SIST EN 12469-2:2026

(Main)Biological safety cabinets - Part 2: BSC class II

Biological safety cabinets - Part 2: BSC class II

This document specifies the specific requirements for class II BSC with respect to design, construction, safety and hygiene.

It sets the specific performance criteria for class II BSC for work with biological agents and specifies test procedures with respect to protection of the worker, the environment and product protection including cross-contamination.

Biologische Sicherheitswerkbänke - Teil 2: BSC Klasse II

Dieses Dokument legt die spezifischen Anforderungen an BSW Klasse II in Bezug auf Konstruktion, Auslegung, Sicherheit und Hygiene fest.

Es legt die spezifischen Leistungskriterien für BSW Klasse II für die Arbeit mit biologischen Arbeitsstoffen sowie Prüfverfahren in Bezug auf den Schutz des Personals, den Schutz der Umgebung und den Produktschutz, einschließlich Kreuzkontamination, fest.

Postes de sécurité biologique - Partie 2: BSC de type II

Le présent document spécifie les exigences spécifiques aux BSC de type II en ce qui concerne la conception, la construction, la sécurité et la santé.

Il définit les critères de performance spécifiques des BSC de type II pour le travail avec des agents biologiques et spécifie les procédures d'essai en matière de protection de l'opérateur, de l'environnement et du produit, y compris la contamination croisée.

Biološke varnostne omare - 2. del: Biološke varnostne omare (BSC) razreda II

General Information

- Status

- Published

- Public Enquiry End Date

- 18-Sep-2024

- Publication Date

- 07-Dec-2025

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 04-Dec-2025

- Due Date

- 08-Feb-2026

- Completion Date

- 08-Dec-2025

Relations

- Splited From

SIST EN 12469:2000 - Biotechnology - Performance criteria for microbiological safety cabinets - Effective Date

- 09-Aug-2023

Overview

EN 12469-2:2025 - "Biological safety cabinets - Part 2: BSC class II" (CEN) defines the specific requirements for Class II biological safety cabinets (BSC class II) with respect to design, construction, safety and hygiene. The standard sets performance criteria and test procedures to demonstrate protection of the worker (operator), the environment, and the product, including measures to prevent cross‑contamination. It is part of the EN 12469 series and was approved by CEN in November 2025.

Key topics and technical requirements

- Scope & objectives: Specifies performance and safety requirements for BSC class II used with biological agents; includes test methods for protection functions.

- Design and construction: Requirements for chassis/carcass, glazing and sash, ergonomics, stability, lighting and UV lamps, sound/vibration control, intake grilles and spillage trays.

- Filter system & liquid protection: Mandates HEPA/filtered exhaust arrangements and tests for liquid penetration protection (filter integrity considerations).

- Airflow performance: Defines requirements and test procedures for downflow and inflow velocities and airflow visualization methods to confirm correct containment and product protection.

- Protective functions: Normative tests for:

- Operator protection (Annex A: microbiological and KI tests)

- Product protection (Annex B)

- Cross‑contamination protection (Annex C)

- Stability of protective functions (Annex D)

- Alarms and indicators: Requirements for alarm indicators, audible/visual alarms and fail‑safe behaviour.

- Cleanability & decontaminability: Construction and materials that allow effective cleaning and decontamination.

- Documentation: Required accompanying documents - operating manual, equipment logbook, brief instructions for use, marking, plus guidance on installation and maintenance.

Applications and who uses it

- Laboratories and facilities handling microorganisms, cell cultures, or biological agents where containment and aseptic workspace are required.

- Users: laboratory managers, biosafety officers, procurement teams, test houses, manufacturers of biological safety cabinets, service and maintenance technicians, and accreditation bodies.

- Practical uses: selecting compliant BSC class II units, verifying installation and commissioning, performing routine acceptance tests, maintenance planning, and ensuring regulatory/biosafety compliance.

Related standards

- EN 12469-2:2025 is part of a series (see EN 12469-1:2025, prEN 12469-3/4, EN 12469-5:2025 referenced in the foreword). Users should consult the other parts of EN 12469 for general requirements and additional BSC classes or methods.

Keywords: EN 12469-2:2025, Biological safety cabinet, BSC class II, CEN standard, operator protection, product protection, cross-contamination, airflow testing, HEPA filter, decontaminability, laboratory biosafety.

Frequently Asked Questions

SIST EN 12469-2:2026 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Biological safety cabinets - Part 2: BSC class II". This standard covers: This document specifies the specific requirements for class II BSC with respect to design, construction, safety and hygiene. It sets the specific performance criteria for class II BSC for work with biological agents and specifies test procedures with respect to protection of the worker, the environment and product protection including cross-contamination.

This document specifies the specific requirements for class II BSC with respect to design, construction, safety and hygiene. It sets the specific performance criteria for class II BSC for work with biological agents and specifies test procedures with respect to protection of the worker, the environment and product protection including cross-contamination.

SIST EN 12469-2:2026 is classified under the following ICS (International Classification for Standards) categories: 07.080 - Biology. Botany. Zoology; 07.100.01 - Microbiology in general. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 12469-2:2026 has the following relationships with other standards: It is inter standard links to SIST EN 12469:2000. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 12469-2:2026 is associated with the following European legislation: EU Directives/Regulations: 90/219/EEC, 90/220/EEC, 90/679/EEC; Standardization Mandates: M/BC/CEN/91/19. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 12469-2:2026 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2026

Biološke varnostne omare - 2. del: Biološke varnostne omare (BSC) razreda II

Biological safety cabinets - Part 2: BSC class II

Biologische Sicherheitswerkbänke - Teil 2: BSC Klasse II

Postes de sécurité biologique - Partie 2: BSC de type II

Ta slovenski standard je istoveten z: EN 12469-2:2025

ICS:

07.080 Biologija. Botanika. Zoologija Biology. Botany. Zoology

07.100.01 Mikrobiologija na splošno Microbiology in general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12469-2

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2025

EUROPÄISCHE NORM

ICS 07.080

English Version

Biological safety cabinets - Part 2: BSC class II

Postes de sécurité microbiologique - Partie 2 : PSM de Biologische Sicherheitswerkbänke - Teil 2: BSC Klasse

type II II

This European Standard was approved by CEN on 5 October 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12469-2:2025 E

worldwide for CEN national Members.

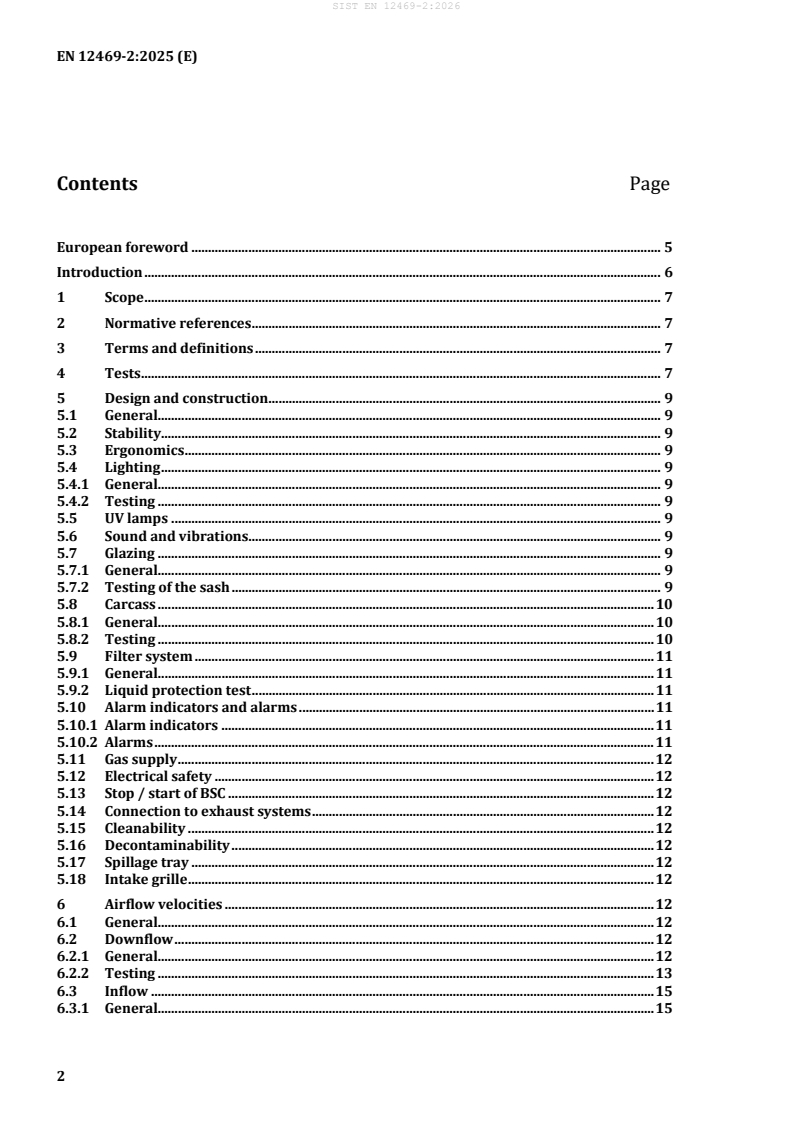

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Tests . 7

5 Design and construction . 9

5.1 General. 9

5.2 Stability . 9

5.3 Ergonomics . 9

5.4 Lighting . 9

5.4.1 General. 9

5.4.2 Testing . 9

5.5 UV lamps . 9

5.6 Sound and vibrations. 9

5.7 Glazing . 9

5.7.1 General. 9

5.7.2 Testing of the sash . 9

5.8 Carcass . 10

5.8.1 General. 10

5.8.2 Testing . 10

5.9 Filter system . 11

5.9.1 General. 11

5.9.2 Liquid protection test . 11

5.10 Alarm indicators and alarms . 11

5.10.1 Alarm indicators . 11

5.10.2 Alarms . 11

5.11 Gas supply . 12

5.12 Electrical safety . 12

5.13 Stop / start of BSC . 12

5.14 Connection to exhaust systems . 12

5.15 Cleanability . 12

5.16 Decontaminability . 12

5.17 Spillage tray . 12

5.18 Intake grille . 12

6 Airflow velocities . 12

6.1 General. 12

6.2 Downflow . 12

6.2.1 General. 12

6.2.2 Testing . 13

6.3 Inflow . 15

6.3.1 General. 15

6.3.2 Testing . 15

6.3.3 Alternative test methods . 19

6.4 Visualization of airflows . 19

6.4.1 General . 19

6.4.2 Material and equipment . 19

6.4.3 Procedure . 19

6.4.4 Documentation . 20

7 Protective functions . 20

7.1 General . 20

7.2 Operator protection . 20

7.2.1 General . 20

7.2.2 Testing . 20

7.3 Product protection . 21

7.3.1 General . 21

7.3.2 Testing . 21

7.4 Cross-contamination protection . 21

7.4.1 General . 21

7.4.2 Testing . 21

7.5 Stability of the protective functions . 21

7.5.1 General . 21

7.5.2 Testing . 21

8 Accompanying documents . 21

8.1 Operating manual . 21

8.2 Equipment logbook . 21

8.3 Brief instructions for use . 22

9 Marking . 22

10 Installation and maintenance . 22

Annex A (normative) Test for operator protection . 23

A.1 Microbiological test . 23

A.1.1 General . 23

A.1.2 Material and equipment . 23

A.1.3 Test procedure . 28

A.1.4 Calculation and expression of results . 30

A.1.5 Acceptance criteria . 30

A.2 Potassium iodide (KI) method . 31

A.2.1 General . 31

A.2.2 Material and equipment . 32

A.2.3 Test procedure . 33

A.2.4 Acceptance criteria . 34

Annex B (normative) Test for product protection . 35

B.1 General . 35

B.2 Material and equipment . 35

B.2.1 Reagents . 35

B.2.2 Equipment . 35

B.3 Test procedure . 36

B.4 Calculation and expression of results . 37

B.5 Acceptance criteria. 37

Annex C (normative) Test for cross-contamination protection . 38

C.1 General. 38

C.2 Material and equipment . 38

C.2.1 Reagents . 38

C.2.2 Equipment . 38

C.3 Test procedure . 39

C.4 Calculation and expression of results . 40

C.5 Acceptance criteria. 40

Annex D (normative) Test of the stability of protective functions . 41

D.1 General. 41

D.2 Material and equipment . 41

D.3 Test procedure . 41

D.4 Calculation and expression of results . 42

D.5 Acceptance criteria. 42

Bibliography . 43

European foreword

This document (EN 12469-2:2025) has been prepared by Technical Committee CEN/TC 332 “Laboratory

Equipment”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2026, and conflicting national standards shall be

withdrawn at the latest by May 2026.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

1 2

, prEN 12469-4:— and

This document, together with EN 12469-1:2025, prEN 12469-3:—

EN 12469-5:2025, will partially supersede EN 12469:2000.

— the structure has been changed to emphasize different classes of biological safety cabinets (BSC);

— additional test of the stability of protective functions;

— the text of the entire document has been revised and references have been updated.

EN 12469 consists of the following parts, under the general title Biological safety cabinets:

— Part 1: Classes, terminology and basic requirements

— Part 2: BSC class II

— Part 3: BSC class III

— Part 4: BSC class I

— Part 5: Installation, commissioning and routine testing

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Under preparation.

Under preparation.

Introduction

Biological safety cabinets (BSC) are designed to protect the operator and the environment against the

risks associated with the handling of biological agents. Depending on the classes, a BSC can additionally

protect the product.

Each BSC class has its own design and performance criteria. The choice of a BSC class depends on the type

of protection required and the assessment of the risk to be controlled.

EN 12469 describes the BSC classes, their design, correct usage, and testing principles.

This document is a product standard. Occupational health and safety assessments methods are not

included.

1 Scope

This document specifies the specific requirements for class II BSC with respect to design, construction,

safety and hygiene.

It sets the specific performance criteria for class II BSC for work with biological agents and specifies test

procedures with respect to protection of the operator, the environment and product protection including

cross-contamination.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12469-1:2025, Biological safety cabinets - Part 1: Classes and basic requirements

EN ISO 14644-7:2004, Cleanrooms and associated controlled environments - Part 7: Separative devices

(clean air hoods, gloveboxes, isolators and mini-environments) (ISO 14644-7:2004)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 12469-1:2025 apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

4 Tests

For the different test sets different requirements shall be verified. Table 1 gives an overview about the

test sets and the requirements to be verified for the different sets.

Table 1 — Requirements to be verified for different tests

Clause Requirement: X = mandatory, R = recommended, O = optional

Type test Factory test Commissioning Routine test

5 Design and construction

5.1 General X X

5.2 Stability X

5.3 Ergonomics X

5.4 Lighting X

a X

5.5 UV lamps

5.6 Sound and vibration X

5.7 Glazing X

X

5.8 Carcass

X X X X

5.9 Filter System

X

5.9.1 Liquid protection test

5.10 Alarm Indicators and alarms

X

5.10.1 Alarm indicators

X X X X

5.10.2 Alarms

X R X R

a

5.11 Gas supply

X X

5.12 Electrical safety

X X X X

5.13 Stop/start of BSC

X X

a

5.14 Connection to exhaust system

5.15 Cleanability X

5.16 Decontaminability X

5.17 Spillage tray X

5.18 Intake grille X

6 Airflow velocities

6.2 Downflow X X X X

6.3 Inflow X X X X

6.4 Visualization of airflows X X X

7 Protective functions

7.2 Operator protection

According to A.1 X

According to A.2 O O O

X

7.3 Product protection

X

7.4 Cross-contamination protection

X

7.5 Stability of the protective functions

b

8 Accompanying documents

X X X X

8.1 Operating manual

X X X X

8.2 Equipment logbook

X X X X

8.3 Brief instruction for use

Clause Requirement: X = mandatory, R = recommended, O = optional

Type test Factory test Commissioning Routine test

9 Marking X X X X

a

if installed

b

for type test check content, for other test check if the documents are available

5 Design and construction

5.1 General

The general design and construction shall be in accordance with EN 12469-1:2025.

5.2 Stability

The stability shall be in accordance with EN 12469-1:2025.

5.3 Ergonomics

The ergonomics shall be in accordance with EN 12469-1:2025.

5.4 Lighting

5.4.1 General

The lighting shall be in accordance with EN 12469-1:2025.

5.4.2 Testing

The lighting shall be tested according to EN 12469-1:2025.

For testing the following measuring grid shall be used: the first measuring line on the work surface shall

start 10 cm behind the intake slots. Starting point from left to right is 15 cm from the side walls. Divide

the lines into equally spaced sections with a maximum of 20 cm. The second line shall be 20 cm behind

the first line.

5.5 UV lamps

If installed, the UV lamps shall be in accordance with EN 12469-1:2025.

5.6 Sound and vibrations

Sound and vibration levels shall be in accordance with EN 12469-1:2025.

5.7 Glazing

5.7.1 General

The glazing material and construction shall be in accordance with EN 12469-1:2025.

5.7.2 Testing of the sash

5.7.2.1 Test procedure

Set the sash to the test sash position. Disconnect one of the suspension devices of the sash.

Repeat the test with the other suspension device.

5.7.2.2 Acceptance criteria

The sash shall not endanger the operator in case of single fault.

5.8 Carcass

5.8.1 General

The carcass shall be in accordance with EN 12469-1:2025.

For a BSC class II the carcass includes the exterior surfaces, welds, gaskets and seals etc. The carcass shall

be leak tight.

There are two alternative methods to check leak tightness. The two methods are described in 5.8.2.1 and

5.8.2.2.

5.8.2 Testing

5.8.2.1 Pressure decay test

5.8.2.1.1 Material and Equipment

— manometer, capable of reading in the range 0 Pa to 500 Pa with an accuracy of ± 5 Pa

— plates to seal opening as needed (provided by the manufacturer).

5.8.2.1.2 Test procedure

The BSC is tested for leakage by subjecting it to an internal pressure.

— seal all openings in the cabinet by any convenient means. The sash can be removed

— attach a manometer to the test area to indicate the internal pressure relative to the room

— pressurize the cabinet to 250 Pa + 20 Pa

— turn off the pressurizing air and measure the internal pressure after 1 min.

5.8.2.2 Constant pressure test

5.8.2.2.1 Material and Equipment

— a volumetric flow meter with an accuracy of 0,1 times the expected leakage rate. Example for class

−1 −3

4 as per Table 2 the accuracy is 0,1 ∙ 1,67 l ∙ min ∙ m

— manometer, capable of reading in the range 0 Pa to 500 Pa. With an accuracy of ± 5 Pa

— plates to seal any opening as needed (provided by the manufacturer).

5.8.2.2.2 Test procedure

— seal all openings in the cabinet by any convenient means

— attach a manometer to the test area to indicate the interior pressure

— pressurize the cabinet to an internal positive pressure of 250 Pa + 20 Pa.

The volumetric flow meter is installed in the hose via which the test air is fed into the cabinet (positive

pressure test). For air feed, a very finely controllable positive pressure connection is required. The

introduced flow rate is regulated in order to maintain the positive pressure at its specific value. This flow

rate divided by the net volume of the cabinet corresponds to the hourly leak rate.

To avoid the effect of atmospheric pressure and temperature changes, the measurement shall be less than

10 min long.

5.8.2.3 Acceptance criteria

The leak tightness shall not be less than class 4 according to EN ISO 14644-7:2004, Table E.1 (see

Table 2).

Table 2 — Comparison of classification of containment enclosures according to their hourly

leakage rate and pressure loss

Class Hourly leak rate Calculated pressure Calculated leakage

a rate per 1 m volume

loss per minute

of the cabinet

R Δp R

h V

Pa

-1 l/min

h

−4 −3

1 ≤ 5 ⋅ 10 0,84 8,3 ⋅ 10

−3

2 < 2,5 ⋅ 10 4,2 0,041

−2

3 < 10 16,9 0,167

−1

4 < 10 168,9 1,67

a

at atmospheric pressure (101 325 Pa).

NOTE The calculation is based on requirements of EN ISO 14644-7:2004, Table E.1

5.9 Filter system

5.9.1 General

The filter system shall be in accordance with EN 12469-1:2025.

5.9.2 Liquid protection test

The liquid protection test shall be in accordance with EN 12469-1:2025.

5.10 Alarm indicators and alarms

5.10.1 Alarm indicators

The alarm indicators for type test shall be in accordance with EN 12469-1:2025.

5.10.2 Alarms

For class II BSC the critical parameters for alarms are:

— downflow: low and high alarm

— inflow: low and high alarm

— sash not in working position.

Check if audible and visual alarms are working correctly.

5.11 Gas supply

If installed, the gas supply shall comply with the requirements of EN 12469-1:2025.

5.12 Electrical safety

The electrical safety shall be in accordance with EN 12469-1:2025.

5.13 Stop / start of BSC

The stop / start shall be in accordance with EN 12469-1:2025.

5.14 Connection to exhaust systems

If the BSC is connected to an exhaust system, it shall be in accordance with EN 12469-1:2025.

5.15 Cleanability

The cleanability shall be in accordance with EN 12469-1:2025.

5.16 Decontaminability

The decontaminability shall be in accordance with EN 12469-1:2025.

5.17 Spillage tray

The spillage tray shall be in accordance with EN 12469-1:2025.

5.18 Intake grille

The design should ensure that the intake grill cannot be obstructed by operator's arms.

The delivery area for the air to the working space should be without interposed projections or cavities

that could interfere with containment performance.

6 Airflow velocities

6.1 General

The target values for airflow velocities, as specified by the manufacturer, are essential to ensure

comprehensive protection for the operator, environment, product, and against cross-contamination.

These four types of protection are detailed in Annex A (A.1), Annex B, and Annex C.

Achieving the correct balance between downflow and inflow velocities is critical to maintaining the

protective functions that a class II BSC offers.

Proper calibration and adherence to these specified airflow velocities are fundamental to the effective

operation and safety of the BSC.

6.2 Downflow

6.2.1 General

The downflow velocity specified by the manufacturer shall ensure that the intended protection function

of the BSC is met. The manufacturer’s specification shall be noted on the data plate of the BSC.

6.2.2 Testing

6.2.2.1 Material and equipment

For airflow velocity measurements an anemometer with the specifications given in Table 3 shall be used.

Table 3 — Specification of anemometers

Item Minimum requirements

Resolution 0,01 m/s (0 m/s to 1,00 m/s)

Accuracy ±(0,02 m/s + 5 % of reading) (0,20 m/s to 1,00 m/s)

For downflow velocities < 0,2 m/s, the manufacturer shall specify the appropriate measurement

methods and device specifications. Accuracy shall be at least 5 % of reading.

6.2.2.2 Test procedure

The below description, including Figure 1, specifies the minimum number of measuring points. An

alternative measuring grid may be used as long as the minimum number of measuring points is more

than described and the points are evenly distributed over the work surface.

The measuring probe of the anemometer shall not be hand-held during downflow measurements.

The measurements shall be done in a horizontal plane at 10 cm above the bottom edge of the sash in its

normal operating position.

The measurement and recording of the individual velocity component shall be performed perpendicular

to the airflow at regular intervals of 1,0 s or less over a period of at least 10 s.

This plane shall be divided in equal areas to be specified by the manufacturer with a maximum of

30 × 30 cm for each area.

The measuring points shall be at the centre of each area.

Key

Measuring Point (MP)

H 10 cm

F – B Front to Back (inner side of the window to inner back wall at a height of 10 cm)

S – S Side to Side (side wall to side wall)

X and Y ≤ 30 cm, maximum area width/depth (=maximum distance between measuring points)

X’ and Y’ X' = X / 2 and Y' = Y/2

Figure 1 — Grid for downflow velocity

An example of a downflow velocity measuring grid for a typical 180 cm BSC is given in Figure 2.

Dimensions in centimetres

Key

Measuring Point (MP)

Maximum spacing between measuring points 30 cm

F-B (Front to Back)

F – B 55,0 cm

Measuring Exact no. of MP's = (Distance F-B) / (Max distance between MP's) 1,8

Points

MP's round up = (Exact no. of MP's) rounded up 2

Y Distance between MP's = (Distance F-B) / (MP's Round up) 27,5 cm

Y’ Distance of the first and last MP (from Front and Back) = Y / 2 13,8 cm

S - S (side wall to side wall)

S - S 177,0 cm

MP's Exact = (Distance S-S) / (Max distance between readings) 5,9

Rounded up = (Exact no. of MP's) rounded up 6

X Distance between MP's = (Distance s-s) / (MP's Round up) 29,5 cm

X' First and last MP (from Side walls) = X / 2 14,8 cm

Figure 2 — Grid for downflow velocity – example

6.2.2.3 Expression of results

Velocity values shall be expressed in two decimal places.

Calculate by Formula (1) the average value v of the recorded velocities at each point in m/s. Round the

result to two decimal places:

1 n

(1)

vv=

∑

dfl i

i=1

n

where

n is the number of measurement points;

is the average downflow velocity in m/s;

v

dfl

is the recorded velocity at each point in m/s.

v

i

6.2.2.4 Acceptance criteria

Average value for the downflow velocity of the cabinet shall be in accordance with the manufacturer’s

specification (including tolerance value). All individual readings shall be within ± 20 % from the average

value.

6.3 Inflow

6.3.1 General

The inflow method specified by the manufacturer shall ensure that the intended protection functions of

the BSC are met and shall be described in the operating manual.

6.3.2 Testing

6.3.2.1 General

At least one of the following methods shall be used as a reference.

— measuring the air volume rate using an airflow capture hood at the front aperture

— measuring the air volume rate using an airflow capture hood at the exhaust

— velocity measurement at the reduced front aperture using an anemometer.

If alternate methods are used and described by the manufacturer they should correlate with one of the

above methods.

If a correction factor for the correlation of different methods is necessary, it shall be provided by the

manufacturer. This information shall be described in the manual and stated on the data plate.

6.3.2.2 Material and equipment

If an airflow capture hood is used, it shall meet the requirements specified in Table 4.

Table 4 — Specifications of airflow capture hood

Item Minimum requirements

Resolution 3

≤ 1 m /h

Maximum permissible error ±3 % of reading

3 3

±12 m /h at flows > 85 m /h

For airflow velocity measurements unidirectional thermal type, vane type or equivalent anemometers

according to Table 5 may be used.

Table 5 — Specifications of anemometers

Item Minimum requirements

Resolution 0,01 m/s (0,20 to 1,0 m/s)

0,1 m/s (>1,00 m/s)

Accuracy ±(0,02 m/s + 5 % of reading) (0,20 m/s to 1,00 m/s)

10 % of reading (>1,00 m/s)

6.3.2.3 Test procedure

6.3.2.3.1 Measurement at the front aperture with airflow capture hood

Follow the steps below in the order presented.

— place the device at the centre of the front aperture

— seal off open areas on the sides to take the entire volume flow into account during measurement

— take at least 5 non back pressure compensated readings and calculate the average.

Calculate the inflow velocity (m/s) by dividing the average inflow volume rate measured, by the area of

the front aperture (m ).

6.3.2.3.2 Measurement at the exhaust with airflow capture hood

Follow the steps below in the order presented.

— place the device over the BSC’s exhaust opening

— seal off open areas on the sides to take the entire volume flow into account during measurement

— take at least 5 non back pressure compensated readings and calculate the average.

Calculate the inflow velocity (m/s) by dividing the average exhaust volume measured, by the area of the

front aperture (m ).

6.3.2.3.3 Velocity measurement at a reduced front aperture

Follow the steps below in the order presented

— reduce the working aperture height according to the manufacture’s specification. The measuring line

is in the middle of the front aperture if not specified otherwise

— the measurement probe shall be positioned securely so that accurate and repeatable readings can be

taken

— measurements shall be taken at several points across the reduced front aperture:

The measuring line shall be divided into even sections as specified by the manufacturer, but with a

maximum of 20 cm between each measuring point, and with the side sections being half of the other

sections. See measuring grid in Figure 3.

Key

measuring Point (MP)

H height of the reduceded front aperture

H’ H/2, distance to the centre of the (reduced) front aperture

X maximum of 20 cm between the measuring points

X’ X/2, distance from the side walls to the first and last measuring point

‘S - S side wall to side wall

Figure 3 — Grid for inflow velocity test - reduced front aperture

An example of inflow velocity measuring points for a typical 180 cm BSC is shown in Figure 4.

Dimensions in centimetres

Key

measuring point (MP)

H height of the reduced front aperture (y) 11,0 cm

H’ centre line (H / 2) 5,5 cm

measuring points along the centre line

S – S 180,0 cm

MP’s exact = (Distance S-S) / (Max distance between readings) 9,0

rounded up = (Exact no. of MP's) rounded up 9

X distance between MP's = (Distance s-s) / (MP's Round up) 20,0 cm

X’ first and last MP (from Side walls) = X / 2 10 cm

Figure 4 — Grid for inflow velocity test – reduced front aperture - example

6.3.2.3.4 Calculation of result

When a flow volume is measured, calculate the inflow velocity (m/s) by dividing the average air volume

rate by the normal working aperture area using Formula (2)

q

v = (2)

ifl

A

N

where

is the average inflow velocity in m/s;

v

ifl

q

is the average air volume rate in m /s;

A 2

N is the normal working aperture area in m .

When a velocity with the reduced front aperture is measured, divide the area of the reduced front

aperture by the normal front aperture area and multiply by the average measured velocity using

Formula (3)

A

c

vv⋅ (3)

ifl c

A

N

where

=

v is the inflow velocity in m/s;

ifl

A 2

N is the normal front aperture area in m ;

A is the area of the reduced front aperture;

C

is the average measured velocity with reduced front aperture in m/s.

v

C

6.3.2.3.5 Expression of results

All individual measured values, a used correction factor given by the manufacturer (if used), the used

calculation and the result shall be reported.

6.3.2.3.6 Acceptance criteria

The average value for the inflow velocity shall be set according to the manufactures specified nominal set

point. The manufacturer should state the acceptance limits or the range (e.g. + or – value).

6.3.3 Alternative test methods

Test methods not described by the manufacturer may be used if a validated correlation with these test

methods has been demonstrated.

6.4 Visualization of airflows

6.4.1 General

Airflows around the installed BSC and in the front aperture should not be disturbed, e.g. by the room

make-up air, in a way that could negatively affect the performance of the BSC.

The visualization of the airflow shall be performed with generation of visible tracers, in front of the

working aperture.

6.4.2 Material and equipment

The aerosols for testing should be harmless to humans and to the environment (no sulphuric acid mist).

The density of the tracer shall be close to the room air density. The test shall be performed according to

the manufacturer’s specification.

6.4.3 Procedure

6.4.3.1 Downflow

6.4.3.1.1 Test procedure

Airflow within the working area of the cabinet shall be visualized at a height of 100 mm above the front

aperture

6.4.3.1.2 Acceptance criteria

The airflow should be directed downward at each point.

6.4.3.2 Inflow

6.4.3.2.1 Test procedure

The tracer shall be emitted at a distance of 5 cm in front of and over the entire front opening.

6.4.3.2.2 Acceptance criteria

The airflow around the front aperture shall be directed inward, without any reflux out of the cabinet or

penetration over the work surface.

6.4.3.3 Reflux

6.4.3.3.1 Test procedure

The tracer shall be released 15 cm below the downflow filter of the designated working area in a line

inside the designated working area with a distance of 5 cm behind the sash.

6.4.3.3.2 Acceptance criteria

The test should indicate airflow is even and downward.

6.4.4 Documentation

The observations should be documented.

7 Protective functions

7.1 General

A BSC class II shall provide operator, product and cross-contamination protection.

Appropriate procedures for testing the protective functions are described in the Annex A, Annex B and

Annex C. Any other test methods may be used provided a validated correlation is established with this

test method.

7.2 Operator protection

7.2.1 General

To ensure operator protection in a Biological Safety Cabinet (BSC), it is crucial to prevent the transfer of

hazardous or potentially hazardous biological agents from the inner space of the BSC to the outside. This

can be achieved through the following measures:

— stable and Effective Airflows: The airflow within the BSC shall be controlled to ensure that

contaminants are contained and directed appropriately. Downflow velocity and inflow velocity shall

be balanced correctly to ensure a stable airflow barrier at the front aperture of the BSC.

— HEPA Filtration of the Exhaust Air: High-Efficiency Particulate Air (HEPA) filters should be used to

filter the exhaust air, removing biological agents from the air before it is released outside the BSC.

— defined Leak Tightness of the Carcass: The structure of the BSC should be leak-tight, ensuri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...