SIST EN 14436:2004

(Main)Copper and copper alloys - Electrolytically tinned strip

Copper and copper alloys - Electrolytically tinned strip

This document specifies:

- the composition and tolerances on dimensions in the thickness range from 0,1 mm up to and including 4 mm of strip of copper and copper alloys to be tinned with tin or a tin lead alloy or other tin alloys;

- the composition of the material to be used for the coating;

- the properties of strip before tinning;

- the properties of the electrolytically tinned strip;

- the preferred thicknesses (mean values) and thickness ranges of coatings and their eventual sub layers;

- the types of coating and sub layer;

- the edgewise curvature of electrolytically tinned strip;

- the sampling procedure;

- the methods of test to be used for verification of conformity to the requirements of this standard;

- the delivery conditions.

Kupfer und Kupferlegierungen - Elektrolytisch verzinnte Bänder

Dieses Dokument legt fest:

¾ die Zusammensetzung und Grenzabmaße von mit Zinn, einer Zinn-Blei-Legierung oder anderen Zinn-Legierungen zu verzinnenden Bänder mit einer Dicke von 0,1 mm bis 4 mm aus Kupfer und Kupfer-Legierungen;

- die Zusammensetzung des für den Überzug zu verwendenden Werkstoffes;

- die Eigenschaften von Bändern vor dem Verzinnen;

- die Eigenschaften des elektrolytisch verzinnten Bandes;

- die bevorzugten Dicken (Mittelwerte) und Dickenbereiche der Überzüge und die ihrer möglichen Zwischen-schichten;

- die Arten der Überzüge und die der Zwischenschichten;

- die Säbelförmigkeit von elektrolytisch verzinnten Bändern;

- den Ablauf der Probenentnahme;

- die Prüfverfahren zur Feststellung der Übereinstimmung mit den Anforderungen dieser Norm;

- die Lieferbedingungen.

Cuivre et alliages de cuivre - Bandes étamées électrolytiquement

Le présent document spécifie :

- la composition et les tolérances des dimensions de la bande de cuivre et d'alliages de cuivre d'épaisseur 0,1 mm à 4 mm inclus à étamer avec de l'étain ou un alliage étain-plomb ou d'autres alliages d'étain ;

- la composition du matériel à utiliser pour le revêtement ;

- les propriétés de la bande avant étamage ;

- les propriétés de la bande étamée électrolytiquement ;

- les épaisseurs recommandées (valeurs moyennes) et les plages d'épaisseurs pour les revêtements et leurs éventuelles sous-couches ;

- les types de revêtement et de sous-couche ;

- la flèche latérale de la bande étamée électrolytiquement ;

- le mode opératoire d'échantillonnage ;

- les méthodes d'essai à utiliser pour la vérification de la conformité des exigences de la présente norme européenne ;

les conditions de livraison.

Baker in bakrove zlitine – Elektrolizno pokositren trak

General Information

- Status

- Published

- Publication Date

- 31-Oct-2004

- Technical Committee

- INEK - Nonferrous metals

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Nov-2004

- Due Date

- 01-Nov-2004

- Completion Date

- 01-Nov-2004

Overview

EN 14436:2004 - Copper and copper alloys - Electrolytically tinned strip is a CEN standard that defines requirements for copper and copper-alloy strip (0.1 mm to 4 mm thickness) coated by continuous electrolytic tin or tin‑alloy processes. The standard covers composition, dimensional tolerances, coating materials and types (matt, bright, reflow‑brightened), preferred coating and sub‑layer thicknesses, edgewise curvature, sampling, test methods and delivery and inspection documentation.

Keywords: EN 14436:2004, electrolytically tinned strip, copper and copper alloys, tin coatings, tin‑lead alloys, coating thickness, solderability.

Key topics and requirements

- Material composition and designations: Composition limits for base copper and copper alloys and for tin or tin‑alloy coatings.

- Dimensional tolerances: Thickness (0.1–4.0 mm) and width tolerances for strip before and after tinning.

- Coating types and properties:

- Matt electrolytic coatings (no brighteners).

- Bright electrolytic coatings (with brightening agents).

- Reflow brightened coatings (post‑coating heating to fuse and brighten; generally not used for coatings >5 µm).

- Sub‑layers: Use of electroplated sub‑layers to limit diffusion (recommended for high‑temperature service, e.g. >120 °C) and to reduce whisker risk.

- Functional properties: Requirements and test methods for solderability, adhesion, surface appearance and mechanical properties of the base strip (tensile, hardness, grain size).

- Edgewise curvature: Limits and measurement of strip curvature after tinning.

- Sampling and conformity testing: Specified sampling procedures and standardized test methods (chemical analysis, coating thickness, adhesion, solderability, mechanical tests).

- Delivery and documentation: Declaration of conformity, inspection documents and marking/packaging requirements.

Applications and who uses the standard

EN 14436:2004 is intended for manufacturers, purchasers and quality engineers involved with tin‑coated copper strip used for:

- Electrical and electronic components (connectors, contacts, lead frames) where corrosion protection, low contact resistance and good solderability are required.

- Automotive and telecommunication hardware requiring consistent coating quality and adhesion.

- General industrial applications where tin coatings protect copper parts from corrosion or facilitate assembly (soldering, insertion/withdrawal of connectors).

- Test laboratories and inspection bodies verifying conformity to European material and coating specifications.

Primary users:

- Copper strip producers and electrolytic tinning plants

- Component manufacturers (connectors, terminals, lead frames)

- Procurement/specification engineers

- Quality assurance and testing laboratories

Related standards

Relevant referenced and companion standards include: EN 1655, EN 1976, EN 10002‑1, EN 10204, EN ISO 2624, EN ISO 2819, EN ISO 6507‑1 and other EN standards on copper products (e.g., EN 1172, EN 1652, EN 13148). These provide complementary requirements for testing, conformity and other copper product types.

Frequently Asked Questions

SIST EN 14436:2004 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Copper and copper alloys - Electrolytically tinned strip". This standard covers: This document specifies: - the composition and tolerances on dimensions in the thickness range from 0,1 mm up to and including 4 mm of strip of copper and copper alloys to be tinned with tin or a tin lead alloy or other tin alloys; - the composition of the material to be used for the coating; - the properties of strip before tinning; - the properties of the electrolytically tinned strip; - the preferred thicknesses (mean values) and thickness ranges of coatings and their eventual sub layers; - the types of coating and sub layer; - the edgewise curvature of electrolytically tinned strip; - the sampling procedure; - the methods of test to be used for verification of conformity to the requirements of this standard; - the delivery conditions.

This document specifies: - the composition and tolerances on dimensions in the thickness range from 0,1 mm up to and including 4 mm of strip of copper and copper alloys to be tinned with tin or a tin lead alloy or other tin alloys; - the composition of the material to be used for the coating; - the properties of strip before tinning; - the properties of the electrolytically tinned strip; - the preferred thicknesses (mean values) and thickness ranges of coatings and their eventual sub layers; - the types of coating and sub layer; - the edgewise curvature of electrolytically tinned strip; - the sampling procedure; - the methods of test to be used for verification of conformity to the requirements of this standard; - the delivery conditions.

SIST EN 14436:2004 is classified under the following ICS (International Classification for Standards) categories: 77.150.30 - Copper products. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14436:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Baker in bakrove zlitine – Elektrolizno pokositren trakKupfer und Kupferlegierungen - Elektrolytisch verzinnte BänderCuivre et alliages de cuivre - Bandes étamées électrolytiquementCopper and copper alloys - Electrolytically tinned strip77.150.30Bakreni izdelkiCopper productsICS:Ta slovenski standard je istoveten z:EN 14436:2004SIST EN 14436:2004en01-november-2004SIST EN 14436:2004SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14436August 2004ICS 77.150.30English versionCopper and copper alloys - Electrolytically tinned stripCuivre et alliages de cuivre - Bandes étaméesélectrolytiquementKupfer und Kupferlegierungen - Elektrolytisch verzinnteBänderThis European Standard was approved by CEN on 27 May 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14436:2004: ESIST EN 14436:2004

EN 1655, Copper and copper alloys — Declarations of conformity. EN 1976, Copper and copper alloys — Cast unwrought copper products. EN 10002-1, Metallic materials — Tensile testing — Part 1: Method of testing (at ambient temperature). EN 10204, Metallic products — Types of inspection documents. SIST EN 14436:2004

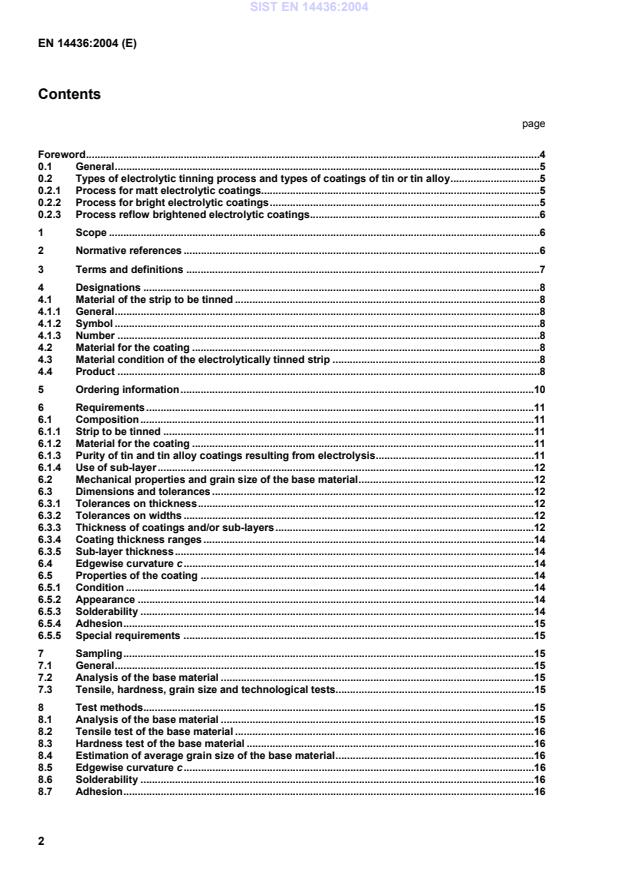

with mandatory tensile strength and elongation requirements; H. Material condition designated by the minimum value of hardness requirement for the product with

mandatory hardness requirements; G. Material condition designated by the mid-range value of grain size requirement for the product with

mandatory grain size and hardness requirements. Exact conversion between material conditions designated R., H. and G. is not possible. Material condition is designated by only one of the above designations. 4.4 Product The product designation provides a standardized pattern of designation from which a rapid and unequivocal description of a product is conveyed in communication. It provides mutual comprehension at the international level with regard to products which meet the requirements of the relevant European Standard. The product designation is no substitute for the full content of the standard. The product designation for products to this standard shall consist of: denomination (electrolytically tinned strip, differentially electrolytically tinned strip, Partially electrolytically tinned strip or combined differentially and partially electrolytically tinned strip); SIST EN 14436:2004

Elektrolytically

tinned strip EN 14436 — CuZn30 — H150 — 0,50A ×××× 200,00 — Cu1 — Snf2 or

Elektrolytically

tinned strip EN 14436 — CW505L — H150 — 0,50A ×××× 200,00 — Cu1 — Snf2 Denomination

Number of this European Standard

Material designation of the strip to be tinned

Material condition designation

Nominal dimensions in millimetres and tolerance class for thickness

Material designation of the sub-layer and thickness of the sub-layer in micrometres

Material designation of the coating and thickness of the coating in micrometres

— nominal inside diameter of coil 400 mm

— maximum outside diameter of coil 950 mm

— approximate specific coil mass 4,5 kg/mm or 1 200 kg electrolytically tinned strip EN 14436 — CW508L — R480 — 0,40C x 160,00 — Snb — 3 to 6

— nominal inside diameter of coil 400 mm

— maximum outside diameter of coil 950 mm

— approximate specific coil mass 4,5 kg/mm 6 Requirements 6.1 Composition 6.1.1 Strip to be tinned The composition of the strip shall conform to the requirements for the appropriate material given in Tables 1 and 2. Percentage content of the elements shown as "remainder" (Rem.) is usually calculated by difference from 100 %. 6.1.2 Material for the coating Unless otherwise specified, the composition of the material for the coating shall conform to the requirements for the appropriate material given in Table 3. Other material for the coating shall conform to the requirements agreed between the purchaser and the supplier [see 5 k)]. 6.1.3 Purity of tin and tin alloy coatings resulting from electrolysis The compositions of tin and tin alloys applied shall be in accordance with Table 3. If the coating operation is followed by a thermal treatment, purity and composition may be modified with respect to the values given in Table 3. This modification is deliberate in certain applications, for example, where special friction forces are demanded. SIST EN 14436:2004

— the composition of the anodes;

— the electrolysis conditions;

— the coating type (matt, reflow brightened, bright);

— the additive agents. 6.1.4 Use of sub-layer The metals commonly used for sub-layers are copper or nickel. Thicknesses of sub-layers applied shall be selected from Table 6 in accordance with the intended application [see 5 j)]. NOTE

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...