ISO/IEC 16382:2000

(Main)Information technology — Data interchange on 12,7 mm 208-track magnetic tape cartridges — DLT 6 format

Information technology — Data interchange on 12,7 mm 208-track magnetic tape cartridges — DLT 6 format

This International Standard specifies the physical and magnetic characteristics of a 12,7 mm wide, 208-track magnetic tape cartridge, to enable physical interchangeability of such cartridges between drives. It also specifies the quality of the recorded signals, a format - called Digital Linear Tape 6 (DLT 6) - and a recording method, thereby allowing data interchange between drives. Together with a labelling standard, for instance International Standard ISO 1001 for Magnetic Tape Labelling, it allows full data interchange by means of such magnetic tape cartridges.

Technologies de l'information — Échange de données sur cartouches de bande magnétique de 12,7 mm à 208 pistes — Format DLT 6

General Information

- Status

- Published

- Publication Date

- 17-May-2000

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 21-Aug-2020

- Completion Date

- 14-Feb-2026

Overview

ISO/IEC 16382:2000 defines the Digital Linear Tape 6 (DLT 6) format for 12.7 mm (0.5 in) wide, 208‑track magnetic tape cartridges. The standard specifies the physical, mechanical and magnetic characteristics of the cartridge and tape to ensure physical interchangeability between drives, plus the recorded‑signal quality, data format, and a recording method to enable reliable data interchange. Used together with labelling rules (for example ISO 1001), ISO/IEC 16382 allows full interchange of DLT 6 cartridges between compliant drive systems.

Key topics and technical requirements

- Physical media: cartridge and tape geometry, tape width (12.7 mm), reel, leader, and cartridge mechanical tolerances to ensure reliable loading and transport.

- Magnetic recording characteristics: definitions of physical recording density (example: reference density shown in the standard), flux transition spacing, average signal amplitude and overwrite/peak‑shift requirements.

- Track and format structure: 208 physical tracks organized into logical tracks, channel bit‑cell lengths, calibration and directory areas, guard areas, data area layout and direction of recording.

- Data format and error control: block, entity and envelope structures; preamble/sync/data/EDC/CRC/CF fields; use of CRC, EDC, and ECC for error detection and correction.

- Conformance and interoperability: requirements for generating systems (compression algorithm registration per ISO/IEC 11576) and receiving systems to handle any compliant recording.

- Reference tapes and calibration: Master and Secondary Standard Reference Tapes (Master established by Quantum Corporation), Standard Reference Amplitude (SRA), test recording current definitions, and calibration procedures.

- Environment, safety and handling: operating/storage conditions, tape durability, abrasion, friction, and handling/transport recommendations (annexes include measurement and test procedures).

Applications and who uses this standard

ISO/IEC 16382 is relevant to:

- Tape drive and media manufacturers ensuring physical and electrical compatibility for DLT 6 cartridges.

- Data centers, backup and archival operations deploying DLT media for long‑term storage and interchange.

- Hardware and firmware developers implementing read/write, calibration, error‑correction and compression/decompression features.

- Test laboratories and quality assurance teams performing media qualification, conformance testing and tape calibration.

- Archivists and IT procurement specifying interoperable tape media and drives for vendor neutrality and data preservation.

Key search terms: ISO/IEC 16382, DLT 6, 12.7 mm magnetic tape, 208‑track cartridge, data interchange, tape format, magnetic recording standard.

Related standards

- ISO 1001 - Magnetic tape labelling (recommended for full interchange).

- ISO/IEC 11576 - Registration procedure for lossless compression algorithms (referenced for compression ID requirements).

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

NYCE

Mexican standards and certification body.

Sponsored listings

Frequently Asked Questions

ISO/IEC 16382:2000 is a standard published by the International Organization for Standardization (ISO). Its full title is "Information technology — Data interchange on 12,7 mm 208-track magnetic tape cartridges — DLT 6 format". This standard covers: This International Standard specifies the physical and magnetic characteristics of a 12,7 mm wide, 208-track magnetic tape cartridge, to enable physical interchangeability of such cartridges between drives. It also specifies the quality of the recorded signals, a format - called Digital Linear Tape 6 (DLT 6) - and a recording method, thereby allowing data interchange between drives. Together with a labelling standard, for instance International Standard ISO 1001 for Magnetic Tape Labelling, it allows full data interchange by means of such magnetic tape cartridges.

This International Standard specifies the physical and magnetic characteristics of a 12,7 mm wide, 208-track magnetic tape cartridge, to enable physical interchangeability of such cartridges between drives. It also specifies the quality of the recorded signals, a format - called Digital Linear Tape 6 (DLT 6) - and a recording method, thereby allowing data interchange between drives. Together with a labelling standard, for instance International Standard ISO 1001 for Magnetic Tape Labelling, it allows full data interchange by means of such magnetic tape cartridges.

ISO/IEC 16382:2000 is classified under the following ICS (International Classification for Standards) categories: 35.220.23 - Cassettes and cartridges for magnetic tapes. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/IEC 16382:2000 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO/IEC

STANDARD 16382

First edition

2000-05-15

Information technology — Data

interchange on 12,7 mm 208-track

magnetic tape cartridges — DLT 6 format

Technologies de l'information — Échange de données sur cartouches

de bande magnétique de 12,7 mm à 208 pistes — Format DLT 6

Reference number

©

ISO/IEC 2000

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this

file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this

area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO/IEC 2000

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 � CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 734 10 79

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

ii © ISO/IEC 2000 – All rights reserved

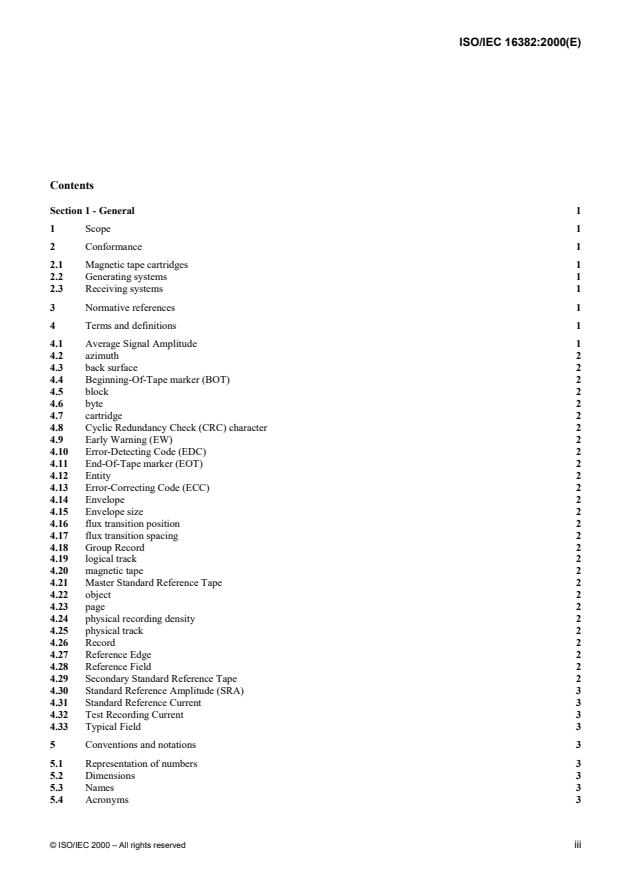

Contents

Section 1 - General 1

1 Scope 1

2 Conformance 1

2.1 Magnetic tape cartridges 1

2.2 Generating systems 1

2.3 Receiving systems 1

3 Normative references 1

4 Terms and definitions 1

4.1 Average Signal Amplitude 1

4.2 azimuth 2

4.3 back surface 2

4.4 Beginning-Of-Tape marker (BOT) 2

4.5 block 2

4.6 byte 2

4.7 cartridge 2

4.8 Cyclic Redundancy Check (CRC) character 2

4.9 Early Warning (EW) 2

4.10 Error-Detecting Code (EDC) 2

4.11 End-Of-Tape marker (EOT) 2

4.12 Entity 2

4.13 Error-Correcting Code (ECC) 2

4.14 Envelope 2

4.15 Envelope size 2

4.16 flux transition position 2

4.17 flux transition spacing 2

4.18 Group Record 2

4.19 logical track 2

4.20 magnetic tape 2

4.21 Master Standard Reference Tape 2

4.22 object 2

4.23 page 2

4.24 physical recording density 2

4.25 physical track 2

4.26 Record 2

4.27 Reference Edge 2

4.28 Reference Field 2

4.29 Secondary Standard Reference Tape 2

4.30 Standard Reference Amplitude (SRA) 3

4.31 Standard Reference Current 3

4.32 Test Recording Current 3

4.33 Typical Field 3

5 Conventions and notations 3

5.1 Representation of numbers 3

5.2 Dimensions 3

5.3 Names 3

5.4 Acronyms 3

© ISO/IEC 2000 – All rights reserved iii

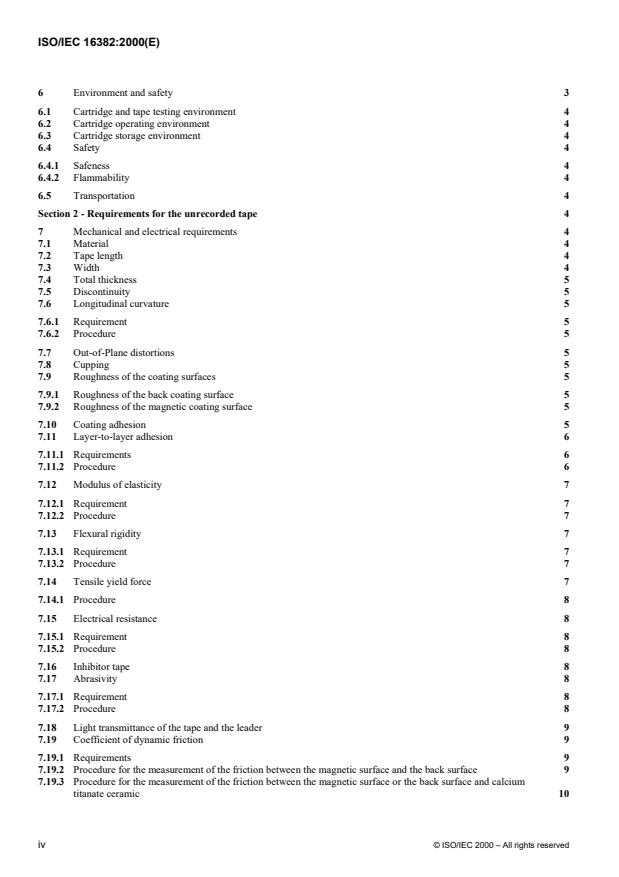

6 Environment and safety 3

6.1 Cartridge and tape testing environment 4

6.2 Cartridge operating environment 4

6.3 Cartridge storage environment 4

6.4 Safety 4

6.4.1 Safeness 4

6.4.2 Flammability 4

6.5 Transportation 4

Section 2 - Requirements for the unrecorded tape 4

7 Mechanical and electrical requirements 4

7.1 Material 4

7.2 Tape length 4

7.3 Width 4

7.4 Total thickness 5

7.5 Discontinuity 5

7.6 Longitudinal curvature 5

7.6.1 Requirement 5

7.6.2 Procedure 5

7.7 Out-of-Plane distortions 5

7.8 Cupping 5

7.9 Roughness of the coating surfaces 5

7.9.1 Roughness of the back coating surface 5

7.9.2 Roughness of the magnetic coating surface 5

7.10 Coating adhesion 5

7.11 Layer-to-layer adhesion 6

7.11.1 Requirements 6

7.11.2 Procedure 6

7.12 Modulus of elasticity 7

7.12.1 Requirement 7

7.12.2 Procedure 7

7.13 Flexural rigidity 7

7.13.1 Requirement 7

7.13.2 Procedure 7

7.14 Tensile yield force 7

7.14.1 Procedure 8

7.15 Electrical resistance 8

7.15.1 Requirement 8

7.15.2 Procedure 8

7.16 Inhibitor tape 8

7.17 Abrasivity 8

7.17.1 Requirement 8

7.17.2 Procedure 8

7.18 Light transmittance of the tape and the leader 9

7.19 Coefficient of dynamic friction 9

7.19.1 Requirements 9

7.19.2 Procedure for the measurement of the friction between the magnetic surface and the back surface 9

7.19.3 Procedure for the measurement of the friction between the magnetic surface or the back surface and calcium

titanate ceramic 10

iv © ISO/IEC 2000 – All rights reserved

8 Magnetic recording characteristics 10

8.1 Typical Field 10

8.2 Signal amplitude 11

8.3 Resolution 11

8.4 Overwrite 11

8.4.1 Requirement 11

8.5 Peak shift 11

8.5.1 Requirement 11

8.5.2 Procedure 11

9 Tape quality 12

9.1 Missing pulses 12

9.1.1 Requirement 12

9.2 Missing pulse zone 12

9.2.1 Requirement 12

9.3 Tape durability 12

Section 3 - Mechanical specifications of the tape cartridge 12

10 General 12

10.1 Bottom side and right side 13

10.2 Back side and left side 14

10.3 Tape reel 14

10.4 Tape leader 15

10.5 Front side 16

10.6 Operation of the cartridge 16

10.7 Tape winding 17

10.8 Moment of inertia 17

10.9 Material 18

Section 4 - Requirements for an interchanged tape 27

11 Method of recording 27

11.1 Physical recording density 27

11.2 Channel bit cell length 27

11.2.1 Average Channel bit cell length 27

11.2.2 Long-term average Channel bit cell length 27

11.2.3 Short-term average Channel bit cell length 27

11.3 Flux transition spacing 27

11.4 Read signal amplitude 27

11.5 Azimuth 28

11.6 Channel skew 28

12 Tape format 28

12.1 Reference Edge 28

12.2 Direction of recording 28

12.3 Tape layout 28

12.4 Calibration and Directory Area 28

12.4.1 Scratch Area 29

12.4.2 Guard Area G1 29

12.4.3 Calibration Tracks Area 29

12.4.4 Guard Area G2 30

12.4.5 Directory Area 30

12.4.6 Guard Area G3 30

12.5 Data Area 30

12.5.1 Physical tracks 31

12.5.2 Logical tracks 32

© ISO/IEC 2000 – All rights reserved v

13 Data format 34

13.1 Data Bytes 34

13.2 Data Blocks 34

13.3 Types of Blocks 34

13.4 Entities 34

13.5 Envelopes 34

13.6 Block format 34

13.6.1 Preamble 35

13.6.2 Sync 35

13.6.3 Data Field 35

13.6.4 EDC 36

13.6.5 Control Field 1 (CF1) 37

13.6.6 Control Field 2 (CF2) 38

13.6.7 CRC 39

13.6.8 Postamble 39

14 Use of blocks 39

14.1 Data Blocks 39

14.2 Filler Blocks 39

14.3 End of Track Blocks (EOTR) 39

14.4 End of Data Blocks (EOD) 40

14.5 ECC Blocks 40

15 Format of Entities 40

16 Format of Envelopes 40

17 Error handling 40

Annexes

A - Measurement of light transmittance 41

B - Generation of the Data Block CRCs 44

C - ECC generation 45

D - Generation of page CRCs 48

E - Format of MAP entries 49

F - Format of Control Field 1 50

G - Format of Control Field 2 51

H - Recommendations for transportation 52

J - Inhibitor tape 53

K - Recommendations on tape durability 54

L - Handling guidelines 55

vi © ISO/IEC 2000 – All rights reserved

Foreword

ISO (the International Organization for Standardization) and IEC (the International Electrotechnical Commission) form the

specialized system for worldwide standardization. National bodies that are members of ISO or IEC participate in the

development of International Standards through technical committees established by the respective organization to deal with

particular fields of technical activity. ISO and IEC technical committees collaborate in fields of mutual interest. Other

international organizations, governmental and non-governmental, in liaison with ISO and IEC, also take part in the work.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

In the field of information technology, ISO and IEC have established a joint technical committee, ISO/IEC JTC 1. Draft

International Standards adopted by the joint technical committee are circulated to national bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the national bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this International Standard may be the subject of patent rights.

ISO and IEC shall not be held responsible for identifying any or all such patent rights.

This International Standard was prepared by ECMA (as Standard ECMA-286) and was adopted, under a special “fast-track

procedure”, by Joint Technical Committee ISO/IEC JTC 1, Information technology, in parallel with its approval by national

bodies of ISO and IEC.

Annexes A to G form a normative part of this International Standard. Annexes H to L are for information only.

© ISO/IEC 2000 – All rights reserved vii

INTERNATIONAL STANDARD ISO/IEC 16382:2000(E)

Information technology — Data interchange on 12,7 mm 208-track magnetic tape

cartridges — DLT 6 format

Section 1 - General

1Scope

This International Standard specifies the physical and magnetic characteristics of a 12,7 mm wide, 208-track magnetic tape

cartridge, to enable physical interchangeability of such cartridges between drives. It also specifies the quality of the recorded

signals, a format - called Digital Linear Tape 6 (DLT 6) - and a recording method, thereby allowing data interchange between

drives. Together with a labelling standard, for instance International Standard ISO 1001 for Magnetic Tape Labelling, it allows

full data interchange by means of such magnetic tape cartridges.

2 Conformance

2.1 Magnetic tape cartridges

A magnetic tape cartridge shall be in conformance with this International Standard if it satisfies all mandatory requirements of

this Standard. The tape requirements shall be satisfied throughout the extent of the tape.

2.2 Generating systems

A system generating a magnetic tape cartridge for interchange shall be in conformance with this International Standard if all

the recordings that it makes on a tape according to 2.1 meet the mandatory requirements of this International Standard.

In addition, a claim of conformance shall state

— whether or not one, or more registered algorithm(s) are implemented within the system, and are able to compress data

received from the host prior to collecting the data into blocks, and

— the registered identification number(s) of the implemented compression algorithm(s).

2.3 Receiving systems

A system receiving a magnetic tape cartridge for interchange shall be in conformance with this International Standard if it is

able to handle any recording made on a tape according to 2.1.

In addition, it shall

— whether or not one, or more de-compression algorithm(s) are implemented within the system, and are able to be applied to

de-compress data prior to making such data available to the host,

— the registered identification number(s) of the implemented compression algorithm(s).

3 Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this

International Standard. For dated references, subsequent amendments to, or revisions of, any of these publications do not

apply. However, parties to agreements based on this International Standard are encouraged to investigate the possibility of

applying the most recent editions of the normative documents indicated below. For undated references, the latest edition of the

normative document referred to applies. Members of ISO and IEC maintain registers of currently valid International Standards.

ISO 1001:1986, Information processing — File structure and labelling of magnetic tapes for information interchange.

ISO 1302:1992, Technical drawings — Method of indicating surface texture.

ISO/IEC 11576:1994, Information technology — Procedure for the registration of algorithms for the lossless compression of

data.

4 Terms and definitions

For the purposes of this International Standard, the following terms and definitions apply.

4.1 Average Signal Amplitude: The average peak-to-peak value of the output signal from the read head at the physical

recording density of 2 578 ftpmm measured over a minimum length of track of 25,4 mm, exclusive of missing pulses.

© ISO/IEC 2000 – All rights reserved 1

4.2 azimuth: The angular deviation, in degrees of arc, of the mean flux transition line of the recording made on a track

fromalinenormaltothe ReferenceEdge.

4.3 back surface: The surface of the tape opposite the magnetic coating which is used to record data.

4.4 Beginning-Of-Tape marker (BOT): A hole punched on the centreline of the tape towards the end nearest to the

leader.

4.5 block: A set of contiguous bytes recorded on a physical track and considered as a unit.

4.6 byte: An ordered set of bits acted upon as a unit.

NOTE - In this International Standard, all bytes are 8-bit bytes.

4.7 cartridge: A case containing a single supply reel of 12,7 mm wide magnetic tape with a leader attached at the outer

end.

4.8 Cyclic Redundancy Check (CRC) character: A 64-bit character, generated by a mathematical computation,

used for error detection.

4.9 Early Warning (EW): A signal generated by the drive indicating the approaching end of the recording area.

4.10 Error-Detecting Code (EDC): A mathematical computation yielding check bytes used for error detection.

4.11 End-Of-Tape marker (EOT): A hole punched on the centreline of the tape towards the end farthest from the

leader.

4.12 Entity: A group of twenty blocks treated as a logical unit and recorded on a logical track, except Filler Blocks, if any.

4.13 Error-Correcting Code (ECC): A mathematical computation yielding check bytes used for the correction of

errors detected by the CRC and the EDC.

4.14 Envelope: A group of Entities.

4.15 Envelope size: The number of Entities in an Envelope.

4.16 flux transition position: The point which exhibits the maximum free-space flux density normal to the tape surface.

4.17 flux transition spacing: The distance on the magnetic tape between successive flux transitions.

4.18 Group Record: A Record consisting of a series of Records of equal size.

4.19 logical track: A group of four physical tracks that are written or read simultaneously.

4.20 magnetic tape: A tape that accepts and retains magnetic signals intended for input, output, and storage purposes on

computers and associated equipment.

4.21 Master Standard Reference Tape: A tape selected as the standard for Reference Field, signal amplitude,

resolution, peakshift, and overwrite characteristics.

NOTE - The Master Standard Reference Tape has been established by the Quantum Corporation.

4.22 object: A Record or a page of type Tape Mark.

4.23 page: A logical division of a block.

4.24 physical recording density: The number of recorded flux transitions per unit length of track, expressed in flux

transitions per millimetre (ftpmm).

4.25 physical track: A longitudinal area on the tape along which a series of magnetic signals can be recorded.

4.26 Record: A collection of User Bytes, the number of which is determined by the host.

4.27 Reference Edge: The bottom edge of the tape when viewing the magnetic coating of the tape with the BOT to the

left and the EOT to the right of the observer.

4.28 Reference Field: The Typical Field of the Master Standard Reference Tape.

4.29 Secondary Standard Reference Tape: A tape the characteristics of which are known and stated in relation to

those of the Master Standard Reference Tape.

NOTE - Secondary Standard Reference Tapes can be ordered under Reference "SSRT/DLT4"from Quantum Corporation, 333 South Street,

Shrewsbury, Mass. 01545-4195, USA. It is intended that these be used for calibrating tertiary reference tapes for routine calibration.

In principle, these Secondary Standard Reference Tapes will be available for a period of 10 years from the publication of the first version of

this International Standard. However, by agreement between ECMA and Quantum Corporation, this period may be changed to take into

account the demand for such Secondary Standard Reference Tapes.

2 © ISO/IEC 2000 – All rights reserved

4.30 Standard Reference Amplitude (SRA): The Average Signal Amplitude from the Master Standard Reference

Tape when it is recorded with the Test Recording Current at 2 578 ftpmm.

4.31 Standard Reference Current: The current that produces the Reference Field.

4.32 Test Recording Current: The current that is 1,1 times the Standard Reference Current.

4.33 Typical Field: In the plot of the Average Signal Amplitude against the recording field at the physical recording

density of 2 578 ftpmm, the minimum field that causes an Average Signal Amplitude equal to 95 % of the maximum

Average Signal Amplitude.

5 Conventions and notations

5.1 Representation of numbers

The following conventions and notations apply in this International Standard, unless otherwise stated.

— A measured value is rounded off to the least significant digit of the corresponding specified value. It implies that a

specified value of 1,26 with a positive tolerance +0,01, and a negative tolerance -0,02 allows a range of measured values

from 1,235 to 1,275.

— In each block and in each field the bytes shall be arranged with Byte 1, the least significant, first. Within each byte the bits

shall be arranged with Bit 1, the least significant, first and Bit 8, the most significant bit, last. This order applies to the

data, and to the input and output of the error-detecting and error-correcting codes, and to the cyclic redundancy characters.

— Letters and digits in parentheses represent numbers in hexadecimal notation.

— The setting of bits is denoted by ZERO or ONE.

— Numbers in binary notation and bit patterns are represented by strings of 0 and 1 shown with the most significant bit to

the left.

5.2 Dimensions

The dimensions in figures 1 to 4 are nominal dimensions. Unless otherwise stated, all dimensions in figures 8 to 24 are in

millimetres with a tolerance of� 50 mm.

5.3 Names

The names of basic elements, e.g. specific fields, are written with a capital initial letter.

5.4 Acronyms

BOT Beginning of Tape

CF1 Control Field 1

CF2 Control Field 2

CRC Cyclic Redundancy Check (character)

CT1 Calibration Track 1

CT2 Calibration Track 2

ECC Error-Correcting Code

EDC Error-Detecting Code

EOD End of Data

EOT End of Tape

EOTR End of Track

EW Early Warning

RLL Run Length Limited

SRA Standard Reference Amplitude

6 Environment and safety

Unless otherwise stated, the conditions specified below refer to the ambient conditions in the test or computer room and not to

those within the tape drive.

© ISO/IEC 2000 – All rights reserved 3

6.1 Cartridge and tape testing environment

Unless otherwise stated, tests and measurements made on the cartridge and tape to check the requirements of this International

Standard shall be carried out under the following conditions:

— temperature: 23 °C� 2 °C

— relative humidity: 40 % to 60 %

— conditioning before testing: 24 h min.

6.2 Cartridge operating environment

Cartridges used for data interchange shall be capable of operating under the following conditions:

— temperature: 10 °Cto 40 °C

— relative humidity: 20 % to 80 %

— wet bulb temperature: 25 °Cmax.

NOTE - Localized tape temperatures in excess of 49 °C may cause tape damage.

If during storage and/or transportation a cartridge has been exposed to conditions outside the above values, it shall be

conditioned before use by exposure to the operating environment for a time equal to, or greater than, the time away from the

operating environment up to a maximum of 24 h. There shall be no deposit of moisture on or in the cartridge.

6.3 Cartridge storage environment

Cartridges shall be stored under the following conditions:

— temperature: 16 °Cto 32 °C

— relative humidity: 20 % to 80 %

The stray magnetic field at any point on the tape shall not exceed 4000 A/m. There shall be no deposit of moisture on or in the

cartridge.

6.4 Safety

6.4.1 Safeness

The cartridge and its components shall not constitute any safety or health hazard when used in the intended manner, or through

any foreseeable misuse in an information processing system.

6.4.2 Flammability

The cartridge and its components shall be made from materials which, if ignited from a match flame, and when so ignited do

not continue to burn in a still carbon dioxide atmosphere.

6.5 Transportation

This International Standard does not specify parameters for the environment in which cartridges should be transported. Annex

H gives some recommendations for transportation.

Section 2 - Requirements for the unrecorded tape

7 Mechanical and electrical requirements

7.1 Material

The tape shall consist of a base material (oriented polyethylene terephthalate film or its equivalent) coated on one surface with

a strong yet flexible layer of ferromagnetic material dispersed in a suitable binder. The back surface of the tape shall be coated

with a non-ferromagnetic conductive coating.

7.2 Tape length

The length of the tape from the leader splice to the hub shall be 557 m�5m.

7.3 Width

The width of the tape shall be 12,649 mm� 0,010 mm.

The width shall be measured across the tape from edge to edge when the tape is under a tension of less than 0,28 N.

4 © ISO/IEC 2000 – All rights reserved

7.4 Total thickness

The total thickness of the magnetic tape at any point shall be between 8,3�mand 9,3�m.

7.5 Discontinuity

There shall be no discontinuities in the tape between the BOT and EOT such as those produced by tape splicing or

perforations.

7.6 Longitudinal curvature

The longitudinal curvature is measured as the departure of the Reference Edge of the tape from a straight line along the

longitudinal dimension of the tape in the plane of the tape surface.

7.6.1 Requirement

Any deviation of the Reference Edge from a straight line shall be continuous and shall not exceed 0,076 mm within any 229

mm length of tape.

7.6.2 Procedure

Measure at a tension of 1,39 N� 0,28 N in a test fixture equipped with two guides spaced at 229 mm. The two guides shall be

spring-loaded to position the Reference Edge of the tape against two edge control surfaces. Measure the maximum deviation of

the Reference Edge of the tape from the line drawn between the two control surfaces.

7.7 Out-of-Plane distortions

All visual evidence of out-of-plane distortion shall be removed when the tape is subjected to a uniform tension of 0,6 N. Out-

of-plane distortions are local deformations which cause portions of the tape to deviate from the plane of the surface of the tape.

Out-of-plane distortions are most readily observed when the tape is lying on a flat surface under no tension.

7.8 Cupping

The departure across the width of the tape from a flat surface shall not exceed 2,54 mm.

Cut a 1,0 m � 0,1 m length of tape. Condition it for a minimum of 3 h in the test environment by hanging it so that both

surfaces are freely exposed to the test environment. From the centre portion of the conditioned tape cut a test piece of

approximately 25 mm length. Stand the test piece on its end in a cylinder which is at least 25 mm high with an inside diameter

of 13,0 mm� 0,2 mm. With the cylinder standing on an optical comparator measure the cupping by aligning the edges of the

test piece to the reticle and determining the distance from the aligned edges to the corresponding surface of the test piece at its

centre.

7.9 Roughness of the coating surfaces

7.9.1 Roughness of the back coating surface

The back coating surface shall have an arithmetic average roughness R between 0,003µm and 0,018µm (ISO 1302:N 2).

a

This measurement shall be made using a contacting stylus of radius 12,5µm with a 20 mg load, and a 254µm cut-off range.

7.9.2 Roughness of the magnetic coating surface

The magnetic coating surface shall have an arithmetic average roughness R between 0,003µm and 0,008µm (ISO 1302: N

a

3). For this measurement, the contacting stylus radius shall be 12,5µm with a 20 mg load, and a 254µm cut-off range.

7.10 Coating adhesion

The force required to peel any part of the coating from the tape base material shall not be less than 0,4 N.

Procedure

i. Take a test piece of the tape approximately 380 mm long and scribe a line through the recording coating across the width

of the tape 125 mm from one end.

ii. Using a double-sided pressure sensitive tape, attach the full width of the test piece to a smooth metal plate, with the

magnetic coating (recording surface) facing the plate, as shown in figure 1.

iii. Fold the test piece over 180°, adjacent to, and parallel with, the scribed line. Attach the metal plate and the free end of the

test piece to the jaws of a universal testing machine and set the speed of the jaw separation to 254 mm per min.

iv. Note the force at which any part of the coating first separates from the base material. If this is less than 0,4 N, the tape has

failed the test. If the test piece peels away from the double-sided pressure sensitive tape before the force exceeds 0,2 N, an

alternative type of double-sided pressure sensitive tape shall be used.

v. Repeat i) to iv) for the back coating.

© ISO/IEC 2000 – All rights reserved 5

Figure 1 — Measurement of the coating adhesion

7.11 Layer-to-layer adhesion

Layer-to-layer adhesion refers to the tendency of a layer, when held in close proximity to the adjacent layer, to bond itself to an

adjacent layer so that free and smooth separation of the layers is difficult.

7.11.1 Requirements

There shall be no evidence of delamination or other damage to the coatings.

7.11.2 Procedure

i. Fasten one end of a 914 mm length of tape, magnetic coating inwards, to a horizontally mounted stainless steel cylinder

with a low cold-flow adhesive material.

ii. The dimensions of the cylinder shall be:

- diameter: 12,7 mm

- length: 102 mm

iii. Attach a mass of 1 000 g to the opposite end of the tape.

iv. Attach, 25,4 mm above the mass, a narrow strip of double-sided adhesive tape to the magnetic coating.

v. Slowly rotate the cylinder, so that the tape winds uniformly around it into a compact and even roll. The double-sided tape

secures the end and prevents unwinding when the mass is removed.

vi. The cylinder with the tape shall then be exposed to the following temperature and humidity cycle:

Time Temperature RH

16 hto18h 54 °C85%

4h 54 °C10%orless

1hto2h 21 °C45%

vii. Open the end of the roll and remove the double-sided adhesive tape.

viii. Release the free end of the tape.

ix. The outer one or two wraps shall spring loose without adhesion.

x. Hold the free end of the tape and allow the cylinder to fall, thereby unwinding the tape.

xi. The tape shall show no coating delamination, except for the 51 mm of tape nearest to the cylinder.

6 © ISO/IEC 2000 – All rights reserved

,

12,7

25,4

strip

1000 g

Figure 2 — Measurement of layer-to-layer adhesion

7.12 Modulus of elasticity

The modulus of elasticity (Young's modulus) is the ratio of stress to strain in the longitudinal direction.

7.12.1 Requirement

2 2

The modulus of elasticity shall be between 4 900 N/mm and11700 N/mm .

7.12.2 Procedure

Clamp a test piece of tape at least 178 mm in length with an initial 102 mm separation between the jaws of a universal testing

machine with a nominal crosshead speed of 3 mm per minute. Calculate the modulus using the chord of the curve between the

force at 0 % and 1 % elongation.

7.13 Flexural rigidity

Flexural rigidity is the ability of the tape to resist bending in the longitudinal direction.

7.13.1 Requirement

-7 -7

The flexural rigidity of the tape in the longitudinal direction shall be between 2 x 10 N�mm and8x10 N�mm.

7.13.2 Procedure

Calculate the flexural rigidity D from the following equation:

Et

D��1 �

��

where:

E = modulus of elasticity obtained from 7.12

t = measured thickness of the tape in mm

� = Poisson's ratio, set to 0,33

7.14 Tensile yield force

The tensile yield force required to elongate the test piece by 3 % shall not be less than 9,6 N.

7.14.1 Procedure

Use a static-weighing-constant-rate-of-grip separation tester capable of indicating the load with an accuracy of 2 %. Clamp a

test piece of tape at least 178 mm long with an initial 102 mm separation between the jaws. Elongate the test piece at a rate of

© ISO/IEC 2000 – All rights reserved 7

51 mm per minute until a minimum elongation of 10 % is reached. The force required to produce an elongation of 3 % is the

tensile yield force.

7.15 Electrical resistance

7.15.1 Requirement

The electrical resistance of any square area of the magnetic coating shall

— be greater than 5 x 10 �

— not exceed 50 x 10 �

The electrical resistance of any square area of the back coating shall

— not exceed 100 x 10 �

7.15.2 Procedure

Condition a test piece of tape in the test environment for 24 h. Position the test piece over two 24-carat gold-plated, semi-

circular electrodes having a radius r = 25,4 mm and a finish of at least N4, so that the recording surface is in contact with each

electrode. These electrodes shall be placed parallel to the ground and parallel to each other at a distance d = 12,7 mm between

their centres. Apply a force F of 1,62 N to each end of the test piece. Apply a d.c. voltage of 100 V � 10 V across the

electrodes and measure the resulting current flow. From this value, determine the electrical resistance.

Repeat for a total of 5 positions along the test piece and average the 5 resistance readings. For the back coating repeat the

procedure with the back surface in contact with the electrodes.

r

r

d

F F

93-0050-B

Figure 3 — Measurement of electrical resistance

When mounting the test piece, make sure that no conducting paths exist between the electrodes except that through the coating

under test.

NOTE - Particular attention should be given to keeping the surfaces clean.

7.16 Inhibitor tape

This Standard does not specify parameters for assessing whether or not a tape is an inhibitor tape. However, annex J gives

further information on inhibitor tapes.

7.17 Abrasivity

Tape abrasivity is the tendency of the magnetic coating to wear the magnetic heads.

7.17.1 Requirement

The depth of the wear pattern in a ferrite wear bar shall be less than 1,27µm.

7.17.2 Procedure

A test piece 61 m in length shall be passed for 100 passes (50 cycles) over a rectangular bar of manganese zinc ferrite. The bar

shall be 0,3 mm wide and its top surface shall be rounded off with a radius r = 5 mm. The tape speed shall be 2,54 m/s, the

tension shall be nominally 1,3 N and the wrap angle shall be 12°. The wear depth is measured with a profilometer across the

width of the tape path.

NOTE - Manganese zinc ferrite should be available from Philips Ceramic Division in Saugerties (NY) under order part number 3H7.

8 © ISO/IEC 2000 – All rights reserved

0,3

6°

6°

r

Figure 4 — Measurement of abrasivity (not to scale)

7.18 Light transmittance of the tape and the leader

The light transmittance of the tape and the leader shall be less than 5 % when measured according to the method specified in

annex A.

7.19 Coefficient of dynamic friction

The coefficient of dynamic friction is measured between the surfaces of the tape, and calcium titanate ceramic.

7.19.1 Requirements

Between the magnetic surface and the back surface: greater than 0,15

Between the magnetic surface and calcium titanate ceramic: 0,05 to 0,35

Between the back surface and calcium titanate ceramic: 0,05 to 0,20

7.19.2 Procedure for the measurement of the friction between the magnetic surface and the back surface

i. Wrap a first piece of tape around a calcium titanate ceramic cylinder (R =0,05 �m) of diameter 25,4 mm and wrap it

a

with a total wrap angle of more than 90° with the back surface outwards.

ii. Wrap a second test piece, with the magnetic surface inwards, around the first test piece with a total wrap angle of 90°.

iii. Exert on one end of the outer test piece a force of F =0,64N.

iv. Attach the other end to a force gauge mounted on a linear slide.

v. Drive the slide at a speed of 1 mm/s, measure the force F required.

vi. Calculate the coefficient of dynamic friction� from the equation

1 ��F

� � ln

��

� ��F

where� is the value of the wrap angle in radians.

© ISO/IEC 2000 – All rights reserved 9

7.19.3 Procedure for the measurement of the friction between the magnetic surface or the back surface and calcium

titanate ceramic

i. Wrap a piece of tape around a calcium titanate ceramic cylinder (R =0,05 �m) of diameter 25,4 mm and wrap it with a

a

total wrap angle of 90° with the magnetic surface or the back surface, as appropriate, inwards.

ii. Exert on one end of the test piece a force of F =0,64N.

iii. Attach the other end to a force gauge mounted on a linear slide.

iv. Drive the slide at a speed of 1 mm/s, measure the force F required.

v. Calculate the coefficient of dynamic friction� from the equation

��

1 F

� � ln

��

� F

��

where� is the value of the wrap angle in radians.

NOTE - Calcium titanate ceramic should be available from Philips Ceramic Division in Saugerties (NY) under order part Ca Ti.

8 Magnetic recording characteristics

The magnetic recording characteristics shall be defined by testing the requirements given below.

When performing the tests, the output or resultant signal shall be measured on the same relative pass for both a tape calibrated

to the Master Standard Reference Tape and the tape under test (read-while-write, or on equipment without read-while-write

capability, on the first forward-read-pass) on the same equipment.

The following conditions shall apply to the testing of all magnetic recording characteristics, unless otherwise noted.

— Tape condition: a.c. erased to 2 % or less of the Average Signal Amplitude

— Tape speed: 4,26 m/s� 0,05 m/s

— Read track: within the written track

— Gap alignment: the read gap and the write gap to be parallel within 38,1�m

— Write gap length: 0,64µm � 0,18µm

— Write gap width: 0,216 mm� 0,010 mm

— Read gap length: 0,18µm � 0,05µm

— Read gap width: 39,4µm � 5,0µm

— Tape tension: 0,79 N� 0,08 N

— Recording current: Test Recording Current

— Physical recording densities: 2f=2578ftpmm� 44 ftpmm, corresponding to 5,5 MHz�2%

1f=1289ftpmm� 22 ftpmm, corresponding to 2,75 MHz�2%

— Bandwidth of the read

amplifier: 10,0 MHz

8.1 Typical Field

The Typical Field shall be between 75 % and 125 % of the Reference Field.

Traceability to the Reference Field is provided by the calibration factors supplied with each Secondary Standard Reference

Tape.

10 © ISO/IEC 2000 – All rights reserved

8.2 Signal amplitude

The Average Signal Amplitude shall be between 85 % and 115 % of the SRA.

Traceability to the SRA is provided by the calibration factors supplied with each Secondary Standard Reference Tape.

8.3 Resolution

The ratio of the average signal amplitude at the physical recording density of 2 578 ftpmm to that at the physical recording

density of 1 289 ftpmm shall be between 90 % and 120 % of the same ratio for the Master Standard Reference Tape.

Traceability to the resolution of the Master Standard Reference Tape is provided by the calibration factors supplied with each

Secondary Standard Reference Tape.

8.4 Overwrite

Overwrite is the ratio of the residual signal of the average signal amplitude recorded at 1 289 ftpmm after being overwritten at

2 578 ftpmm to the average signal amplitude of the 1 289 ftpmm signal.

8.4.1 Requirement

The overwrite for the tape shall be less than 110 % of the overwrite for the Master Standard Reference Tape.

Traceability to the overwrite of the Master Standard Reference Tape is provided by the calibration factors supplied with each

Secondary Standard Reference Tape.

8.5 Peak shift

Peak shift is measured as the time displacement from nominal of the ONEs transitions in the recorded pattern 110110110.with

a bit cell length of 0,129µm.

8.5.1 Requirement

For a peak shift ratio of n % for the Master Standard Reference Tape, the measured peak shift ratio shall be between (n-2) %

and (n+2) %.

Traceability to the peak shift ratio of the Master Standard Reference Tape is provided by the calibration factors supplied with

each Secondary Standard Reference Tape.

8.5.2 Procedure

The time interval measurements shall be averaged over 250 ONE-ONE-ZERO patterns taken at a sampling rate of 96 times 2f.

The time between adjacent peaks in the ONE-ONE interval is denoted as t . The time between the last ONE in the ONE-ONE

interval to the last ONE in the following ONE-ONE interval is denoted as t .

��

3tt�

Peak shift � 100 %

��

2t

��

0 110 11 0

t

t

94-0087-A

Figure 5 —Measurementofpeakshift

© ISO/IEC 2000 – All rights reserved 11

9 Tape quality

9.1 Missing pulses

A missing pulse is a loss of read signal amplitude. When a base-to-peak read signal amplitude is less than 35 % of half the

Average Signal Amplitude (see 8.2) for the preceding 25,4 mm of track, then these 25,4 mm constitute a missing pulse. This

measurement shall be carried out in steps of 25,4 mm of track.

9.1.1 Requirement

The average missing pulse rate shall be less than 20 missing pulses for any recorded length of track of 100 m.

9.2 Missing pulse zone

A missing pulse zone is a sequence of missing pulses exceeding 100 mm.

9.2.1 Requirement

Missing pulse zones shall not occur.

9.3 Tape durability

This International Standard does not specify parameters for assessing tape durability. However, a recommended procedure is

described in annex K.

Section 3 - Mechanical specifications of the tape cartridge

10 General

The tape cartridge shall consist of the following elements

— a case

— a reel for the magnetic tape

— a locking mechanism for the reel

— a magnetic tape wound on the hub of the reel

— a write-inhibit mechanism

— a tape leader

Dimensional characteristics are specified for those parameters deemed mandatory for interchange and compatible use of the

cartridge. Where there is freedom of design, only the functional characteristics of the elements described are indicated.

Where they are purely descriptive the dimensions are referred to three reference planes A, B, and C forming a geometrical

trihedral. Where the dimensions are related to the position of the cartridge in the drive, they may be referenced to another

surface of the cartridge.

In the enclosed drawings a typical implementation is represented.

Figure 6 shows a general view of the cartridge.

Figure 7 shows the reference planes A, B, C.

Figure 8 shows the bottom side of the cartridge.

Figure 9 shows the right side of the cartridge.

Figure 10 shows the back side of the cartridge.

Figure 11 shows the left side of the cartridge.

Figure 12 shows a partial cross-section of the cartridge in locked position.

Figure 13 shows a partial cross-section of the cartridge in operating position.

Figure 14 shows the leader-to-tape connection.

Figure 15 shows the splice of the leader-to-tape connection.

Figure 16 shows the leader.

Figure 17 shows the front side of the cartridge.

Figure 18 shows the back side of the cartridge with partial cut.

Figure 19 shows the top side of the cartridge with partial cut and the door open.

Figure 6 shows a general view of the cartridge. When it is not in the operating position, the reel of magnetic tape is locked and

cannot rotate. When loaded into the drive, the back side is introduced first and the front side remains visible during operation.

During the loading process the tape reel is unlocked and the position of the cartridge within the drive is fixed by elements of

the drive engaging with corresponding elements of the case.

12 © ISO/IEC 2000 – All rights reserved

The position of the case relative to the reference planes A, B and C is shown in figure 7. The top side lies in reference plane A,

the right side lies in reference plane B and the back side lies in reference plane C.

10.1 Bottom side and right side (figures 8 and 9)

The overall dimensions of the cartridge shall be

l =105,79mm� 0,20 mm

l =105,41mm� 0,20 mm

l =25,40 mm� 0,25 mm

The bottom side shall have a window the dimensions and the position of which shall be defined by

l =6,25mm� 0,10 mm

l =4,85mm� 0,05 mm

l =84,07 mm� 0,20 mm

l =3,81mm� 0,05 mm

This window allows one of the fingers of the drive to penetrate into the case for partially unlocking the reel of tape (see 10.6).

A positioning hole on the bottom side and a guiding notch, followed by a positioning notch in the right side determine the

position of the cartridge in the drive.

The dimensions and the position of the positioning hole shall be defined by

l = 21,59 mm� 0,10 mm

� 0,13 mm

l =4,45mm

9 � 0,00 mm

l =2,79mm� 0,05 mm

l = 44,58 mm� 0,20 mm

The dimensions and the position of the positioning notch shall be defined by

l =5,56 mm� 0,10 mm

l = 33,30 mm� 0,20 mm

l =5,08 mm� 0,10 mm

h =9,02mm� 0,10 mm

a =14°� 30'

The dimensions and the position of the guiding notch shall be defined by

l =8,59 mm� 0,10 mm

l = 24,64 mm� 0,10 mm

l =1,50 mm� 0,05 mm

a =45°� 30'

a =14°� 30'

The right side shall have an indicator connected to the manually operable write-inhibit switch described in 10.5. The

dimensions and the position of this indicator shall be defined by

l =8,64 mm� 0,10 mm

l =5,08 mm� 0,10 mm

© ISO/IEC 2000 – All rights reserved 13

l = 86,11 mm� 0,20 mm

l = 10,16 mm� 0,10 mm

Writing is enabled when the surface of the indicator is substantially flush with the cartridge wall. When this surface is recessed

by at least 5,1 mm writing is inhibited. When a force of up to 1,0 N is exerted perpendicularly on the centre of the surface of

the indicator, it shall not recede by more than 0,5 mm from reference plane B.

10.2 Back side and left side (figures 10 and 11)

The back side shall have a window the dimensions and position of which shall be

l =8,76 mm� 0,10 mm

l =4,25 mm� 0,10 mm

l =4,45 mm� 0,10 mm

l =8,89 mm� 0,10 mm

This window allows a further finger of the drive to penetrate into the case to finally unlock the reel of tape (see also 10.6).

A door shall be rotatably mounted at the corner of the back side and the left side. It is described in 10.6.

The left side shall have two edges the positions and lengths of which shall be

l = 61,47 mm� 0,20 mm

+0,13mm

l =9,65 mm

-0,00mm

l = 41,9 mm� 0,20 mm

+0,18mm

l =6,18 mm

-0,00mm

10.3 Tape reel (figures 8, 12 and 13)

The bottom side of the case shall have a circular window through which the drive spindle contacts the hub of the reel and

transmits torque. The diameter of this window shall be

d = 35,05 mm� 0,08 mm

The position of its centre shall be defined by

l = 50,42 mm� 0,31 mm

l = 52,83 mm� 0,10 mm

The interface between the spindle and the hub is provided by 48 evenly spaced teeth in the hub. In the non-operating position,

the surface of the hub shall be recessed from the outside surface of the case by

l =0,38 mm� 0,05 mm

The tooth profile consists of straight flanks. The envelope dimensions of the teeth shall be

d = 23,88 mm� 0,13 mm

d = 29,21 mm� 0,13 mm

d = 34,29 mm� 0,13 mm

a =22°� 30'

a =15°� 30'

where d is the pitch diameter of the teeth.

14 © ISO/IEC 2000 – All rights reserved

In the operating position the surface of the hub shall be at a distance

l = 23,55 mm� 0,10 mm

from reference plane A.

10.4 Tape leader (figures 14, 15 and 16)

The positions of the BOT and EOT relative to the leader/tape connection and to the physical end of the tape shall be as follows.

The BOT shall be at a distance

l =13 260 mm� 150 mm

from the leader/tape connection.

The EOT shall be at a distance

l =6 096 mm� 150 mm

from the physical end of the tape, which is fixed to the hub of the reel. Both the BOT hole and EOT hole shall have a diameter

d =4,78mm� 0,10 mm

Figure 15 shows the relative positions of the tape, the leader and the splice ta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...