SIST EN 13763-26:2004

(Main)Explosives for civil uses - Detonators and relays - Part 26: Definitions, methods, and requirements for devices and accessories for reliable and safe function of detonators and relays

Explosives for civil uses - Detonators and relays - Part 26: Definitions, methods, and requirements for devices and accessories for reliable and safe function of detonators and relays

1.1 This document specifies the constructional and functional requirements and methods for testing of devices and accessories needed for the reliable and safe initiation of detonators and shock tubes, under normal working conditions. It covers the following six types of equipment:

¾ blasting machines for initiating electric detonators;

¾ blasting machine checkers;

¾ initiating circuit field testers;

¾ shot firing cables for use with electric blasting machines;

¾ detonator connecting wires;

¾ shock tube initiators for non-electric systems.

1.2 Equipment indented only for use indoors is excluded from the environmental testing in Annex B.

1.3 Blasting machines for use with electronic detonators and magnetically coupled detonators are outside the scope of this document.

NOTE This document does not meet all of the requirements of all relevant European Directives, such as the ATEX Directive 94/9/EC and the low voltage Directive 73/23/EEC. For example, EN 61010 (Safety requirements for electrical equipment for measurement, control and laboratory use) might also be relevant for some devices and accessories described in this document.

Explosivstoffe für zivile Zwecke - Zünder und Verzögerungselemente - Teil 26: Definitionen, Verfahren und Anforderungen für Geräte und Zubehör für die zuverlässige und sichere Funktion von Zündern und Verzögerern

1.1 Dieses Dokument legt die konstruktiven und funktionstechnischen Anforderungen und Verfahren für die Prüfung von Geräten und Zubehör fest, die für eine zuverlässige und sichere Zündung von Zündern und Verzögerern unter üblichen Arbeitsbedingungen benötigt werden. Die Norm behandelt folgende sechs Arten von Ausrüstungsgegenständen:

- Zündmaschinen zum Zünden von elektrischen Zündern;

- Zündmaschinen Prüfgeräte;

- Zündkreisprüfgeräte für die Vorort Prüfung;

- Zündkabel für die Verwendung in Verbindung mit elektrischen Zündmaschinen;

- Verbindungsdrähte für Zünder;

- Zündschlauchzünder für nichtelektrische Systeme.

1.2 Geräte für die ausschließliche Verwendung in Gebäuden sind von der Umgebungsprüfung nach Anhang B ausgeschlossen.

1.3 Zündmaschinen für die Verwendung mit elektronischen Zündern und magnetisch gekoppelten Zündern gehören nicht zum Anwendungsbereich dieses Dokuments.

ANMERKUNG Dieses Dokument erfüllt nicht alle Anforderungen aller relevanten Europäischen Richtlinien, wie der ATEX Richtlinie 94/9/EG und der Niederspannungsrichtlinie 73/23/EWG. Zum Beispiel könnte EN 61010 (Sicherheitsanforderungen für elektrische Geräte für Messungen, Überwachungen und Laborzwecke) auch für einige Geräte und einiges Zubehör in diesem Dokument relevant sein.

Explosifs a usage civil - Détonateurs et relais - Partie 26: Définitions, méthodes et exigences relatives aux dispositifs et accessoires pour la fiabilité et la sécurité de fonctionnement des détonateurs et relais

Eksplozivi za civilno uporabo – Detonatorji in zakasnilniki – 26. del: Definicije, metode in zahteve za naprave in sredstva za zanesljivo in varno delovanje detonatorjev in zakasnilnikov

General Information

- Status

- Published

- Publication Date

- 31-Oct-2004

- Technical Committee

- IEKS - Explosives

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Nov-2004

- Due Date

- 01-Nov-2004

- Completion Date

- 01-Nov-2004

Overview

EN 13763-26:2004 (CEN) is part of the European series "Explosives for civil uses - Detonators and relays." This part defines constructional and functional requirements, plus test methods, for devices and accessories used to achieve the reliable and safe initiation of detonators and shock tubes under normal working conditions. It covers six equipment types: blasting machines, blasting machine checkers, initiating circuit field testers, shot‑firing cables, detonator connecting wires, and shock tube initiators. Note: equipment intended only for indoor use is excluded from Annex B environmental testing, and blasting machines for electronic or magnetically coupled detonators are out of scope. The standard also notes other directives (for example ATEX and low voltage) and standards (such as EN 61010) may be relevant.

Key Topics

- Scope & definitions: Terminology and the six device categories referenced above.

- Constructional and functional requirements: Design, marking and basic build specifications to ensure safe, repeatable operation.

- Electrical safety tests: Insulation resistance, dielectric/voltage withstand, short‑circuit current limitation, output voltage and output energy measurements for blasting machines and field testers.

- Performance and reliability tests: Output energy/output voltage, battery‑low indicators, sequential firing safety, capacitor discharge safety, and accuracy checks.

- Environmental & mechanical testing: Climatic, ingress protection (IP), vibration/bump, thermostability and mechanical strength tests (Annex B).

- Electromagnetic compatibility (EMC): Immunity and emissions testing to limit interference with initiation systems (normative Annex A).

- Cable and wire tests: Resistance, tensile strength, flexural and abrasion tests, insulation breakdown and thermostability for shot‑firing cables and connecting wires.

- Intrinsic safety & hazardous atmospheres: Requirements and tests where devices are intended for potentially explosive atmospheres.

Applications

Who uses EN 13763-26:2004 and why:

- Manufacturers of blasting machines, field testers, shot‑firing cables and shock tube initiators - to design products that meet European functional and safety expectations.

- Testing laboratories and conformity assessors - to perform standardized electrical, mechanical, climatic and EMC tests.

- Blasting contractors, quarries and mines - to select reliable equipment for civil blasting operations and ensure safe initiation practices.

- Safety engineers and procurement teams - to specify compliant devices and document performance requirements.

- Regulators and notified bodies - to reference when evaluating safety, marking and test evidence.

Practical value: the standard improves safety, reduces misfires, clarifies test evidence for procurement, and supports interoperability of initiation equipment in civil blasting operations.

Related Standards

- EN 13763-1 (General requirements)

- EN 13763-4, -5, -6 (Mechanical tests on leading wires and shock tubes)

- EN 13763-22 (Capacitance, insulation resistance and breakdown of leading wires)

- EN 13763-24 (Electrical non‑conductivity of shock tube)

- EN 13763-25 (Transfer capability of connectors and relays)

- CEN/TS 13763-27 (Electronic initiation systems)

Keywords: EN 13763-26:2004, detonators, blasting machines, shot‑firing cables, field circuit testers, shock tube initiators, explosives for civil uses, CEN, EMC, ingress protection.

Frequently Asked Questions

SIST EN 13763-26:2004 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Explosives for civil uses - Detonators and relays - Part 26: Definitions, methods, and requirements for devices and accessories for reliable and safe function of detonators and relays". This standard covers: 1.1 This document specifies the constructional and functional requirements and methods for testing of devices and accessories needed for the reliable and safe initiation of detonators and shock tubes, under normal working conditions. It covers the following six types of equipment: ¾ blasting machines for initiating electric detonators; ¾ blasting machine checkers; ¾ initiating circuit field testers; ¾ shot firing cables for use with electric blasting machines; ¾ detonator connecting wires; ¾ shock tube initiators for non-electric systems. 1.2 Equipment indented only for use indoors is excluded from the environmental testing in Annex B. 1.3 Blasting machines for use with electronic detonators and magnetically coupled detonators are outside the scope of this document. NOTE This document does not meet all of the requirements of all relevant European Directives, such as the ATEX Directive 94/9/EC and the low voltage Directive 73/23/EEC. For example, EN 61010 (Safety requirements for electrical equipment for measurement, control and laboratory use) might also be relevant for some devices and accessories described in this document.

1.1 This document specifies the constructional and functional requirements and methods for testing of devices and accessories needed for the reliable and safe initiation of detonators and shock tubes, under normal working conditions. It covers the following six types of equipment: ¾ blasting machines for initiating electric detonators; ¾ blasting machine checkers; ¾ initiating circuit field testers; ¾ shot firing cables for use with electric blasting machines; ¾ detonator connecting wires; ¾ shock tube initiators for non-electric systems. 1.2 Equipment indented only for use indoors is excluded from the environmental testing in Annex B. 1.3 Blasting machines for use with electronic detonators and magnetically coupled detonators are outside the scope of this document. NOTE This document does not meet all of the requirements of all relevant European Directives, such as the ATEX Directive 94/9/EC and the low voltage Directive 73/23/EEC. For example, EN 61010 (Safety requirements for electrical equipment for measurement, control and laboratory use) might also be relevant for some devices and accessories described in this document.

SIST EN 13763-26:2004 is classified under the following ICS (International Classification for Standards) categories: 71.100.30 - Explosives. Pyrotechnics and fireworks. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13763-26:2004 is associated with the following European legislation: Standardization Mandates: M/055. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13763-26:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Eksplozivi za civilno uporabo – Detonatorji in zakasnilniki – 26. del: Definicije, metode in zahteve za naprave in sredstva za zanesljivo in varno delovanje detonatorjev in zakasnilnikovExplosivstoffe für zivile Zwecke - Zünder und Verzögerungselemente - Teil 26: Definitionen, Verfahren und Anforderungen für Geräte und Zubehör für die zuverlässige und sichere Funktion von Zündern und VerzögerernExplosifs a usage civil - Détonateurs et relais - Partie 26: Définitions, méthodes et exigences relatives aux dispositifs et accessoires pour la fiabilité et la sécurité de fonctionnement des détonateurs et relaisExplosives for civil uses - Detonators and relays - Part 26: Definitions, methods, and requirements for devices and accessories for reliable and safe function of detonators and relays71.100.30Eksplozivi. PirotehnikaExplosives. PyrotechnicsICS:Ta slovenski standard je istoveten z:EN 13763-26:2004SIST EN 13763-26:2004en01-november-2004SIST EN 13763-26:2004SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13763-26August 2004ICS 71.100.30English versionExplosives for civil uses - Detonators and relays - Part 26:Definitions, methods, and requirements for devices andaccessories for reliable and safe function of detonators andrelaysExplosifs à usage civil - Détonateurs et relais - Partie 26:Définitions, méthodes et exigences relatives aux dispositifset accessoires pour la fiabilité et la sécurité defonctionnement des détonateurs et relaisExplosivstoffe für zivile Zwecke - Zünder undVerzögerungselemente - Teil 26: Definitionen, Verfahrenund Anforderungen für Geräte und Zubehör für diezuverlässige und sichere Funktion von Zündern undVerzögerernThis European Standard was approved by CEN on 21 June 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13763-26:2004: ESIST EN 13763-26:2004

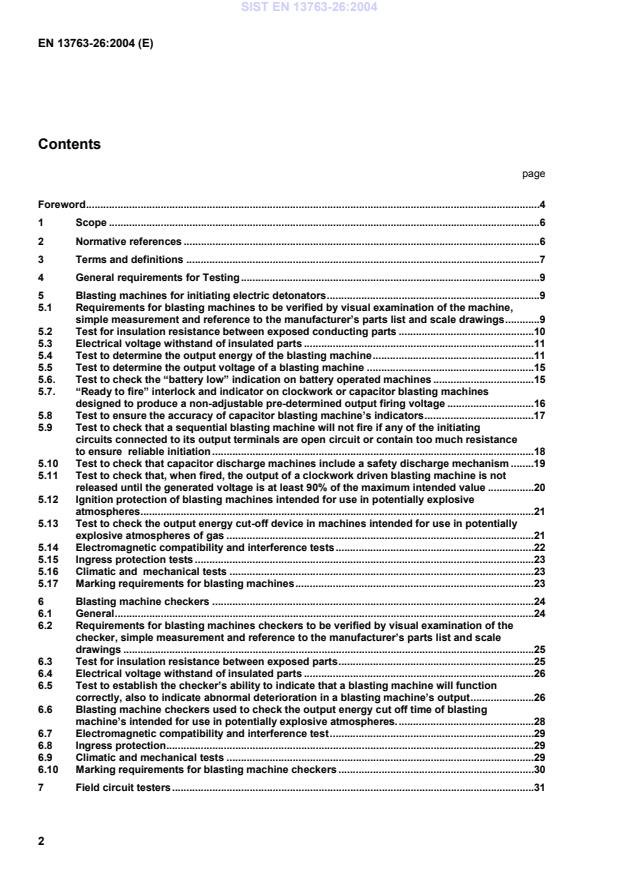

reliable initiation.18 5.10 Test to check that capacitor discharge machines include a safety discharge mechanism.19 5.11 Test to check that, when fired, the output of a clockwork driven blasting machine is not released until the generated voltage is at least 90% of the maximum intended value.20 5.12 Ignition protection of blasting machines intended for use in potentially explosive atmospheres.21 5.13 Test to check the output energy cut-off device in machines intended for use in potentially explosive atmospheres of gas.21 5.14 Electromagnetic compatibility and interference tests.22 5.15 Ingress protection tests.23 5.16 Climatic and

mechanical tests.23 5.17 Marking requirements for blasting machines.23 6 Blasting machine checkers.24 6.1 General.24 6.2 Requirements for blasting machines checkers to be verified by visual examination of the checker, simple measurement and reference to the manufacturer’s parts list and scale drawings.25 6.3 Test for insulation resistance between exposed parts.25 6.4 Electrical voltage withstand of insulated parts.26 6.5 Test to establish the checker’s ability to indicate that a blasting machine will function correctly, also to indicate abnormal deterioration in a blasting machine’s output.26 6.6 Blasting machine checkers used to check the output energy cut off time of blasting machine’s intended for use in potentially explosive atmospheres.28 6.7 Electromagnetic compatibility and interference test.29 6.8 Ingress protection.29 6.9 Climatic and mechanical tests.29 6.10 Marking requirements for blasting machine checkers.30 7 Field circuit testers.31 SIST EN 13763-26:2004

Electromagnetic compatibility and interference testing.52 As described in the relevant European Standard.52 Annex B (normative)

Climatic and mechanical tests.55 Bibliography.59

Part 1: Requirements EN 13763-2

Part 2: Determination of thermal stability EN 13763-3

Part 3: Determination of sensitiveness to impact EN 13763-4

Part 4: Determination of resistance to abrasion of leading wires and shock tubes EN 13763-5

Part 5: Determination of resistance to cutting damage of leading wires and shock tubes EN 13763-6

Part 6: Determination of resistance to cracking in low temperatures of leading wires EN 13763-7 Part 7: Determination of the mechanical strength of leading wires, shock tubes, connections, crimps and closures EN 13763-8

Part 8: Determination of resistance to vibration of plain detonators EN 13763-11

Part 11: Determination of resistance to damage by dropping of detonators and relays EN 13763-12

Part 12: Determination of resistance to hydrostatic pressure EN 13763-13

Part 13: Determination of resistance of electric detonators against electrostatic discharge prEN 13763-15 Part 15: Determination of equivalent initiating capability EN 13763-16

Part 16: Determination of delay accuracy EN 13763-17

Part 17: Determination of no-fire current of electric detonators EN 13763-18

Part 18: Determination of series firing current of electric detonators EN 13763-19

Part 19: Determination of firing impulse of electric detonators EN 13763-20

Part 20: Determination of total electrical resistance of electric detonators EN 13763-21

Part 21: Determination of flash-over voltage of electric detonators EN 13763-22 Part 22: Determination of capacitance, insulation resistance and insulation breakdown of leading wires EN 13763-23 Part 23: Determination of the shock-wave velocity of shock tube SIST EN 13763-26:2004

Part 24: Determination of the electrical non-conductivity of shock tube EN 13763-25 Part 25: Determination of transfer capability of surface connectors, relays and coupling accessories CEN/TS 13763-27 Part 27: Definitions, methods and requirements for electronic initiation systems According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

1 Scope 1.1 This document specifies the constructional and functional requirements and methods for testing of devices and accessories needed for the reliable and safe initiation of detonators and relays, under normal working conditions. It covers the following six types of equipment: blasting machines for initiating electric detonators; blasting machine checkers; initiating circuit field testers; shot firing cables for use with electric blasting machines; detonator connecting wires; shock tube initiators for non-electric systems. 1.2 Equipment indented only for use indoors is excluded from the environmental testing in Annex B. 1.3 Blasting machines for use with electronic detonators and magnetically coupled detonators are outside the scope of this document. NOTE This document does not meet all of the requirements of all relevant European Directives, such as the ATEX Directive 94/9/EC and the low voltage Directive 73/23/EEC. For example, EN 61010 (Safety requirements for electrical equipment for measurement, control and laboratory use) might also be relevant for some devices and accessories described in this document. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 13857-1:2003, Explosives for civil uses – Part 1: Terminology. EN 13763-4:2003, Explosives for civil uses – Detonators and relays – Part 4: Determination of resistance to abrasion of leading wires and shock tubes. EN 13763-5, Explosives for civil uses – Detonators and relays – Part 5: Determination of resistance to cutting damage of leading wires and shock tubes. EN 13763-6, Explosives for civil uses – Detonators and relays – Part 6: Determination of resistance to cracking in low temperatures of leading wires. EN 13763-22:2003, Explosives for civil uses – Detonators and relays – Part 22: Determination of capacitance, insulation resistance and insulation breakdown of leading wires. EN 55011:1998, Industrial, scientific and medical (ISM) radio-frequency equipment – Radio disturbance characteristics – Limits and methods of measurement (CISPR 11:1997, modified). EN 60068-2-1:1993, Environmental testing – Part 2: Tests – Tests A: Cold (IEC 60068-2-1:1990). SIST EN 13763-26:2004

blasting machine equipment intended to supply electrical energy to a circuit of electric detonators to initiate them 3.2

sequential blasting machine blasting machine incorporating a means to control the sequence of firing of the electric detonators connected to it SIST EN 13763-26:2004

blasting machine checker equipment specifically designed for connection to a blasting machine’s output terminals to verify that the machine’s output performance is within the operating limits specified by its manufacturer and that it is capable of initiating the maximum number of detonators claimed NOTE

Blasting machine checkers are usually supplied by the blasting machine manufacturer and are designed for use with a particular type of machine. They are designed to allow the blasting machine user to perform periodic checks to verify that the machine is functioning correctly before it is used on site. The indication provided by checkers may vary from one type to another. For example, some have a simple “Go/No-Go” indicator lamp and others have analogue or digital displays capable of indicating the blasting machine’s actual output energy. In some E.U. member state countries, the regular use of such checkers is required by national legislation as part of a users “blasting machine maintenance scheme”. 3.4

initiating circuit electrical circuit intended to be connected to a blasting machine, consisting of shot firing cable, electric detonators, detonator leading wires and any extensions to them by connecting wires 3.5

field circuit tester instrument intended for measuring, checking, or testing an initiating circuit outdoors on site, usually before an attempt is made to initiate the detonators with a blasting machine 3.6

continuity and resistance tester type of field circuit tester, intended for measuring, checking or testing the continuity and resistance of an initiating circuit 3.7

continuity and impedance tester type of field circuit tester, intended for measuring, checking or testing the continuity and impedance of an alternating current initiating circuit at a frequency specified by the manufacturer 3.8

circuit insulation tester type of field circuit tester, intended to measure, check or test the electrical resistance of the insulation between the main electrical conductors in an initiating circuit and the general mass of earth 3.9

connecting wires electrically insulated conductors that can be connected between the shot-firing cable and the detonator leading wire NOTE Connecting wires are normally used only once in service because they are located so close to the explosive devices that they are usually damaged by the explosive blast. 3.10

maximum initiating circuit resistance

(Re) maximum electrical resistance of a particular configuration of an electrical detonator initiating circuit. NOTE The maximum initiating circuit resistance is given by the equation.

R e = R t + NR s n 2 SIST EN 13763-26:2004

where Rt is the shot firing cable electrical resistance in ; N is the total number of electric detonators; Rs

is the total resistance in

of one electric detonator; n

is the number of parallel circuits 3.11

shock tube initiator equipment intended to supply a spark or a similar energy impulse to the explosive coating material inside a non electric shock tube so as to initiate it 4 General requirements for Testing 4.1

Unless otherwise specified in the test instructions, testing shall be performed within an ambient temperature range of (20 ± 5) °C, a relative humidity of (60 ± 15) % and an air pressure of (960 ± 100) hPa. If these conditions cannot be achieved or maintained, the actual conditions shall be recorded in the test report. 4.2

The order of checking and testing of each device or accessory shall be in the same order as they appear in this document. NOTE If there are no influences to the test results, tests may also be carried out in parallel using more than one test piece. 4.3

Equipment and devices intended for use outdoors shall be subjected to the environmental tests in Annex B. 5 Blasting machines for initiating electric detonators 5.1 Requirements for blasting machines to be verified by visual examination of the machine, simple measurement and reference to the manufacturer’s parts list and scale drawings 5.1.1 Every blasting machine shall have output terminals or outlets incorporating means to securely attach the type of shot firing cable intended to be used with them. The area of electrical contact of each terminal shall be a least twice the cross sectional area of the shot firing cable intended to be used with it. The blasting machine’s output terminals shall have a barrier of insulating material between them which protrudes at least

4 mm higher than the conductive part. 5.1.2 Every blasting machine shall contain a means for the operator to control the instant of firing, or control the commencement of the firing sequence. SIST EN 13763-26:2004

500 V DC. 5.2.2 Test pieces One complete blasting machine of each type. 5.2.3 Apparatus Electrical insulation test meter, capable of applying 500 V with a tolerance of ± 10 V and measuring the insulation resistance over a range between 0 MΩ to 3 MΩ, within a tolerance of ± 0,1 MΩ. 5.2.4 Procedure Short circuit the terminals of the blasting machine and apply the test voltage of 500 V between the terminals and the casing of the equipment. Measure and record the insulation resistance in MΩ. 5.2.5 Test report The test report shall conform to EN ISO/IEC 17025. In addition, the following information shall be given: a) the insulation resistance in MΩ; b) whether or not the insulation is ≥ 2 MΩ. SIST EN 13763-26:2004

(with a tolerance of ± 5 %) up to twice the blasting machine’s peak output voltage, or 1 000 V AC RMS which ever is the greater and a voltage rise time of 10 s maximum. 5.3.3.2 An ammeter. 5.3.4 Procedure Short circuit the terminals of the blasting machine and apply the test voltage, in series with the ammeter, between the terminals and the conductive parts of the enclosure or casing for a time period of 1 min. In the case of blasting machines designed to disconnect the output voltage after a predetermined time, the disconnecting device or switch shall be bypassed in such a way as to enable the internal components of the blasting machine to be exposed to the applied test voltage. Record whether or not the insulation breaks down during the test. NOTE A breakdown of insulation is usually indicated by a sudden increase in the flow of electrical current on the ammeter. 5.3.5 Test report The test report shall conform to EN ISO/IEC 17025. In addition, the following information shall be given: whether or not the insulation breaks down. 5.4 Test to determine the output energy of the blasting machine 5.4.1 Requirements The output current and output energy of blasting machines shall: a) be capable of reliably providing enough firing energy (KRe) to initiate the maximum number of electric detonators, with the allowed resistance of shot firing cable in circuit, in all permissible configurations of initiating circuits specified by the blasting machine manufacturer; SIST EN 13763-26:2004

The maximum number of electric detonators in a particular initiating circuit configuration is information provided by the blasting machine manufacturer. b) include a safety factor (S), to ensure that (a) above takes account of variations in the electrical resistance of leading wire connections made on site by the operator; c) deliver the required amount of energy, specified in (a) above, before the first detonator in any series/parallel configuration explodes to open the electrical circuit, thereby preventing further flow of electrical current and delivery of initiating energy. NOTE 2 The duration for the delivery of energy in (c) above, is normally the time taken for the output current (I) to reduce from its initial value at the commencement of initiation, to a value equal to or greater than the electric detonator series firing current

(Iseries) and safety factor (I≥nSIseries). In the case of blasting machines intended for use in potentially explosive atmospheres (e.g. coal mines), the duration is determined by the 4 ms maximum output time of the blasting machine (see 5.13). NOTE 3 For example, a capacitor type blasting machine with a maximum circuit resistance (Re) connected across its output terminals needs to provide an initiating energy of at least KRe for the required duration. Also an output current greater than the all fire series firing current of the particular detonators intended for use with the blasting machine.

Where K is equal to, or greater than

"n2S2Waf“ for the required duration. This is shown in Figure 1 which is a graph below, of the blasting machine's output current (I) against time from the commencement of firing, to the time where the machine's output current reduces to a value equal to the detonator's series firing current. The energy delivered by the blasting machine during this period is derived the shaded area under the graph. The energy is calculated from the integral of the current squared over this period multiplied by the maximum initiating circuit resistance (Re). and where: Waf is the all fire impulse of detonator claimed by the manufacturer, in J/Ω or Ws/Ω; I is the blasting machine output current in A; Iseries is the series firing current in A for the detonator; n is the number of parallel circuits (see Table 1); S is the safety factor (see Table 1); Re maximum initiating circuit resistance (see definition 3.10); K is the blasting machine firing impulse in J/Ω or Ws/Ω. SIST EN 13763-26:2004

Key 1 Discharge curve 2 Area used to calculate the blasting machine output energy 3 Electric detonator series firing current and safety factor (nSIseries) 4 The output energy cut-off time for blasting machines intended for use in potentially explosive atmospheres of gas (see 5.13) Figure 1 — Discharge curve

Table 1 — Safety factor

5.4.2 Test pieces One complete blasting machine of each type. 5.4.3 Apparatus a) Resistances R1 + R2 corresponding to the maximum circuit resistance Re and capable of withstanding the highest output voltage of the blasting machine. R2 shall be low ohmic (less than 2 Ω). n 1 2 3 ≥4 S 1,15 1,25 1,35 1,4 SIST EN 13763-26:2004

and the oscilloscope according to Figure 2. Charge and fire the blasting machine in accordance with the manufacturer’s instructions or in accordance with the details on the label rating plate and record the output firing impulse (K) as an oscillogram for a period long enough to establish that: in the case of a capacitor blasting machine, the output current (calculated as Uosc/R2) has fallen to a value of nSIseries ; or in the case of other blasting machines, it provides an output current (calculated as Uosc/R2) greater than nSIseries and ensures that all of the detonators will initiate; in the case of blasting machine intend to use for potentially explosives atmospheres, the 4 ms cut off time has occurred

Key 1 Blasting machine 2 Resistances R1 and R2 3 Oscilloscope Figure 2 — Blasting machine connected to resistances and oscilloscope If the blasting machine is intended for both series and/or parallel firing, or for use with several different electric detonators, perform the test for each of the alternative configurations (see 3.10). Repeat the tests so as to produce three oscillograms for each test, which allow the output energy of the blasting machine to be calculated. Record the minimum value of output energy from the three oscillograms and whether or not it is capable of initiating the configurations of initiating circuits claimed by the blasting machine manufacturer. SIST EN 13763-26:2004

Such machines shall also contain a device to indicate to the operator when the machine is fully charged with energy (i.e. the clockwork spring or capacitor, as appropriate) and is “Ready To Fire”. 5.7.2 Test pieces One complete blasting machine of each type. 5.7.3 Apparatus 5.7.3.1 Storage oscilloscope or voltmeter capable of indicating the manufacturer’s specified output voltage of the blasting machine with maximum circuit resistance (Re) across its output terminals. 5.7.3.2 Resistor(s) with an resistance value equal to (Re) for each configuration and of sufficient power rating for the blasting machine’s output. 5.7.4 Procedure 5.7.4.1 Connect the resistor (Re) and the measuring instrument across the blasting machine’s output terminals.

Commence the manufacturer’s recommended firing procedure, but stop the charging process before the machine is ready to fire and attempt to fire it. Record whether or not the machine produces an output voltage. Repeat four times, attempting to stop the charging process as near as possible to the point where the machine is just about ready to fire. Repeat for each configuration of initiating circuit. SIST EN 13763-26:2004

Fire the blasting machine and record whether or not it achieves the manufacturer’s specified output voltage. Repeat for each configuration of initiating circuit. 5.7.5 Test report The test report shall conform to EN ISO/IEC 17025. In addition, the following information shall be given: a) whether or not the machine produces an output voltage when the blasting machine is not ready to fire; b) whether or not the machine produces the manufacturer’s specified output voltage when the blasting machine is ready to fire. 5.8 Test to ensure the accuracy of capacitor blasting machine’s indicators 5.8.1 Requirements Capacitor blasting machines capable of providing a range of voltage outputs, according to the initiating circuit to be fired, shall contain a device which indicates when the machine is capable of delivering the manufacturer’s specified output voltages. 5.8.2 Test pieces One complete blasting machine of each type. 5.8.3 Apparatus 5.8.3.1 Storage oscilloscope or voltmeter capable of indicating the manufacturer’s specified output voltages of the blasting machine with resistance (Re) across its output terminals. 5.8.3.2 Resistor(s) with an resistance value equal to (Re) for each configuration of initiating circuit and of sufficient power rating for the blasting machine’s output. 5.8.4 Procedure Connect the resistor (Re) and the measuring instrument across the blasting machine terminals. Carry out the manufacturer’s recommended firing procedure until the indicator shows that the machine is charged to the first of the manufacturer’s specified firing voltages. Fire the blasting machine and record the output voltage shown on the voltmeter or oscilloscope. Repeat the test for each of the other specified firing voltages and for each configuration of initiating circuit. Also record whether or not the output voltage is equal or greater than that specified by the manufacturer for each voltage. 5.8.5 Test Report The test report shall conform to EN ISO/IEC 17025. In addition, the following information shall be given: - the output voltage for each of the manufacturer’s specified firing voltages and whether or not the recorded voltage is equal or greater than that specified by the manufacturer SIST EN 13763-26:2004

reliable initiation 5.9.1 Requirements A device shall be incorporated to prevent a sequential firing blasting machine from producing an output from any of its sequential output circuits, if any one of the initiating circuits contains too much resistance to ensure reliable initiation. 5.9.2 Test pieces One complete sequential blasting machine of each type. 5.9.3 Apparatus One resistor for each sequential output circuit, having a resistance value equal to the maximum initiating circuit resistance (Re) for that sequential circuit and a power rating adequate for the maximum output power on the blasting machine. One resistor with an ohmic rating 10 % higher that the maximum initiating circuit resistance of the blasting machine’s sequential circuit and of adequate rating for the maximum output power of the blasting machine. 5.9.4 Procedure Connect the resistor (Re) to each of the separate output circuits of the sequential blasting machine. Follow the manufacturer’s recommended firing procedure and check that the machine fires correctly. Repeat the process but replace one of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...