ASTM D1404-99

(Test Method)Standard Test Method for Estimation of Deleterious Particles in Lubricating Grease

Standard Test Method for Estimation of Deleterious Particles in Lubricating Grease

SCOPE

1.1 This test method describes a procedure for the detection and estimation of deleterious particles in lubricating grease.

1.2 This test method is applicable to all lubricating greases. It can also be used to test other semi-solid or viscous materials. Grease fillers, such as graphite and molybdenum disulfide, can be tested for abrasive contaminants by first mixing them into petrolatum or grease known to be free of deleterious particles.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system shall be used independently of the other. Combining values from the two systems could result in nonconformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 1404 – 99

Standard Test Method for

Estimation of Deleterious Particles in Lubricating Grease

This standard is issued under the fixed designation D 1404; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 lubricant, n—any material interposed between two

surfaces that reduces the friction or wear between them.

1.1 This test method describes a procedure for the detection

3.1.2 lubricating grease, n—a semi-fluid to solid product of

and estimation of deleterious particles in lubricating grease.

a dispersion of a thickener in a liquid lubricant.

1.2 This test method is applicable to all lubricating greases.

3.1.2.1 Discussion—The dispersion of the thickener forms a

It can also be used to test other semi-solid or viscous materials.

two-phase system and immobilizes the liquid lubricant by

Grease fillers, such as graphite and molybdenum disulfide, can

surface tension and other physical forces. Other ingredients are

be tested for abrasive contaminants by first mixing them into

commonly included to impart special properties.

petrolatum or grease known to be free of deleterious particles.

3.1.3 thickener, n—in lubricating grease, a substance com-

1.3 The values stated in either inch-pound units or SI units

posed of finely-divided particles dispersed in a liquid lubricant

are to be regarded separately as standard. Within the text, the

to form the product’s structure.

SI units are shown in brackets. The values stated in each

3.1.3.1 Discussion—The solid thickener can be fibers (such

system shall be used independently of the other. Combining

as various metallic soaps) or plates or spheres (such as certain

values from the two systems could result in nonconformance

non-soap thickeners), which are insoluble or, at the most, only

with the standard.

very slightly soluble in the liquid lubricant. The general

1.4 This standard does not purport to address all of the

requirements are that the solid particles be extremely small,

safety concerns, if any, associated with its use. It is the

uniformly dispersed, and capable of forming a relatively stable,

responsibility of the user of this standard to establish appro-

gel-like structure with the liquid lubricant.

priate safety and health practices and determine the applica-

3.2 Definitions of Terms Specific to This Standard:

bility of regulatory limitations prior to use.

3.2.1 deleterious particles, n—in lubricating grease, minute

2. Referenced Documents bits of solid material present as a contaminant and abrasive to

acrylic plastic.

2.1 ASTM Standards:

D 217 Test Methods for Cone Penetration of Lubricating

4. Summary of Test Method

Grease

4.1 A small portion of the lubricating grease sample is

D 235 Specification for Mineral Spirits (Petroleum Spirits)

placed between two clean, highly polished acrylic-plastic

(Hydrocarbon Dry Cleaning Solvent)

plates held rigidly and parallel in metal holders. A pressure of

D 785 Test Method for Rockwell Hardness of Plastics and

200 psi [1.38 MPa] pressure is applied, and one plate is rotated

Electrical Insulating Materials

30° relative to the other. Particles harder than the plastic and

D 4175 Standard Terminology Relating to Petroleum, Pe-

exceeding in size the distance between the plates will imbed in

troleum Products, and Lubricants

the plates and cause characteristic, arc-shaped scratches in the

3. Terminology

plates.

4.2 The relative number of such solid particles can be

3.1 Definitions:

estimated by counting the total number of arc-shaped scratches

on the two plates.

This test method is under the jurisdiction of ASTM Committee D-2 on

Petroleum Products and Lubricantsand is the direct responsibility of Subcommittee 5. Significance and Use

D02.Gon Lubricating Grease.

5.1 The significance of the number of scratches as far as

Current edition approved Nov. 10, 1999. Published January 2000. Originally

correlation with field performance is concerned has not been

published as D 1404 – 56 T. Last previous edition D 1404 – 94.

Annual Book of ASTM Standards, Vol 05.01.

established. A particle which is abrasive to plastic will not

Annual Book of ASTM Standards, Vol 06.04.

necessarily be abrasive to steel or other bearing materials.

Annual Book of ASTM Standards, Vol 08.01.

5 Some correlation was obtained in that the contaminant used in

Annual Book of ASTM Standards, Vol 05.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D1404–99

(a) Assembled View

(b) Unassembled View

FIG. 1 Apparatus for Determining Deleterious Particles in Lubricating Grease

Sample 3 (see 10.1.1) had a greater wear rate in a laboratory

3 . . more than 40 scratches

ball bearing abrasive wear test than the contaminant in Sample

5.2 An advantage of this test method is that each test takes

2.

only a few minutes to run.

5.3 This test method is used for quality control and speci-

NOTE 1—The number of scratches obtained cannot be used to draw fine

differences between greases, but rather, to group them into two or three fication purpose.

general classes. One such possible division could be:

6. Apparatus

1 . . less than 10 scratches

2 . . 10 to 40 scratches

6.1 The test apparatus is shown in Figs. 1 and 2. As

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D1404–99

6.2 Plastic Test Plates —acrylic plastic test plates (two per

test), 1 6 0.050 in. square by ⁄86 0.025 in. [25.4 6 1.3 mm

square by 3.2 6 0.64 mm] uniformly thick, having a Rockwell

M hardness of 94 6 10 (Test Method D 785), and having

highly polished surfaces protected on both sides with protec-

tive paper.

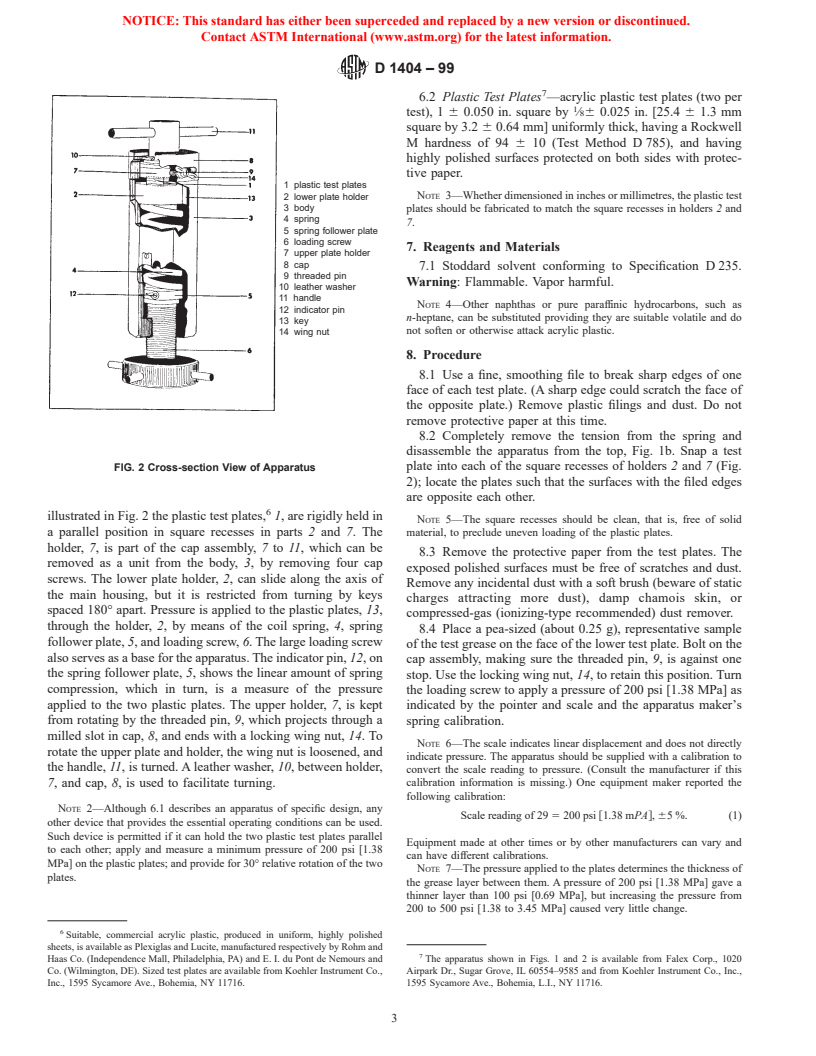

1 plastic test plates

2 lower plate holder NOTE 3—Whether dimensioned in inches or millimetres, the plastic test

3 body

plates should be fabricated to match the square recesses in holders 2 and

4 spring

7.

5 spring follower plate

6 loading screw

7. Reagents and Materials

7 upper plate holder

8 cap

7.1 Stoddard solvent conforming to Specification D 235.

9 threaded pin

Warning: Flammable. Vapor harmful.

10 leather washer

11 handle

NOTE 4—Other naphthas or pure paraffinic hydrocarbons, such as

12 indicator pin

n-heptane, can be substituted providing they are suitable volatile and do

13 key

not soften or otherwise attack acrylic plastic.

14 wing nut

8. Procedure

8.1 Use a fine, smoothing file to break sharp edges of one

face of each test plate. (A sharp edge could scratch the face of

the opposite plate.) Remove plastic filings and dust. Do not

remove protective paper at this time.

8.2 Completely remove the tension from

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.