ASTM D7594-10

(Test Method)Standard Test Method for Determining Fretting Wear Resistance of Lubricating Greases Under High Hertzian Contact Pressures Using a High-Frequency, Linear-Oscillation (SRV) Test Machine

Standard Test Method for Determining Fretting Wear Resistance of Lubricating Greases Under High Hertzian Contact Pressures Using a High-Frequency, Linear-Oscillation (SRV) Test Machine

SCOPE

1.1 This test method covers a procedure for determining the lubricating action of greases in order to prevent “fretting” wear under linear oscillation with associated low strokes and high Hertzian contact pressures under high-frequency linear-oscillation motion using the SRV test machine. By performing additional, nonmandatory extreme-pressure tests in accordance with Test Method D5706, the test grease should be shown to be able to withstand a Hertzian contact pressure of at least 2200 MPa without adhesive failure.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7594 – 10

Standard Test Method for

Determining Fretting Wear Resistance of Lubricating

Greases Under High Hertzian Contact Pressures Using a

High-Frequency, Linear-Oscillation (SRV) Test Machine

This standard is issued under the fixed designation D7594; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope erties of Extreme Pressure (EP) Lubricating Oils Using

SRV Test Machine

1.1 This test method covers a procedure for determining the

D7421 Test Method for Determining Extreme Pressure

lubricating action of greases in order to prevent “fretting” wear

Properties of Lubricating Oils Using High-Frequency,

under linear oscillation with associated low strokes and high

Linear-Oscillation (SRV) Test Machine

Hertzian contact pressures under high-frequency linear-

E45 Test Methods for Determining the Inclusion Content of

oscillation motion using the SRV test machine. By performing

Steel

additional, nonmandatory extreme-pressure tests in accordance

G40 Terminology Relating to Wear and Erosion

withTestMethodD5706,thetestgreaseshouldbeshowntobe

2.2 DIN Standards:

able to withstand a Hertzian contact pressure of at least

DIN 51834-3:2008-12 Testing of lubricants – Tribological

2200 MPa without adhesive failure.

test in translatory oscillation apparatus – Part 3: Determi-

1.2 The values stated in SI units are to be regarded as

nation of tribological behaviour of materials in coopera-

standard. No other units of measurement are included in this

tion with lubricants

standard.

DIN 51631:1999 Special-boiling-point spirits - Require-

1.3 This standard does not purport to address all of the

ments and testing

safety concerns, if any, associated with its use. It is the

DIN EN ISO 683-17 Heat-treated steels, alloy steels and

responsibility of the user of this standard to establish appro-

free-cutting steels - Part 17: Ball and roller bearing steels

priate safety and health practices and determine the applica-

(replaces DIN 17230-1980)

bility of regulatory limitations prior to use.

DIN EN ISO 13565-2:1998 Geometrical Product Specifica-

2. Referenced Documents

tions (GPS) - Surface texture: Profile method - Surfaces

having stratified functional properties - Part 2: Height

2.1 ASTM Standards:

characterization using the linear material ratio curve

A295/A295M Specification for High-Carbon Anti-Friction

(replaces DIN 4776-1990)

Bearing Steel

2.3 ISO Standards

D217 Test Methods for Cone Penetration of Lubricating

ISO 1250:1972 Mineral solvents for paints -- White spirits

Grease

and related hydrocarbon solvents

D4175 Terminology Relating to Petroleum, Petroleum

Products, and Lubricants

3. Terminology

D5706 Test Method for Determining Extreme Pressure

3.1 Definitions:

Properties of Lubricating Greases Using a High-

3.1.1 break-in, n—in tribology, an initial transition process

Frequency, Linear-Oscillation (SRV) Test Machine

occurring in newly established wearing contacts, often accom-

D6425 Test Method for Measuring Friction and Wear Prop-

panied by transients in coefficient of friction or wear rate, or

both,thatareuncharacteristicofthegiventribologicalsystem’s

This test method is under the jurisdiction of ASTM Committee D02 on long-term behavior. G40

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.G0.04 on Functional Tests - Tribology.

Current edition approved May 1, 2010. Published August 2010. DOI:10.1520/ Available from Available from Beuth Verlag GmbH (DIN-- DIN Deutsches

D7594-10. Institut fur Normung e.V.), Burggrafenstrasse 6, 10787, Berlin, Germany, http://

For referenced ASTM standards, visit the ASTM website, www.astm.org, or www.en.din.de.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from International Organization for Standardization (ISO), 1, ch. de

Standards volume information, refer to the standard’s Document Summary page on la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

the ASTM website. www.iso.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7594 – 10

3.1.2 coeffıcient of friction, µ or ƒ, n—in tribology, the 3.2.3 seizure, n—localized adhesion of polymer onto metal

dimensionless ratio of the friction force (F) between two between the rubbing surfaces of the test pieces.

bodies to the normal force (N) pressing these bodies together. 3.2.3.1 Discussion—In this test method, seizure is indicated

G40 by a sharp rise in the coefficient of friction, over steady state,

of greater than 0.2 for over 20 s, or a coefficient of friction

3.1.3 Hertzian contact area, n—apparent area of contact

between two nonconforming solid bodies pressed against each >0.35 or by any examples shown in Test Method D5706 and

other, as calculated from Hertz’ equations of elastic deforma- D7421). If any of these conditions occur, the test is not valid.

tion. G40 (These criteria were believed to be right, because this standard

is related to greases.) The evidence of adhesive wear mor-

3.1.4 Hertzian contact pressure, n—magnitude of the pres-

sure at any specified location in a Hertzian contact area, as phologies should be controlled by micro-optical examination

of the wear scar and track. In severe cases, a stoppage in the

calculated from Hertz’ equations of elastic deformation. G40

3.1.5 lubricant, n—any material interposed between two motor will occur.

3.2.4 SRV, n—Schwingung, Reibung, Verschleiß (Ger-

surfaces that reduces the friction or wear between them.

D4175 man); oscillating, friction, wear (English translation).

3.1.6 lubricating grease, n—asemi–fluidtosolidproductof

4. Summary of Test Method

a dispersion of a thickener in a liquid lubricant. D217

4.1 This test method is performed on an SRV test machine

3.1.6.1 Discussion—Thedispersionofthethickenerformsa

using a steel test ball oscillating under constant frequency,

two-phase system and immobilizes the liquid lubricant by

short stroke amplitude and under constant load (F ), against a

n

surface tension and other physical forces. Other ingredients are

stationary steel test disk with a grease lubricant between them

commonly included to impart special properties.

in order to determine the coefficient of friction and wear scar

3.1.7 Ra (C.L.A.), n—in measuring surface finish, the arith-

diameter.

metic average of the absolute distances of all profile points

4.2 For the non-mandatory extreme pressure test (see Ap-

from the mean line for a given distance.

pendixX1),thetestloadisincreasedin100-Nincrementsuntil

3.1.7.1 Discussion—C.L.A. means center line average, and

seizure occurs (see Test Method D5706). The load, immedi-

it is a synonym to Ra. Amstutz, p. 21

ately prior to the load at which seizure occurs, is measured and

3.1.8 Rpk, n—Reduced peak height according to DIN EN

reported.

ISO 13565-2:1998. Rpk is the mean height of the peak sticking

out above the core profile section. NOTE 1—Test frequency, stroke length, temperature, and ball and disk

material can be varied to simulate field conditions. The test ball yields

3.1.9 Rvk, n—Reduced valley height according to DIN EN

point-contact geometry. To obtain line or area contact, test pieces of

ISO 13565-2:1998. Rvk is the mean depth of the valley

differing configurations can be substituted for the test balls.

reaching into the material below the core profile section.

4.3 The friction force, F, is measured by a piezo-electric

3.1.10 Ry, n—in measuring surface finish, the vertical f

device in the test disk assembly. Peak values of coefficient of

distance between the top of the highest peak and the bottom of

friction, f,aredeterminedandrecordedasafunctionoftimefor

the deepest valley in one sampling length. Amstutz, p. 25

SRV I and II models. SRV III and IV models can display the

3.1.11 Rz (DIN), n—in measuring surface finish, the aver-

hysteresis (Friction force or coefficient of friction over stroke

age of all Ry values (peak to valley heights) in the assessment

length) and save test data electronically.

length. Amstutz, pp. 29, 31

4.4 After a preset test period, the test machine and chart

3.1.12 thickener, n—in lubricating grease, a substance

recorder stopped and the wear scar on the ball is measured. If

composed of finely divided particles dispersed in a liquid

a profilometer is available, a trace of the wear track on the test

lubricant to form the product’s structure. D217

disk and the wear scar of the ball (See DIN 51834-3 and

3.1.12.1 Discussion—The thickener can be fibers (such as

Appendix X1) can also be used to obtain additional wear

various metallic soaps) or plates or spheres (such as certain

information. Wear volume in mm and wear rate of disk and

non-soap thickeners) which are insoluble or, at most, only very

ball in mm /Nm).

slightly soluble in the liquid lubricant. The general require-

mentsarethatthesolidparticlesbeextremelysmall,uniformly

5. Significance and Use

dispersed, and capable of forming a relatively stable, gel-like

5.1 This test method can be used to determine anti-wear

structure with the liquid lubricant.

properties and coefficient of friction of greases in order to

3.2 Definitions of Terms Specific to This Standard:

prevent “fretting” wear under linear oscillation with associated

3.2.1 extreme pressure, adj—in lubrication, characterized

low strokes and high Hertzian contact pressures at selected

by metal surface in contact under high-stress rubbing condi-

temperatures and loads specified for use in applications in

tions.

which induced, high-speed vibrational motions are present for

3.2.2 fretting wear, n—wear arising as a result of fretting.

extended periods of time. It has found application as a

Small amplitude oscillatory motion, usually tangential, be-

screening test for grease lubricants used in ball and roller

tween two solid surfaces in contact.

bearings, roller or ball screw (spindle) drives or side shaft

systems (Tripode or Rzeppa type) for example, so-called

constant velocity (CV) joints. Users of this test method should

determine whether results correlate with field performance or

Amstutz, Hu, “Surface Texture: The Parameters,” Bulletin MI-TP-003–0785,

Sheffield Measurement Division, Warner and Swasey, 1985. other applications.

D7594 – 10

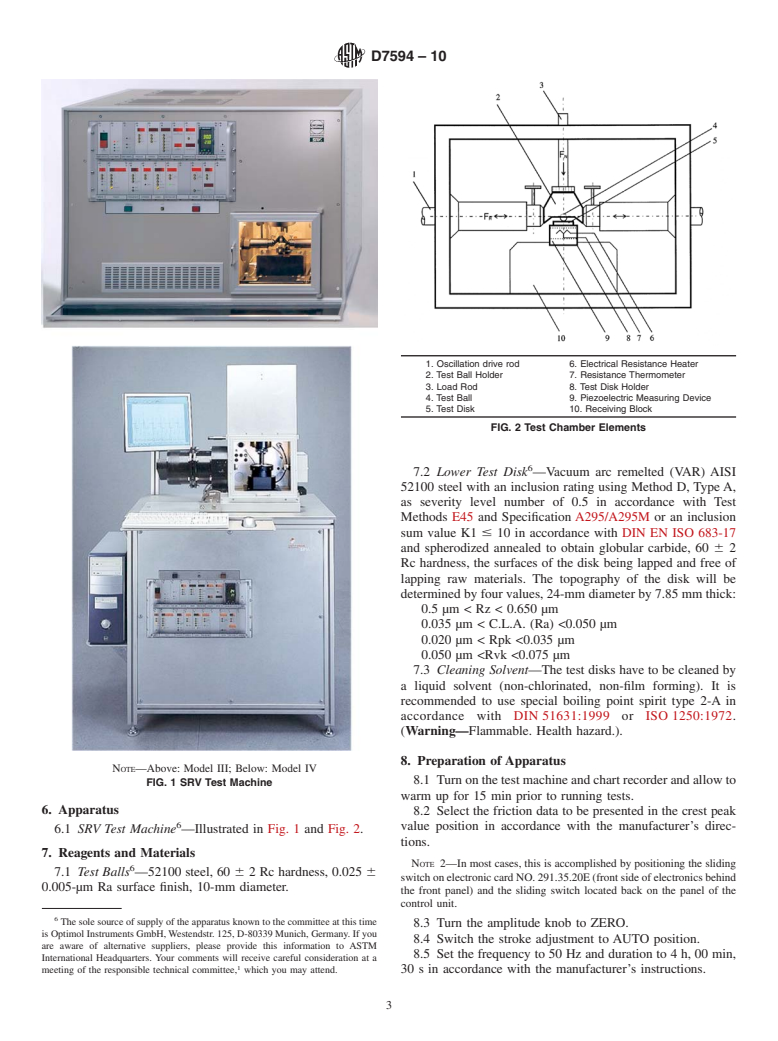

1. Oscillation drive rod 6. Electrical Resistance Heater

2. Test Ball Holder 7. Resistance Thermometer

3. Load Rod 8. Test Disk Holder

4. Test Ball 9. Piezoelectric Measuring Device

5. Test Disk 10. Receiving Block

FIG. 2 Test Chamber Elements

7.2 Lower Test Disk —Vacuum arc remelted (VAR) AISI

52100 steel with an inclusion rating using Method D, Type A,

as severity level number of 0.5 in accordance with Test

Methods E45 and Specification A295/A295M or an inclusion

sum value K1# 10 in accordance with DIN EN ISO 683-17

and spherodized annealed to obtain globular carbide, 60 6 2

Rc hardness, the surfaces of the disk being lapped and free of

lapping raw materials. The topography of the disk will be

determined by four values, 24-mm diameter by 7.85 mm thick:

0.5 µm < Rz < 0.650 µm

0.035 µm < C.L.A. (Ra) <0.050 µm

0.020 µm < Rpk <0.035 µm

0.050 µm

7.3 Cleaning Solvent—The test disks have to be cleaned by

a liquid solvent (non-chlorinated, non-film forming). It is

recommended to use special boiling point spirit type 2-A in

accordance with DIN 51631:1999 or ISO 1250:1972.

(Warning—Flammable. Health hazard.).

8. Preparation of Apparatus

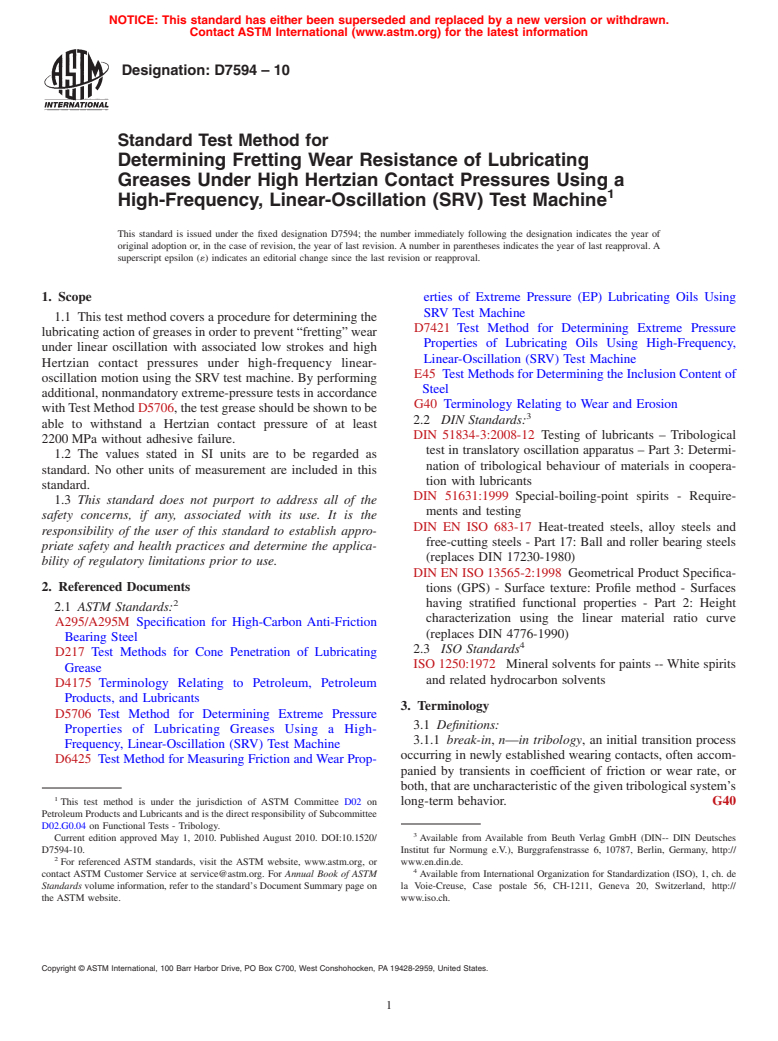

NOTE—Above: Model III; Below: Model IV

8.1 Turnonthetestmachineandchartrecorderandallowto

FIG. 1 SRV Test Machine

warm up for 15 min prior to running tests.

6. Apparatus 8.2 Select the friction data to be presented in the crest peak

value position in accordance with the manufacturer’s direc-

6.1 SRV Test Machine —Illustrated in Fig. 1 and Fig. 2.

tions.

7. Reagents and Materials

NOTE 2—In most cases, this is accomplished by positioning the sliding

7.1 Test Balls —52100 steel, 60 6 2 Rc hardness, 0.025 6

switchonelectroniccardNO.291.35.20E(frontsideofelectronicsbehind

0.005-µm Ra surface finish, 10-mm diameter.

the front panel) and the sliding switch located back on the panel of the

control unit.

The sole source of supply of the apparatus known to the committee at this time

8.3 Turn the amplitude knob to ZERO.

is Optimol Instruments GmbH,Westendstr. 125, D-80339 Munich, Germany. If you

8.4 Switch the stroke adjustment to AUTO position.

are aware of alternative suppliers, please provide this information to ASTM

8.5 Set the frequency to 50 Hz and duration to 4 h, 00 min,

International Headquarters. Your comments will receive careful consideration at a

meeting of the responsible technical committee, which you may attend. 30 s in accordance with the manufacturer’s instructions.

D7594 – 10

8.6 Set the load charge amplifier to the setting that corre- 9.2.5 For SRV III and IV models only In the SRV basic

sponds to the load foreseen for the test in accordance with the software, enter the following test parameters:

manufacturer’s instructions. Select the desired chart speed.

Frequency = 50 Hz

Stroke = 0.3 mm (300 µm)

NOTE 3—In later SRV models, the load charge amplifier is set auto-

Temperature = 50°C

matically.

Load 50 N for 30 s, then increase load to 100 N

9. Procedure

Test duration = 240 min

9.1 Installation of the Test Pieces and Lubricating Oil

To fully tighten the specimen combination, follow the

Specimen in the Test Chamber: instructions of the SRV software.

9.1.1 Using solvent resistant gloves, clean the test ball, ball

9.2.6 Terminating the Test Run:

holder, and disk by wiping the surfaces with laboratory tissue

9.2.6.1 The test is automatically terminated by the timer

soaked with the cleaning solvent (single boiling point spirit

when the preset test time has elapsed. The machine will

type 2-A in accordance with DIN 51631:1999.(Warning—

automatically stop.

This mixture is flammable and health hazard.) Repeat wiping

NOTE 6—Power automatically turns off at the end of the test.

until no dark residue appears on the tissue. Immerse the test

NOTE 7—If, due to seizure, the friction coefficient exceeds the limit of,

ball and disk in a beaker of the cleaning solvent under

for example, f = 0.35, the test should be terminated (see 3.2.3). If the

ultrasonic vibration for 10 min. Dry the test ball and disk with

machine does not automatically shut down at this point, it may have to be

a clean tissue to ensure no streaking occurs on the surface.

switched off manually.

9.1.2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.