SIST EN 10202:2022

(Main)Cold reduced tinmill products - Electrolytic tinplate and electrolytic chromium/chromium oxide coated steel

Cold reduced tinmill products - Electrolytic tinplate and electrolytic chromium/chromium oxide coated steel

This document specifies requirements for tinmill products in the form of sheets or coils. Tinmill products consist of single and double reduced low carbon mild steel electrolytically coated with either tin (tinplate) or chromium/chromium oxide (ECCS) or (ECCS-RC) (see 3.3).

Single reduced tinmill products are specified in nominal thicknesses that are multiples of 0,005 mm from 0,16 mm up to and including 0,49 mm. Double reduced tinmill products are specified in nominal thicknesses that are multiples of 0,005 mm from 0,12 mm up to and including 0,29 mm.

NOTE 1 Other thicknesses can be ordered upon agreement.

This document applies to coils and sheets cut from coils in nominal minimum widths of 600 mm.

NOTE 2 Standard width coils for specific uses, e.g. tabstock, can be slit into narrow strip for supply in coil form.

Kaltgewalzte Verpackungsblecherzeugnisse - Elektrolytisch verzinnter und spezialverchromter Stahl

Dieses Dokument legt die Anforderungen an Verpackungsblecherzeugnisse in Form von Tafeln oder Coils fest. Verpackungsblecherzeugnisse sind einfach reduzierte oder doppelt reduzierte unlegierte Stähle mit niedrigem Kohlenstoffgehalt, die entweder elektrolytisch verzinnt (Weißblech) oder elektrolytisch spezialverchromt (ECCS) oder (ECCS-RC) sind (siehe 3.3).

Einfach reduzierte Verpackungsblecherzeugnisse werden in Nenndicken von 0,16 mm bis einschließlich 0,49 mm in Stufen von 0,005 mm geliefert. Doppelt reduzierte Verpackungsblecherzeugnisse werden in Nenndicken von 0,12 mm bis einschließlich 0,29 mm in Stufen von 0,005 mm geliefert.

ANMERKUNG 1 Auf Anfrage können auch andere Dicken bestellt werden.

Dieses Dokument gilt für Coils und für aus Bandmaterial geschnittene Tafeln in Nennbreiten von mindestens 600 mm.

ANMERKUNG 2 Für besondere Anwendungen, z. B. „Laschenband“, können Coils in Standardbreite zur Lieferung in Coilform auch in schmaleres Band geteilt werden.

Aciers pour emballage laminés à froid - Fer blanc électrolytique et fer chromé électrolytique

Le présent document spécifie les exigences relatives aux aciers pour emballage sous la forme de feuilles ou de bobines. Les aciers pour emballage sont constitués d’acier doux à faible teneur en carbone à simple et double laminage recouvert par électrolyse d’étain (fer blanc) ou de chrome ou d’oxyde de chrome (ECCS ou ECCS-RC) (voir 3.3).

Les aciers pour emballage à simple laminage sont spécifiés dans des épaisseurs nominales qui sont des multiples de 0,005 mm à partir de 0,16 mm jusqu’à 0,49 mm inclus. Les aciers pour emballage à double laminage sont spécifiés dans des épaisseurs nominales qui sont des multiples de 0,005 mm à partir de 0,12 mm jusqu’à 0,29 mm inclus.

NOTE 1 Après accord, il est possible de commander d’autres épaisseurs.

Le présent document s’applique aux bobines et aux feuilles découpées dans des bobines dont les largeurs nominales sont égales à 600 mm au minimum.

NOTE 2 Les bobines de largeurs normalisées pour usages spéciaux, tels que feuillard, peuvent être découpées en bandes refendues à longueur pour conditionnement en bobines.

Hladno valjani jekleni izdelki za embalažo - Elektrolizno pokositreni in pokromani izdelki

Ta dokument določa zahteve za jeklene izdelke za embalažo v obliki plošč ali zvitkov. Jekleni izdelki za embalažo vključujejo enkrat in dvakrat valjano maloogljično mehko jeklo, elektrolitsko prevlečeno s kositrom (bela pločevina) ali kromom/kromovim oksidom (ECCS) oz. (ECCS-RC) (glej točko 3.3).

Enkrat valjani jekleni izdelki za embalažo so podani z nazivnimi debelinami, ki so večkratniki vrednosti 0,005 mm v razponu od 0,16 mm do vključno 0,49 mm. Dvakrat valjani jekleni izdelki za embalažo so podani z nazivnimi debelinami, ki so večkratniki vrednosti 0,005 mm v razponu od 0,12 mm do vključno 0,29 mm.

OPOMBA 1: Po dogovoru je mogoče naročiti druge debeline.

Ta dokument se uporablja za zvitke in plošče, izrezane iz zvitkov, z najmanjšo nazivno širino 600 mm.

OPOMBA 2: Zvitke s standardno širino za specifično uporabo (npr. zavihki na pločevinkah) je mogoče narezati v ozke trakove za dobavo v obliki zvitkov.

General Information

- Status

- Published

- Public Enquiry End Date

- 28-Apr-2021

- Publication Date

- 02-Mar-2022

- Technical Committee

- IFEK - Ferrous metals

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 02-Mar-2022

- Due Date

- 07-May-2022

- Completion Date

- 03-Mar-2022

Relations

- Effective Date

- 02-Mar-2022

- Effective Date

- 02-Mar-2022

Overview

EN 10202:2022 is the CEN standard for cold reduced tinmill products - specifically electrolytic tinplate and electrolytic chromium / chromium‑oxide coated steel (ECCS / ECCS‑RC). It defines the scope, product classification and designation, manufacturing features, required tests and quality criteria for sheets and coils made from single and double reduced low‑carbon mild steel electrolytically coated with tin or chromium/chromium oxide.

Key scope facts:

- Covers sheets and coils (cut from coils) in nominal minimum widths of 600 mm (narrower strips may be supplied by agreement).

- Single reduced thicknesses: multiples of 0.005 mm from 0.16 mm to 0.49 mm.

- Double reduced thicknesses: multiples of 0.005 mm from 0.12 mm to 0.29 mm.

- Applies to tinplate and ECCS / ECCS‑RC for packaging and related applications.

Key topics and technical requirements

EN 10202:2022 specifies technical requirements and test methods across the product lifecycle:

- Classification & designation of tinmill products (single/double reduced, coating type).

- Information to be supplied by the purchaser (ordering details and options).

- Manufacturing features: steelmaking, annealing, finishing, passivation (titanium/zirconium and chromium options), oiling and allowable imperfections.

- Coating requirements and test methods: properties and measurement for electrolytic tinplate and electrolytic chromium coatings.

- Mechanical properties: tensile testing, aging, strength characteristics specific to tinmill products.

- Dimensional tolerances & shape: thickness, feather edge, width/length, camber, edge wave, bow, centre fullness.

- Welds in coils, marking, sampling, retests, and packaging/dispatch rules.

- Normative annexes with laboratory methods (e.g., diphenylcarbazide for chromium, ICP for titanium, galvanostatic potentiometry for tin oxides, electromechanical coating mass determination, and de‑tinning procedures).

Applications

EN 10202:2022 is focused on packaging steels and is widely used where coated flat steel is specified:

- Food and beverage cans (tinplate)

- Aerosol and general packaging components

- Can ends, closures and tabstock (converted narrow strip by agreement)

- Decorative and corrosion‑resistant coated steel applications in the packaging industry

Who should use this standard

- Steel producers and tinplate manufacturers for product specification and QA

- Packaging converters, canmakers and closure manufacturers for material procurement

- Quality and test laboratories performing mechanical and coating tests

- Purchasing and specification engineers preparing purchase orders or compliance documents

Related standards

EN 10202:2022 supersedes EN 10202:2001 and sits within CEN/ICS group 77.140.50 (flat steel products and semi‑products). For complete procurement and testing programs, users should also consult other relevant EN standards for flat steel tolerances and packaging material safety where applicable.

Keywords: EN 10202:2022, electrolytic tinplate, ECCS, cold reduced tinmill products, tinplate coating, electrolytic chromium coated steel, packaging steel, coating mass, passivation, tolerances.

Frequently Asked Questions

SIST EN 10202:2022 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Cold reduced tinmill products - Electrolytic tinplate and electrolytic chromium/chromium oxide coated steel". This standard covers: This document specifies requirements for tinmill products in the form of sheets or coils. Tinmill products consist of single and double reduced low carbon mild steel electrolytically coated with either tin (tinplate) or chromium/chromium oxide (ECCS) or (ECCS-RC) (see 3.3). Single reduced tinmill products are specified in nominal thicknesses that are multiples of 0,005 mm from 0,16 mm up to and including 0,49 mm. Double reduced tinmill products are specified in nominal thicknesses that are multiples of 0,005 mm from 0,12 mm up to and including 0,29 mm. NOTE 1 Other thicknesses can be ordered upon agreement. This document applies to coils and sheets cut from coils in nominal minimum widths of 600 mm. NOTE 2 Standard width coils for specific uses, e.g. tabstock, can be slit into narrow strip for supply in coil form.

This document specifies requirements for tinmill products in the form of sheets or coils. Tinmill products consist of single and double reduced low carbon mild steel electrolytically coated with either tin (tinplate) or chromium/chromium oxide (ECCS) or (ECCS-RC) (see 3.3). Single reduced tinmill products are specified in nominal thicknesses that are multiples of 0,005 mm from 0,16 mm up to and including 0,49 mm. Double reduced tinmill products are specified in nominal thicknesses that are multiples of 0,005 mm from 0,12 mm up to and including 0,29 mm. NOTE 1 Other thicknesses can be ordered upon agreement. This document applies to coils and sheets cut from coils in nominal minimum widths of 600 mm. NOTE 2 Standard width coils for specific uses, e.g. tabstock, can be slit into narrow strip for supply in coil form.

SIST EN 10202:2022 is classified under the following ICS (International Classification for Standards) categories: 77.140.50 - Flat steel products and semi-products. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 10202:2022 has the following relationships with other standards: It is inter standard links to SIST EN 10202:2002/AC:2004, SIST EN 10202:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 10202:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2022

Nadomešča:

SIST EN 10202:2002

SIST EN 10202:2002/AC:2004

Hladno valjani jekleni izdelki za embalažo - Elektrolizno pokositreni in pokromani

izdelki

Cold reduced tinmill products - Electrolytic tinplate and electrolytic chromium/chromium

oxide coated steel

Kaltgewalzte Verpackungsblecherzeugnisse - Elektrolytisch verzinnter und

spezialverchromter Stahl

Aciers pour emballage laminés à froid - Fer blanc électrolytique et fer chromé

électrolytique

Ta slovenski standard je istoveten z: EN 10202:2022

ICS:

77.140.50 Ploščati jekleni izdelki in Flat steel products and semi-

polizdelki products

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 10202

EUROPEAN STANDARD

NORME EUROPÉENNE

February 2022

EUROPÄISCHE NORM

ICS 77.140.50 Supersedes EN 10202:2001

English Version

Cold reduced tinmill products - Electrolytic tinplate and

electrolytic chromium/chromium oxide coated steel

Aciers pour emballage laminés à froid - Fer blanc Kaltgewalzte Verpackungsblecherzeugnisse -

électrolytique et acier revêtu de chrome/d'oxyde de Elektrolytisch verzinnter und spezialverchromter Stahl

chrome électrolytique

This European Standard was approved by CEN on 26 December 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 10202:2022 E

worldwide for CEN national Members.

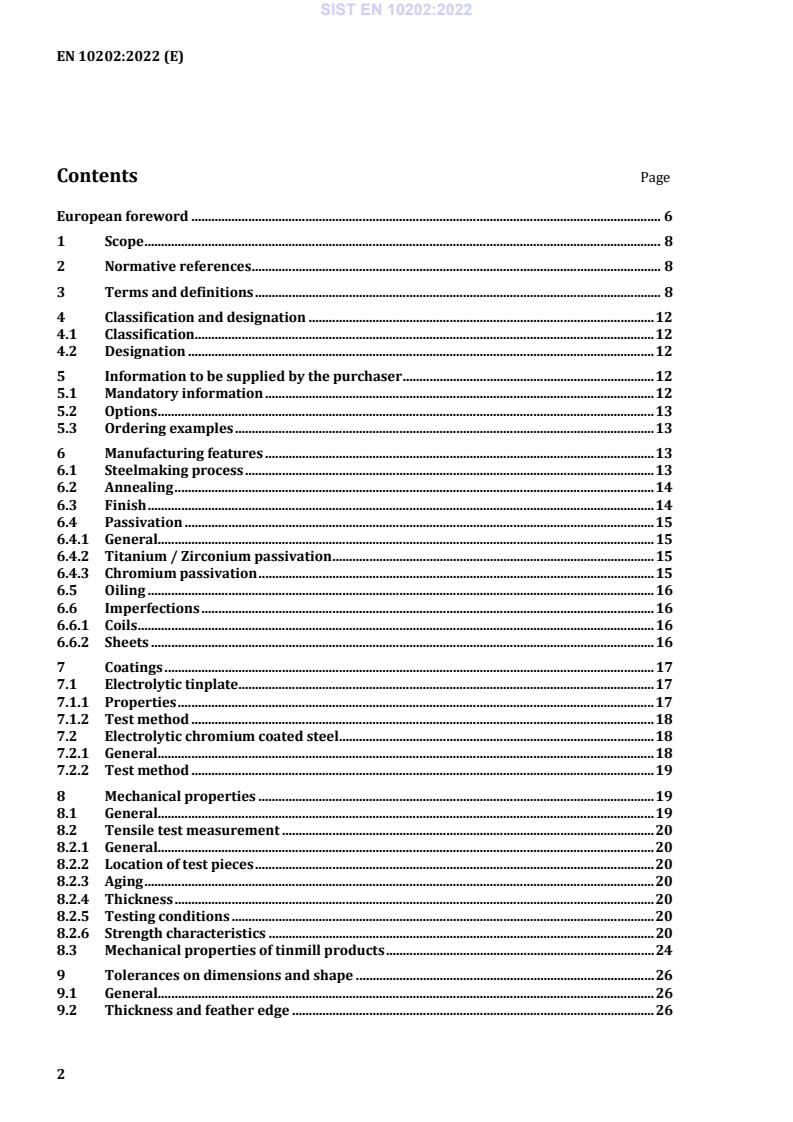

Contents Page

European foreword . 6

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 8

4 Classification and designation . 12

4.1 Classification. 12

4.2 Designation . 12

5 Information to be supplied by the purchaser . 12

5.1 Mandatory information . 12

5.2 Options . 13

5.3 Ordering examples . 13

6 Manufacturing features . 13

6.1 Steelmaking process . 13

6.2 Annealing . 14

6.3 Finish . 14

6.4 Passivation . 15

6.4.1 General. 15

6.4.2 Titanium / Zirconium passivation . 15

6.4.3 Chromium passivation . 15

6.5 Oiling . 16

6.6 Imperfections . 16

6.6.1 Coils . 16

6.6.2 Sheets . 16

7 Coatings . 17

7.1 Electrolytic tinplate . 17

7.1.1 Properties . 17

7.1.2 Test method . 18

7.2 Electrolytic chromium coated steel . 18

7.2.1 General. 18

7.2.2 Test method . 19

8 Mechanical properties . 19

8.1 General. 19

8.2 Tensile test measurement . 20

8.2.1 General. 20

8.2.2 Location of test pieces . 20

8.2.3 Aging . 20

8.2.4 Thickness . 20

8.2.5 Testing conditions . 20

8.2.6 Strength characteristics . 20

8.3 Mechanical properties of tinmill products . 24

9 Tolerances on dimensions and shape . 26

9.1 General. 26

9.2 Thickness and feather edge . 26

9.2.1 Thickness . 26

9.2.2 Test method for thickness . 26

9.2.3 Feather edge . 26

9.2.4 Test method for feather edge . 26

9.3 Linear dimensions . 27

9.3.1 Width and length . 27

9.3.2 Out-of-squareness of sheets. 27

9.3.3 Short pitch camber (lateral weave) of coils . 28

9.3.4 Test method for short pitch camber . 28

9.4 Shape . 29

9.4.1 Edge wave . 29

9.4.2 Test method for edge wave . 29

9.4.3 Bow . 29

9.4.4 Test method for bow. 30

9.4.5 Centre fullness . 30

9.4.6 Test method for centre fullness. 31

9.4.7 Burr . 32

10 Welds within a coil . 32

10.1 General . 32

10.2 Number of welds . 32

10.3 Location of welds . 32

10.4 Dimensions of welds . 32

10.4.1 Thickness . 32

10.4.2 Overlap . 33

11 Marking of differentially coated cold reduced tinplate . 33

12 Selection of samples . 33

12.1 For quality control. 33

12.2 In case of dispute . 34

13 Retests . 34

14 Dispatch and packaging . 35

14.1 Coils . 35

14.1.1 Coil dispatch . 35

14.1.2 Coil winding . 35

14.2 Sheets . 35

Annex A (informative) De-tinning . 36

A.1 Principle . 36

A.2 Clarke’s solution . 36

A.3 Procedure . 36

Annex B (normative) Determination of chromium using the diphenylcarbazide method . 37

B.1 General . 37

B.2 Principle . 37

B.3 Reagent . 37

B.4 Apparatus . 37

B.5 Procedure . 37

B.6 Calibration. 38

Annex C (normative) Determination of titanium content using the Inductively Coupled

Plasma (ICP) method . 39

C.1 General. 39

C.2 Principle . 39

C.3 Reagent . 39

C.4 Apparatus . 40

C.5 Procedure . 40

Annex D (normative) Determination of tin oxides by galvanostatic potentiometry . 41

D.1 General. 41

D.2 Principle . 41

D.3 Reagents . 41

D.4 Apparatus . 41

D.5 Procedure . 41

Annex E (normative) Electromechanical method for determining tin coating mass . 43

E.1 Principle . 43

E.2 Reagents . 43

E.3 Apparatus . 43

E.3.1 Cell and electrodes . 43

E.3.2 Power supply . 43

E.3.3 Voltmeter . 43

E.4 Procedure . 43

E.5 Calibration of the measuring system . 43

E.6 Calculation . 44

Annex F (normative) Methods for determination of metallic chromium and chromium in the

oxide on the surface of electrolytic chromium coated steel (ECCS or ECCS-RC) . 47

F.1 Determination of chromium in the oxide . 47

F.1.1 Principle . 47

F.1.2 Reagents . 47

F.1.3 Apparatus . 47

F.1.4 Preparation of the chromium calibration curve . 48

F.1.5 Procedure . 48

F.1.6 Calculation . 48

F.2 Determination of metallic chromium . 48

F.2.1 Principle . 48

F.2.2 Reagents . 49

F.2.3 Apparatus . 49

F.2.4 Preparation of the chromium calibration curve . 49

F.2.5 Procedure . 50

F.2.5.1 General . 50

F.2.5.2 Removal of chromium oxide layer . 50

F.2.5.3 Removal and determination of metallic chromium . 50

F.2.6 Calculation . 50

Annex G (informative) The Rockwell Hardness test for routine determination of proof

strength for double reduced materials . 54

G.1 General . 54

G.2 Test pieces . 54

G.3 Test method . 54

G.4 Hardness for tinmill products . 56

Annex H (informative) The springback test for routine determination of proof strength for

double reduced material. 57

H.1 General . 57

H.2 Principle . 57

H.3 Test pieces . 57

H.4 Test method . 57

Annex I (normative) Tensile testing conditions in case of dispute . 58

I.1 General . 58

I.2 Tensile test piece dimensions . 58

I.3 Elongation measurement. 58

I.4 Testing velocity . 58

I.4.1 General . 58

I.4.2 Material displaying no discontinuous yielding . 58

I.4.3 Discontinuous yielding material . 59

Annex J (informative) Indicative tensile strength of tinmill products . 60

Annex K (informative) Alternative marking system for electrolytic tinplate — differentially

coated . 61

Bibliography . 63

European foreword

This document (EN 10202:2022) has been prepared by Technical Committee CEN/TC 459 “ECISS -

European Committee for Iron and Steel Standardization” , the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by August 2022, and conflicting national standards shall be

withdrawn at the latest by August 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 10202:2001.

In comparison with the previous edition, the following technical modifications have been made:

— normative references have been updated;

— revision of the definition of electrolytic chromium coated steel with the addition of the symbol ECCS-

RC which allows the use of a trivalent process;

— rewording of Clause 5 with the split into mandatory information (5.1) and options (5.2);

— modification of Clause 6 with the rewording of 6.1 and the addition of 6.2 and 6.3 about annealing

and finish respectively;

— Table 1 has been updated;

— major modifications of 6.4 about passivation;

— addition of a new subclause 6.6 on imperfections that includes 6.6.1 and 6.6.2 for coils and sheets

respectively;

— major modifications of Clause 7 about coatings including changes of Table 2, Table 3 and Table 4;

— major modifications of Clause 8 about mechanical properties with the addition of stress-strain curves

for batch and continuous annealed material, curve showing the plateau height for continuous

annealed material and stress-strain curves for the determination of the yield strength of some

continuous annealed grades;

— removal of the tensile strength values from Table 5 and transfer into informative Annex J;

— modification of 9.4.6 about test method for centre fullness;

— modifications of the ordering of Annexes;

— new Annex I about tensile testing conditions in case of dispute;

— deletion of the Annex giving the previous designations and of the Annex giving examples of steel

types and chemical composition.

Through its sub-committee SC 9 “Coated and uncoated flat products to be used for cold forming” (secretariat:

AFNOR).

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

1 Scope

This document specifies requirements for tinmill products in the form of sheets or coils. Tinmill products

consist of single and double reduced low carbon mild steel electrolytically coated with either tin (tinplate)

or chromium/chromium oxide (ECCS) or (ECCS-RC) (see 3.3).

Single reduced tinmill products are specified in nominal thicknesses that are multiples of 0,005 mm from

0,16 mm up to and including 0,49 mm. Double reduced tinmill products are specified in nominal

thicknesses that are multiples of 0,005 mm from 0,12 mm up to and including 0,29 mm.

NOTE 1 Other thicknesses can be ordered upon agreement.

This document applies to coils and sheets cut from coils in nominal minimum widths of 600 mm.

NOTE 2 Standard width coils for specific uses, e.g. tabstock, can be slit into narrow strip for supply in coil form.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 610, Tin and tin alloys - Ingot tin

EN 10204, Metallic products - Types of inspection documents

EN 10334:2005, Steel for packaging - Flat steel products intended for use in contact with foodstuffs,

products and beverages for human and animal consumption - Non-coated steel (blackplate)

EN ISO 6892-1:2019, Metallic materials - Tensile testing - Part 1: Method of test at room temperature

(ISO 6892-1:2019)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

electrolytic tinplate

cold reduced low carbon mild steel sheet or coil coated on both surfaces with tin that is applied in

continuous electrolytic operation

3.2

differentially coated electrolytic tinplate

electrolytic tinplate, one surface of which carries a heavier tin coating than the other

Note 1 to entry: In some cases, one surface does not have any tin coating.

3.3

electrolytic chromium coated steel

ECCS

ECCS-RC

cold reduced low carbon mild steel sheet or coil electrolytically treated to produce on both surfaces a

duplex film of metallic chromium adjacent to the steel substrate with a top layer of hydrated chromium

oxides or hydroxides

Note 1 to entry: This can either be produced by a hexavalent chromium process (ECCS) or by a trivalent chromium

process (ECCS-RC).

3.4

blackplate

cold-reduced low-carbon mild steel, applied for manufacturing electrolytic metallic coated plate

3.5

single reduced

product in which the blackplate has been reduced to the desired thickness in a cold-reduction mill and

subsequently annealed and temper rolled

3.6

double reduced

product in which the blackplate has been reduced to the desired thickness in a cold-reduction mill and

subsequently annealed and temper rolled mostly with the help of a water-based lubricant to achieve a

higher gauge reduction often in excess of 5%

3.7

temper rolling

secondary rolling process to obtain desired roughness and mechanical properties

3.8

standard grade

material in sheet or coil form that is suitable, under normal conditions of storage, for its ordered use

3.9

batch annealed

box annealed

BA

process in which the cold reduced strip is heated in tight coil form, within a controlled atmosphere, for a

pre-determined time/temperature cycle

3.10

continuously annealed

CA

process in which cold reduced coils are unwound and heated in strip form within a controlled atmosphere

for a pre-determined time/temperature cycle

3.11

finish

surface appearance of tinmill products determined by the surface characteristics of the steel base

together with the condition of the coating, either flow-melted or unflow-melted

3.11.1

flow-melting

process by which the ‘as deposited’ tin is heated above its melting point of 232 °C and is quickly quenched

in cool water resulting in a composite coating iron/tin alloy and free tin which exhibits a bright reflective

appearance

3.11.2

bright finish

finish resulting from the use of temper mill work rolls that have been ground to a high degree of polish

and, in the case of tinplate, together with a flow-melted tin coating

3.11.3

stone finish

fine stone finish

finish characterized by a directional pattern, resulting from the use of final mill work rolls that have been

ground to a lower degree of polish than those used for the bright finish, in the case of tinplate together

with a flow-melted tin coating

3.11.4

silver finish

finish resulting from the use of temper mill work rolls with surface textured by shot blast, electro

discharge texturing (EDT), electron beam texturing (EBDT) or another similar method, together with a

flow-melted tin coating

3.11.5

matt finish

finish resulting from the use of temper mill work rolls with surface textured by shot blast, electro

discharge texturing (EDT), electron beam texturing (EBDT) or another similar method, together with an

unflow-melted tin coating

3.12

coil

rolled flat strip product which is wound into regularly superimposed laps so as to form a coil with almost

flat sides

3.13

bow

residual curvature in sheet or coil such that the distance between the edges is less than the appropriate

sheet or coil dimension

3.13.1

longitudinal bow

line bow

residual curvature in the strip remaining along the direction of rolling

3.13.2

transverse bow

cross bow

mode of curvature in the sheet such that the distances between its edges parallel to the rolling direction

is less than the sheet width

3.14

centre fullness

full centre

centre buckle

intermittent vertical displacement occurring other than at the edge of the sheet or coil when the material

is laid on a flat horizontal surface

3.15

short pitch camber

deviation of the coil from a straight line forming its chord

3.16

edge wave

intermittent vertical displacement occurring at the edge of a sheet or a sample from a coil when laid on a

flat horizontal surface

3.17

feather edge

transverse thickness profile

variation in thickness, characterized by a reduction of thickness close to the edges, at right angles to the

rolling direction

3.18

burr

metal displaced beyond the plane of the surface of the strip by shearing action

3.19

rolling width

width of the strip perpendicular to the rolling direction

3.20

consignment

quantity of material of the same specification made available for dispatch at the same time

3.21

bulk package

packaging unit comprising a stillage platform, the sheets and packaging material

3.22

stillage platform

platform on which sheets are stacked to facilitate packing and ready transportation

3.23

line inspection

final inspection of the finished product performed by instruments and/or by visual examination at

normal production line speeds

3.24

SITA

2 2

area of 100 m of material taken from a total surface area of 200 m

4 Classification and designation

4.1 Classification

The classification of the relevant steel grades is according to EN 10020. Steel grades for this document

are generally classified as non-alloy quality steels, but in some cases low-alloy quality steels may be

encountered.

4.2 Designation

For the steel grades covered by this document, the steel names as given in the relevant tables are allocated

in accordance with EN 10027-1. TS grades are batch annealed grades and TH grades are continuous

annealed grades. The steel numbers as given in the relevant tables are allocated in accordance with

EN 10027-2. See ordering examples below (see 5.3).

5 Information to be supplied by the purchaser

5.1 Mandatory information

The following information shall be given by the purchaser on the enquiry and order to assist the

manufacturer in supplying the correct material:

a) quantity expressed as an area (square metres or SITA's) or mass (tons);

b) description of the material (coil or sheet) and type of metallic coating (typically tin or chromium);

c) dimensions in millimetres:

— for coil: thickness X width;

— for sheets: thickness X rolling width X cutting length;

d) number of this document (EN 10202:2022);

e) steel name or steel number (see Table 5);

f) type of annealing;

g) finish (see Table 1);

h) in the case of tinplate, the coating masses and their combinations, E (for equally coated) or D (for

differentially coated marked) described in Clause 11 (standard marking); in the case of chromium

coated steel specify ECCS or ECCS-RC;

i) in the case of tinplate, the passivation (see 6.4);

j) type of oiling;

k) intended use of the material e.g. stamping, drawing, beading, bending and assembly work such as joint

forming, soldering and welding, surface coating (metallic and organic coating);

l) dispatch and packaging conditions (see Clause 14), e.g. inner diameter of coils, coils core vertical or

horizontal and the coil winding direction if core vertical, maximum and minimum mass and/or

outside diameter of coils;

m) maximum weight of bulk package for sheets, direction of runners if is different from 14.2;

n) if required standard designation for a test report 2.2 or an inspection certificate 3.1 or 3.2 in

accordance with EN 10204.

5.2 Options

In addition to the information in 5.1, the purchaser shall provide further information to the supplier to

ensure that the order requirements are consistent with the end use of the product.

It is generally recommended that supplier and purchaser agree on the best product specifications to fit

the targeted use and other requirements. Eventually, the purchaser is responsible for the product

designation in the order (see 5.3).

The purchaser shall inform the supplier of any modifications to its manufacturing process that will

significantly affect the way in which the tinmill products are used.

It should be noted that double cold reduced tinmill products are relatively less ductile than single cold

reduced products and have very distinct directional properties, so for some uses, e.g. for three-piece can

bodies, the direction of rolling should be stated.

When double cold reduced products are used for three-piece can bodies, it is recommended to have the

can weld perpendicular to the strip rolling direction so as to minimize the hazard of flange cracking.

5.3 Ordering examples

EXAMPLE 1 10 t of tinplate in sheet, in accordance with this document of steel grade TS275, batch annealed,

stone finish, equally coated with a coating mass of 2,8 g/m , passivation 311, with a thickness of 0,22 mm, a rolling

width of 800 mm and cut length of 900 mm is designated:

10 t tinplate sheet EN 10202-TS275-BA-ST-E2,8/2,8-311-0,22 × 800 × 900

EXAMPLE 2 10 t of tinplate in coil in accordance with this document, of steel grade TH620, continuously

2 2

annealed, stone finish, differentially coated with coating masses of 8,4 g/m and 5,6 g/m , and marking on side

8,4 g/m positioned on the outside of coil, passivation Titanium/Zirconium 555 with a thickness of 0,18 mm and a

rolling width of 750 mm is designated:

10 t tinplate coil EN 10202-TH620-CA-ST-D8,4/5,6-555-0,18 × 750

EXAMPLE 3 10 t of chromium coated steel (ECCS or ECCS-RC) in coil in accordance with this document, of

steel grade TH550, continuously annealed, fine stone finish, with a thickness of 0,185 mm and a rolling width of

750 mm is designated:

10 t ECCS coil EN 10202-TH550-CA-FS-ECCS-0,185 × 750

10 t ECCS-RC coil EN 10202-TH550-CA-FS-ECCS-RC −0,185 × 750

NOTE These ordering examples do not cover all the specifications of the products; further mandatory

information is requested; see 5.1.

6 Manufacturing features

6.1 Steelmaking process

The steelmaking process is under the responsibility of the manufacturer with the exception that the steel

is continuously cast. All steels shall be fully killed.

The purchaser should be informed of any change made to the method of manufacture if the manufacturer

suspects that the change may affect the ordered end use of the product.

If the product is ordered for food contact, the product should be manufactured in accordance with food

safety regulations. The steel shall be manufactured according to EN 10334:2005, 6.2.

If the product is not ordered for food contact, a different steelmaking process may be agreed between

manufacturer and purchaser.

The purchaser shall inform the manufacturer about all relevant regulations which may influence the

manufacturing of the product.

Each product shall be traceable to the cast.

6.2 Annealing

Annealing for tinmill products shall be either batch annealing or continuous annealing and shall be

specified by the purchaser at the time of enquiry and order (see 5.1 f).

NOTE The forming properties of tinmill products will differ depending on the type of annealing employed.

6.3 Finish

Tinplate is usually available in the finishes as indicated in Table 1. The type of finish is designated by the

product finish or the code shown in Table 1.

Table 1 — Recognized finishes

Flow-

Nominal surface

Product melted

Code Steel base roughness of the

finish (tinplate

steel base

only)

µm R

a

Bright

BR Smooth Yes ≤ 0,35

(tinplate only)

Fine stone FS Fine stone Yes 0,25 - 0,45

Stone ST Stone Yes 0,35 - 0,60

Silver Shot blast or

SG Yes ≥ 0,90

(tinplate only) alternative

Shot blast or

Matt MM No Various

alternative

NOTE 1 The appearance is governed by:

a) the surface characteristics of the steel base, which principally result from controlled preparation of

the work rolls used during the final stages of temper rolling;

b) the mass of the applied coating; and

c) whether the tin layer is flow-melted or unflow-melted.

NOTE 2 Special surface finishes are available by agreement at the time of ordering for example: tin unmelted or

other surface roughnesses.

NOTE 3 For shot blast, alternative roll preparation is possible, for example: EDT, EBDT or another similar

method.

NOTE 4

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...