fig. 20).

3.1.17 protuberance—bulge or swelling that protrudes

above the surface of the rubber that may have occurred during

manufacture (see Fig. 21).

3.1.18 puncture—penetration by a sharp object through the

entire thickness of the rubber product (see Fig. 22).

3.1.19 repair marks—an area on the surface of the finished

product that has a different texture due to the repair or

reworking of an irregularity in the mold or form (see Fig. 23).

3.1.20 runs— raised flow marks that may occur on the

FIG. 14 Mold Marks

fingers of rubber gloves during the dipping process.

3.1.21 skin breaks—cavities in the surface of the rubber

with filmy ragged edges and smooth interior surfaces that are

normally caused by embedded dirt specks during manufacture.

F 1236 – 96 (2001)

FIG. 17 Snag

FIG. 15 Mold Marks

FIG. 18 Ozone Cracks

FIG. 16 Nick

3.1.22 soft spots—surface areas of the rubber that have

become soft and sometimes tacky as a result of exposure to

heat, oils, or chemical solvents.

3.1.23 tears— a separation of the rubber through its entire

thickness, usually at an edge, that has been created by a

forceful pulling apart of the rubber (see Fig. 24).

3.1.24 tracking—the formation of a carbonized path on the

surface of a solid insulating me

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.