SIST EN 14662-1:2024

(Main)Ambient air quality - Standard method for measurement of benzene concentrations - Part 1: Pumped sampling followed by thermal desorption and gas chromatography

Ambient air quality - Standard method for measurement of benzene concentrations - Part 1: Pumped sampling followed by thermal desorption and gas chromatography

This document gives general guidance for the sampling and analysis of benzene in air by pumped sampling, thermal desorption and capillary gas chromatography.

This document is in accordance with the generic methodology selected as the basis of the European Union reference method for the determination of benzene in ambient air [1] for the purpose of comparison of measurement results with limit values with a one-year reference period.

This document is valid for the measurement of benzene in a concentration range of approximately 0,5 μg/m3 to 50 μg/m3. Air samples are typically collected over periods ranging from a few hours to 7 days.

The upper limit of the useful range is set by the sorptive capacity (the safe sampling volume) of the sorbent and by the linear dynamic range of the gas chromatograph column and detector or by the sample splitting capacity of the analytical instrumentation used. The lower limit of the useful range depends on the noise level of the detector and on blank levels of benzene and/or interfering artefacts on the sorbent. Artefacts are typically sub ng for graphitised carbon sorbents, but higher levels of aromatic hydrocarbons have been noted in other sorbents - e.g. porous polymers. The detection limit will be approximately 1/10 of the lower concentration range.

This document provides general guidance for the sampling of benzene using either a single sampler, which is changed manually after every exposure period, or a multi-sampler capable of storing and exposing multiple samples without user intervention.

Außenluft - Verfahren zur Messung von Benzolkonzentrationen - Teil 1: Probenahme mit einer Pumpe, gefolgt von Thermodesorption und Gaschromatographie

Dieses Dokument gibt eine allgemeine Anleitung zur Probenahme und Analyse von Benzol in Luft durch Probenahme mit einer Pumpe, Thermodesorption und Kapillargaschromatographie.

Dieses Dokument ist in Übereinstimmung mit der allgemeinen Methodik, die als Grundlage des Referenzverfahrens der Europäischen Union zur Bestimmung von Benzol in Außenluft [1] gewählt wurde, um Messergebnisse mit Grenzwerten mit einem einjährigen Bezugszeitraum zu vergleichen.

Dieses Dokument ist anwendbar für die Messung von Benzol in einem Konzentrationsbereich von ungefähr 0,5 µg/m3 bis 50 µg/m3. Luftproben werden typischerweise über einen Zeitraum von einigen Stunden bis 7 Tagen gesammelt.

Die Obergrenze des nutzbaren Bereichs ist durch die Sorptionskapazität (das sichere Probenahmevolumen) des Sorbens und den linearen dynamischen Bereich der Säule und des Detektors des Gaschromatographen oder durch das Probeteilungsvermögen des verwendeten Analysengeräts gegeben. Die Untergrenze des nutzbaren Bereichs hängt vom Rauschpegel des Detektors sowie den Benzolblindwerten und/oder störenden Artefakten auf dem Sorbens ab. Bei Sorbenzien aus graphitiertem Kohlenstoff liegen Artefakte typischerweise im sub-ng-Bereich, in anderen Sorbenzien, z. B. porösen Polymeren, wurden auch größere Mengen aromatischer Kohlenwasserstoffe nachgewiesen. Die Nachweisgrenze beträgt ungefähr 1/10 der unteren Grenze des Konzentrationsbereichs.

Dieses Dokument gibt eine allgemeine Anleitung zur Probenahme von Benzol mit entweder einer Einzelprobenahmeeinrichtung, die nach jedem Expositionszeitraum manuell ausgetauscht wird, oder einer sequentiellen Probenahmeeinrichtung, mit der mehrere Proben ohne Eingriff des Anwenders gelagert und exponiert werden können. Es gibt verschiedene Analysenverfahren und eine geeignete Vorgehensweise zur Analyse von Proben und Blindproben und zur Berechnung von Benzolkonzentrationen wird in Anhang B beschrieben.

ANMERKUNG Das in diesem Dokument beschriebene Verfahren kann unter der Bedingung dokumentierter Validierungsprüfungen zur Bestimmung anderer Verbindungen neben Benzol angewandt werden.

Qualité de l'air ambiant - Méthode normalisée pour le mesurage de la concentration en benzène - Partie 1 : Prélèvement par pompage suivi d'une désorption thermique et d'une chromatographie en phase gazeuse

Le présent document fournit des recommandations pour le prélèvement et l'analyse du benzène dans l'air par prélèvement par pompage, désorption thermique et chromatographie en phase gazeuse sur colonne capillaire.

Le présent document correspond à la méthodologie générique choisie comme base de la méthode de référence de l'Union européenne pour la détermination du benzène dans l'air ambiant [1] pour les besoins de comparaison des résultats de mesurage avec des valeurs limites pour une période de référence d'un an.

Le présent document s'applique au mesurage du benzène dans une gamme de concentration d'approximativement 0,5 µg/m3 à 50 µg/m3. Les échantillons d'air sont généralement prélevés sur des périodes allant de quelques heures à 7 jours.

La limite supérieure de la gamme utile est fixée par la capacité de sorption du sorbant (volume limite de prélèvement) et par la gamme linéaire dynamique de la colonne et du détecteur du chromatographe en phase gazeuse ou par la capacité de séparation des échantillons et des instruments d'analyse utilisés. La limite inférieure de la gamme utile dépend du niveau de bruit du détecteur et des niveaux de blanc du benzène et/ou des artéfacts interférant sur le sorbant. Les niveaux des artéfacts sont généralement inférieurs au nanogramme pour les sorbants à base de carbone graphitisé, mais des niveaux plus élevés d'hydrocarbures aromatiques ont été notés dans d'autres sorbants, par exemple les polymères poreux. La limite de détection représente approximativement 1/10 de la gamme inférieure de concentration.

Le présent document fournit des recommandations générales pour le prélèvement de benzène à l'aide d'un préleveur individuel, qui est remplacé manuellement après chaque période d'exposition, ou d'un prélèvement multiplexé capable de stocker et d'exposer plusieurs échantillons sans l'intervention de l'utilisateur.

Kakovost zunanjega zraka - Standardna metoda za določevanje koncentracije benzena - 1. del: Vzorčenje s črpanjem in določevanje s plinsko kromatografijo po termični desorpciji

Ta del standarda EN 14662 podaja splošne napotke za vzorčenje in analizo benzena v zraku z vzorčenjem s črpanjem in določevanje s plinsko kromatografijo po termični desorpciji.

Ta del standarda EN 14662 je v skladu s splošno metodologijo, ki je bila izbrana kot podlaga za referenčno metodo Evropske unije za določevanje benzena v zunanjem zraku [1] za namen primerjave rezultatov meritev z mejnimi vrednostmi v enoletnem referenčnem obdobju.

Ta del standarda EN 14662 se uporablja za merjenje benzena v območju koncentracije med približno 0,5 μg/m3 in 50 μg/m3 v vzorcu zraka, ki je običajno pridobljen v obdobju 24 ur.

Zgornja meja uporabnega območja je določena s sorpcijsko kapaciteto sorbenta in linearnim dinamičnim razponom kolone plinskega kromatografa in detektorja ali cepilno zmogljivostjo vzorcev uporabljenih analitičnih instrumentov. Spodnja meja uporabnega območja je odvisna od ravni hrupa detektorja in slepih vrednosti benzena in/ali motečih artefaktih za benzen. Artefakti so običajno vrednosti sub ng za sorbente, vendar so bile v drugih sorbentih zaznane všije ravni aromatskih ogljikovodikov. Zaznavna meja bo približno 1/10 nižjega območja koncentracije.

Razširitev področja uporabe:

Del standard EN 14662 podaja splošne smernice za vzorčenje benzena z enojnim vzorčevalnikom, ki se ga ročno zamenja po vsakem obdobju izpostavljanja, ali z večcevnim vzorčevalnikom za shranjevanje in izpostavljanje več vzorcev zaporedoma brez posega uporabnika.

General Information

- Status

- Published

- Public Enquiry End Date

- 02-Oct-2022

- Publication Date

- 15-Jan-2024

- Technical Committee

- KAZ - Air quality

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 11-Jan-2024

- Due Date

- 17-Mar-2024

- Completion Date

- 16-Jan-2024

Relations

- Effective Date

- 01-Feb-2024

SIST EN 14662-1:2024 - Ambient air quality: Benzene measurement (Pumped sampling, thermal desorption, GC)

Overview

SIST EN 14662-1:2024 specifies a standard method for measuring benzene in ambient air using pumped sampling onto sorbent tubes followed by thermal desorption and capillary gas chromatography (GC). It provides the general guidance and performance framework chosen as the basis of the European Union reference method for annual comparison of benzene concentrations with limit values. The method is applicable to typical benzene concentrations of approximately 0.5 μg/m³ to 50 μg/m³, with sampling durations from a few hours up to 7 days.

Key technical topics and requirements

- Sampling principle: Pumped collection of air through sorbent tubes (single or multi-sampler) with control of sampling flow rate and sample volume.

- Sorbent selection and safe sampling volume: Guidance on sorbent types (e.g., graphitised carbon), breakthrough volumes and limits set by sorbent capacity and GC/detector linearity.

- Thermal desorption and analysis: Procedures for thermal desorption of exposed sorbent tubes and analysis by capillary GC with appropriate detectors. Includes desorption efficiency, calibration, and determination of sample concentration.

- Performance testing and type testing: Requirements for equipment performance characteristics, reproducibility, and validation. Tables define minimum performance criteria for sampling and analysis.

- Quality control and field operations: Calibration, maintenance, leak checks, sensor and flow verifications, blank profiling, and recommended frequencies for checks.

- Uncertainty and reporting: Methods for estimating measurement uncertainty (including contributors such as sample volume, desorption efficiency, blanks) and reporting requirements.

- Supporting procedures: Informative annexes covering sorbent guidance, breakthrough-volume determination (from gas standards or extrapolated retention volumes), and uncertainty assessment examples.

Practical applications and users

- Environmental laboratories performing regulatory ambient air monitoring for benzene.

- National and regional air quality agencies implementing EU reference methods to compare measurements with limit values.

- Manufacturers and operators of active air samplers and thermal desorption–GC systems (for type testing and compliance).

- Research groups studying benzene trends, exposure assessment, and source apportionment.

This standard is most useful where robust, traceable benzene measurements are required over regulatory (one-year) reference periods.

Related standards and context

- Part of the EN 14662 series (this document is Part 1). It aligns with the EU reference methodology for benzene in ambient air and supersedes earlier editions (EN 14662‑1:2005). Users should consult other parts of the series and relevant national transpositions for complementary methods and diffusion sampling alternatives.

Keywords: SIST EN 14662-1:2024, ambient air quality, benzene measurement, pumped sampling, thermal desorption, gas chromatography, sorbent tubes, air monitoring, measurement uncertainty.

Frequently Asked Questions

SIST EN 14662-1:2024 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Ambient air quality - Standard method for measurement of benzene concentrations - Part 1: Pumped sampling followed by thermal desorption and gas chromatography". This standard covers: This document gives general guidance for the sampling and analysis of benzene in air by pumped sampling, thermal desorption and capillary gas chromatography. This document is in accordance with the generic methodology selected as the basis of the European Union reference method for the determination of benzene in ambient air [1] for the purpose of comparison of measurement results with limit values with a one-year reference period. This document is valid for the measurement of benzene in a concentration range of approximately 0,5 μg/m3 to 50 μg/m3. Air samples are typically collected over periods ranging from a few hours to 7 days. The upper limit of the useful range is set by the sorptive capacity (the safe sampling volume) of the sorbent and by the linear dynamic range of the gas chromatograph column and detector or by the sample splitting capacity of the analytical instrumentation used. The lower limit of the useful range depends on the noise level of the detector and on blank levels of benzene and/or interfering artefacts on the sorbent. Artefacts are typically sub ng for graphitised carbon sorbents, but higher levels of aromatic hydrocarbons have been noted in other sorbents - e.g. porous polymers. The detection limit will be approximately 1/10 of the lower concentration range. This document provides general guidance for the sampling of benzene using either a single sampler, which is changed manually after every exposure period, or a multi-sampler capable of storing and exposing multiple samples without user intervention.

This document gives general guidance for the sampling and analysis of benzene in air by pumped sampling, thermal desorption and capillary gas chromatography. This document is in accordance with the generic methodology selected as the basis of the European Union reference method for the determination of benzene in ambient air [1] for the purpose of comparison of measurement results with limit values with a one-year reference period. This document is valid for the measurement of benzene in a concentration range of approximately 0,5 μg/m3 to 50 μg/m3. Air samples are typically collected over periods ranging from a few hours to 7 days. The upper limit of the useful range is set by the sorptive capacity (the safe sampling volume) of the sorbent and by the linear dynamic range of the gas chromatograph column and detector or by the sample splitting capacity of the analytical instrumentation used. The lower limit of the useful range depends on the noise level of the detector and on blank levels of benzene and/or interfering artefacts on the sorbent. Artefacts are typically sub ng for graphitised carbon sorbents, but higher levels of aromatic hydrocarbons have been noted in other sorbents - e.g. porous polymers. The detection limit will be approximately 1/10 of the lower concentration range. This document provides general guidance for the sampling of benzene using either a single sampler, which is changed manually after every exposure period, or a multi-sampler capable of storing and exposing multiple samples without user intervention.

SIST EN 14662-1:2024 is classified under the following ICS (International Classification for Standards) categories: 13.040.20 - Ambient atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14662-1:2024 has the following relationships with other standards: It is inter standard links to SIST EN 14662-1:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14662-1:2024 is associated with the following European legislation: EU Directives/Regulations: 2008/50/EC, 2011-01-2525. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 14662-1:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2024

Nadomešča:

SIST EN 14662-1:2005

Kakovost zunanjega zraka - Standardna metoda za določevanje koncentracije

benzena - 1. del: Vzorčenje s črpanjem in določevanje s plinsko kromatografijo po

termični desorpciji

Ambient air quality - Standard method for measurement of benzene concentrations - Part

1: Pumped sampling followed by thermal desorption and gas chromatography

Außenluft - Verfahren zur Messung von Benzolkonzentrationen - Teil 1: Probenahme mit

einer Pumpe, gefolgt von Thermodesorption und Gaschromatographie

Qualité de l'air ambiant - Méthode normalisée pour le mesurage de la concentration en

benzène - Partie 1 : Prélèvement par pompage suivi d'une désorption thermique et d'une

chromatographie en phase gazeuse

Ta slovenski standard je istoveten z: EN 14662-1:2023

ICS:

13.040.20 Kakovost okoljskega zraka Ambient atmospheres

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14662-1

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2023

EUROPÄISCHE NORM

ICS 13.040.20 Supersedes EN 14662-1:2005

English Version

Ambient air quality - Standard method for measurement of

benzene concentrations - Part 1: Pumped sampling

followed by thermal desorption and gas chromatography

Qualité de l'air ambiant - Méthode normalisée pour le Außenluft - Verfahren zur Messung von

mesurage de la concentration en benzène - Partie 1 : Benzolkonzentrationen - Teil 1: Probenahme mit einer

Prélèvement par pompage suivi d'une désorption Pumpe, gefolgt von Thermodesorption und

thermique et d'une chromatographie en phase gazeuse Gaschromatographie

This European Standard was approved by CEN on 20 November 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14662-1:2023 E

worldwide for CEN national Members.

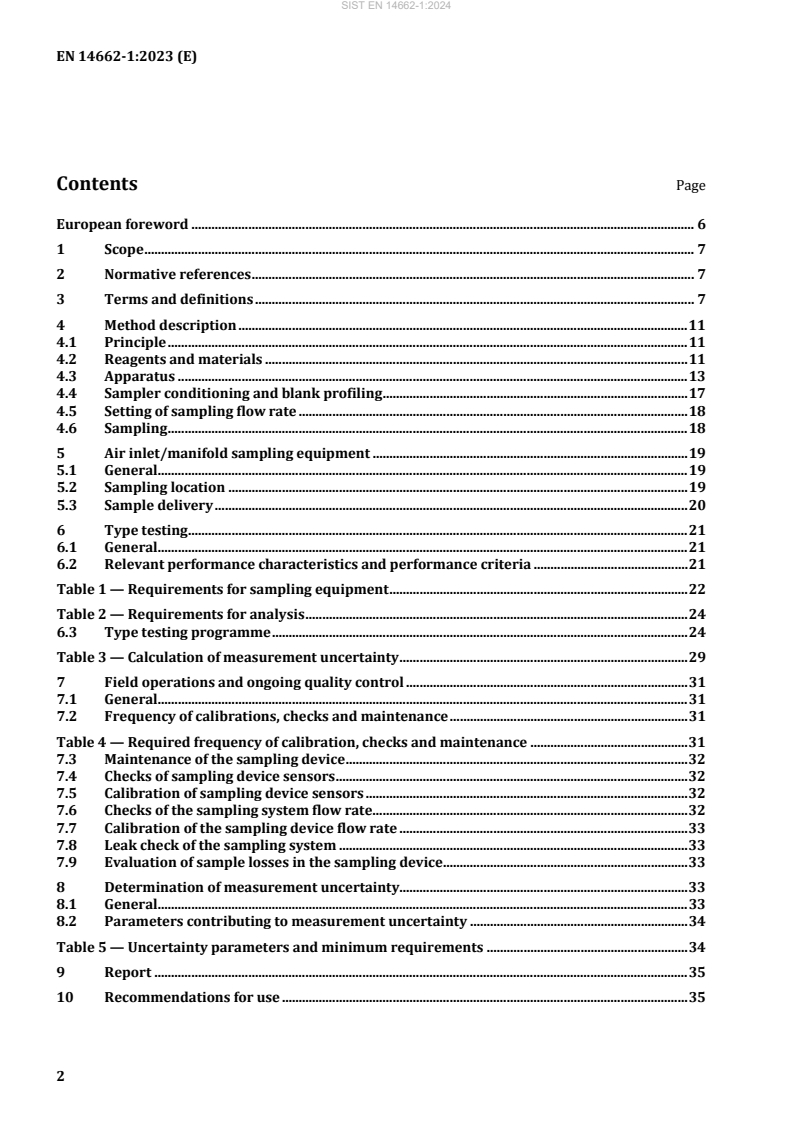

Contents Page

European foreword . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Method description . 11

4.1 Principle . 11

4.2 Reagents and materials . 11

4.3 Apparatus . 13

4.4 Sampler conditioning and blank profiling . 17

4.5 Setting of sampling flow rate . 18

4.6 Sampling . 18

5 Air inlet/manifold sampling equipment . 19

5.1 General . 19

5.2 Sampling location . 19

5.3 Sample delivery . 20

6 Type testing . 21

6.1 General . 21

6.2 Relevant performance characteristics and performance criteria . 21

Table 1 — Requirements for sampling equipment . 22

Table 2 — Requirements for analysis . 24

6.3 Type testing programme . 24

Table 3 — Calculation of measurement uncertainty . 29

7 Field operations and ongoing quality control . 31

7.1 General . 31

7.2 Frequency of calibrations, checks and maintenance . 31

Table 4 — Required frequency of calibration, checks and maintenance . 31

7.3 Maintenance of the sampling device . 32

7.4 Checks of sampling device sensors . 32

7.5 Calibration of sampling device sensors . 32

7.6 Checks of the sampling system flow rate . 32

7.7 Calibration of the sampling device flow rate . 33

7.8 Leak check of the sampling system . 33

7.9 Evaluation of sample losses in the sampling device . 33

8 Determination of measurement uncertainty . 33

8.1 General . 33

8.2 Parameters contributing to measurement uncertainty . 34

Table 5 — Uncertainty parameters and minimum requirements . 34

9 Report . 35

10 Recommendations for use . 35

Annex A (informative) Sorbent selection and characteristics . 36

Table A.1 — Extrapolated retention volumes and safe sampling volumes for benzene at 20 °C

............................................................................................................................................................................. 36

Table A.2 — Guidance on sorbent selection . 36

Table A.3 — Guidance on sorbent use . 37

Annex B (informative) Analysis of exposed samples . 38

B.1 Safety precautions . 38

B.2 Thermal desorption . 38

B.3 Determination of desorption efficiency . 39

B.4 Calibration . 39

B.5 Determination of sample concentration . 40

B.6 Calculation of mass concentration of benzene . 40

Annex C (informative) Determination of breakthrough volume from gas standards . 41

C.1 Reagents . 41

C.2 Apparatus . 41

C.3 Determination. 41

C.4 Calculations. 42

Figure C.1 — Schematic representation of set up for determination of breakthrough volume . 42

Annex D (informative) Determination of breakthrough volumes from extrapolated

retention volumes . 43

D.1 Apparatus . 43

D.2 Reagents . 43

D.3 Determination. 43

D.4 Expression of results . 43

Annex E (informative) Assessment of performance indicators and uncertainty contributions

............................................................................................................................................................................. 44

E.1 General . 44

E.2 Sample volume . 44

E.2.1 General . 44

E.2.2 Sample flow calibration and measurement . 45

E.2.3 Sampling time . 46

E.2.4 Conversion of sampling volume to STP . 46

E.2.4.1 Mass-flow controlled sampling devices . 46

E.2.4.2 Volume-controlled sampling devices . 47

E.3 Desorption efficiency and analytical repeatability . 48

E.3.1 Introduction. 48

E.3.2 Desorption efficiency . 48

E.3.3 Analytical repeatability . 48

E.4 Mass of benzene sampled. 49

E.4.1 General . 49

E.4.2 Sampling efficiency . 49

E.4.3 Sample stability . 49

E.4.4 Corrections to the measured mass of benzene . 50

E.4.4.1 General . 50

E.4.4.2 Calibration standards . 50

E.4.4.3 Lack-of-fit of calibration function . 50

E.4.4.4 Response drift between calibrations . 51

E.4.4.5 Selectivity. 51

Table E.1 — Test guidance on sorbent selectivity . 52

E.4.5 Combined uncertainty in the measured mass of benzene . 52

E.4.6 Combined uncertainty in the sampled mass of benzene . 53

E.5 Mass of benzene in sample blank . 53

E.6 Combined uncertainty in benzene concentration . 53

E.7 Expanded uncertainty . 54

E.8 Uncertainty from performance requirements . 54

E.8.1 General . 54

E.8.2 Analyte Ingress from air being sampled . 54

Table E.2 — Uncertainties contribution to the reproducibility test for exclusion of AIFABS . 55

Figure E.1 — Maximum deviation due to AIFABS . 56

E.8.3 Analyte Ingress from Surrounding Air . 56

E.8.4 Loss of Retained Analyte . 56

Table E.3 — Uncertainties contribution to the reproducibility test for LORA evaluation . 57

Figure E.2 — Maximum deviation due to LORA . 58

Figure E.3 — Linear decay of analyte and maximum number of sampling days . 59

E.9 Between-laboratory uncertainty . 59

E.10 Example for uncertainty budget calculation . 60

Table E.4 — Example uncertainty budget . 60

Annex F (informative) Reproducibility, validation and comparison exercises . 62

Annex G (informative) Performance characteristics . 63

G.1 Prior art . 63

Table G.1 — Uncertainty data from literature surveys . 63

G.2 Results of inter-laboratory comparisons . 64

Table G.2 — Results of inter-laboratory comparisons . 65

Annex H (informative) Sampling equipment . 66

Annex I (informative) Significant technical changes . 70

Bibliography . 71

European foreword

This document (EN 14662-1:2023) has been prepared by Technical Committee CEN/TC 264

“Air quality”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2024, and conflicting national standards shall be

withdrawn at the latest by June 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 14662-1:2005.

In comparison with the previous edition, the following technical modifications have been made:

— inclusion of the option of multi-tube sampling devices such that a series of samples can be collected

sequentially and/or in parallel without user intervention in the field;

— specification of associated ‘type testing’ requirements to allow multi-tube sampling devices to be

tested and approved;

— inclusion of gas standard calibration options, alongside liquid spiking, in line with best practice;

— extensive updates to technical aspects, including uncertainty calculations, in line with the latest

standards.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

1 Scope

This document gives general guidance for the sampling and analysis of benzene in air by pumped

sampling, thermal desorption and capillary gas chromatography.

This document is in accordance with the generic methodology selected as the basis of the European Union

reference method for the determination of benzene in ambient air [1] for the purpose of comparison of

measurement results with limit values with a one-year reference period.

This document is valid for the measurement of benzene in a concentration range of approximately

3 3

0,5 μg/m to 50 μg/m . Air samples are typically collected over periods ranging from a few hours

to 7 days.

The upper limit of the useful range is set by the sorptive capacity (the safe sampling volume)

of the sorbent and by the linear dynamic range of the gas chromatograph column and detector or by

the sample splitting capacity of the analytical instrumentation used. The lower limit of the useful range

depends on the noise level of the detector and on blank levels of benzene and/or interfering artefacts

on the sorbent. Artefacts are typically sub ng for graphitised carbon sorbents, but higher levels of

aromatic hydrocarbons have been noted in other sorbents – e.g. porous polymers. The detection limit will

be approximately 1/10 of the lower concentration range.

This document provides general guidance for the sampling of benzene using either a single sampling

device, which is changed manually after every exposure period, or sequential sampling device capable

of storing and exposing multiple samples without user intervention. The analysis methods are diverse,

but a suitable approach for analysing samples and blanks and calculating benzene levels is described

in Annex B.

NOTE The method described in this document can be used for the determination of other compounds besides

benzene, under the condition of documented validation tests.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 16017-1, Indoor, ambient and workplace air - Sampling and analysis of volatile organic

compounds by sorbent tube/thermal desorption/capillary gas chromatography - Part 1: Pumped sampling

(ISO 16017-1)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

breakthrough volume

volume of a vapour-in-air sample for a sorbent tube/analyte combination that can be passed through the

front section of a sorbent tube before the eluting concentration of the analyte vapour reaches 5 % of the

applied test concentration

3.2

calibration gas mixture

traceable gas mixture of sufficient stability and homogeneity whose composition is properly established

for use in the calibration of a measuring instrument or for the validation of a measurement or gas

analytical method

3.3

certified reference material

CRM

reference material (RM) characterized by a metrologically valid procedure for one or more specified

properties, accompanied by an RM certificate that provides the value of the specified property,

its associated uncertainty, and a statement of metrological traceability

[SOURCE: ISO Guide 30:2015, 2.1.2 [2]]

3.4

combined standard uncertainty

standard uncertainty of the result of a measurement when that result is obtained from the values

of a number of other quantities, equal to the positive square root of a sum of terms, the terms being

the variances or covariances of these other quantities weighted according to how the measurement result

varies with changes in these quantities

[SOURCE: JCGM 100:2008, 2.3.4 [3]]

3.5

competent authority

organization which implements the requirements of EU Directives and regulates installations, which

complies with the requirements of applicable European Standards

Note 1 to entry: In ambient air quality monitoring this is an authority that performs one or more of the tasks listed

in Article 3 of Directive 2008/50/EC.

3.6

competent body

organization which can demonstrate its competence for a specific task to the competent authority in the

Member State

Note 1to entry: It is recommended that the competent body performing the required tests be able to demonstrate

that it works in conformity with the requirements of internationally accepted standards for test laboratories.

Note 2 to entry: EN ISO/IEC 17025 is the harmonized internationally accepted standard that applies.

Note 3 to entry: A formal accreditation by a member body of the European Accreditation Organization to EN

ISO/IEC 17025 is a demonstration of conformity.

3.7

desorption efficiency

ratio of the mass of analyte desorbed from a sampler to that collected

3.8

expanded uncertainty

quantity defining an interval about the result of a measurement that may be expected to encompass

a large fraction of the distribution of values that could reasonably be attributed to the measurand

Note 1 to entry: The fraction may be viewed as the coverage probability or level of confidence of the interval.

Note 2 to entry: To associate a specific level of confidence with the interval specified by the expanded uncertainty

requires explicit or implicit assumptions regarding the probability distribution characterized by the measurement

result and its combined standard uncertainty (3.4). The level of confidence that can be attributed to the interval can

be known only to the extent to which such assumptions may be justified.

[SOURCE: JCGM 100:2008, 2.3.5] [3]

3.9

reference material

RM

material, sufficiently homogeneous and stable with respect to one or more specified properties, which

has been established to be fit for its intended use in a measurement process

[SOURCE: ISO Guide 30:2015, 2.1.1] [2]

3.10

repeatability condition of measurement

repeatability condition

condition of measurement, out of a set of conditions that includes the same measurement procedure,

same operators, same measuring system, same operating conditions and same location, and replicate

measurements on the same or similar objects over a short period of time

[SOURCE: JCGM 200:2012, 2.20] [4]

3.11

retention volume

elution volume at peak maximum of a small aliquot of a benzene vapour eluted from the tube by air

or chromatographic carrier gas

3.12

safe sampling volume

SSV

volume of air that can be safely drawn through a sampler under prescribed conditions without significant

breakthrough of benzene

Note 1 to entry: See EN ISO 16017-1 for more information.

3.13

sample delivery

inert assembly of components needed to transfer the air to the sampling device (3.15) or sequential

sampling device (3.17) inlet without impacting the concentration of benzene

3.14

sampler

sampling tube packed with a known mass of sorbent to retain benzene from ambient air

3.15

sampling device

device capable of exposing one or more samplers (3.14) to a constant flow of air for one prescribed

sampling period, until the required volume of air has been sampled

3.16

sampling efficiency

ratio of the mass of analyte collected by a sampler (3.14) to that applied

3.17

sequential sampling device

automated sampling device capable of storing multiple samplers (3.14) and exposing them in sequence

to a constant flow of air for prescribed periods without user intervention, until all the required volumes

of air have been collected in the samplers

3.18

signal to noise ratio

measure that compares the level of the signal to the level of background noise

Note 1 to entry: It is also possible to estimate the chromatographic detection limit with the aid of the signal-to-noise

ratio. For example, the mean noise level can be estimated across a distance of ten half-peak widths before and after

the peak. The threefold of this noise level is then defined as the detection limit [5].

3.19

standard uncertainty

uncertainty of the result of a measurement expressed as a standard deviation

[SOURCE: JCGM 100:2008, 2.3.1] [3]

3.20

uncertainty (of measurement)

parameter, associated with the results of a measurement, that characterises the dispersion of values

that could reasonably be attributed to the measurand

Note 1 to entry: The parameter may be, for example, a standard deviation (or given multiple of it), or the half width

of an interval having a stated level of confidence.

Note 2 to entry: Uncertainty of measurement comprises, in general, many components. Some of these components

may be evaluated from the statistical distribution of the results of a series of measurements and can be

characterized by experimental standard deviations. The other components, which can also be characterized

by standard deviations, are evaluated from assumed probability distributions based on experience or other

information.

Note 3 to entry: It is understood that the result of a measurement is the best estimate of the value of a measurand,

and that all components of uncertainty, including those arising from systematic effects, such as components

associated with corrections and reference standards, contribute to this dispersion

[SOURCE: JCGM 100:2008, 2.2.3] [3].

Attention is drawn to the fact that the terms Ambient Air and Limit Value are specified in Directive

2008/50/EC [1].

4 Method description

4.1 Principle

A measured volume of sample air is drawn through a sampler (3.14). Provided suitable sorbents are

chosen, benzene is retained by the sorbent and thus is removed from the flowing air stream. The collected

vapour (on each sampler) is desorbed by heat and is transferred under inert carrier gas into a gas

chromatograph equipped with a chromatography column and a suitable detector, where it is analysed.

The equipment shall be calibrated by one of the following means:

— Vapour or liquid spiking onto a sampler;

— Reference material (3.9) in sampler.

4.2 Reagents and materials

The determination of the impurities contained in each material (gas or liquid) used in the preparation

has an impact on the uncertainty (3.20) associated with the content of the component. Requirements

for the purity analysis of reagent and materials used in the preparation of calibration standards for gases

are described in ISO 19229:2019 [7].

Use only volumetric glassware and syringes that are calibrated to ensure traceability of volume

to primary standards.

4.2.1 Benzene

Benzene is required for calibration purposes, using either vapour spiking (4.2.6 to 4.2.7) or liquid spiking

(4.2.8 to 4.2.10) onto samplers (3.14). The benzene used shall be of a minimum purity of 99,5 %.

4.2.2 Dilution solvent

A dilution solvent is required for preparing calibration blend solution for liquid spiking (4.2.8).

The presence of benzene impurity in the solvent or any other gas chromatographic interferent

with benzene shall be assessed and it shall be lower than 10 % of the lowest mass of benzene introduced

as a calibration standard. During the assessment of the purity the same volume shall be introduced as the

volume of the lowest calibration standard.

Methanol is frequently used. Alternative solvents may be used provided they do not interfere with the gas

chromatographic analysis, either by co-elution or by altering detector response.

4.2.3 Dilution gas

Dilution gas, such as dry air or nitrogen, is required for preparing calibration gas mixtures (3.2),

for preparation of calibration standards in samplers (3.14) and for sampler cleaning. The presence of

benzene impurity in the gas or any other gas chromatographic interferent with benzene shall be lower

than 10 % of the lowest mass of benzene introduced as a calibration standard. During the assessment of

the purity the same volume shall be introduced as the volume of the lowest calibration standard.

4.2.4 Inert gas for sampler conditioning

The purity of the inert gases used for sampler (3.14) conditioning, typically nitrogen or helium, shall be

such that the conditioned samplers meet the blank requirements specified in Table 1.

Oxygen filters are recommended in the inert gas supply line to minimize the risk of sorbent oxidation.

4.2.5 Calibration standards in samplers

Calibration standards in samplers (3.14) are preferably prepared by loading the required amount of

benzene in vapour phase on the samplers from calibration gas mixtures (3.2) (see 4.2.6 and 4.2.7) as this

procedure most closely resembles the practical sampling situation.

NOTE 1 The loading ranges given in 4.2.7 to 4.2.10 are not mandatory and approximate to the application range

given in the scope.

If this way of preparation is not practicable, calibration standards may be prepared by a benzene liquid

spiking procedure (see 4.2.8 to 4.2.10) provided that the accuracy of the spiking technique is either:

a) established by using procedures giving spiking levels fully traceable to primary standards of mass,

or,

b) confirmed by comparison with reference materials (3.9) (if available), standards produced using

calibration gas mixtures, or results of reference measurement procedures.

NOTE 2 See 4.2.10 relating to the mass of solvent retained in the calibration standard.

To minimize matrix effects, calibration standards should be closely matched to the samplers with respect

to sorbent type, particle size and mass of sorbent.

Calibration standards are required at a minimum of 5 mass levels for a full calibration (4.7.3)

and the mass range of benzene shall cover the maximum range of benzene masses that are expected to be

collected/trapped during field monitoring.

Maximum permitted uncertainty (3.20) in the preparation of calibration standards in samplers is 5 %

with a level of confidence of 95 %.

4.2.6 Preparation of calibration gas mixtures

Prepare calibration gas mixtures (3.2) of known concentrations of benzene by a recognized procedure.

Methods described in EN ISO 6142-1 [8], EN ISO 6144 [9] and EN ISO 6145-1 [10] are suitable. If the

procedure is not applied under conditions that will allow the establishment of full metrological

traceability of the generated concentrations to primary standards of amount of substance, mass and/or

volume, the concentrations need to be confirmed using an independent procedure, e.g. EN ISO 6143 [11]

or ISO 12963 [12].

For the conversion of the calibration gas mixture composition into mass concentration (mass per volume)

use e.g. EN ISO 14912 [13].

NOTE Calibration gas mixtures can be prepared or obtained at the full range of benzene ambient concentration

3 3

levels. The lower concentrations (0,5 μg/m to 5 μg/m ) are typically obtained by dynamic methods (ISO 6145-1).

4.2.7 Calibration standards in samplers prepared by vapour spiking of calibration gas mixtures

Prepare loaded samplers (3.14) by passing an accurately known volume of the calibration gas mixture

(3.2) through the sampling end of conditioned samplers e.g. by means of a constant controlled flow using

a pump as described in 4.5 and 4.6. The volume of calibration gas sampled shall not exceed the safe

sampling volume (3.12) of the sorbent. After loading the sampler is disconnected and sealed. Prepare

fresh standards representing benzene levels in the samples corresponding to the concentration range

3 3

of 0,5 µg/m to 50 µg/m with each batch of samples or use spiked control samples to ensure consistency

of detector response.

NOTE In ambient air monitoring, benzene masses collected typically range from 5 ng to 5 µg per sampler.

3 3

Therefore, loading volumes of 1 l of a 5 µg/m calibration standard to 10 l of a 500 µg/m calibration standard,

will allow covering the lower and upper concentration ranges.

4.2.8 Preparation of standard solutions for liquid spiking

4.2.8.1 General

The recommended approach for preparation of standard solutions is by gravimetry.

4.2.8.2 Solution containing approximately 5 mg/ml of benzene

Weigh a 100 ml volumetric flask and introduce approximately 75 ml of dilution solvent (4.2.2) into

a 100 ml volumetric flask. Then weigh approximately 500 mg benzene into the flask. Make up to 100 ml

with dilution solvent, stopper, weigh and shake to mix.

In order to ensure an uncertainty (3.20) of the mass of benzene introduced appropriate to the application

the weighing uncertainty of the equipment used (k = 2) shall be less than ±70 µg.

Dilute this stock solution down to appropriate concentrations to provide masses that match those

expected during ambient air monitoring.

NOTE In ambient air monitoring, benzene masses collected typically range from 5 ng to 5 µg per sampler

(3.14). Therefore, loading 1 µl volumes of liquid standard solutions within the concentration range 5 µg/ml to

5 mg/ml will allow covering the lower and upper concentration ranges.

4.2.9 Stability of standard solutions

Fresh standard solutions shall be prepared weekly, or more frequently if evidence is noted

of deterioration.

4.2.10 Calibration standards in samplers prepared by liquid spiking of standard solutions

Prepare calibration standards by introducing 1 µl of a liquid standard solution into the sampling end

of conditioned samplers (3.14) in a stream of dilution gas using a calibrated precision 1 µl syringe. A

sampler is fitted to a suitable ambient temperature injection facility, incorporating a septum inlet,

through which dilution gas is introduced at 100 ml/min. Inject the standard solution through the septum

and purge for at least 5 min. The sampler is then disconnected and sealed. Prepare fresh calibration

standards with each batch of samples. The samplers used for calibration shall be kept at ambient

temperature.

Depending on the dilution solvent volatility and associated choice of sampler sorbent it may or may not

be possible to selectively purge the dilution solvent during the loading process without compromising

retention of benzene. Liquid standard injection volumes should be kept to 1 µl or below to minimize

solvent interference in the subsequent analysis because in most cases it is not possible to selectively

purge the solvent.

NOTE Use PTFE or similar fittings to connect the sampler to the injection facility such that they ensure a leak

tight seal without damaging the end of the sampler.

4.3 Apparatus

The following specific items of laboratory equipment are required.

4.3.1 Samplers

These samplers (3.14) shall be compatible with the thermal desorption apparatus to be used (4.3.8).

Typically, but not exclusively, they are constructed of stainless steel tubing, 6,4 mm (1/4 inch) OD, 5 mm

ID and 90 mm long. Samplers of other dimensions may be used but the safe sampling volumes (SSV)

(3.12) given in Annex A are based on these sampler dimensions. One end of the sampler is marked, for

example by a scored ring about 10 mm from the sampling inlet end. The samplers are packed with

preconditioned sorbent so that the sorbent bed will be within the desorber heated zone and a gap of at

least 14 mm is retained at each end to minimize errors due to diffusive ingress at very low pump flow

rates. Samplers contain between 200 mg and 1000 mg sorbent, depending on sorbent density. The

sorbents are retained by stainless steel gauzes and/or unsilanised glass wool plugs.

4.3.2 Sampler and caps

The samplers (3.14) shall be sealed, according to the requirements of EN ISO 16017-1 or equivalent,

e.g. with metal screw cap fittings with PTFE seals.

4.3.3 Types of sampling devices

4.3.3.1 General

There are a number of possible configurations for sampling devices (3.15), which would meet different

specific requirements.

For all the sampling devices described below, the flow rate and sampling time should be such that the safe

sampling volumes (3.12) specified in Annex A are not exceeded.

Potential configurations for sampling devices are presented below.

4.3.3.2 Single sampling device

Sampling device (3.15), incorporating a sampler (3.14), capable of maintaining a constant calibrated flow

rate of air in the range 5 ml/min to 200 ml/min throughout the required sampling period (typically a few

hours to 7 days). As such, the following flow control mechanisms may be used:

— a pump with an adjustable flow rate;

— a vacuum pump with a critical orifice;

— a mass-flow controller operated by a vacuum pump;

— a vacuum pump with a constant pressure drop over a restriction.

The flow rate and sampling time should be such that the safe sampling volumes (3.12) specified in

Annex A are not exceeded.

The flow rate and sampling time should allow collection of at least 20 ng of benzene on the sampler

to minimize the analytical uncertainty (3.20).

NOTE If a mass flow controller is not used

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...