SIST EN 14915:2013+A2:2020

(Main)Solid wood panelling and cladding - Characteristics, requirements and marking

Solid wood panelling and cladding - Characteristics, requirements and marking

This European Standard defines and specifies the relevant characteristics and the appropriate test methods to determine these characteristics for solid wood products to be used as panelling and cladding (including siding) for:

- wall and ceiling panelling for internal use,

- wall and ceiling cladding for external uses.

It provides for the assessment and verification of constancy of performance and the requirements for marking these products.

This European Standard does not cover panels intended for use as stiffening elements.

This European Standard does not cover suspended ceiling in wood panelling and cladding.

This European Standard does not cover the processes for treatment, surface coating or modification.

This European standard does not cover products which are produced from laminated layer section.

This European Standard covers treated, untreated and surface coated products, including those made of thermally or chemically modified wood, as well as finger jointed and edge glued products.

NOTE Prescriptions for surface coating and treatment can be found in documents valid in the place of use.

This European Standard covers products in compliance with EN 14519, EN 15146 and EN 14951, and other solid timber products manufactured for use as panelling and cladding.

Wand- und Deckenbekleidungen aus Massivholz - Eigenschaften, Anforderungen und Kennzeichnung

Diese Europäische Norm legt die wesentlichen Eigenschaften für Massivholz-Produkte fest, die als Innen- und Außenbekleidungen verwendet werden (einschließlich seitlicher Wandbekleidungen), sowie die geeigneten Prüfverfahren zur Bestimmung dieser Eigenschaften für:

- Wand und Deckenbekleidungen zur Verwendung im Innenbereich;

- Wand und Deckenbekleidungen zur Verwendung im Außenbereich.

Sie legt die Bewertung der Konformität und die Anforderungen an die Kennzeichnung dieser Produkte fest.

Diese Europäische Norm gilt nicht für Platten, die für Versteifungszwecke vorgesehen sind.

Diese Europäische Norm gilt nicht für abgehängte Unterdecken-Bekleidungen aus Holz.

Diese Europäische Norm gilt nicht für den Prozess der Behandlung, Oberflächenbeschichtung oder Modifizierung.

Diese Europäische Norm gilt nicht für Produkte, die aus schichtverklebten Teilen hergestellt sind.

Diese Europäische Norm gilt für behandelte, unbehandelte und beschichtete Produkte, einschließlich solcher, die aus thermisch oder chemisch modifiziertem Holz hergestellt worden sind, sowie für keilgezinkte und kantenverleimte Produkte.

ANMERKUNG Vorschriften für die Oberflächenbeschichtung und Oberflächenbehandlung können in anderen, am Verwendungsort gültigen Dokumenten gefunden werden.

Diese Europäische Norm gilt für Produkte nach EN 14519, EN 15146 und EN 14951 und andere Massivholz-Produkte, die für die Verwendung als Innen- und Außenbekleidungen hergestellt sind.

Lambris et bardages en bois - Caractéristiques, exigences et marquage

La présente Norme européenne définit et spécifie les caractéristiques pertinentes, ainsi que les méthodes d'essais appropriées, pour déterminer les caractéristiques des produits bois destinés à être utilisés en tant que lambris et bardages utilisés en :

- Ouvrage de revêtement de mur et de plafond pour usage intérieur (lambris) ;

- Ouvrage de revêtement de mur et de plafond abrité pour usage extérieur (bardages).

Elle traite de l'évaluation de la conformité et des exigences concernant le marquage de ces produits.

La présente Norme européenne ne s'applique pas aux panneaux destinés à être utilisés comme éléments raidisseurs.

La présente Norme européenne ne s'applique pas aux plafonds suspendus en lambris et bardages en bois.

La présente Norme européenne ne traite pas des procédés de traitement, de revêtement de surface ou de modification du bois.

La présente Norme européenne ne s'applique pas aux produits qui proviennent de section lamellée.

La présente Norme européenne s'applique aux produits traités, non traités et revêtus, y compris ceux fabriqués à partir de bois modifié chimiquement ou thermiquement, ainsi qu'aux produits aboutés et collés sur chant.

NOTE Les prescriptions de finition et de traitement sont à rechercher dans les exigences prescrites pour le lieu d'utilisation

La présente Norme européenne s'applique aux produits conformes à l'EN 14519, à l'EN 15146, et à l'EN 14951, ainsi qu'aux autres produits bois fabriqués en vue de la réalisation de lambris et de bardages.

Stenske in stropne obloge iz masivnega lesa - Lastnosti, zahteve in označevanje

Ta evropski standard opredeljuje in navaja veljavne značilnosti in primerne preskusne metode za določanje lastnosti izdelkov iz masivnega lesa, ki se uporabljajo za notranje in zunanje obloge, za:

– stenske in stropne opaže za notranjo uporabo,

– stenske in stropne opaže za zunanjo uporabo.

Omogoča ocenjevanje in preverjanje nespremenljivosti lastnosti teh izdelkov in podaja zahteve za njihovo označevanje.

Ta evropski standard ne vključuje plošč, ki se uporabljajo kot ojačitveni elementi.

Ta evropski standard ne vključuje visečih lesenih stropnih opažev.

Ta evropski standard ne vključuje procesov za obdelavo, premazovanje ali spreminjanje površin.

Ta evropski standard ne vključuje izdelkov z laminirano plastjo.

Ta evropski standard vključuje vse obdelane, neobdelane in površinsko premazane izdelke, vključno s tistimi iz toplotno ali kemično obdelanega lesa, ter izdelke z zobatimi spoji in robno lepljenimi izdelki.

OPOMBA: Predpise za površinske premaze in obdelavo lahko najdete v dokumentih, veljavnih na mestu uporabe.

Ta evropski standard vključuje izdelke, navedene v standardih EN 14519, EN 15146 in EN 14951, ter druge izdelke iz masivnega lesa, proizvedene za stenske in stropne opaže.

General Information

- Status

- Published

- Publication Date

- 13-Feb-2020

- Technical Committee

- LLZ - Les, lesni izdelki in zaščita lesa

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 22-Jan-2020

- Due Date

- 28-Mar-2020

- Completion Date

- 14-Feb-2020

Relations

- Effective Date

- 01-Mar-2020

- Consolidates

SIST EN 14915:2013+A1:2017 - Solid wood panelling and cladding - Characteristics, requirements and marking - Effective Date

- 18-Jan-2023

Overview

EN 14915:2013+A2:2020 (CEN) is the European standard that defines the characteristics, test methods, performance requirements and marking for solid wood panelling and cladding (including siding). It covers internal wall and ceiling panelling and external wall and ceiling cladding, and sets out how to assess and declare product performance. The standard applies to treated, untreated and surface‑coated solid wood products - including thermally or chemically modified wood, finger‑jointed and edge‑glued items - but excludes laminated layer products, suspended ceilings and processes for surface treatment or coating.

Key Topics and Requirements

- Scope and definitions: Terms for panelling, cladding and assembled products; scope limits (no stiffening panels, no laminated layered sections).

- Durability against biological attack: Requirements tied to species durability or EN 350 assessment; provisions for preservative‑treated wood (use class per EN 335, penetration & retention per EN 351‑1 and performance per EN 599‑2).

- Reaction to fire: Classification in accordance with EN 13501‑1 after specified testing and mounting/conditioning rules; declared reaction-to-fire class required.

- Dangerous substances: Formaldehyde release classification (Annex C) and PCP content considerations; laboratory test methods referenced.

- Physical performance tests: Methods for water vapour permeability (EN ISO 12572), sound absorption (EN ISO 354 / EN ISO 11654), thermal conductivity (EN 12664) and resistance to fixing.

- Assessment & conformity: Procedures for Assessment and Verification of Constancy of Performance (AVCP), required type testing and Factory Production Control (FPC) requirements for manufacturers.

- Marking and labelling: Required product information, declared performance values and packaging/label requirements; Annex ZA links the standard to EU Construction Products Regulation (CPR).

Applications and Who Uses It

EN 14915 is essential for anyone specifying, manufacturing, testing or inspecting solid wood panelling and cladding:

- Manufacturers - product design, FPC and CE marking compliance

- Architects & specifiers - selecting materials meeting fire, durability and hygrothermal requirements

- Test laboratories & certification bodies - type testing, formaldehyde and reaction‑to‑fire classification

- Installers & contractors - understanding declared performance and correct mounting conditions

- Regulators & product compliance teams - linking to CPR and national requirements

Practical uses include internal wall/ceiling panelling, external timber cladding/siding, and product datasheets where declared thermal, acoustic, durability and fire properties are required.

Related Standards

EN 14915 references and integrates with other standards commonly used for timber products, including:

- EN 335 (use classes / durability)

- EN 351‑1, EN 599‑2 (preservatives, penetration/retention)

- EN 13501‑1 (reaction to fire)

- EN ISO 12572, EN ISO 354/11654 (hygrothermal & acoustic tests)

- EN 13986 (wood‑based panels) and EN 13556 (timber nomenclature)

Keywords: EN 14915:2013+A2:2020, solid wood panelling, cladding, characteristics, requirements, marking, reaction to fire, formaldehyde, durability, AVCP, FPC.

Frequently Asked Questions

SIST EN 14915:2013+A2:2020 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Solid wood panelling and cladding - Characteristics, requirements and marking". This standard covers: This European Standard defines and specifies the relevant characteristics and the appropriate test methods to determine these characteristics for solid wood products to be used as panelling and cladding (including siding) for: - wall and ceiling panelling for internal use, - wall and ceiling cladding for external uses. It provides for the assessment and verification of constancy of performance and the requirements for marking these products. This European Standard does not cover panels intended for use as stiffening elements. This European Standard does not cover suspended ceiling in wood panelling and cladding. This European Standard does not cover the processes for treatment, surface coating or modification. This European standard does not cover products which are produced from laminated layer section. This European Standard covers treated, untreated and surface coated products, including those made of thermally or chemically modified wood, as well as finger jointed and edge glued products. NOTE Prescriptions for surface coating and treatment can be found in documents valid in the place of use. This European Standard covers products in compliance with EN 14519, EN 15146 and EN 14951, and other solid timber products manufactured for use as panelling and cladding.

This European Standard defines and specifies the relevant characteristics and the appropriate test methods to determine these characteristics for solid wood products to be used as panelling and cladding (including siding) for: - wall and ceiling panelling for internal use, - wall and ceiling cladding for external uses. It provides for the assessment and verification of constancy of performance and the requirements for marking these products. This European Standard does not cover panels intended for use as stiffening elements. This European Standard does not cover suspended ceiling in wood panelling and cladding. This European Standard does not cover the processes for treatment, surface coating or modification. This European standard does not cover products which are produced from laminated layer section. This European Standard covers treated, untreated and surface coated products, including those made of thermally or chemically modified wood, as well as finger jointed and edge glued products. NOTE Prescriptions for surface coating and treatment can be found in documents valid in the place of use. This European Standard covers products in compliance with EN 14519, EN 15146 and EN 14951, and other solid timber products manufactured for use as panelling and cladding.

SIST EN 14915:2013+A2:2020 is classified under the following ICS (International Classification for Standards) categories: 79.080 - Semi-manufactures of timber. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14915:2013+A2:2020 has the following relationships with other standards: It is inter standard links to SIST EN 14915:2013+A1:2017, SIST EN 14915:2013+A1:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14915:2013+A2:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2020

Nadomešča:

SIST EN 14915:2013+A1:2017

Stenske in stropne obloge iz masivnega lesa - Lastnosti, zahteve in označevanje

Solid wood panelling and cladding - Characteristics, requirements and marking

Wand- und Deckenbekleidungen aus Massivholz - Eigenschaften, Anforderungen und

Kennzeichnung

Lambris et bardages en bois - Caractéristiques, exigences et marquage

Ta slovenski standard je istoveten z: EN 14915:2013+A2:2020

ICS:

79.080 Polizdelki iz lesa Semi-manufactures of timber

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14915:2013+A2

EUROPEAN STANDARD

NORME EUROPÉENNE

January 2020

EUROPÄISCHE NORM

ICS 79.080 Supersedes EN 14915:2013+A1:2017

English Version

Solid wood panelling and cladding - Characteristics,

requirements and marking

Lambris et bardages en bois - Caractéristiques, Wand- und Deckenbekleidungen aus Massivholz -

exigences et marquage Eigenschaften, Anforderungen und Kennzeichnung

This European Standard was approved by CEN on 10 April 2017 and includes Amendment 2 approved by CEN on 17 July 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14915:2013+A2:2020 E

worldwide for CEN national Members.

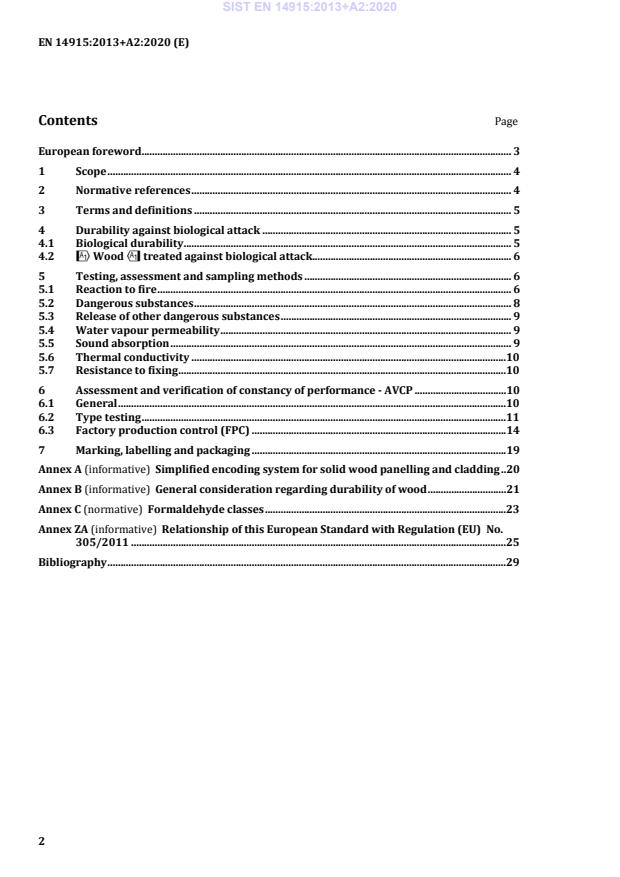

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms and definitions . 5

4 Durability against biological attack . 5

4.1 Biological durability . 5

4.2 !Wood" treated against biological attack. 6

5 Testing, assessment and sampling methods . 6

5.1 Reaction to fire . 6

5.2 Dangerous substances . 8

5.3 Release of other dangerous substances . 9

5.4 Water vapour permeability . 9

5.5 Sound absorption . 9

5.6 Thermal conductivity .10

5.7 Resistance to fixing .10

6 Assessment and verification of constancy of performance - AVCP .10

6.1 General .10

6.2 Type testing .11

6.3 Factory production control (FPC) .14

7 Marking, labelling and packaging .19

Annex A (informative) Simplified encoding system for solid wood panelling and cladding .20

Annex B (informative) General consideration regarding durability of wood .21

Annex C (normative) Formaldehyde classes .23

Annex ZA (informative) Relationship of this European Standard with Regulation (EU) No.

305/2011 .25

Bibliography .29

European foreword

This document (EN 14915:2013+A2:2020) has been prepared by Technical Committee CEN/TC 175

“Round and sawn timber”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by July 2020, and conflicting national standards shall be

withdrawn at the latest by October 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1 approved by CEN on 10 April 2017 and Amendment 2 approved

by CEN on 17 July 2019.

This document supersedes #EN 14915:2013+A1:2017$.

The start and finish of text introduced or altered by amendment is indicated in the text by tags !"

and #$.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

!For relationship with EU Construction Products Regulation (CPR), see informative Annex ZA, which

is an integral part of this standard."

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

This European Standard defines and specifies the relevant characteristics and the appropriate test

methods to determine these characteristics for solid wood products to be used as panelling and

cladding (including siding) for:

— wall and ceiling panelling for internal use,

— wall and ceiling cladding for external uses.

!It provides for the assessment and verification of constancy of performance and the requirements

for marking these products."

This European Standard does not cover panels intended for use as stiffening elements.

This European Standard does not cover suspended ceiling in wood panelling and cladding.

This European Standard does not cover the processes for treatment, surface coating or modification.

This European standard does not cover products which are produced from laminated layer section.

This European Standard covers treated, untreated and surface coated products, including those made of

thermally or chemically modified wood, as well as finger jointed and edge glued products.

NOTE Prescriptions for surface coating and treatment can be found in documents valid in the place of use.

This European Standard covers products in compliance with EN 14519, EN 15146 and EN 14951, and

other solid timber products manufactured for use as panelling and cladding.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 335:2013, Durability of wood and wood-based products - Use classes: definitions, application to solid

wood and wood-based products

!EN 350, Durability of wood and wood-based products - Testing and classification of the durability to

biological agents of wood and wood-based materials"

EN 351-1, Durability of wood and wood-based products - Preservative-treated solid wood - Part 1:

Classification of preservative penetration and retention

EN 599-2, Durability of wood and wood-based products - Performance of preventive wood preservatives as

determined by biological tests - Part 2: Classification and labelling

EN 717-1, Wood-based panels - Determination of formaldehyde release - Part 1: Formaldehyde emission

by the chamber method

EN 717-2, Wood based panels - Determination of formaldehyde release - Part 2: Formaldehyde release by

the gas analysis method

EN 844-9:1997, Round and sawn timber - Terminology - Part 9: Terms relating to features of sawn timber

EN 1309-1:1997, Round and sawn timber - Method of measurement of dimensions - Part 1: Sawn timber

EN 12664, Thermal performance of building materials and products - Determination of thermal resistance

by means of guarded hot plate and heat flow meter methods - Dry and moist products of medium and low

thermal resistance

EN 13501-1, Fire classification of construction products and building elements - Part 1: Classification

using data from reaction to fire tests

EN 13556, Round and sawn timber - Nomenclature of timbers used in Europe

EN 13756:2002, Wood flooring - Terminology

EN 13986, Wood-based panels for use in construction - Characteristics, evaluation of conformity and

marking

EN ISO 354, Acoustics - Measurement of sound absorption in a reverberation room (ISO 354)

EN ISO 10456:2007, Building materials and products - Hygrothermal properties -Tabulated design values

and procedures for determining declared and design thermal values (ISO 10456:2007)

EN ISO 11654, Acoustics - Sound absorbers for use in buildings - Rating of sound absorption (ISO 11654)

EN ISO 12572, Hygrothermal performance of building materials and products - Determination of water

vapour transmission properties (ISO 12572)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 13756:2002, EN 844-9:1997

and EN 1309-1:1997 and the following apply.

3.1

siding

North American term, synonymous with exterior cladding; material attached to exterior of the building

wall where length predominates over the other two dimensions, having reduced thickness

3.2

assembled panelling/cladding

products put together, according to their method of assembly as given by the manufacturer (e.g. joined

tongue to groove), to form a panelling or cladding assembly

!Note 1 to entry: For the purpose of this document panelling relates to interior applications; cladding to

exterior applications"

!

4 Durability against biological attack

4.1 Biological durability

!If sapwood is not specifically excluded this shall be identified."

If the species is listed in !EN 350", the biological durability shall be as given therein; otherwise it

shall be assessed in accordance with !EN 350".

4.2 !Wood" treated against biological attack

4.2.1 General

!Wood" treated against biological attack shall meet regulatory requirements valid in the place of

use of the products.

Preservative treated products shall be defined by:

— use class in accordance with EN 335,

— wood preservative in accordance with EN 599-2,

— penetration class in accordance with EN 351-1,

— retention of preservative in accordance with EN 351-1.

4.2.2 !Wood"

Any machining, boring, planing, etc. shall be completed before preservative treatment. In case of wane,

the bark shall be removed.

4.2.3 Preservatives

Wood preservatives used shall conform to the performance requirements given in EN 599-2

appropriate for the use class.

4.2.4 Penetration

The minimum penetration shall be declared in terms of penetration classes listed in EN 351-1.

4.2.5 Retention

The mean retention in the analytical zone (see EN 351-1) shall be equal to or greater than the retention

requirement for the preservative used in the declared use class.

"

5 Testing, assessment and sampling methods

5.1 Reaction to fire

The reaction to fire performance of a solid wood panelling and cladding product, whether treated or

not, shall be classified in accordance with EN 13501-1, after being tested in accordance with the test

standards given therein and the relevant reaction to fire class declared.

When tested, the product shall be mounted and fixed in accordance with the same mounting and fixing

conditions used for obtaining the classification of products without the need of testing (i.e. those in

relevant footnotes a to j of Table 1). !Given that climatic conditions provided for testing in EN 13501-

1 represent average interior climatic conditions, as an alternative for exterior use to represent average

exterior conditions, the test specimen may be conditioned at 20 °C and 65 % relative humidity."

1)

In case the product meets the requirements given in Table 1 it may be classified without the need for

further testing (CWFT) in one of the appropriate classes shown therein. In this case, the relevant

reaction to fire class shall be declared (together with the corresponding mean density of the product,

the overall thickness of the product as well as the end-use conditions).

Table 1 — Classes of reaction to fire performance

Minimum

thickness

Minimum

e total/ d c

Material f

Product detail End-use condition Class

mean density

g

(kg/m )

minimum

(mm)

Panelling and Wood pieces with or Without air gap or with

9/6 D - s2,d 2

a without tongue and closed air gap behind

cladding

groove and with or 390

without profiled

12/8 D - s2,d 0

surface

Panelling and Wood pieces with or With open air gap ≤ 20

9/6

b without tongue and mm behind

cladding

groove and with or

390 D - s2,d 0

without profiled

Without air gap or with

18/12

surface

open air gap behind

Wood ribbon Wood pieces Surrounded by open air

h mounted on a j

390 18 D - s2,d 0

elements on all sides

i

support frame

a

Mounted mechanically on a wood batten support frame, with the gap closed or filled with a substrate of at least class A2 - s1,

d0 with minimum density of 10 kg/m or filled with a substrate of cellulose insulation material of at least class E and with or

without a vapour barrier behind. The wood product shall be designed to be mounted without open joints.

b

Mounted mechanically on a wood batten support frame, with or without an open air gap behind. The wood product shall be

designed to be mounted without open joints.

c

Class as provided for in Table 1 of the annex to Commission Decision 2000/147/EC.

d

An open air gap may include possibility for ventilation behind the product, while a closed air gap will exclude such ventilation.

The substrate behind the air gap shall be of at least class A2 - s1, d0 with a minimum density of 10 kg/m . Behind a closed air gap of

maximum 20 mm and with vertical wood pieces, the substrate may be of at least class D - s2, d0.

e

Joints include all types of joints, e.g. butt joints and tongue and groove joints.

f

Conditioned according to EN 13238.

g

As illustrated in Figure 1 below. Profiled area of the exposed side of the panel not more than 20 % of the plane area, or 25 % if

measured at both exposed and unexposed side of the panel. For butt joints, the larger thickness applies at the joint interface.

h

Rectangular wood pieces, with or without rounded corners, mounted horizontally or vertically on a support frame and

surrounded by air on all sides, mainly used close to other building elements, both in interior and exterior applications.

i

Maximum exposed area (all sides of rectangular wood pieces and wood support frame) not more than 110 % of the total plane

area, see Figure 2.

j

Other building elements closer than 100 mm from the wood ribbon element (excluding its support frame) shall be of at least

class A2 - s1, d0, at distances 100 mm - 300 mm of at least class B - s1, d0 and at distances more than 300 mm of at least class D - s2,

d0.

1)

This table and Figures 1 and 2 correspond to Table 2 and Figures a and b respectively of the Commission Decision

2006/213/EC (OJEU L79/27 of 16.3.2006).

Table 1 (continued)

Figure 1 — Profiles for solid wood panelling and cladding

Maximum exposed area of wood ribbon element:

2n (t+w) + a ≤ 1,10

where

n is number of wood pieces per metre

t is thickness of each wood piece, in metre

w is width of each wood piece, in metre

2 2

a is exposed area of wood support frame (if any), in m , per m of wood ribbon

element

Figure 2 — Maximum exposed area

5.2 Dangerous substances

2)

5.2.1 Formaldehyde release

The formaldehyde release of solid wood panelling and cladding products shall be determined according

to Annex C. The declared values !shall be" expressed in term of classes.

5.2.2 Content of pentachlorophenol

Solid wood panelling and cladding as such, without chemical treatment, without adhesive, without

coating or finishing, does not contain PCP. If the product contains raw materials that include PCP (may

concern only soft wood treated against blue stain), then the product shall be tested in accordance with

-6n -6n

is exceeded, the indication “PCP > 5 × 10 shall be added

CEN/TR 14823. In case the value of 5 × 10

-6n -6n

to the marking. In case the value is less than 5 × 10 , the indication PCP ≤ 5 × 10 shall be added to the

marking.

2)

Products CE marked according to this European Standard emitting formaldehyde above class E1 might be prohibited in

some Member States.

5.3 Release of other dangerous substances

National regulations on dangerous substances may require, verification and declaration on release, and

sometimes content, of other dangerous substances, in addition to those dealt with in other clauses,

when construction products covered by this standard are placed on those markets.

In the absence of European harmonised test methods, verification and declaration on release/content

should be done taking into account national provisions in the place of use.

NOTE An informative database covering European and national provisions on dangerous substances is

available at the Construction web site on EUROPA accessed through:

http://ec.europa.eu/enterprise/construction/cpd-ds/.

5.4 Water vapour permeability

If water vapour permeability is required, either the water vapour resistance factor of the product tested

as assembled panelling shall either be taken from Table 2 or, if the manufacturer wishes to declare a

better value, obtained by testing the product as assembled panelling according to EN ISO 12572.

Table 2 — Characteristic values of water vapour permeability of wood as given in EN

ISO 10456:2007 , Table 3

a

Wood type Density Water vapour resistance factor µ

kg/m

wet dry

timber 450 20 50

500 20 50

700 50 200

a

For other densities, interpolation is possible.

5.5 Sound absorption

If the sound absorption coefficient of a product is required, it shall either be taken from Table 3 or, if the

manufacturer wishes to declare a better value, obtained by testing the product as assembled panelling

to EN ISO 354 and the result expressed according to EN ISO 11654.

NOTE The sound absorption depends on finishing, geometrical characteristics, etc.

Table 3 — Sound absorption coefficient

Wood type Sound absorption coefficient

Frequency range Frequency range

250 Hz to 500 Hz 1 000 Hz to 2 000 Hz

Solid wood panelling and cladding 0,10 0,30

) EN ISO 10456 is currently impacted by EN ISO 10456:2007/AC:2009.

5.6 Thermal conductivity

The thermal conductivity shall be determined only for uses subject to thermal insulation requirements

for solid wood panelling !deleted text" for use on internal walls and ceilings. It shall either be

determined according to EN 12664 or given by using tabulated values related to density as shown in

Table 4, taken from EN ISO 10456.

The thermal resistance R (m K/W) of solid wood panelling and cladding of uniform thickness is given

by the formula:

t

R =

λ

where

t is the uniform minimum thickness of the wood panelling and cladding, in metres;

λ .

is the thermal conductivity, in W/m K.

Table 4 — Design thermal conductivity values (λ) (in conformity with EN ISO 10456)

a

Wood type Mean density ρ Thermal conductivity λ

at a moisture content of .

in W/(m K) (design value)

12 % in kg/m

Solid wood 300 0,09

400 0,11

500 0,13

600 0,15

700 0,18

1 000 0,24

a

For densities not given in this table, λ may be found by interpolation.

5.7 Resistance to fixing

Resistance to fixing of solid wood is dependent on species and with higher density hardwoods may

necessitate pre-drilling, especially if the wood has been dried. For wood species with an average density

(at 20 % moisture content) the manufacturer shall indicate whether pre-

greater than 600 kg/m

drilling is either advisable or necessary.

When mechanically fixed (by means of nails, anchors, etc.) to walls/ceiling, the panelling/cladding shall

be designed to take into account its own weight and other possible loads acting on it, e.g. wind load.

!

6 Assessment and verification of constancy of performance - AVCP

6.1 General

The compliance of solid wood panelling product and cladding product with the requirements of this

standard and with the performance declared by the manufacturer in the DoP shall be demonstrated by:

— determination of the product-type on the basis of type testing;

— factory production control by the manufacturer, including product assessment.

6.2 Type testing

6.2.1 General

Performance related to characteristics included in this standard shall be determined when the

manufacturer intends to declare the respective performance unless the standard gives provisions for

declaring them without performing tests. (e.g. use of previously existing data, CWFT and conventionally

accepted performance).

Assessment previously performed in accordance with the provisions of this standard, may be taken into

account provided that they were made to the same or a more rigorous test method, under the same

AVCP system on the same product-type, such that the results are applicable to the product in question.

NOTE 1 Same AVCP system means testing by an independent third party laboratory where relevant, under the

responsibility of a notified product certification body where relevant.

For the purposes of assessment, the manufacturer's products may be grouped into families, where it is

considered that the results for one or more characteristics from any one product within the family are

representative for that same characteristics for all products within that same family.

NOTE 2 Products may be grouped in different families for different characteristics.

Reference to the assessment method standards should be made to allow the selection of a suitable

representative sample.

In addition, the determination of the product-type shall be performed for all essential characteristics

included in the standard for which the manufacturer declares the performance:

— at the beginning of the production of a new or modified solid wood panelling product and cladding

product (unless it is a member of a same product range), or

— at the beginning of a new or modified method of production (where this may affect the stated

properties); or

— they shall be repeated for the appropriate essential characteristic(s), whenever a change occurs in

the solid wood panelling product and cladding product design, in the raw material or in the

supplier of the components, or in the method of production (subject to the definition of a family),

which would affect significantly one or more of the performance.

Where components are used whose performance have already been determined, by the component

manufacturer, on the basis of assessment methods of other product standards, these performance need

not be re-assessed. The specifications of these components shall be documented.

Products bearing regulatory marking in accordance with appropriate harmonized European

specifications may be presumed to have the performance declared in the DoP, although this does not

replace the responsibility on solid wood panelling product and cladding product manufacturer to

ensure that the solid wood panelling product and cladding product as a whole is correctly

manufactured and its component products have the declared performance values.

6.2.2 Test samples, testing and compliance criteria

The number of samples of solid wood panelling product and cladding product to be tested/assessed

shall be in accordance with Table 5.

Table 5 — Number of samples to be tested and compliance criteria

No. of

samples Compliance criteria

Assessment

Characteristic Requirement

method

[to be

assessed]

Reaction to fire 5.1 Table 1 or CWFT, Table 1

EN 13501-1 see Table 1

Classes according to

EN 13501-1 EN 13501-1

Release of dangerous substances

Release of 5.2.1 Annex C see Annex C Only for internal use

formaldehyde According to Annex C

E1 or E2

Content of 5.2.2 CEN/TR 14823 See Only for internal use

CEN/TR 14823

pentachlorophenol according to

CEN/TR 14823

-6n

> 5 × 10 or

-6n

≤ 5 × 10

Release of other 5.3 - As relevant Only for internal use

according to

dangerous As relevant acc. to 5.3

5.3

substances

Water vapour 5.4 Table 2 or - Not when there is an

EN ISO 12572 air gap between

permeability

cladding/panelling

and wall.

Tested in accordance

with 5.4 and value

not under declared

value.

Sound absorption 5.5 Table 3 or - Only for internal use

EN ISO 354

Value not under

declared value

Thermal resistance 5.6 5.6 - Only for internal use

expressed as See 5.6

thermal Value not under

declared value

conductivity

Resistance to 5.7 5.7 - See 5.7

fixings

No. of

samples Compliance criteria

Assessment

Characteristic Requirement

method

[to be

assessed]

Durability

Biological 4.1 For species listed - Natural durability in

in EN 350 accordance with

durability

EN 350

For species and

origins not listed Value same as the

in EN 350, declared value

assessed

according to

EN 350

Wood treated 4.2 See 4.2.1 - See 4.2.1

against biological

attack

6.2.3 Test reports

The results of the determination of the product type shall be documented in test reports. All test reports

shall be retained by the manufacturer for at least 10 years after the last date of production of the solid

wood panelling product and cladding product to which they relate.

6.2.4 Shared other party results

A manufacturer may use the results of the product type determination obtained by someone else (e.g.

by another manufacturer, as a common service to manufacturers, or by a product developer), to justify

his own declaration of performance regarding a product that is manufactured according to the same

design and with raw materials, constituents and manufacturing methods of the same kind, provided

that:

— the results are known to be valid for products with the same essential characteristics relevant for

the product performance;

— in addition to any information essential for confirming that the product has such same

performances related to specific essential characteristics, the other party who has carried out the

4)

determination of the product type concerned or has had it carried out, has expressly accepted to

transmit to the manufacturer the results and the test report to be used for the latter’s product type

determination, as well as information regarding production facilities and the production control

process that can be taken into account for FPC;

— the manufacturer using other party results accepts to remain responsible for the product having

the declared performances and he also:

— ensures that the product has the same characteristics relevant for performance asthe one that

has been subjected to the determination of the product type, and that there are no significant

4)

The formulation of such an agreement can be done by licence, contract, or any other type of written consent.

.

differences with regard to production facilities and the production control process compared

to that used for the product that was subjected to the determination of the product type;

— keeps available a copy of the determination of the product type report that also contains the

information needed for verifying that the product is manufactured according to the same

design and with raw materials, constituents and manufacturing methods of the same kind.

6.3 Factory production control (FPC)

6.3.1 General

The manufacturer shall establish, document and maintain an FPC system to ensure that the products

placed on the market comply with the declared performance of the essential characteristics.

The FPC system shall consist of procedures, regular inspections and tests and/or assessments and the

use of the results to control raw and other incoming materials or components, equipment, the

production process and the product.

All the elements, requirements and provisions adopted by the manufacturer shall be documented.

In case the manufacturer has used shared or cascading product type results, the FPC shall also include

the appropriate documentation as foreseen in 6.2.4.

6.3.2 Requirements

6.3.2.1 General

The effective implementation of the FPC system shall be organised in line with the content of this

product standard. Tasks and responsibilities in the production control organization shall be

documented and this documentation shall be kept up-to-date.

The responsibility, authority and the relationship between personnel that manages, performs or verifies

work affecting constancy of performance of the product, shall be defined. This applies in particular to

personnel that need to initiate actions preventing product non-constancies of performance of the

product from occurring, actions in case of non-constancies of performance of the product and to

identify and register product constancy of performance of the product problems.

The competence (e.g. on the basis of education, training, skills, or experience) of personnel performing

work affecting the constancy of performance of the product shall be recorded.

In each factory the manufacturer may delegate the action to a person having the necessary authority to:

— identify procedures to demonstrate constancy of performance of the product at appropriate stages;

— identify and record any instance of non-constancy of performance;

— identify procedures to correct instances of non-constancy of performance.

The manufacturer shall draw up and keep up-to-date documents defining the factory production

control. The manufacturer's documentation and procedures should be appropriate to the product and

manufacturing process. The FPC system should achieve an appropriate level of confidence in the

constancy of performance of the product. This involves:

a) the preparation of documented procedures and instructions relating to factory production control

operations, in accordance with the requirements of the technical specification to which reference is

made;

b) the effective implementation of these procedures and instructions;

c) the recording of these operations and their results;

d) the use of these results to correct any deviations, repair the effects of such deviations, treat any

resulting instances of non-conformity and, if necessary, revise the FPC to rectify the cause of non-

constancy of performance.

Where subcontracting takes place, the manufacturer shall retain the overall control of the product and

ensure that he receives all the information that is necessary.

If the manufacturer has part of the product designed, manufactured, assembled, packed, processed

and/or labelled by subcontracting, the FPC of the subcontractor may be taken into account, where

appropriate for the product in question.

The manufacturer who subcontracts all of his activities may in no circumstances pass the above

responsibilities on to a subcontractor.

NOTE Manufacturers having an FPC system, which complies with EN ISO 9001 standard and which addresses

the provisions of the present European standard are considered as satisfying the FPC requirements of the

Regulation (EU) No 305/2011.

6.3.2.2 Equipment

6.3.2.2.1 Testing

All weighing, measuring and testing equipment shall be checked and regularly inspected according to

documented procedures, frequencies and criteria.

6.3.2.2.2 Manufacturing

All equipment used in the manufacturing process shall be regularly inspected and maintained to ensure

use, wear or failure does not cause inconsistency in the manufacturing process. Inspections and

maintenance shall be carried out and recorded in accordance with the manufacturer’s written

procedures and the records retained for the period defined in the manufacturer's FPC procedures.

6.3.2.3 Raw materials and components

The specifications of all incoming raw materials and components shall be documented, as shall the

inspection scheme for ensuring their compliance.

6.3.2.4 Controls during manufacturing process

The manufacturer shall plan and carry out production under controlled conditions.

6.3.2.5 Product testing and evaluation

The manufacturer shall establish procedures to ensure that the stated values of the characteristics he

declares are maintained. The characteristics, and the means of control, are:

— Reaction to fire shall be subject to the tests indicated in 5.1;

The composition of the product shall be regularly controlled at a frequency to ensure that, for the

CWFT product, the requirements of Table 1 are satisfied and, for the tested product, to ensure that

the product remains in the same class as that obtained in the type testing. If a fire retardant treated

product (e.g. some surface coated products) is used, the indications given by the manufacturer to

maintain the characteristics shall be observed.

— Formaldehyde content shall be subject to the tests indicated in 5.2.1;

Where the manufacturer uses no formaldehyde containing materials, he shall continue to check,

with a frequency defined in his FPC manual, that no such material is used. For formaldehyde

containing materials, the manufacturer shall use the provisions of Table C.1 or Table C.2 with a

frequency to ensure that the class is obtained. A manufacturer declaring Class E2 need perform no

FPC testing, unless he wishes to change this declaration.

— Where Pentachlorophenol content shall be subject to the tests indicated in 5.2.2;

Where the manufacturer uses no pentachlorophenol containing materials, he shall continue to

check, with a frequency defined in his FPC manual, that no such material is used. For

pentachlorophenol containing materials, the manufacturer shall use the provisions of 5.2.2 with a

-6n

frequency to ensure that the class is obtained. A manufacturer declaring "PCP > 5 × 10 " need

perform no FPC testing, unless he wishes to change this declaration.

— Release of other dangerous substances shall be subject to the tests indicated in 5.3; Where no other

dangerous substances containing materials are used for the products, this shall be regularly

checked with a frequency defined in the FPC manual.

— Water vapour permeability shall be subject to the tests indicated in 5.4;

Where the manufacturer wishes to provide values for water vapour permeability, sound absorption

or thermal conductivity, the requirements in Clause 5 shall be followed. The values in Table 2, Table

3 and Table 4 refer to wood in the natural state and after thermal or chemical modification or

treatment but without surface coating. Otherwise, the manufacturer shall declare NPD.

— Sound absorption shall be subject to the tests indicated in 5.5; If a change in the product is made

(change of dimensions), such that it would significantly affect the sound absorption performance of

the product, the type testing shall be repeated

— Thermal resistance expressed as thermal conductivity: shall be subject to the tests indicated 5.6;

Where a thermal conductivity value is declared, it shall be ensured that the continuous mean

density of the material used for the product does not change by more than ±10 % from that of the

product used in the type testing (whether tested or using reference data).

— Resistance to fixings shall be subject to considerations indicated in 5.7; Where a resistance to fixing

is declared, it shall be ensured that the continuous mean density of the material used for the

product does not change by more than ±10 % from that of the product used in the type testing

(whether tested or using reference data).

— Biological durability: shall be subject to the tests indicated in Clause 4;

For biological durability, the manufacturer shall ensure that the timber species used in the finished

panelling and cladding product remain the same or do not change to an extent that would change

the declared durability class. For conferred durability classes, the producer shall apply the principle

defined in 4.2.1 and 4.2.2, knowing that less durable species will provide only limited service life in

fully exposed exterior situations unless appropriate preservative treatment or design are

employed. No FPC testing is necessary as long as the wood used does not change and the

preservative characteristics and the application method are maintained. For preservative use, the

panelling and cladding manufacturer shall follow indications of internal control expressed by the

preservative manufacturer. If the product, the characteristics of the product or the method of

application of the preservative change, the manufacturer shall repeat the type test using three

samples

6.3.2.6 Non-complying products

The manufacturer shall have written procedures which specify how non-complying products shall be

dealt with. Any such events shall be recorded as they occur and these records shall be kept for the

period defined in the manufacturer’s written procedures.

Where the product fails to satisfy the acceptance criteria, the provisions for non-complying products

shall apply, the necessary corrective action(s) shall immediately be taken and the products or batches

not complying shall be isolated and properly identified.

Once the fault has been corrected, the test where relevant or verification in question shall be repeated.

The results of controls and tests where relevant shall be properly recorded. The product description,

date of manufacture, test method adopted, test results and acceptance criteria shall be entered in the

records under the signature of the person responsible for the control/test.

With regard to any control result not meeting the requirements of this European standard, the

corrective measures taken to rectify the situation (e.g. a further test carried out, modification of

manufacturing process, throwing away or putting right of product) shall be indicated in the records.

6.3.2.7 Corrective action

The manufacturer shall have documented procedures that instigate action to eliminate the cause of

non-conformities in order to prevent recurrence.

6.3.2.8 Handling, storage and packaging

The manufacturer shall have procedures providing methods of product handling and shall provide

suitable storage areas preventing damage or deterioration.

6.3.3 Product specific requirements

The FPC system shall include a product specific FPC, which identifies procedures to demonstrate

compliance of the product at appropriate stages, i.e.:

a) the controls and tests to be carried out prior to and/or during manufacture according to a

frequency laid down in the FPC test plan;

and/or

b) the verifications and tests to be carried out on finished products according to a frequency laid down

in the FPC test plan.

If the manufacturer uses only finished products, the operations under b) shall lead to an equivalent

level of compliance of the product as if FPC had been carried out during the production.

If the manufacturer carries out parts of the production himself, the operations under b) may be reduced

and partly replaced by operations under a). Generally, the more parts of the production that are carried

out by the manufacturer, the more operations under b) may be replaced by operations under a).

In any case the operation shall lead to an equivalent level of compliance of the product as if FPC had

been carried out during the production.

The operations under a) refer to the intermediate states of the product as on manufacturing machines

and their adjustment, and measuring equipment etc. These controls and tests and their frequency shall

be chosen based on product type and composition, the manufacturing process and its complexity, the

sensitivity of pro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...