SIST EN 1400:2013+A2:2018

(Main)Child use and care articles - Soothers for babies and young children - Safety requirements and test methods

Child use and care articles - Soothers for babies and young children - Safety requirements and test methods

This European Standard specifies safety requirements relating to the materials, construction, performance, packaging and product information for soothers.

This European Standard is applicable to products that resemble or function as a soother. Some soothers may be marketed with other functions. This standard is applicable to these products (some examples are given in Annex C).

This European Standard does not apply to products designed for specialist clinical medical applications, e.g. those relating to Pierre-Robin Syndrome or premature babies (see Annex C).

The standard is not applicable to feeding teats. Safety requirements and test methods for feeding teats are included in all parts of EN 14350 [2], [3].

Artikel für Säuglinge und Kleinkinder - Schnuller für Säuglinge und Kleinkinder - Sicherheitstechnische Anforderungen und Prüfverfahren

Diese Europäische Norm legt Sicherheitsanforderungen hinsichtlich der Werkstoffe, der Gestaltung, der Leistungsmerkmale, Verpackung und der Produktinformationen für Schnuller fest.

Diese Europäische Norm gilt für Produkte, die das Aussehen eines Schnullers haben oder die als Schnuller dienen. Einige Schnuller können mit weiteren Funktionen verkauft werden. Diese Norm gilt auch für solche Produkte (einige Beispiel dafür sind in Anhang C angegeben).

Diese Europäische Norm gilt nicht für Produkte für besondere klinische medizinische Anwendungen, z. B. beim Pierre-Robin-Syndrom oder bei Frühgeborenen (siehe Anhang C).

Die Norm gilt nicht für Ernährungssauger. Sicherheitsanforderungen und Prüfverfahren für Ernährungs-sauger sind in EN 14350 [2], [3] festgelegt.

Articles de puériculture - Sucettes pour nourrissons et jeunes enfants - Exigences de sécurité et méthodes d'essai

La présente Norme européenne spécifie les exigences de sécurité relatives aux matériaux constitutifs, à la construction, à la performance, à l’emballage et aux informations relatives au produit des sucettes.

La présente Norme européenne est applicable aux produits qui ressemblent à une sucette ou qui fonctionnent de la même façon. Certaines sucettes mises sur le marché peuvent avoir d’autres fonctions. La norme s’applique également à ces produits (l’Annexe C donne des exemples).

La présente Norme européenne n’est pas applicable aux produits destinés à des applications médicales cliniques spécialisées, tels que ceux destinés aux nourrissons prématurés ou présentant le Syndrome de Pierre Robin (voir l’Annexe C).

La présente norme ne s’applique pas aux tétines de biberons. Les exigences de sécurité et méthodes d’essai applicables aux tétines de biberons sont incluses dans toutes les parties de l’EN 14350 [2], [3].

Izdelki za otroke - Dude za dojenčke in mlajše otroke - Varnostne zahteve in preskusne metode (z dopolnili do vključno A2)

Ta evropski standard določa varnostne zahteve v zvezi z materiali, sestavo, lastnostmi, pakiranjem in informacijami o izdelku za dude.

Ta evropski standard se uporablja za izdelke, ki so podobni dudam ali delujejo kot dude. Nekatere dude se lahko oglašujejo z drugimi funkcijami. Ta standard velja za te izdelke (nekateri primeri so podani v Dodatku C).

Ta evropski standard se ne uporablja za izdelke, namenjene specialistični klinični medicinski uporabi, npr. v zvezi s Pierre-Robinovim sindromom ali nedonošenčki (glej Dodatek C).

Ta standard se ne uporablja za cuclje za hranjenje. Varnostne zahteve in preskusne metode za cuclje za hranjenje so vključene v vse dele standarda EN 14350 [2], [3].

General Information

- Status

- Published

- Publication Date

- 19-Sep-2018

- Technical Committee

- OTR - Child use and care article

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 05-Sep-2018

- Due Date

- 10-Nov-2018

- Completion Date

- 20-Sep-2018

Relations

- Effective Date

- 01-Oct-2018

- Effective Date

- 01-Oct-2018

Overview

SIST EN 1400:2013+A2:2018 (also published as EN 1400:2013+A2:2018) is the European safety standard for soothers (pacifiers, babies’ dummies). It defines minimum safety requirements and test methods for materials, construction, performance, consumer packaging and product information for products that resemble or function as soothers. The standard harmonises test procedures used across CEN member countries and includes Amendments A1 and A2 (2014, 2018).

Key topics and technical requirements

- Scope and applicability: applies to consumer soothers and similar products; excludes specialist clinical devices (e.g. for Pierre‑Robin syndrome or premature babies) and feeding teats (see EN 14350).

- Materials and chemical safety: sets requirements and test methods for migration of elements and selected organic compounds. Amendment A2 updated migration considerations (e.g. arsenic, barium, nickel) and includes requirements for substances such as Bisphenol A (BPA); phthalates are controlled separately under REACH.

- Construction and mechanical safety: addresses shield design, teat attachment (plug/cover), ring/knob integrity, ventilation holes, and resistance to stresses. The standard includes specific test equipment and fixtures (for example a Polyoxymethylene (POM) shield template, and stainless‑steel test spheres of defined diameters).

- Performance tests: mechanical properties (tensile, puncture resistance, ageing) and specific tests for teat protectors and detachable parts to reduce choking and inhalation hazards.

- Labelling and product information: mandatory warnings, user instructions and packaging requirements to ensure safe use by caregivers (Annex A contains multi‑language warning phrases).

- Test methods and annexes: normative and informative annexes provide sampling plans (Annex E), rationale, examples of products resembling soothers (Annex C), HPLC method references for certain chemical analyses (Annex F), and guidance on puncture resistance (Annex G).

Practical applications - who uses this standard

- Manufacturers and product designers - to design compliant soothers and select suitable materials and components.

- Test laboratories and quality managers - to perform required mechanical and chemical tests and to implement sampling plans (ISO/IEC 17025 recommended).

- Regulatory bodies and conformity assessors - to evaluate product safety and harmonise national regulations.

- Retailers and procurement teams - to specify safe products for sale and ensure correct labelling.

- Consumer safety organisations and importers - to verify claims and inform caregivers.

Related standards (selection)

- EN 14350 - Feeding teats (all parts)

- EN 71 series - Safety of toys (mechanical/physical and migration tests)

- EN 12868 - Release of N‑nitrosamines from rubber teats and soothers

- ISO 9001, ISO/IEC 17025 - Quality management and testing competence

Using SIST EN 1400:2013+A2:2018 helps reduce risk of accidents, ensures consistent testing across Europe, and supports regulatory compliance and consumer confidence in soothers and similar child care articles.

Frequently Asked Questions

SIST EN 1400:2013+A2:2018 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Child use and care articles - Soothers for babies and young children - Safety requirements and test methods". This standard covers: This European Standard specifies safety requirements relating to the materials, construction, performance, packaging and product information for soothers. This European Standard is applicable to products that resemble or function as a soother. Some soothers may be marketed with other functions. This standard is applicable to these products (some examples are given in Annex C). This European Standard does not apply to products designed for specialist clinical medical applications, e.g. those relating to Pierre-Robin Syndrome or premature babies (see Annex C). The standard is not applicable to feeding teats. Safety requirements and test methods for feeding teats are included in all parts of EN 14350 [2], [3].

This European Standard specifies safety requirements relating to the materials, construction, performance, packaging and product information for soothers. This European Standard is applicable to products that resemble or function as a soother. Some soothers may be marketed with other functions. This standard is applicable to these products (some examples are given in Annex C). This European Standard does not apply to products designed for specialist clinical medical applications, e.g. those relating to Pierre-Robin Syndrome or premature babies (see Annex C). The standard is not applicable to feeding teats. Safety requirements and test methods for feeding teats are included in all parts of EN 14350 [2], [3].

SIST EN 1400:2013+A2:2018 is classified under the following ICS (International Classification for Standards) categories: 97.190 - Equipment for children. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1400:2013+A2:2018 has the following relationships with other standards: It is inter standard links to SIST EN 1400:2013+A1:2014, SIST EN 1400:2013+A1:2014/kFprA2:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1400:2013+A2:2018 is associated with the following European legislation: EU Directives/Regulations: 2001/95/EC, EUR-PUB; Standardization Mandates: M/264. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1400:2013+A2:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-oktober-2018

Nadomešča:

SIST EN 1400:2013+A1:2014

Izdelki za otroke - Dude za dojenčke in mlajše otroke - Varnostne zahteve in

preskusne metode (z dopolnili do vključno A2)

Child use and care articles - Soothers for babies and young children - Safety

requirements and test methods

Artikel für Säuglinge und Kleinkinder - Schnuller für Säuglinge und Kleinkinder -

Sicherheitstechnische Anforderungen und Prüfverfahren

Articles de puériculture - Sucettes pour nourrissons et jeunes enfants - Exigences de

sécurité et méthodes d'essai

Ta slovenski standard je istoveten z: EN 1400:2013+A2:2018

ICS:

97.190 Otroška oprema Equipment for children

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1400:2013+A2

EUROPEAN STANDARD

NORME EUROPÉENNE

September 2018

EUROPÄISCHE NORM

ICS 97.190 Supersedes EN 1400:2013+A1:2014

English Version

Child use and care articles - Soothers for babies and young

children - Safety requirements and test methods

Articles de puériculture - Sucettes pour nourrissons et Artikel für Säuglinge und Kleinkinder - Schnuller für

jeunes enfants - Exigences de sécurité et méthodes Säuglinge und Kleinkinder - Sicherheitstechnische

d'essai Anforderungen und Prüfverfahren

This European Standard was approved by CEN on 25 February 2014 and includes Amendment 2 approved by CEN on 23 April

2018.

This European Standard was corrected and reissued by the CEN-CENELEC Management Centre on 9 January 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISA T IO N

EUROPÄISCHES KOMITEE FÜR NORMUN G

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2018 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1400:2013+A2:2018 E

worldwide for CEN national Members.

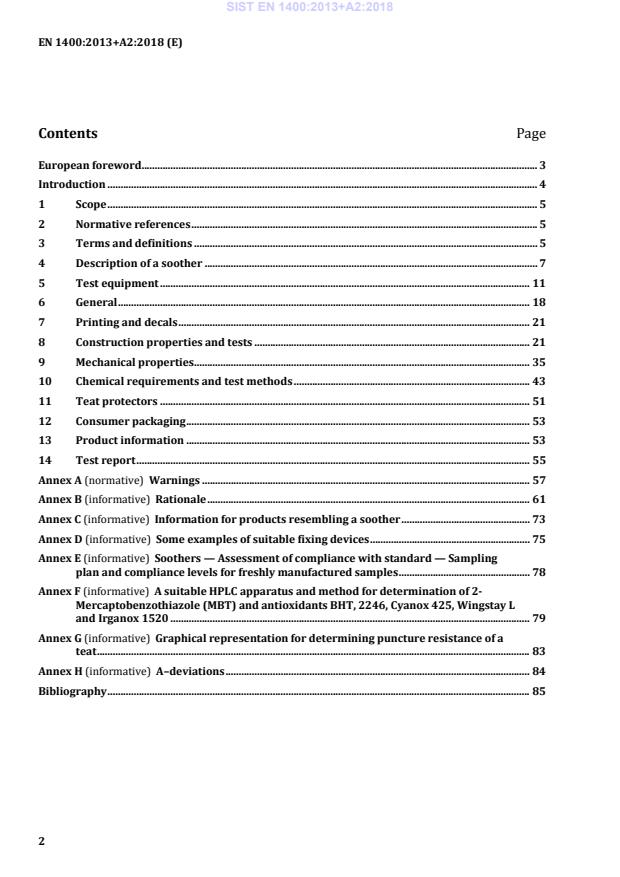

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Description of a soother . 7

5 Test equipment . 11

6 General . 18

7 Printing and decals . 21

8 Construction properties and tests . 21

9 Mechanical properties . 35

10 Chemical requirements and test methods . 43

11 Teat protectors . 51

12 Consumer packaging . 53

13 Product information . 53

14 Test report . 55

Annex A (normative) Warnings . 57

Annex B (informative) Rationale . 61

Annex C (informative) Information for products resembling a soother . 73

Annex D (informative) Some examples of suitable fixing devices . 75

Annex E (informative) Soothers — Assessment of compliance with standard — Sampling

plan and compliance levels for freshly manufactured samples . 78

Annex F (informative) A suitable HPLC apparatus and method for determination of 2-

Mercaptobenzothiazole (MBT) and antioxidants BHT, 2246, Cyanox 425, Wingstay L

and Irganox 1520 . 79

Annex G (informative) Graphical representation for determining puncture resistance of a

teat . 83

Annex H (informative) A–deviations . 84

Bibliography . 85

European foreword

This document (EN 1400:2013+A2:2018) has been prepared by Technical Committee CEN/TC 252

“Child care articles”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by March 2019, and conflicting national standards shall

be withdrawn at the latest by March 2019.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1, approved by CEN on 2014-02-25 and Amendment 2, approved

by CEN on 2018-04-23.

This document supersedes #EN 1400:2013+A1:2014$.

The start and finish of text introduced or altered by amendment is indicated in the text by tags !"

and #$.

This document has been prepared under a mandate (M/264) given to CEN by the European

Commission and the European Free Trade Association.

This standard is linked to the General Product Safety Directive (GPSD) but no Annex ZA is needed

because GPSD is not a New Approach Directive and does not include Essential Requirements to which

such an annex should refer.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

Introduction

Soothers are widely used throughout Europe to satisfy non-nutritive sucking needs and to pacify

children.

They are designed to be in the mouths of babies and young children for long periods. Accidents, some of

which have been fatal, have occurred in the past and a prime purpose of this standard is to reduce the

risk of accidents occurring in the future. It is stressed that this European Standard cannot eliminate all

possible risks to babies and young children using such a product and that parental or guardian control

is of paramount importance. It is essential that all warnings and instructions specified in this standard

are given clearly by the manufacturer, to allow the consumer to ensure that the soother is used

correctly and safely.

This European Standard harmonises minimum safety requirements and test methods for soothers. Most

of the provisions have been taken from other existing national and European Standards.

It is recommended that manufacturers and suppliers operate to EN ISO 9001, the standard for quality

management systems [1]. It is also recommended that laboratories operate to ISO/IEC 17025, General

requirements for the competence of testing and calibration laboratories [4].

In addition, it is recognised that some organisations require reference testing. A suggested sampling

plan and compliance levels for freshly manufactured soothers are provided in Annex E (informative).

This procedure can be used as a voluntary type approval procedure.

Latex protein allergy risk has not been included in this standard. Nevertheless, provision for packaging

information for soothers containing natural rubber has been made in this standard. There is no

published information that sensitisation is caused by soother teats. In addition, there is an extremely

low incidence of latex protein allergy among young children and babies. However, the issue of

subsequent allergic reaction from rubber teats will be reconsidered when further information becomes

available.

Phthalates have not been included in this standard because the use of phthalates in childcare articles is

restricted by Annex XVII of REACH Regulation [5].

A normative annex has been included which contains translations of warning phrases into the main

European languages.

# Since the publication of EN 1400:2013+A1:2014 it has come to the attention of the Technical

Committee that some of the TDI's used to calculate the limits of a certain number of element migration

from soothers are out of date. During the drafting of this amendment the Technical committee reviewed

all the previous sources of TDI's to ascertain the current state of knowledge.

The migration limits for Arsenic, Barium, and Nickel have been changed to reflect the latest information.

In addition migration limits for Chromium VI and Organic Tin have been added.

The Technical Committee has also included a requirement for Bisphenol A (BPA) in soothers based on

the most recent TDI from the 2015 EFSA Opinion and an A-Deviation from France.$

1 Scope

This European Standard specifies safety requirements relating to the materials, construction,

performance, packaging and product information for soothers.

This European Standard is applicable to products that resemble or function as a soother. Some soothers

may be marketed with other functions. This standard is applicable to these products (some examples

are given in Annex C).

This European Standard does not apply to products designed for specialist clinical medical applications,

e.g. those relating to Pierre-Robin Syndrome or premature babies (see Annex C).

The standard is not applicable to feeding teats. Safety requirements and test methods for feeding teats

are included in all parts of EN 14350 [2], [3].

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

DIN 53160-1, Determination of the colourfastness of articles for common use — Part 1: Test with artificial

saliva

EN 71-1, Safety of toys — Part 1: Mechanical and physical properties

EN 71-3, Safety of toys — Part 3: Migration of certain elements

EN 71-11:2005, Safety of toys — Part 11: Organic chemical compounds — Methods of analysis

EN 12868, Child use and care articles — Methods for determining the release of N-Nitrosamines and N-

Nitrosatable substances from elastomer or rubber teats and soothers

EN 20105-A03, Textiles — Tests for colour fastness — Part A03: Grey scale for assessing staining

(ISO 105-A03)

EN ISO 1302, Geometrical Product Specifications (GPS) — Indication of surface texture in technical

product documentation (ISO 1302)

EN ISO 3696, Water for analytical laboratory use — Specification and test methods (ISO 3696)

ISO 188, Rubber, vulcanized or thermoplastic — Accelerated ageing or heat resistance tests

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

soother

article which includes a teat and which is intended to satisfy the non-nutritive sucking need of children

Note 1 to entry: Soothers are also known as pacifiers or babies' dummies.

3.2

teat

part of the soother designed to be placed in the mouth

3.3

shield

structure positioned at the rear of the teat to reduce the likelihood of the soother being drawn entirely

into the child's mouth

3.4

ring

structure positioned adjacent to or on the shield to facilitate handling of the soother

Note 1 to entry: The ring, knob or cover can be integral with the shield or plug or it can be a separate component

that is attached to the shield or plug

Note 2 to entry: See Figure 1.

3.5

knob

structure positioned adjacent to or on the shield to facilitate gripping of the soother

Note 1 to entry: The ring, knob or cover can be integral with the shield or plug or it can be a separate component

that is attached to the shield or plug.

Note 2 to entry: See Figure 2.

3.6

plug

device located within the neck of the teat that secures the teat to the shield

Note 1 to entry: See Figure 3.

3.7

cover

device that prevents open access to the plug

Note 1 to entry: The ring, knob or cover can be integral with the shield or plug or it can be a separate component

that is attached to the shield or plug.

Note 2 to entry: See Figure 3.

3.8

ventilation hole (see B.7)

any shape of hole in the shield or teat protector that is large enough to allow sufficient passage of air to

sustain life

Note 1 to entry: See also 8.4.1 and 11.3.1.

3.9

teat protector

device that can be attached to and detached from the soother to cover the teat

3.10

outer packaging

any packaging used for storage of the product by a retailer, not including the packaging intended for the

consumer

3.11

major axis of the soother

major axis of the soother goes at right angles to the shield and through the centre of the teat, where the

teat enters the shield

Note 1 to entry: See Figure 14.

3.12

major axis of the shield

major axis of the shield is parallel to the longest dimension of the shield and in the middle of the width

Note 1 to entry: See Figure 15.

4 Description of a soother

A soother, as shown in Figures 1, 2, 3 and 4, normally consists of:

— a teat,

— a shield, and

— either a ring or knob,

and can include:

— a plug, and

— a cover.

NOTE 1 Similar components are marked with the same number in Figures 1 to 4.

NOTE 2 Some or all of the components may be manufactured from the same material which may result in the

components not being separately distinguishable.

NOTE 3 The ring, knob or cover can be integral with the shield or plug or it can be a separate component that is

attached to the shield or plug.

Key

1 teat

2 shield

3 ring

5 cover

7 sucking face of shield

8 rear face of shield

Figure 1 — Example of a soother with ring

Key

1 teat

2 shield

4 plug

6 knob

Figure 2 — Example of a soother with knob

Key

1 teat

2 shield

4 plug

5 cover

6 knob

7 sucking face of shield

8 rear face of shield

Figure 3 — Example of a soother with plug and cover

Key

1 teat

2 shield

4 plug

6 knob

Figure 4 — Example of a soother with a combined plug and knob

5 Test equipment

5.1 Shield template

The shield template shall be made from Polyoxymethylene (POM), standard (natural, non pigmented,

unfilled), E-modulus: 3000 MPa to 3300 MPa, hardness: 80 to 90 Shore D, Surface roughness: lower

than Ra 2,2.

NOTE Extruded sheets of POM normally meet the surface roughness requirement.

The dimensions shall be as shown in Figure 5.

Dimensions in millimetres

Key

1 enlarged part section A – A

2 permanent marks for major and minor axes

Figure 5 — Shield template

5.2 Test spheres

Test spheres A, B, C and D, shall be made from stainless steel of diameters given in Table 1.

Table 1 — Test sphere diameters

Test sphere Diameter

mm

+0,1

A

4,0

−0

+0

B

5,5

−0,1

+0,1

C

−0

+0,1

D

−0

5.3 Indentor

The indentor is made from H13 high chrome tool steel or equivalent and hardened to a minimum of

50 Rockwell C and shall have dimensions as shown in Figure 6. All dimensions with a tolerance are

Ra 0,4

machined as in EN ISO 1302 to .The larger diameter of the indentor has not been specified, as it

should be of a size to fit into the equipment for applying the necessary force specified in the test

methods.

Dimensions in millimetres

Key

a This face is flat and has dimensions of (3,0 x 0,20) mm.

Figure 6 — Indentor

5.4 Cutting board

The cutting board is made from a polymeric material of (70 ± 5) Shore D hardness with a stop made

from any suitable material to the dimensions as shown in Figure 7. All dimensions shall have a tolerance

of ± 2 mm except where indicated. A centre line and point of puncture is to be marked onto the surface

as shown in Figure 7.

Dimensions in millimetres

Key

1 stop for cut edge of teat

2 position of teat

3 point of puncture

Figure 7 — Cutting board

5.5 Bite endurance jaws

The jaws are made from H13 high chrome tool steel or equivalent and hardened to (45 to 50) Rockwell

C and shall have dimensions as shown in Figure 8.

Ra 0,4

All dimensions with a tolerance are machined as in EN ISO 1302 to . All dimensions for the top

and bottom jaws are identical.

Dimensions in millimetres

Figure 8 — Bite endurance jaws

5.6 Impact mass

A flat stainless steel weight with radiused edges (2 ± 0,5) mm and a mass of (1 ± 0,02) kg, distributed

over an area of diameter (80 ± 2) mm, see Figure 9.

Dimensions in millimetres

Key

a radius (2 ± 0,5) mm

Figure 9 — Impact mass

5.7 Guides

Guides 1, 2 and 3 with dimensions as shown in Figures 10, 11 and 12.

Dimensions in millimetres

Figure 10 — Guide 1

Dimensions in millimetres

Figure 11 — Guide 2

Dimensions in millimetres

Figure 12 — Guide 3

6 General

6.1 Tolerances for construction and mechanical properties

Unless otherwise stated, the following tolerances apply:

— forces: ± 5 % of the nominal force;

— masses: ± 0,5 % of the nominal mass;

— dimensions: ±1,0 mm of the nominal

dimension;

— angles: ± 2º of the nominal angle;

— duration of forces for durability tests: ± 1 s;

— duration of forces for static load tests: ± 2 s.

The tests are described in terms of the application of forces. Masses can however be used. 1 kg mass

may be used for 10 N force.

Unless otherwise specified, the test forces may be applied by any suitable device which does not

adversely affect the results.

6.2 Order of tests for construction and mechanical properties

The tests shall be carried out in the order given in Table 2.

Table 2 — Order of testing for construction and mechanical properties

Order of Test Samples taken direct from All Other samples

Testing manufacturer prior to being

Clause

placed on the market

6.3.1 Pre-treatment No pre-treatment

6.3.2 Boiling

6.3.3 Conditioning

6.3.4 A sample used in any of the tests below shall not be used in any

further tests

1 8.1 - 8.9 Construction properties and tests

2 9.1.2 Impact resistance

9.7.2.2 followed by

Tensile test along the major axis

(see Annex D, Figure D.1)

3 9.2.2.1 Puncture resistance of teat

4 9.3.2.1 Tear resistance of teat

9.7.2.2 followed by

Tensile test

at right angles to the major axis

(see Annex D, Figure D.2)

5 9.4.2 Knob, plug and/or cover retention

6 9.5.2 Bite endurance of elastomeric components

9.7.2.2 followed by

Tensile test

at right angles to the major axis

(see Annex D, Figure D.2)

7 9.7.2.3 Tensile tests for single components and pairs of components

8 9.7.2 Integrity

Additional requirements for soothers with knobs made of

flexible materials

9 9.2.2.2 Puncture resistance of knob made of flexible materials

Order of Test Samples taken direct from All Other samples

Testing manufacturer prior to being

Clause

placed on the market

10 9.3.2.2 Tear resistance of knob made of flexible materials

9.7.2.2 followed by

Tensile test

at right angles to the major axis

(see Annex D, Figure D.2)

11 9.5.2 Bite endurance of elastomeric components

9.7.2.2 followed by

Tensile test

at right angles to the major axis

(see Annex D, Figure D.2)

Additional tests for soothers where a part rotates inside the teat

(See 9.6)

12 9.6.2 Rotation endurance

9.7.2.2 followed by

Tensile test

along the major axis

(see Annex D, Figure D.1)

6.3 Preparation of samples for construction and mechanical tests

6.3.1 Pre-treatment

Only samples taken directly from the manufacturer (see B.4.1) prior to being placed on the market shall

be artificially aged for (7 days) ± 2 h in a cabinet oven with forced air circulation by means of a fan and a

ventilation of three to ten changes per hour (as described as Method B in ISO 188) at a temperature of

(70 ± 2) °C and conditioned as described in 6.3.3.

6.3.2 Boiling

All samples shall be immersed in boiling water, to the requirements of EN ISO 3696, Grade 3, for (10 ±

1) min without touching the walls of the container and removed (see B.4.2). Afterwards, allow the

samples to cool to room temperature.

6.3.3 Conditioning

All samples shall be conditioned before the tests. The conditioning of the samples shall be performed

for at least 40 h in a temperature (23 ± 2) °C, and relative humidity (50 ± 5) %. Samples shall remain in

the conditioning atmosphere until the test is carried out. The tests may be carried out in a non-

conditioned room.

6.3.4 New samples

New samples, preferably from the same batch, shall be used for each test (i.e. samples used in one test

shall not be used in another test) or for each testing orientation, unless otherwise stated.

6.4 Preparation of samples for chemical tests

6.4.1 General

The sample preparation (6.4.2) applies to all tests except N-Nitrosamines and N-Nitrosatable

substances release; see 10.4.

Samples and test portions shall only be handled with suitable (for example, non-rubber) gloves and

shall only be stored in securely fastened, migration free containers and protected from the light.

6.4.2 Boiling

All samples shall be immersed in boiling water, to the requirements of EN ISO 3696, Grade 3, for (10 ±

1) min without touching the walls of the container and removed. Store in a closed container; a

desiccator for example is ideal for this purpose. This is to reduce the risk of contamination.

6.4.3 New samples

New samples, preferably from the same batch, shall be used for each test, i.e. samples used in one test

shall not be used in another test unless otherwise stated.

7 Printing and decals

There shall be no printing on the sucking face of the shield.

Adhesive decals and labels shall not be attached to any part of the soother. No decorations shall be

attached to any part of the soother by glue.

A soother may be decorated, including moulded in, imprinting and printing. Imprinting may include

techniques such as stamping and laser etching. No form of decoration shall be removed during the

boiling stage (see 6.3.2).

8 Construction properties and tests

8.1 General

The soother shall be free from any sharp points or edges and free of flash and burrs.

The soother shall have no removable parts other than a teat protector (see Clause 11).

Soothers have been known to become lodged in a child's mouth. Attention should therefore be made to

the design of all soother components to allow the assembled soother to be gripped as easily as possible,

thereby facilitating removal of the soother from the child's mouth.

Attention should also be made to the design of the soother to ensure that it may be cleaned as easily and

as efficiently as possible (see B.3).

8.2 Teat (see B.5)

8.2.1 Requirements

When tested in accordance with 8.2.2, the effective penetration of the teat shall not be greater than 35

mm.

The teat shall not include any hole in front of the sucking face side of the shield.

Any hollow section of the teat shall not contain solid, fluid or gaseous substances (except air) nor shall it

contain any inserts except for the plug.

8.2.2 Test method for effective penetration

The effective penetration is the distance from the tip of the teat to where the teat enters the shield along

the major axis, see Figure 13, and shall be measured using a suitable measuring device with an accuracy

of 0,1 mm.

Dimensions in millimetres

Figure 13 — Measurement of teat penetration

8.3 Shield (see B.6)

8.3.1 Requirements

The soother shall incorporate a shield.

When tested in accordance with 8.3.2, the shield shall not pass through the shield template.

8.3.2 Test method

The shield template, see 5.1, shall be supported horizontally so that it remains firm and horizontal

throughout the test and there is no lateral movement of the shield template.

NOTE It will assist the test if the shield is marked with its major and minor axes on both the sucking face and

the rear face. These marked axes can then be lined up with the permanent marks on the shield template (see

Figure 5).

Immerse the soother for at least 10 s in an aqueous solution of a wetting agent. A 2 % (V/V) solution of

polyoxyethylene (20) sorbitan mono-oleate is suitable.

Position the wet soother with the sucking face of the shield against the opening in the template; such

that the major axis of the soother goes through the intersection of the axes marked on the template (see

Figure 14). Orientate the soother, until the major axis of the shield (see Figure 15) is parallel to the

major axis of the template.

At a crosshead speed of (100 ± 5) mm per min, apply a tensile force of (10 ± 0,5) N to the teat along the

direction of the major axis of the soother, ensuring that there is no lateral movement causing a

pendulum effect. That is, the major axis of the soother shall always be aligned with the centre of the

template throughout the test. Maintain the load for (10 ± 0,5) s (see Figure 16 a)).

Reverse the soother and repeat the test by pulling on the ring or the knob, using a suitable device

(see Figure 16 b)).

If the design or position of the soother ring or knob makes this impossible, or if the shield slides

sideways through the template during the test then cut off the teat and repeat the test with the soother

reversed over the template. The force is applied from above through a rod centred in the hole left by the

teat and along the major axis (see Figure 16 c)). The rod shall be a little larger in diameter than the size

of the hole left by the teat.

With some soothers (e.g. full rubber or full silicone soothers) using this rod may not be possible. In

these instances a tube with an internal diameter of (15 ± 0/1) mm and a wall thickness of (1 ± 0,1) mm

shall be used (see Figure 16d)). The teat shall be cut off as far as necessary to accommodate the tube.

Key

a major axis of soother

b intersection of major and minor axes of shield template

c shield template (side view)

d shield template (top view)

Figure 14 — Major axis of soother in relation to the intersection of the axes marked on the shield

template

Key

w half of shield width

a-a major axis of shield

Figure 15 — Example of the major axis of a shield

Key

a) force applied to the teat

b) force applied to the ring or knob

c) force applied from above through a rod centred in the hole left by the teat

d) force applied from above through a tube

Figure 16 — Examples of positions of a soother on the shield template

8.4 Shield ventilation (see B.7)

8.4.1 Requirements

The shield shall be provided with at least two ventilation holes (see 3.8) each of which shall include a

circular area of at least 4 mm diameter and a minimum area of 20 mm .

When tested in accordance with 8.4.2.1, each ventilation hole shall allow the unhindered passage of test

sphere A, see 5.2, even when the ring, if present, is in contact with the shield. In this respect,

"unhindered" means that the test sphere falls through the hole under its own weight, even if it touches

the edges of the hole or other parts of the soother, such as the ring.

When tested in accordance with 8.4.2.2, each ventilation hole shall have a minimum area of 20 mm .

If any part of the soother, in any position, is equal to or more than 1,3 mm from the entrance to the hole

then the hole shall be considered to be unobstructed and area measurement shall be made on the

complete hole (see Figures 17 a) and Figure 17 b)).

An obstructed hole is when any part of the soother, for example the ring, covers part of the hole in at

least one position and when the obstruction is less than 1,3 mm at its closest point to the surface of the

hole (see Figures 17 c) and Figure 17 d)).

If a ring or other part of the soother obstructs a ventilation hole it shall be the unobstructed part of this

ventilation hole that is tested.

Additional holes in any position, even if smaller than ventilation holes, may be provided and shall

comply with the requirements of 8.9.

The centres of two of the ventilation holes shall be at least 15 mm apart and located either side of the

minor axis of the shield, see Figure 18.

The edges of two ventilation holes shall be at least 5 mm from the edge of the shield.

The minimum diameter of a ventilation hole is 4mm, however it is recommended that ventilation holes

are as large as possible, but consistent with the requirement for openings (see 8.9).

Certain types of ventilation holes have given rise to finger injuries. Non-circular holes should avoid

acute V-shaped angles or inward facing angles that are not well rounded, as both these features can lead

to fingers becoming caught and injured. See also 8.9.

NOTE The shape of the edge of the shield and the size, shape and position of ventilation holes affect the ease

with which the shield can be gripped in the event of the soother becoming lodged in a child’s mouth.

Dimensions in millimetres

Key

O obstructing part

S soother shield

H ventilation hole

L lateral view

T top view showing examples of permissible measurement areas (shaded)

Figure 17 — Examples of obstructed and unobstructed holes in the shield

Dimensions in millimetres

Key

A minor axis

B major axis

C shaded area – no mandatory holes

Figure 18 — Examples of permissible positions for mandatory ventilation holes

8.4.2 Test Methods

8.4.2.1 Minimum diameter

The ventilation hole to be tested shall be orientated so that the entry to the hole shall be horizontal. Any

part of the soother whether it obstructs or does not obstruct the hole (see 8.4.1) shall be in its most

onerous position.

Place test sphere A, see 5.2, on the hole so that its mass allows it to pass through the ventilation hole.

Check whether the sphere passes completely through the hole.

8.4.2.2 Minimum area

Measurement of the area of the hole may be made by any suitable method including graph paper,

shadow technology etc. Any part of the soother whether it obstructs or does not obstruct the hole (see

8.4.1) shall be in its most onerous position.

If the hole is unobstructed (any part of the soother, in any position, is equal to or more than 1,3 mm

from the entrance to the hole) then the area measurement shall be made on the complete hole (see

Figure 17 a) and Figure 17 b)).

If the hole is obstructed then the measurement of area shall be made by including the area occupied by

the Test Sphere A (12,57mm ) plus the area immediately surrounding Test Sphere A (see Figure 17 c)

and Figure 17 d)).

8.5 Ring (see B.8)

8.5.1 Requirements

A flow chart for ring requirements is shown in Table 3.

Table 3 — Flow chart for ring requirements

Rings made of non- Rings made of flexible

flexible materials materials

8.5.1 8.8.1

If rings made of non-

flexible materials fail any

of the requirements then

treat as if it is a knob made

from non-flexible

materials; see 8.7.1

Rings made of flexible materials shall comply with the requirements of 8.8.1.

Rings made of non-flexible materials shall comply with the following requirements.

— When tested in accordance with 8.5.2, the effective penetration, dimension A, which is the distance

from the tip of the ring to the rear face of the shield, shall not be greater than 35 mm (see Figure

19).

— Dimension A shall not be greater than 1,4 times dimension B, the widest width of the ring, see

Figure 19, 8.5.2.2 and B.8.

— When tested in accordance with 8.5.2.3 the opening in the ring shall allow test sphere D, see 5.2, to

pass through, see Figure 19.

— When tested in accordance with 8.5.2.4 the ring shall collapse to 16 mm or less above the shield

(see B.9).

Soothers fitted with rings that do not meet all the above requirements shall be treated as if they are

fitted with a knob made from non-flexible materials, see 8.7.

Dimensions in millimetres

Key

A effective penetration of ring = Dimension ‘A’

B widest width of ring = Dimension ‘B’

1 test sphere D

Figure 19 — Ring dimension nomenclature

8.5.2 Test methods

8.5.2.1 Effective penetration of ring

The dimension A from the tip of the ring to the rear face of the shield, see Figure 19, along the major

axis shall be measured using a suitable measuring device with an accuracy of 0,1 mm.

8.5.2.2 Width of ring

The dimension B, the maximum width of the ring, see Figure 19, shall be measured using a suitable

measuring device with an accuracy of 0,1 mm.

8.5.2.3 Size of opening in the ring

Position the ring 90° to the shield, see Figure 19, and check that test sphere D passes through the

opening in the ring.

8.5.2.4 Collapse of ring

Support the soother so that the movement of the ring is not restricted.

Apply a (10 ± 0,5) N force along the major axis of the ring through a test plate as shown in Figure 20.

Measure the distance between the rear face of the shield and the face of the test plate along the major

axis of the soother, as shown in Figure 20, using a suitable measuring device with an accuracy of 0,1

mm.

If necessary, the ring shall be offset slightly from the 90° position, before applying the force, to ensure it

does not lock in the 90° position.

Dimensions in millimetres

Key

1 position of ring following application of the 10 N force

2 test plate

3 rear face of shield along the major axis

Figure 20 — Collapse of ring measurement

8.6 Plug (see B.10)

8.6.1 Requirement

A plug shall not project more than 3 mm beyond the sucking face of the shield, see Figure 21.

Dimensions in millimetres

Key

a sucking face of shield with teat removed

b exposed plug

Figure 21 — Section through soother showing measurement of the projection of the plug

8.6.2 Test Method

Carefully cut off the teat. If the plug projects beyond the sucking face of the shield, measure from the

end of the plug to the sucking face of the shield using a suitable device with an accuracy of 0,1 mm .

8.7 Knobs, plugs and/or covers made from non-flexible materials (see B.11)

8.7.1 Requirements

A knob, plug or cover made from non-flexible materials, whichever projects furthest beyond the rear

face of the shield, shall not be less than 10 mm and not more than 16 mm, see Figure 22, unless the

soother is fitted with a ring that meets requirement 8.5.1.

Requirement 8.7.1 shall also apply to a ring made of non-flexible materials that does not meet

requirement 8.5.1.

8.7.2 Test Method

The distance from the tip of the knob, plug or cover to the shield template (see 5.1), down the central

axis, see Figure 21, shall be measured using a suitable measuring device with an accuracy of 0,1 mm.

The thickness of the shield template shall be added to the length measured to give the effective

projection. The knob, plug and/or cover shall be tested in all orientations about the major axis of the

soother relative to the intersection of the major and minor axes of the shield template.

Key

b knob

c cover

d shield template

e dimension to be measured

f effective penetration

g thickness of shield template

M major axis of soother

Figure 22 — Measurement of effective penetration of knob, plug and/or cover made from non-

flexible materials using the shield template

8.8 Rings, knobs, plugs and/or covers made of flexible materials (see B.12)

8.8.1 Requirement

If made of flexible materials, the effective penetration of the ring knob, plug and/or cover shall not be

less than 10 mm and not more than 35 mm when tested in accordance with 8.8.2.

8.8.2 Test method

The distance from the tip of the ring, knob, plug and/or cover to the shield template (see 5.1), down the

central axis, see Figure 23, shall be measured using a suitable measuring device with an accuracy of 0,1

mm. The thickness of the shield template shall be added to the length measured to give the overall

effective penetration length. The ring, knob, plug and/or cover shall be tested in all orientations about

the major axis of the soother relative to the intersection of the major and minor axes of the shield

template.

Key

a ring

b knob

c cover

d shield template

e dimension to be measured

f effective penetration

g thickness of shield template

M major axis of the soother

Figure 23 — Measurement of effective penetration of ring, knob, plug and/or cover made of

flexible materials using the shield template

8.9 Openings (see B.13)

8.9.1 Requirement

When tested in accordance with 8.9.2, there shall be no openings that allow test sphere B, see 5.2, to

enter and penetrate at least the complete size of test sphere B (5,5 mm), unless test sphere C, see 5.2,

enters the opening at least the same depth that test sphere B penetrated.

This requirement only applies to components made of materials with a Shore A hardness of more than

60.

Circular holes not meeting this requirement present a risk of restricting circulation. Non-circular holes

with acute V-shaped angles or inward facing angles that are not well rounded are to be avoided.

8.9.2 Test method

The opening to be tested shall be orientated so that the entry to the opening is horizontal. Place test

sphere C, see 5.2, on the hole so that its mass allows it to pass through the opening. If test sphere C does

not pass through any opening, check whether test sphere B, see 5.2, enters 5,5 mm into the opening.

This test shall be repeated from the other side of the opening.

9 Mechanical properties

9.1 Impact resistance

9.1.1 Requirements

When tested in accordance with 9.1.2 no part of the soother shall break, tear or separate. Subsequently

when tested in accordance with 9.7.2.2, tensile test, no part of the same soother shall break, tear or

separate.

9.1.2 Test method

Place the soother to be tested unsupported on a flat, horizontal steel surface. Drop the

...

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Artikel für Säuglinge und Kleinkinder - Schnuller für Säuglinge und Kleinkinder - Sicherheitstechnische Anforderungen und PrüfverfahrenArticles de puériculture - Sucettes pour nourrissons et jeunes enfants - Exigences de sécurité et méthodes d'essaiChild use and care articles - Soothers for babies and young children - Safety requirements and test methods97.190Otroška opremaEquipment for childrenICS:Ta slovenski standard je istoveten z:EN 1400:2013+A2:2018SIST EN 1400:2013+A2:2018en,fr,de01-oktober-2018SIST EN 1400:2013+A2:2018SLOVENSKI

STANDARDSIST EN 1400:2013+A1:20141DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1400:2013+A2

September 2018 ICS 97.190

English Version

Child use and care articles - Soothers for babies and young children - Safety requirements and test methods

Articles de puériculture - Sucettes pour nourrissons et jeunes enfants - Exigences de sécurité et méthodes d'essai

Artikel für Säuglinge und Kleinkinder - Schnuller für Säuglinge und Kleinkinder - Sicherheitstechnische Anforderungen und Prüfverfahren This European Standard was approved by CEN on 25 February 2014 and includes Amendment 1, approved by CEN on 2014-02-25 and Amendment 2, approved by CEN on 2018-04-23.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels © 2018 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1400:2013+A2:2018 E SIST EN 1400:2013+A2:2018

Warnings . 57 Annex B (informative)

Rationale . 61 Annex C (informative)

Information for products resembling a soother . 73 Annex D (informative)

Some examples of suitable fixing devices . 75 Annex E (informative)

Soothers — Assessment of compliance with standard — Sampling plan and compliance levels for freshly manufactured samples . 78 Annex F (informative)

A suitable HPLC apparatus and method for determination of 2-Mercaptobenzothiazole (MBT) and antioxidants BHT, 2246, Cyanox 425, Wingstay L and Irganox 1520 . 79 Annex G (informative)

Graphical representation for determining puncture resistance of a teat . 83 Annex H (informative)

A–deviations . 84 Bibliography . 85 SIST EN 1400:2013+A2:2018

Key 1 teat 2 shield 3 ring 5 cover 7 sucking face of shield 8 rear face of shield Figure 1 — Example of a soother with ring SIST EN 1400:2013+A2:2018

Key 1 teat 2 shield 4 plug 6 knob Figure 2 — Example of a soother with knob SIST EN 1400:2013+A2:2018

Key 1 teat 2 shield 4 plug 5 cover 6 knob 7 sucking face of shield 8 rear face of shield Figure 3 — Example of a soother with plug and cover

Key 1 teat 2 shield 4 plug 6 knob Figure 4 — Example of a soother with a combined plug and knob 5 Test equipment 5.1 Shield template The shield template shall be made from Polyoxymethylene (POM), standard (natural, non pigmented, unfilled), E-modulus: 3000 MPa to 3300 MPa, hardness: 80 to 90 Shore D, Surface roughness: lower than Ra 2,2. NOTE Extruded sheets of POM normally meet the surface roughness requirement. The dimensions shall be as shown in Figure 5. SIST EN 1400:2013+A2:2018

Key 1 enlarged part section A – A 2 permanent marks for major and minor axes Figure 5 — Shield template 5.2 Test spheres Test spheres A, B, C and D, shall be made from stainless steel of diameters given in Table 1. SIST EN 1400:2013+A2:2018

Key a This face is flat and has dimensions of (3,0 x 0,20) mm. Figure 6 — Indentor 5.4 Cutting board The cutting board is made from a polymeric material of (70 ± 5) Shore D hardness with a stop made from any suitable material to the dimensions as shown in Figure 7. All dimensions shall have a tolerance SIST EN 1400:2013+A2:2018

Key 1 stop for cut edge of teat 2 position of teat 3 point of puncture Figure 7 — Cutting board 5.5 Bite endurance jaws The jaws are made from H13 high chrome tool steel or equivalent and hardened to (45 to 50) Rockwell C and shall have dimensions as shown in Figure 8. All dimensions with a tolerance are machined as in EN ISO 1302 to Ra0,4. All dimensions for the top and bottom jaws are identical. SIST EN 1400:2013+A2:2018

Figure 8 — Bite endurance jaws 5.6 Impact mass A flat stainless steel weight with radiused edges (2 ± 0,5) mm and a mass of (1 ± 0,02) kg, distributed over an area of diameter (80 ± 2) mm, see Figure 9. Dimensions in millimetres

Key a radius (2 ± 0,5) mm Figure 9 — Impact mass SIST EN 1400:2013+A2:2018

Figure 10 — Guide 1 SIST EN 1400:2013+A2:2018

Figure 11 — Guide 2 SIST EN 1400:2013+A2:2018

Figure 12 — Guide 3 6 General 6.1 Tolerances for construction and mechanical properties Unless otherwise stated, the following tolerances apply: — forces: ± 5 % of the nominal force; — masses: ± 0,5 % of the nominal mass; — dimensions: ±1,0 mm of the nominal dimension; — angles: ± 2º of the nominal angle; SIST EN 1400:2013+A2:2018

± 1 s; — duration of forces for static load tests: ± 2 s. The tests are described in terms of the application of forces. Masses can however be used. 1 kg mass may be used for 10 N force. Unless otherwise specified, the test forces may be applied by any suitable device which does not adversely affect the results. 6.2 Order of tests for construction and mechanical properties The tests shall be carried out in the order given in Table 2. Table 2 — Order of testing for construction and mechanical properties Order of Testing Test Clause Samples taken direct from manufacturer prior to being placed on the market All Other samples

6.3.1 Pre-treatment No pre-treatment

6.3.2 Boiling

6.3.3 Conditioning

6.3.4 A sample used in any of the tests below shall not be used in any further tests 1 8.1 - 8.9 Construction properties and tests 2 9.1.2 9.7.2.2 Impact resistance followed by Tensile test along the major axis (see Annex D, Figure D.1) 3 9.2.2.1 Puncture resistance of teat 4 9.3.2.1 9.7.2.2 Tear resistance of teat followed by Tensile test at right angles to the major axis (see Annex D, Figure D.2) 5 9.4.2 Knob, plug and/or cover retention 6 9.5.2 9.7.2.2 Bite endurance of elastomeric components followed by Tensile test at right angles to the major axis (see Annex D, Figure D.2) 7 9.7.2.3 Tensile tests for single components and pairs of components 8 9.7.2 Integrity

Additional requirements for soothers with knobs made of flexible materials 9 9.2.2.2 Puncture resistance of knob made of flexible materials SIST EN 1400:2013+A2:2018

Additional tests for soothers where a part rotates inside the teat (See 9.6) 12 9.6.2 9.7.2.2 Rotation endurance followed by Tensile test along the major axis (see Annex D, Figure D.1)

6.3 Preparation of samples for construction and mechanical tests 6.3.1 Pre-treatment Only samples taken directly from the manufacturer (see B.4.1) prior to being placed on the market shall be artificially aged for (7 days) ± 2 h in a cabinet oven with forced air circulation by means of a fan and a ventilation of three to ten changes per hour (as described as Method B in ISO 188) at a temperature of (70 ± 2) °C and conditioned as described in 6.3.3. 6.3.2 Boiling All samples shall be immersed in boiling water, to the requirements of EN ISO 3696, Grade 3, for (10 ± 1) min without touching the walls of the container and removed (see B.4.2). Afterwards, allow the samples to cool to room temperature. 6.3.3 Conditioning All samples shall be conditioned before the tests. The conditioning of the samples shall be performed for at least 40 h in a temperature (23 ± 2) °C, and relative humidity (50 ± 5) %. Samples shall remain in the conditioning atmosphere until the test is carried out. The tests may be carried out in a non-conditioned room. 6.3.4 New samples New samples, preferably from the same batch, shall be used for each test (i.e. samples used in one test shall not be used in another test) or for each testing orientation, unless otherwise stated. SIST EN 1400:2013+A2:2018

Figure 13 — Measurement of teat penetration 8.3 Shield (see B.6) 8.3.1 Requirements The soother shall incorporate a shield. When tested in accordance with 8.3.2, the shield shall not pass through the shield template. 8.3.2 Test method The shield template, see 5.1, shall be supported horizontally so that it remains firm and horizontal throughout the test and there is no lateral movement of the shield template. NOTE It will assist the test if the shield is marked with its major and minor axes on both the sucking face and the rear face. These marked axes can then be lined up with the permanent marks on the shield template (see Figure 5). Immerse the soother for at least 10 s in an aqueous solution of a wetting agent. A 2 % (V/V) solution of polyoxyethylene (20) sorbitan mono-oleate is suitable. Position the wet soother with the sucking face of the shield against the opening in the template; such that the major axis of the soother goes through the intersection of the axes marked on the template (see Figure 14). Orientate the soother, until the major axis of the shield (see Figure 15) is parallel to the major axis of the template. At a crosshead speed of (100 ± 5) mm per min, apply a tensile force of (10 ± 0,5) N to the teat along the direction of the major axis of the soother, ensuring that there is no lateral movement causing a pendulum effect. That is, the major axis of the soother shall always be aligned with the centre of the template throughout the test. Maintain the load for (10 ± 0,5) s (see Figure 16 a)). Reverse the soother and repeat the test by pulling on the ring or the knob, using a suitable device (see Figure 16 b)). SIST EN 1400:2013+A2:2018

Key a major axis of soother b intersection of major and minor axes of shield template c shield template (side view) d shield template (top view) Figure 14 — Major axis of soother in relation to the intersection of the axes marked on the shield template

Key w half of shield width a-a major axis of shield Figure 15 — Example of the major axis of a shield

Key a) force applied to the teat b) force applied to the ring or knob c) force applied from above through a rod centred in the hole left by the teat d) force applied from above through a tube Figure 16 — Examples of positions of a soother on the shield template 8.4 Shield ventilation (see B.7) 8.4.1 Requirements The shield shall be provided with at least two ventilation holes (see 3.8) each of which shall include a circular area of at least 4 mm diameter and a minimum area of 20 mm2. When tested in accordance with 8.4.2.1, each ventilation hole shall allow the unhindered passage of test sphere A, see 5.2, even when the ring, if present, is in contact with the shield. In this respect, SIST EN 1400:2013+A2:2018

Key O obstructing part S soother shield H ventilation hole L lateral view T top view showing examples of permissible measurement areas (shaded) Figure 17 — Examples of obstructed and unobstructed holes in the shield

Key A minor axis B major axis C shaded area – no mandatory holes Figure 18 — Examples of permissible positions for mandatory ventilation holes 8.4.2 Test Methods 8.4.2.1 Minimum diameter The ventilation hole to be tested shall be orientated so that the entry to the hole shall be horizontal. Any part of the soother whether it obstructs or does not obstruct the hole (see 8.4.1) shall be in its most onerous position. Place test sphere A, see 5.2, on the hole so that its mass allows it to pass through the ventilation hole. Check whether the sphere passes completely through the hole. SIST EN 1400:2013+A2:2018

Rings made of flexible materials shall comply with the requirements of 8.8.1. Rings made of non-flexible materials shall comply with the following requirements. — When tested in accordance with 8.5.2, the effective penetration, dimension A, which is the distance from the tip of the ring to the rear face of the shield, shall not be greater than 35 mm (see Figure 19). — Dimension A shall not be greater than 1,4 times dimension B, the widest width of the ring, see Figure 19, 8.5.2.2 and B.8. — When tested in accordance with 8.5.2.3 the opening in the ring shall allow test sphere D, see 5.2, to pass through, see Figure 19. — When tested in accordance with 8.5.2.4 the ring shall collapse to 16 mm or less above the shield (see B.9). Soothers fitted with rings that do not meet all the above requirements shall be treated as if they are fitted with a knob made from non-flexible materials, see 8.7. SIST EN 1400:2013+A2:2018

Key A effective penetration of ring = Dimension ‘A’ B widest width of ring = Dimension ‘B’ 1 test sphere D Figure 19 — Ring dimension nomenclature 8.5.2 Test methods 8.5.2.1 Effective penetration of ring The dimension A from the tip of the ring to the rear face of the shield, see Figure 19, along the major axis shall be measured using a suitable measuring device with an accuracy of 0,1 mm. 8.5.2.2 Width of ring The dimension B, the maximum width of the ring, see Figure 19, shall be measured using a suitable measuring device with an accuracy of 0,1 mm. 8.5.2.3 Size of opening in the ring Position the ring 90° to the shield, see Figure 19, and check that test sphere D passes through the opening in the ring. 8.5.2.4 Collapse of ring Support the soother so that the movement of the ring is not restricted. SIST EN 1400:2013+A2:2018

Key 1 position of ring following application of the 10 N force 2 test plate 3 rear face of shield along the major axis Figure 20 — Collapse of ring measurement 8.6 Plug (see B.10) 8.6.1 Requirement A plug shall not project more than 3 mm beyond the sucking face of the shield, see Figure 21. SIST EN 1400:2013+A2:2018

Key a sucking face of shield with teat removed b exposed plug Figure 21 — Section through soother showing measurement of the projection of the plug 8.6.2 Test Method Carefully cut off the teat. If the plug projects beyond the sucking face of the shield, measure from the end of the plug to the sucking face of the shield using a suitable device with an accuracy of 0,1 mm . 8.7 Knobs, plugs and/or covers made from non-flexible materials (see B.11) 8.7.1 Requirements A knob, plug or cover made from non-flexible materials, whichever projects furthest beyond the rear face of the shield, shall not be less than 10 mm and not more than 16 mm, see Figure 22, unless the soother is fitted with a ring that meets requirement 8.5.1. Requirement 8.7.1 shall also apply to a ring made of non-flexible materials that does not meet requirement 8.5.1. 8.7.2 Test Method The distance from the tip of the knob, plug or cover to the shield template (see 5.1), down the central axis, see Figure 21, shall be measured using a suitable measuring device with an accuracy of 0,1 mm. The thickness of the shield template shall be added to the length measured to give the effective SIST EN 1400:2013+A2:2018

Key b knob c cover d shield template e dimension to be measured f effective penetration g thickness of shield template M major axis of soother Figure 22 — Measurement of effective penetration of knob, plug and/or cover made from non-flexible materials using the shield template 8.8 Rings, knobs, plugs and/or covers made of flexible materials (see B.12) 8.8.1 Requirement If made of flexible materials, the effective penetration of the ring knob, plug and/or cover shall not be less than 10 mm and not more than 35 mm when tested in accordance with 8.8.2. 8.8.2 Test method The distance from the tip of the ring, knob, plug and/or cover to the shield template (see 5.1), down the central axis, see Figure 23, shall be measured using a suitable measuring device with an accuracy of 0,1 SIST EN 1400:2013+A2:2018

Key a ring b knob c cover d shield template e dimension to be measured f effective penetration g thickness of shield template M major axis of the soother Figure 23 — Measurement of effective penetration of ring, knob, plug and/or cover made of flexible materials using the shield template 8.9 Openings (see B.13) 8.9.1 Requirement When tested in accordance with 8.9.2, there shall be no openings that allow test sphere B, see 5.2, to enter and penetrate at least the complete size of test sphere B (5,5 mm), unless test sphere C, see 5.2, enters the opening at least the same depth that test sphere B penetrated. This requirement only applies to components made of materials with a Shore A hardness of more than 60. Circular holes not meeting this requirement present a risk of restricting circulation. Non-circular holes with acute V-shaped angles or inward facing angles that are not well rounded are to be avoided. 8.9.2 Test method The opening to be tested shall be orientated so that the entry to the opening is horizontal. Place test sphere C, see 5.2, on the hole so that its mass allows it to pass through the opening. If test sphere C does SIST EN 1400:2013+A2:2018

Key A impact mass centre line B steel surface Figure 24 — Examples of positions of the soother for the impact test The subsequent tensile test, 9.7.2.2, shall be conducted along the major axis of the soother. For a soother with a ring, apply the force between the ring and the teat. For a soother with a knob which can be gripped, the force shall be applied between the knob and the teat. For a soother with a plug, cover or knob, which cannot be held by a fixture device, the force shall be applied between the shield and the teat. SIST EN 1400:2013+A2:2018

Key a indentor (see 5.3) b teat c cutting board (see 5.4) d stop for cut edge of teat Figure 25 — Positioning of indentor on the teat Place the indentor, see 5.3, with the 3 mm edge of the indentor centred over and at right angles to the major axis of the teat and (5 ± 0,5) mm from the cut edge of the teat using the markings on the cutting board, see 5.4. In the case of teats not having a circular cross section, the indentor shall be positioned over the flattest surface of the neck of the teat. At a cross-head speed of (10 ± 1) mm/min, apply a load until the indentor cuts completely through the upper wall of the teat. The upper wall of the teat is completely cut when the first maximum load has been detected. See Annex G for an example of a graph produced during the puncture resistance test, showing the first point o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...