SIST EN 12697-35:2025

(Main)Bituminous mixtures - Test methods - Part 35: Laboratory mixing

Bituminous mixtures - Test methods - Part 35: Laboratory mixing

This document describes the laboratory mixing of bituminous materials for the manufacture of specimens. This document specifies the reference compaction temperatures for mixtures and the reference installation temperature for mastic asphalt mixtures based on the grade of the binder for paving grade and hard paving grade bitumen.

Annex A describes the method for laboratory mixing using foamed bitumen.

Annex B describes the method for laboratory mixing using bitumen emulsion.

Annex C describes the preparation of mastic asphalt specimens after laboratory mixing.

Asphalt - Prüfverfahren - Teil 35: Labormischen

Dieses Dokument beschreibt das Mischen von Asphalt im Labor zur Herstellung von Probekörpern. Dieses Dokument legt die Bezugstemperaturen für die Verdichtung von Gemischen und die Bezugstemperaturen für den Einbau von Gussasphaltgemischen auf der Grundlage der Bindemittelsorte für Straßenbaubitumen und hartes Straßenbaubitumen fest.

Anhang A beschreibt das Verfahren für das Mischen im Labor unter Verwendung von Schaumbitumen.

Anhang B beschreibt das Verfahren für das Mischen im Labor unter Verwendung von Bitumenemulsion.

Anhang C beschreibt die Vorbereitung von Gussasphalt-Probekörpern nach dem Mischen im Labor.

Mélanges bitumineux - Méthodes d'essais - Partie 35: Malaxage de laboratoire

Le présent document décrit le malaxage de matériaux bitumineux en laboratoire dans le cadre de la fabrication d’éprouvettes. Il définit les températures de compactage de référence des mélanges bitumineux ainsi que la température de mise en œuvre de référence des asphaltes coulés, en fonction du grade du liant pour les bitumes routiers usuels et de grade dur.

L'annexe A décrit la méthode de malaxage en laboratoire pour les mélanges bitumineux à la mousse de bitume.

L'annexe B décrit la méthode de mélange en laboratoire pour les mélanges bitumineux à l’émulsion de bitume.

L'annexe C décrit la préparation des échantillons d'asphalte coulé après malaxage en laboratoire

Bitumenske zmesi - Preskusne metode - 35. del: Laboratorijska zmes

Ta dokument opisuje laboratorijske zmesi iz bitumenskih materialov za izdelavo vzorcev. Ta dokument določa referenčne temperature zgoščevanja za zmesi in referenčno inštalacijsko temperaturo za zmesi litega asfalta na podlagi na vrsto veziva za cestogradbeni in trši cestogradbeni bitumen. V dodatku A je opisana metoda za laboratorijsko zmes, pri kateri se uporablja penasti bitumen. V dodatku B je opisana metoda za laboratorijsko zmes, pri kateri se uporablja bitumenska emulzija. V dodatku C je opisana priprava vzorcev litega asfalta po laboratorijskem mešanju.

General Information

- Status

- Published

- Public Enquiry End Date

- 19-Dec-2023

- Publication Date

- 03-Apr-2025

- Technical Committee

- CES - Roads

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 13-Mar-2025

- Due Date

- 18-May-2025

- Completion Date

- 04-Apr-2025

Relations

- Effective Date

- 28-Jan-2023

Overview

EN 12697-35:2025 - "Bituminous mixtures - Test methods - Part 35: Laboratory mixing" (CEN) defines procedures for the laboratory mixing of bituminous materials used to manufacture test specimens. The standard specifies reference compaction temperatures for mixtures and the reference installation temperature for mastic asphalt mixtures, determined by binder grade (paving grade and hard paving grade bitumen). It also contains three normative annexes covering laboratory mixing with foamed bitumen (Annex A), bitumen emulsion (Annex B) and the preparation of mastic asphalt specimens (Annex C).

Key topics and requirements

- Scope and purpose: Procedures for producing representative laboratory specimens of hot, warm and specialist bituminous mixtures.

- Reference temperatures: Defines how to determine reference compaction temperature for mixtures and reference installation temperature for mastic asphalt based on binder grade.

- Materials preparation: Requirements for preparation of aggregates, filler, reclaimed asphalt and binders prior to mixing.

- Mixing procedures: Detailed mixing steps including heating, addition of reclaimed asphalt, dosing of additives, and recommended conditioning and timing for subsequent testing.

- Annexed methods:

- Annex A - Laboratory mixing using foamed bitumen (including use of foam generators and alternatives).

- Annex B - Laboratory mixing using bitumen emulsion (procedures for wet and dry particles).

- Annex C - Preparation of mastic asphalt specimens after mixing.

- Apparatus and test report: Lists required laboratory equipment and mandatory information to include in test reports (e.g., temperatures, materials, reclaimed asphalt temperature).

Practical applications and users

EN 12697-35:2025 is used to ensure reproducible, comparable specimens for testing performance and conformity of asphalt and bituminous mixtures. Typical users:

- Materials laboratories performing routine quality control and research testing.

- Pavement engineers and designers specifying or verifying mix properties.

- Contractors and producers preparing lab-scale mixes for mix design and trialing.

- Road authorities and test institutes assessing reclaimed asphalt, warm mix technologies (foamed bitumen, emulsions) and mastic asphalt installations.

Related standards

EN 12697-35:2025 references and complements other binder and test standards, for example:

- EN 58 (sampling bituminous binders)

- EN 1097-5 (aggregate water content)

- EN 12697-42 (foreign matter in reclaimed asphalt)

- EN 13302, EN 13702 (dynamic viscosity methods)

By following EN 12697-35:2025, laboratories and industry stakeholders achieve consistent laboratory mixing practices for reliable asphalt testing and mix design validation.

Frequently Asked Questions

SIST EN 12697-35:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Bituminous mixtures - Test methods - Part 35: Laboratory mixing". This standard covers: This document describes the laboratory mixing of bituminous materials for the manufacture of specimens. This document specifies the reference compaction temperatures for mixtures and the reference installation temperature for mastic asphalt mixtures based on the grade of the binder for paving grade and hard paving grade bitumen. Annex A describes the method for laboratory mixing using foamed bitumen. Annex B describes the method for laboratory mixing using bitumen emulsion. Annex C describes the preparation of mastic asphalt specimens after laboratory mixing.

This document describes the laboratory mixing of bituminous materials for the manufacture of specimens. This document specifies the reference compaction temperatures for mixtures and the reference installation temperature for mastic asphalt mixtures based on the grade of the binder for paving grade and hard paving grade bitumen. Annex A describes the method for laboratory mixing using foamed bitumen. Annex B describes the method for laboratory mixing using bitumen emulsion. Annex C describes the preparation of mastic asphalt specimens after laboratory mixing.

SIST EN 12697-35:2025 is classified under the following ICS (International Classification for Standards) categories: 93.080.20 - Road construction materials. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 12697-35:2025 has the following relationships with other standards: It is inter standard links to SIST EN 12697-35:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 12697-35:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2025

Bitumenske zmesi - Preskusne metode - 35. del: Laboratorijska zmes

Bituminous mixtures - Test methods - Part 35: Laboratory mixing

Asphalt - Prüfverfahren - Teil 35: Labormischen

Mélanges bitumineux - Méthodes d'essais - Partie 35: Malaxage de laboratoire

Ta slovenski standard je istoveten z: EN 12697-35:2025

ICS:

93.080.20 Materiali za gradnjo cest Road construction materials

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12697-35

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2025

EUROPÄISCHE NORM

ICS 93.080.20 Supersedes EN 12697-35:2016

English Version

Bituminous mixtures - Test methods - Part 35: Laboratory

mixing

Mélanges bitumineux - Méthodes d'essai - Partie 35 : Asphalt - Prüfverfahren - Teil 35: Labormischen

Mélange de laboratoire

This European Standard was approved by CEN on 6 January 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12697-35:2025 E

worldwide for CEN national Members.

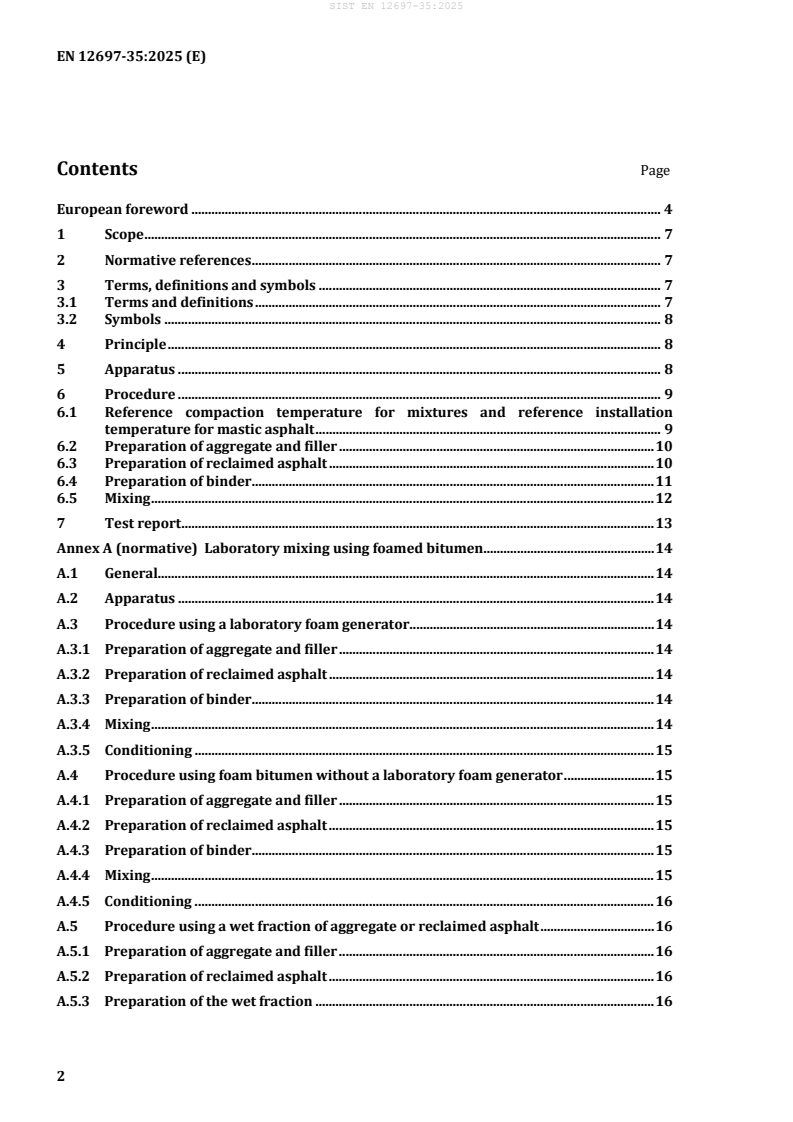

Contents Page

European foreword . 4

1 Scope . 7

2 Normative references . 7

3 Terms, definitions and symbols . 7

3.1 Terms and definitions . 7

3.2 Symbols . 8

4 Principle . 8

5 Apparatus . 8

6 Procedure . 9

6.1 Reference compaction temperature for mixtures and reference installation

temperature for mastic asphalt . 9

6.2 Preparation of aggregate and filler . 10

6.3 Preparation of reclaimed asphalt . 10

6.4 Preparation of binder . 11

6.5 Mixing . 12

7 Test report . 13

Annex A (normative) Laboratory mixing using foamed bitumen. 14

A.1 General. 14

A.2 Apparatus . 14

A.3 Procedure using a laboratory foam generator . 14

A.3.1 Preparation of aggregate and filler . 14

A.3.2 Preparation of reclaimed asphalt . 14

A.3.3 Preparation of binder . 14

A.3.4 Mixing . 14

A.3.5 Conditioning . 15

A.4 Procedure using foam bitumen without a laboratory foam generator . 15

A.4.1 Preparation of aggregate and filler . 15

A.4.2 Preparation of reclaimed asphalt . 15

A.4.3 Preparation of binder . 15

A.4.4 Mixing . 15

A.4.5 Conditioning . 16

A.5 Procedure using a wet fraction of aggregate or reclaimed asphalt . 16

A.5.1 Preparation of aggregate and filler . 16

A.5.2 Preparation of reclaimed asphalt . 16

A.5.3 Preparation of the wet fraction . 16

A.5.4 Preparation of binder . 16

A.5.5 Mixing . 16

A.5.6 Conditioning . 16

Annex B (normative) Laboratory mixing using bitumen emulsion . 17

B.1 General . 17

B.2 Procedure 1 with wet particles . 17

B.2.1 Preparation of aggregate and filler . 17

B.2.2 Preparation of reclaimed asphalt . 17

B.2.3 Preparation of binder (emulsion) . 17

B.2.4 Mixing . 18

B.3 Procedure 2 with dry particles . 18

B.3.1 Preparation of aggregate and filler . 18

B.3.2 Preparation of reclaimed asphalt . 18

B.3.3 Preparation of binder (emulsion) . 18

B.3.4 Mixing . 19

Annex C (normative) Preparation of mastic asphalt specimens . 20

Bibliography . 21

European foreword

This document (EN 12697-35:2025) has been prepared by Technical Committee CEN/TC 227 “Road

materials”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by September 2025, and conflicting national standards shall

be withdrawn at the latest by September 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12697-35:2016.

35:2016:

— (Clause 1) Scope modified to be in line with subclause 6.1 and the amended titles for the Annexes;

— (Clause 2) deletion of normative references that are considered informative. Listed in the

Bibliography;

— (Clause 2) deletion of normative reference to EN 12697-38 as it is obsolete and will be deleted from

the EN 12697 series;

— (Clause 2) correction of title of EN 12697-42 by deletion of “for hot mix asphalt”;

— (Clause 4) NOTE completed with “of a mixture or for the reference installation temperature of mastic

asphalt” due to the amended subclause 6.1 and Table 1.

— (3.2) explanation of symbol p: completed with “expressed in %”;

— (5.1) NOTE reworded to normal text;

— (5.2) deletion of reference to EN 12697-38. Paragraph completed for clarity with « for mixtures or

the reference installation temperature for mastic asphalt due to the amended subclause 6.1 and

Table 1. Replacement of “accuracy” with “maximum permissible error of 5°C;

— (5.3) “measuring” altered to “weighing”. Deletion of reference to EN 12697-38. Replacement of

“accuracy” with “maximum permissible error at least 0,1 g for masses up to 5 kg, and 1 g for masses

over 5 kg;

— (5.4) introduction of new Clause with requirements for balance for the weighing of additives (smaller

amounts). Following Clauses re-numbered accordingly;

— (5.5) deletion of reference to EN 12697-38. Replacement of “accuracy” with “maximum permissible

error of 2°C. (Previously 5.4);

— (5.6) deletion of reference to EN 12697-38. Replacement of “accuracy” with “maximum permissible

error of 2°C. (Previously 5.5);

— (6.1) clause title “Mixing temperature” amended to read to read “Reference compaction temperature

for mixtures and reference installation temperature for mastic asphalt”;

— (6.1) paragraph amended for clarity. References to EN 12591, EN 13924-1, EN 14023, EN 13924-2

placed in new NOTE 1 and new NOTE 2. References to EN 13108-1 to −7 and −9 deleted and replaced

by new NOTE 3 for the guidance of calculations of the penetration or the softening point of the binder.

Existing NOTE re-numbered to NOTE 4;

— (6.1) Table 1: Title completed with “reference installation temperature for mastic asphalt mixtures”.

Table 1 completed with column for the reference installation temperature for mastic asphalt

mixtures;

— (6.1) completion with paragraphs for the reference to the respective normative Annexes A and B;

— (6.2.2) replacement of “accuracy” with “to the nearest”;

— (6.2.3) replacement of “accuracy of 1%” with “to the nearest 0,1 g”;

— (6.2.4) completion of paragraph to take into account additives such as pigments and fibres;

— (6.3.1) replacement of “accuracy” with “to the nearest”;

— (6.3.2) paragraph modified for clarity;

— (6.3.3, 6.3.4) text in clauses merged and reworded for clarity. Following clauses re-numbered;

— (6.3.3) NOTE with examples of precautions to avoid build-up pressure reworded to normal text;

— (6.3.4) (previously 6.3.5). Paragraph clarified regarding the introduction of reclaimed asphalt when

the reclaimed asphalt is note heated to the full target laboratory mixing temperature at the mixing

plant or when the procedure is not determined with the completion that the reclaimed asphalt

temperature shall be indicated in the test report;

— (6.3.4) (previously 6.3.5). NOTE deleted.

— (6.3.6) (previously 6.3.7). NOTE in 6.3.8 (previous version) reworded to normal text and introduced

in 6.3.6;

— (6.4) paragraph introduced for the preheating of binders for mastic asphalt. 1st paragraph of NOTE 2

has been altered to normal text;

— (6.5.2) introduction of new NOTE 2 with reference to EN 13043. “NOTE” renumbered to NOTE 1;

— (6.5.3) NOTE reworded to normal text;

— (6.5.6) addition of informative NOTE regarding laboratory mixing times for mastic asphalt;

— (6.5.8) paragraph added with recommendation to proceed with subsequent testing within 1 h after

completed mixing;

— (6.5.8) completion with paragraph for the reference to the normative Annex C.

— (Clause 7) introductory paragraph and list of bullets revised. Addition of bullet h) for temperature of

the added reclaimed asphalt;

— (Annex A) title amended to read “Laboratory mixing using foamed bitumen” for clarity;

— (A.1) completion with a general description for the procedure;

— (A.3.4.2) paragraph clarified regarding optimum water content for foamed bitumen. NOTE revised

for clarity;

— (A.4.4.2) paragraph revised for clarity. Addition of optimum water content;

— (A.5.3.2) replacement of “accuracy” with “to the nearest 0,1g;

— (Annex B) title amended to read “Laboratory mixing using bitumen emulsion” for clarity;

— (B.2.1.3) NOTE reworded to normal text;

— (B.2.2.4) introduction of new subclause for the measurement of the water content of the reclaimed

asphalt;

— (B.2.3.2) last paragraph transferred to new subclause B.2.3.3 for clarity and in line with B.3.3.2. NOTE

reworded to normal text;

— (B.2.4.4) deletion of Clause for waiting time after mixing. Following Clause re-numbered;

— (B.3.3.2) NOTE reworded to normal text and introduced in paragraph in line with B.3.3.2;

— (B.3.4.4) amendment of waiting time after mixing “(30 ± 5) s” to read (300 ± 5) s;

— (Annex C) title amended to read “Preparation of mastic asphalt specimens” for clarity;

— (C.1) NOTE revised to refer to EN 12697-20;

— (C.2) amendment of maximum temperature of the temperature ranges from 150°C to read 160°C.

NOTE reworded to normal text;

— (Bibliography) completed with references to documents that are referred to informatively in this

document. Deletion of reference to EN 12595 as not referred to in this document.

A list of all parts in a series can be found on the CEN website: www.cencenelec.eu.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

1 Scope

This document describes the laboratory mixing of bituminous materials for the manufacture of

specimens. This document specifies the reference compaction temperatures for mixtures and the

reference installation temperature for mastic asphalt mixtures based on the grade of the binder for

paving grade and hard paving grade bitumen.

Annex A describes the method for laboratory mixing using foamed bitumen.

Annex B describes the method for laboratory mixing using bitumen emulsion.

Annex C describes the preparation of mastic asphalt specimens after laboratory mixing.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 58, Bitumen and bituminous binders — Sampling bituminous binders

EN 1097-5, Tests for mechanical and physical properties of aggregates — Part 5: Determination of the

water content by drying in a ventilated oven

EN 12697-42, Bituminous mixtures — Test methods — Part 42: Amount of foreign matter in reclaimed

asphalt

EN 13302, Bitumen and bituminous binders — Determination of dynamic viscosity of bituminous binder

using a rotating spindle apparatus

EN 13702, Bitumen and bituminous binders — Determination of dynamic viscosity of bitumen and

bituminous binders by the cone and plate method

3 Terms, definitions and symbols

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1.1

reference compaction temperature

target value at which compaction (or installation for mastic asphalt) of an asphalt mixture starts

Note 1 to entry: The term “reference compaction temperature” is used here for mastic asphalt despite mastic

asphalt not being compacted.

3.1.2

target laboratory mixing temperature

value at which component materials are mixed to form an asphalt mixture

3.1.3

maximum laboratory mixing temperature

value that an asphalt mixture shall not exceed during the mixing process

3.1.4

reclaimed asphalt temperature

target value to which a reclaimed asphalt shall be heated before mixing

3.2 Symbols

θ is the reference compaction temperature

RCT

θ is the target laboratory mixing temperature

TLMT

θ is the reclaimed asphalt temperature

RA

θ is the temperature to which the fresh aggregate shall be heated

FA

p is the proportion of reclaimed asphalt expressed in %

4 Principle

The bituminous mixture is prepared at a target laboratory mixing temperature within a time that is

limited in order to reduce mechanical degradation of the aggregates and thermal degradation of the

binder.

NOTE The target laboratory mixing temperature for mixing is related to the grade of binder and to the

reference compaction temperatures used for its subsequent compaction of a mixture or for the reference

installation temperature of mastic asphalt.

5 Apparatus

5.1 Laboratory mixer capable of entirely coating all mineral substances in not more than 5 min.

The mixer shall be of the whisk or other type that is not so rigid that it can damage either the aggregate

particles or the bowl.

The mixer can be equipped with a thermostatically controlled heating system, a mechanical speed

control; and a mixing time programmer.

5.2 Ventilated oven, for heating aggregates and bitumen up to a temperature at least 20 °C above the

relevant reference compaction temperature for mixtures or the reference installation temperature for

mastic asphalt indicated in Table 1 with a maximum permissible error of 5 °C.

5.3 Balance, capable of weighing mass of the intended mixture with a maximum permissible error of

not more than 0,1g for masses up to 5 kg, and 1 g for masses over 5 kg.

5.4 Balance, capable of weighing additives with a maximum permissible error of 0,05 g.

5.5 Device, capable of measuring the target laboratory mixing temperature with a maximum

permissible error of 2 °C.

5.6 Adjustable hot plate, capable of maintaining the target laboratory mixing temperature during the

manual mixing with a maximum permissible error of 2 °C.

6 Procedure

6.1 Reference compaction temperature for mixtures and reference installation

temperature for mastic asphalt

The reference compaction temperature for mixture or reference installation temperature for mastic

asphalt shall be either:

— for mixtures with paving grade bitumen or hard paving grade bitumen, the temperatures given in

Table 1, or

— for mixtures with modified binders or other additives or with polymer modified bitumen in

accordance with EN 14023 or multigrade bitumen in accordance with EN 13924-2, a temperature at

which the binder has a viscosity similar to the binders at the temperature provided in Table 1 or the

temperature at which the binder has a dynamic viscosity of (0,28 ± 0,03) Pa·s measured to EN 13702

or EN 13302, or the temperatures indicated by the supplier, or

— for asphalts designed to be produced at lower temperatures, the temperature at which compaction

is intended for the asphalt during normal production, or

— for mixtures with reclaimed asphalt, the temperature shall be calculated in accordance with the

relevant product standard using the overall penetration or softening point or viscosity calculated

from the penetrations or softening points or viscosities and proportions of both the added binder

and the binder recovered from the reclaimed asphalt.

NOTE 1 Paving grade bitumen is covered by EN 12591, and hard paving grade bitumen is covered by EN 13924-

1.

NOTE 2 Polymer modified bitumen is covered by EN 14023, and multigrade bitumen is covered by EN 13924-2.

NOTE 3 Guidance for the calculations of the penetration or the softening point of the binder of a mixture when

reclaimed asphalt is used can be found in relevant product standards in the EN 13108 series.

Table 1 — Reference compaction temperatures for mixtures and reference installation

temperature for mastic asphalt mixtures with paving grade and hard paving grade bitumen

Reference

Reference

installation

compaction

Reference compaction

temperature

Paving Paving

temperature for

temperature for mixtures

for mastic

grade of grade of

mixtures other than

other than mastic asphalt

asphalt

bitumen bitumen

mastic asphalt

(in °C)

mixtures

(in °C)

(in °C)

10/20 to

180 230 250/330 130

20/30

30/45 175 220 330/430 125

35/50 165 210 500/650 120

40/60 155 200 650/900 115

50/70 150 - V12000 115

70/100 145 - V6000 110

100/150 140 - V3000 100

Reference

Reference

installation

compaction

Reference compaction

temperature

Paving Paving

temperature for

temperature for mixtures

for mastic

grade of grade of

mixtures other than

other than mastic asphalt

asphalt

bitumen bitumen

mastic asphalt

(in °C)

mixtures

(in °C)

(in °C)

160/220 135 - V1500 90

The maximum laboratory mixing temperature reached shall not be more than 20 °C above the reference

compaction temperature or the reference installation temperature of mastic asphalt mixtures. The target

laboratory mixing temperature shall be selected so that the mixture will have cooled to the reference

compaction temperature ± 5 °C when compaction is due to commence but shall not be greater than the

maximum laboratory mixing temperature. For mastic asphalt, the target lab

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...