ISO 15634:2015

(Main)Iron ores — Determination of chromium content — Flame atomic absorption spectrometric method

Iron ores — Determination of chromium content — Flame atomic absorption spectrometric method

ISO 15634:2015 specifies a flame atomic absorption spectrometric method for the determination of the chromium content of iron ores. This method is applicable to chromium contents between 0,001 6 % and 0,1 % (mass fractions) in natural iron ores, iron ore concentrates, and agglomerates including sinter products.

Minerais de fer — Dosage du chrome — Méthode par spectrométrie d'absorption atomique dans la flamme

General Information

- Status

- Published

- Publication Date

- 27-Jul-2015

- Technical Committee

- ISO/TC 102/SC 2 - Chemical analysis

- Drafting Committee

- ISO/TC 102/SC 2 - Chemical analysis

- Current Stage

- 9020 - International Standard under periodical review

- Start Date

- 15-Jan-2026

- Completion Date

- 15-Jan-2026

Relations

- Effective Date

- 18-Oct-2014

Overview

ISO 15634:2015 - "Iron ores - Determination of chromium content - Flame atomic absorption spectrometric method" specifies a validated laboratory procedure for measuring chromium content in iron ores, concentrates and agglomerates (including sinter). The method uses flame atomic absorption spectrometry (AAS) after chemical decomposition, iron removal and reconstitution of the sample solution. It applies to chromium mass fractions from 0.0016 % to 0.1 %.

Key topics and technical requirements

- Scope and applicability: Natural iron ores, iron ore concentrates and agglomerates; chromium content range 0.0016–0.1 % (mass fraction).

- Sample preparation: Use a laboratory sample prepared according to ISO 3082 and predried test samples as per ISO 7764. Typical particle size <100 µm (or <160 µm for ores with combined water/oxidizable compounds).

- Decomposition and matrix treatment:

- Acid decomposition with hydrochloric and nitric acids.

- Removal of the bulk iron by organic extraction using methylpentan-2-one (MIBK).

- Treatment of insoluble residue including HF/sulfuric acid evaporation and fusion with sodium carbonate/sodium tetraborate, then recombining with main solution.

- Analytical measurement:

- Aspirate prepared solution into a dinitrogen oxide–acetylene flame AAS burner.

- Compare sample absorbances against calibration solutions prepared from chromium standards.

- Instrument performance criteria:

- Minimum sensitivity: most concentrated calibration solution absorbance ≥ 0.3.

- Linearity: slope for top 20% of range ≥ 0.7 of slope for bottom 20%.

- Stability: standard deviation limits for calibration and zero solutions as specified.

- Quality control and reporting:

- At least duplicate determinations, with blank and certified reference material (CRM) analyses in each run.

- Procedures for calculation, repeatability, between-laboratory precision and check for trueness are provided.

- Safety: The standard warns about hazardous reagents and operations (HF, strong acids, N2O–acetylene flames); follow appropriate health and safety practices.

Applications and users

ISO 15634:2015 is used by:

- Analytical laboratories performing chemical characterization of iron ores and concentrates.

- Mining companies and ore processors monitoring trace chromium for quality control, product compliance and metallurgical planning.

- Quality assurance teams in steel and raw-material supply chains needing reproducible chromium data.

- Research groups comparing chromium concentrations across deposits or processing steps.

Benefits include reproducible, internationally recognized chromium determinations for material specification, regulatory compliance and process control.

Related standards

- ISO 3082 - Sampling and sample preparation procedures (iron ores)

- ISO 7764 - Preparation of predried test samples for chemical analysis

- ISO 3696 - Water for analytical laboratory use

- ISO 648 / ISO 1042 - Laboratory glassware (pipettes and volumetric flasks)

Keywords: ISO 15634:2015, chromium determination, flame atomic absorption spectrometry, AAS, iron ores, chromium content, MIBK extraction, sample preparation, analytical method.

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Chile

Bureau Veritas certification services in Chile.

Bureau Veritas Peru

Bureau Veritas certification services in Peru.

BVQI Peru

Bureau Veritas certification in Peru.

Sponsored listings

Frequently Asked Questions

ISO 15634:2015 is a standard published by the International Organization for Standardization (ISO). Its full title is "Iron ores — Determination of chromium content — Flame atomic absorption spectrometric method". This standard covers: ISO 15634:2015 specifies a flame atomic absorption spectrometric method for the determination of the chromium content of iron ores. This method is applicable to chromium contents between 0,001 6 % and 0,1 % (mass fractions) in natural iron ores, iron ore concentrates, and agglomerates including sinter products.

ISO 15634:2015 specifies a flame atomic absorption spectrometric method for the determination of the chromium content of iron ores. This method is applicable to chromium contents between 0,001 6 % and 0,1 % (mass fractions) in natural iron ores, iron ore concentrates, and agglomerates including sinter products.

ISO 15634:2015 is classified under the following ICS (International Classification for Standards) categories: 73.060.10 - Iron ores. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 15634:2015 has the following relationships with other standards: It is inter standard links to ISO 15634:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 15634:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 15634

Second edition

2015-08-01

Iron ores — Determination of

chromium content — Flame atomic

absorption spectrometric method

Minerais de fer — Dosage du chrome — Méthode par spectrométrie

d’absorption atomique dans la flamme

Reference number

©

ISO 2015

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

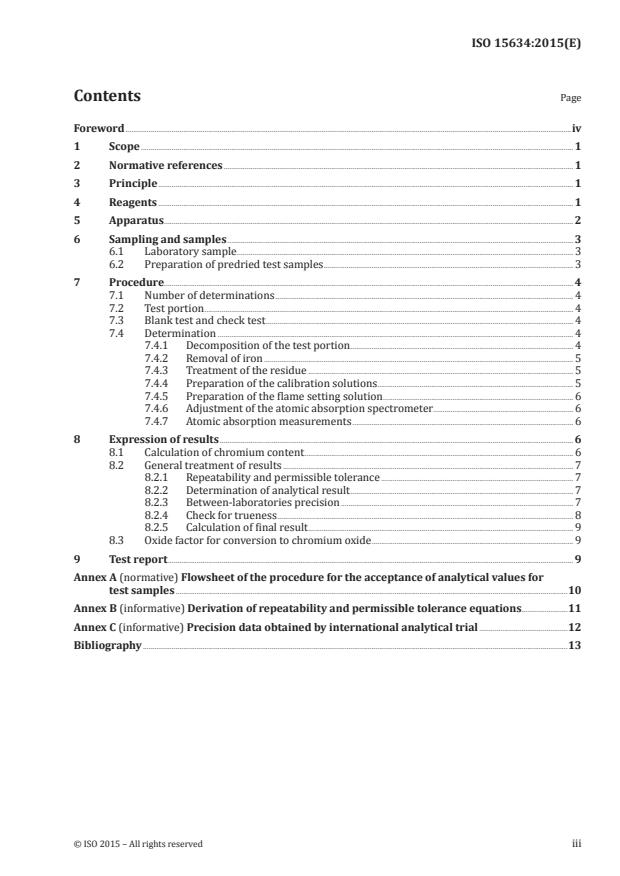

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Principle . 1

4 Reagents . 1

5 Apparatus . 2

6 Sampling and samples . 3

6.1 Laboratory sample . 3

6.2 Preparation of predried test samples . 3

7 Procedure. 4

7.1 Number of determinations . 4

7.2 Test portion . 4

7.3 Blank test and check test . 4

7.4 Determination . 4

7.4.1 Decomposition of the test portion . 4

7.4.2 Removal of iron . 5

7.4.3 Treatment of the residue . 5

7.4.4 Preparation of the calibration solutions . 5

7.4.5 Preparation of the flame setting solution . 6

7.4.6 Adjustment of the atomic absorption spectrometer. 6

7.4.7 Atomic absorption measurements . 6

8 Expression of results . 6

8.1 Calculation of chromium content . 6

8.2 General treatment of results . 7

8.2.1 Repeatability and permissible tolerance . 7

8.2.2 Determination of analytical result . 7

8.2.3 Between-laboratories precision . 7

8.2.4 Check for trueness . 8

8.2.5 Calculation of final result . 9

8.3 Oxide factor for conversion to chromium oxide . 9

9 Test report . 9

Annex A (normative) Flowsheet of the procedure for the acceptance of analytical values for

test samples .10

Annex B (informative) Derivation of repeatability and permissible tolerance equations .11

Annex C (informative) Precision data obtained by international analytical trial .12

Bibliography .13

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary Information

The committee responsible for this document is ISO/TC 102, Iron ore and direct reduced iron,

Subcommittee SC 2, Chemical analysis.

This second edition cancels and replaces the first edition (ISO 15634:2005), which has been

technically revised.

iv © ISO 2015 – All rights reserved

INTERNATIONAL STANDARD ISO 15634:2015(E)

Iron ores — Determination of chromium content — Flame

atomic absorption spectrometric method

WARNING — This International Standard may involve hazardous materials, operations, and

equipment. This International Standard does not purport to address all of the safety problems

associated with its use. It is the responsibility of the user of this International Standard to

establish appropriate health and safety practices and determine the applicability of regulatory

limitations prior to use.

1 Scope

This International Standard specifies a flame atomic absorption spectrometric method for the

determination of the chromium content of iron ores.

This method is applicable to chromium contents between 0,001 6 % and 0,1 % (mass fractions) in

natural iron ores, iron ore concentrates, and agglomerates including sinter products.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 648, Laboratory glassware — Single-volume pipettes

ISO 1042, Laboratory glassware — One-mark volumetric flasks

ISO 3082, Iron ores — Sampling and sample preparation procedures

ISO 3696, Water for analytical laboratory use — Specification and test methods

ISO 7764, Iron ores — Preparation of predried test samples for chemical analysis

3 Principle

The test portion is decomposed by treatment with hydrochloric and nitric acids.

The major portion of iron in the filtrate is removed by extraction with 4-methylpentan-2-one.

The insoluble residue is ignited and the silicon dioxide is removed by evaporation with hydrofluoric

and sulfuric acids. The residue is fused with a mixture of sodium carbonate and sodium tetraborate,

and then dissolved with hydrochloric acid and combined with the main solution.

The solution is aspirated into the flame of an atomic absorption spectrometer using a nitrous oxide-

acetylene burner.

The absorbance values obtained are compared with those obtained from the calibration solutions.

4 Reagents

During the analysis, use only reagents of recognized analytical grade.

4.1 Water, complying with grade 2 as defined in ISO 3696.

4.2 Sodium carbonate, (Na CO ), anhydrous powder.

2 3

4.3 Sodium tetraborate, (Na B O ), anhydrous powder.

2 4 7

4.4 Lithium tetraborate, (Li B O ), anhydrous powder.

2 4 7

4.5 Hydrochloric acid, ρ 1,16 g/ml to 1,19 g/ml.

4.6 Hydrochloric acid, ρ 1,16 g/ml to 1,19 g/ml, diluted 2 + 1.

4.7 Hydrochloric acid, ρ 1,16 g/ml to 1,19 g/ml, diluted 1 + 1.

4.8 Hydrochloric acid, ρ 1,16 g/ml to 1,19 g/ml, diluted 2 + 100.

4.9 Nitric acid, ρ 1,4 g/ml.

4.10 Nitric acid, ρ 1,4 g/ml, diluted 1 + 1.

4.11 Hydrofluoric acid, ρ 1,13 g/ml, 40 % (mass fraction) or ρ 1,19 g/ml, 48 % (mass fraction).

4.12 Sulfuric acid, ρ 1,84 g/ml.

4.13 Sulfuric acid, ρ 1,84 g/ml, diluted 1 + 1.

4.14 Methylpentan-2-one, (methyl isobutyl ketone, MIBK).

4.15 Chromium standard solution A, 100 µg Cr/ml.

Dissolve 0,100 0 g of chromium metal [purity >99,9 % (mass fraction) (see Note of 4.16)] in 20 ml of

hydrochloric acid (4.7). After cooling, transfer to a 1 000 ml one-mark volumetric flask quantitatively,

dilute to volume with water (4.1), and mix.

4.16 Chromium standard solution B, 10 µg Cr/ml.

Transfer 100,0 ml of chromium standard solution A (4.15) to a 1 000 ml one-mark volumetric flask.

Dilute to volume with water and mix.

NOTE The purity of the metals stated on the certificates does not generally take into account the presence of

adsorbed gases like oxygen, carbon monoxide, etc.

5 Apparatus

Ordinary laboratory apparatus including one-mark pipettes and one-mark volumetric flasks complying

with the specifications of ISO 648 and ISO 1042, and the following.

5.1 Platinum crucible, of minimum capacity 25 ml.

5.2 Muffle furnace.

5.3 Atomic absorption spectrometer, equipped with a dinitrogen oxide-acetylene burner.

WARNING — Follow the manufacturer’s instructions for igniting and extinguishing the

dinitrogen oxide-acetylene flame to avoid possible explosion hazards. Wear tinted safety glasses

whenever the burner is in operation.

2 © ISO 2015 – All rights reserved

The atomic absorption spectrometer used in this method shall meet the following criteria:

a) Minimum sensitivity — The absorbance of the most concentrated calibration solution (see 7.4.4) is

at least 0,3;

b) Graph linearity — The slope of the calibration graph covering the top 20 % of the concentration

range (expressed as a change in absorbance) is not less than 0,7 of the value of the slope for the

bottom 20 % of the concentration range determined in the same way;

c) Minimum stability — The standard deviation of the absorbance of the most concentrated calibration

solution and that of the zero calibration solution each being calculated from a sufficient number

of repetitive measurements are less than 1,5 % and 0,5 %, respectively of the mean value of the

absorbance of the most concentrated solution.

The use of a strip-chart recorder and/or digital readout device is recommended to evaluate criteria a),

b), and c) and for all subsequent measurements.

NOTE Instrument parameters will vary with each instrument. The following parameters were successfully

used in several laboratories and they can be used as guidelines:

— hollow-cathode lamp 10 mA;

— wavelength 357,9 nm;

— dinitrogen oxide flow rate ≈10 l/min;

— acetylene flow rate 5 l/min.

A dinitrogen oxide-acetylene flame was used.

In systems where the values shown above for gas flow rates do not apply, the ratio of the gas flow rates

can still be a useful guideline.

6 Sampling and samples

6.1 Laboratory sample

For analysis, use a laboratory sample of particle size of less than 100 µm which has been taken and

prepared in accordance with ISO 3082. In the case of ores containing significant contents of combined

water or oxidizable compounds, use a particle size of less than 160 µm.

NOTE A guideline on significant contents of combined water and oxidizable compounds is incorporated in

ISO 7764.

Ensure that the sample has not been pulverized in a nickel/chromium pot.

6.2 Preparation of predried test samples

Thoroughly mix the laboratory sample and taking multiple increments, extract a test sample in such a

way that it is representative of the whole contents of the container. Dry the test sample at (105 ± 2) °C as

specified in ISO 7764 (this is the predried test sample).

7 Procedure

7.1 Number of determinations

Carry out the analysis at least in duplicate in accordance with Annex A, independently on one

predried test sample.

NOTE The expression “independently” means that the second and any subsequent result is not affected

by the previous result(s). For this particular analytical method, this condition implies that the repetition of the

procedure be carried out either by the same operator at a different time or by a different operator including, in

either case, appropriate recalibration.

7.2 Test portion

Taking several increments, weigh to the nearest 0,000 2 g, app

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...