ASTM D7917-14

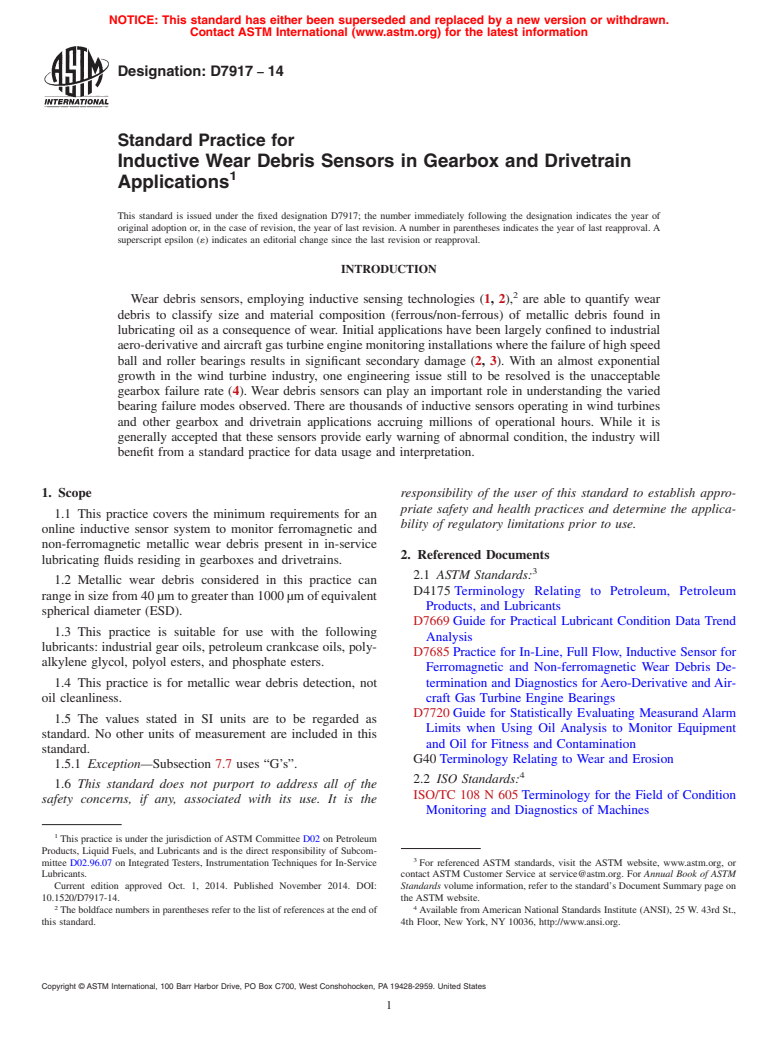

(Practice)Standard Practice for Inductive Wear Debris Sensors in Gearbox and Drivetrain Applications

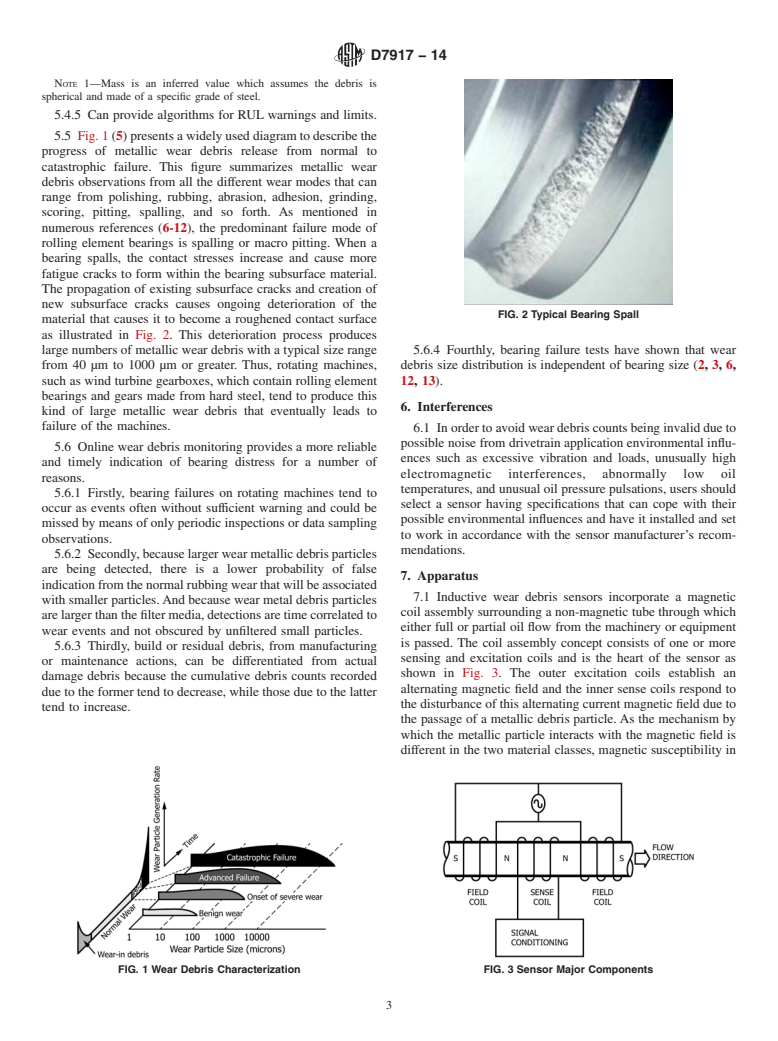

Standard Practice for Inductive Wear Debris Sensors in Gearbox and Drivetrain Applications

SIGNIFICANCE AND USE

5.1 This practice is intended for the application of online, full-flow, or slip-stream sampling of wear debris via inductive sensors for gearbox and drivetrain applications.

5.2 Periodic sampling and analysis of lubricants have long been used as a means to determine overall machinery health. The implementation of smaller oil filter pore sizes for machinery has reduced the effectiveness of sampled oil analysis for determining abnormal wear prior to severe damage. In addition, sampled oil analysis for equipment that is remote or otherwise difficult to monitor or access is not always sufficient or practical. For these machinery systems, in-line wear debris sensors can be very useful to provide real-time and near-real-time condition monitoring data.

5.3 Online inductive debris sensors have demonstrated the capability to detect and quantify both ferromagnetic and non-ferromagnetic metallic wear debris (1, 2). These sensors record metallic wear debris according to size, count, and type (ferromagnetic or non-ferromagnetic). Sensors can be fitted to virtually any lubricating system. The sensors are particularly effective for the protection of rolling element bearings and gears in critical machine applications. Bearings are key elements in machines since their failure often leads to significant secondary damage that can adversely affect safety, operational availability, operational/maintenance costs, or combinations thereof.

5.4 The key advantage of online metallic debris sensors is the ability to detect early bearing and gear damage and to quantify the severity of damage and rate of progression toward failure. Sensor capabilities are summarized as follows:

5.4.1 Can detect both ferromagnetic and non-ferromagnetic metallic wear debris.

5.4.2 Can detect 95 % or more of metallic wear debris above some minimum particle size threshold.

5.4.3 Can count and size wear debris detected.

5.4.4 Can provide total mass loss.

Note 1: Mass is an inferred value which ...

SCOPE

1.1 This practice covers the minimum requirements for an online inductive sensor system to monitor ferromagnetic and non-ferromagnetic metallic wear debris present in in-service lubricating fluids residing in gearboxes and drivetrains.

1.2 Metallic wear debris considered in this practice can range in size from 40 μm to greater than 1000 μm of equivalent spherical diameter (ESD).

1.3 This practice is suitable for use with the following lubricants: industrial gear oils, petroleum crankcase oils, polyalkylene glycol, polyol esters, and phosphate esters.

1.4 This practice is for metallic wear debris detection, not oil cleanliness.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5.1 Exception—Subsection 7.7 uses “G’s”.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7917 − 14

Standard Practice for

Inductive Wear Debris Sensors in Gearbox and Drivetrain

1

Applications

This standard is issued under the fixed designation D7917; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

2

Wear debris sensors, employing inductive sensing technologies (1, 2), are able to quantify wear

debris to classify size and material composition (ferrous/non-ferrous) of metallic debris found in

lubricating oil as a consequence of wear. Initial applications have been largely confined to industrial

aero-derivative and aircraft gas turbine engine monitoring installations where the failure of high speed

ball and roller bearings results in significant secondary damage (2, 3). With an almost exponential

growth in the wind turbine industry, one engineering issue still to be resolved is the unacceptable

gearbox failure rate (4). Wear debris sensors can play an important role in understanding the varied

bearing failure modes observed. There are thousands of inductive sensors operating in wind turbines

and other gearbox and drivetrain applications accruing millions of operational hours. While it is

generally accepted that these sensors provide early warning of abnormal condition, the industry will

benefit from a standard practice for data usage and interpretation.

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 This practice covers the minimum requirements for an

bility of regulatory limitations prior to use.

online inductive sensor system to monitor ferromagnetic and

non-ferromagnetic metallic wear debris present in in-service

2. Referenced Documents

lubricating fluids residing in gearboxes and drivetrains.

3

2.1 ASTM Standards:

1.2 Metallic wear debris considered in this practice can

D4175 Terminology Relating to Petroleum, Petroleum

rangeinsizefrom40µmtogreaterthan1000µmofequivalent

Products, and Lubricants

spherical diameter (ESD).

D7669 Guide for Practical Lubricant Condition Data Trend

1.3 This practice is suitable for use with the following

Analysis

lubricants: industrial gear oils, petroleum crankcase oils, poly-

D7685 Practice for In-Line, Full Flow, Inductive Sensor for

alkylene glycol, polyol esters, and phosphate esters.

Ferromagnetic and Non-ferromagnetic Wear Debris De-

1.4 This practice is for metallic wear debris detection, not termination and Diagnostics for Aero-Derivative and Air-

craft Gas Turbine Engine Bearings

oil cleanliness.

D7720 Guide for Statistically Evaluating Measurand Alarm

1.5 The values stated in SI units are to be regarded as

Limits when Using Oil Analysis to Monitor Equipment

standard. No other units of measurement are included in this

and Oil for Fitness and Contamination

standard.

G40 Terminology Relating to Wear and Erosion

1.5.1 Exception—Subsection 7.7 uses “G’s”.

4

2.2 ISO Standards:

1.6 This standard does not purport to address all of the

ISO/TC 108 N 605 Terminology for the Field of Condition

safety concerns, if any, associated with its use. It is the

Monitoring and Diagnostics of Machines

1

This practice is under the jurisdiction ofASTM Committee D02 on Petroleum

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

3

mittee D02.96.07 on Integrated Testers, Instrumentation Techniques for In-Service For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Lubricants. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Oct. 1, 2014. Published November 2014. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D7917-14. the ASTM website.

2 4

The boldface numbers in parentheses refer to the list of references at the end of Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

this standard. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7917 − 14

3. Terminology installationbutshouldsupplyarepresentativeportionoftheoil

flow and debris from the gearbox or drivetrain through the

3.1 Definitions:

sensor before any filtration. The minimum requirements of a

3.1.1 condition monitoring, n—a field of technical activity

system are the detection and counting of ferrous and non-

in which selected physical parameters associated with an

ferrous metallic wear debris carried in the oil flow. Counts are

operating machine are periodically or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.