ISO 22682:2017

(Main)Iron ores — Determination of trace elements — Plasma spectrometric method

Iron ores — Determination of trace elements — Plasma spectrometric method

ISO 22682:2017 specifies a method for the determination of phosphorus, vanadium, titanium, copper, nickel, chromium, barium and cobalt in iron ores, by inductively coupled plasma atomic emission spectrometry (ICP-AES).

Minerais de fer — Détermination d'éléments traces — Méthode par spectrométrie avec plasma

General Information

- Status

- Published

- Publication Date

- 14-Aug-2017

- Technical Committee

- ISO/TC 102/SC 2 - Chemical analysis

- Drafting Committee

- ISO/TC 102/SC 2 - Chemical analysis

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 03-Mar-2025

- Completion Date

- 12-Feb-2026

Overview

ISO 22682:2017 - "Iron ores - Determination of trace elements - Plasma spectrometric method" defines a laboratory procedure for measuring trace elements in iron ores using inductively coupled plasma atomic emission spectrometry (ICP‑AES). The standard covers the determination of phosphorus, vanadium, titanium, copper, nickel, chromium, barium and cobalt in natural iron ores, concentrates and agglomerates (including sinter products), and specifies sample decomposition, reagent and apparatus requirements, calibration and performance checks.

Key features

- Method: ICP‑AES (inductively coupled plasma atomic emission spectrometry)

- Elements covered: P, V, Ti, Cu, Ni, Cr, Ba, Co

- Includes detailed sample decomposition, calibration and spectrometer performance procedures

- Notes safety considerations for hazardous reagents and equipment

Key topics and technical requirements

- Principle and sample preparation: Test portions are decomposed with L‑ascorbic acid, hydrofluoric, concentrated hydrochloric and nitric acids, evaporated to dryness, then dissolved in HCl (1+1) and made up to volume prior to ICP analysis.

- Reagents and solutions: Use high‑purity reagents and water (ISO 3696 grade 2). The standard gives recipes for 1 000 µg/ml stock solutions for each analyte and guidance on preparing calibration/reference solutions.

- Apparatus and performance: Specifies laboratory equipment such as analytical balances (0.0001 g), platinum crucibles, muffle furnace (≥ 1 020 °C) and any conventional ICP spectrometer (radial or axial) that meets the method’s performance tests.

- Calibration and interference control: Requires a minimum of five calibration solutions across the concentration range, checks for spectral interference, background correction, and drift (standardization) procedures. Suggested analytical emission lines (wavelengths) for each element are provided for line selection and interference assessment.

- Quality control: Blank tests, check tests, repeatability and tolerances, and procedures for validating trueness and reporting analytical results are defined.

Practical applications and users

ISO 22682:2017 is intended for:

- Analytical and metallurgical laboratories performing routine and refereed trace element assays in iron ores

- Mining companies and iron‑ore concentrators for quality control (QC) and product specification

- Contract laboratories and third‑party testing organizations involved in trade, compliance and product certification

- Researchers and method developers needing a standardized ICP‑AES procedure for iron ore matrices

Benefits include reproducible trace element data, standardized calibration and interference controls, and compatibility with international trade and QC requirements.

Related standards

Normative references include ISO 648, ISO 1042 (glassware), ISO 3082 (sampling and sample preparation), ISO 7764 (preparation of predried test samples), ISO 3696 (water quality) and ISO 11323 (vocabulary). These support accurate sampling, reagent handling and laboratory practice for ICP‑AES analysis.

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Chile

Bureau Veritas certification services in Chile.

Bureau Veritas Peru

Bureau Veritas certification services in Peru.

BVQI Peru

Bureau Veritas certification in Peru.

Sponsored listings

Frequently Asked Questions

ISO 22682:2017 is a standard published by the International Organization for Standardization (ISO). Its full title is "Iron ores — Determination of trace elements — Plasma spectrometric method". This standard covers: ISO 22682:2017 specifies a method for the determination of phosphorus, vanadium, titanium, copper, nickel, chromium, barium and cobalt in iron ores, by inductively coupled plasma atomic emission spectrometry (ICP-AES).

ISO 22682:2017 specifies a method for the determination of phosphorus, vanadium, titanium, copper, nickel, chromium, barium and cobalt in iron ores, by inductively coupled plasma atomic emission spectrometry (ICP-AES).

ISO 22682:2017 is classified under the following ICS (International Classification for Standards) categories: 73.060.10 - Iron ores. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 22682:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 22682

First edition

2017-08

Iron ores — Determination of trace

elements — Plasma spectrometric

method

Minerais de fer — Détermination d’éléments traces — Méthode par

spectrométrie avec plasma

Reference number

©

ISO 2017

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

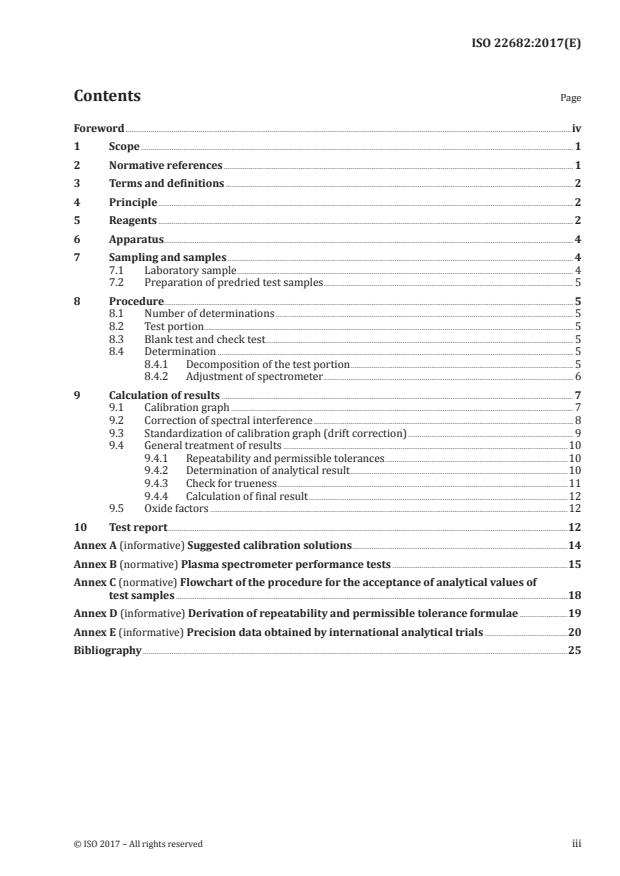

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Principle . 2

5 Reagents . 2

6 Apparatus . 4

7 Sampling and samples . 4

7.1 Laboratory sample . 4

7.2 Preparation of predried test samples . 5

8 Procedure. 5

8.1 Number of determinations . 5

8.2 Test portion . 5

8.3 Blank test and check test . 5

8.4 Determination . 5

8.4.1 Decomposition of the test portion . 5

8.4.2 Adjustment of spectrometer . 6

9 Calculation of results . 7

9.1 Calibration graph . 7

9.2 Correction of spectral interference . 8

9.3 Standardization of calibration graph (drift correction) . 9

9.4 General treatment of results .10

9.4.1 Repeatability and permissible tolerances .10

9.4.2 Determination of analytical result .10

9.4.3 Check for trueness .11

9.4.4 Calculation of final result .12

9.5 Oxide factors .12

10 Test report .12

Annex A (informative) Suggested calibration solutions .14

Annex B (normative) Plasma spectrometer performance tests .15

Annex C (normative) Flowchart of the procedure for the acceptance of analytical values of

test samples .18

Annex D (informative) Derivation of repeatability and permissible tolerance formulae .19

Annex E (informative) Precision data obtained by international analytical trials .20

Bibliography .25

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO’s adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see the following

URL: w w w . i s o .org/ iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 102, Iron ore and direct reduced iron,

Subcommittee SC 2, Chemical analysis.

iv © ISO 2017 – All rights reserved

INTERNATIONAL STANDARD ISO 22682:2017(E)

Iron ores — Determination of trace elements — Plasma

spectrometric method

CAUTION — This document may involve hazardous operations and equipment. This document

does not purport to address all of the safety issues associated with its use. It is the responsibility

of the user of this document to establish appropriate safety and health practices and determine

the applicability of regulatory limitations prior to its use.

1 Scope

This document specifies a method for the determination of phosphorus, vanadium, titanium, copper,

nickel, chromium, barium and cobalt in iron ores, by inductively coupled plasma atomic emission

spectrometry (ICP-AES).

This method is applicable to the concentration ranges (mass fraction) given in Table 1, in natural iron

ores, iron ore concentrates and agglomerates, including sinter products.

Table 1 — Concentration ranges

Concentration range for Concentration range for

Element referee purpose non-referee purpose

% (mass fraction) % (mass fraction)

P 0,000 2 to 0,150 0,000 2 to 0,150

V 0,003 0 to 0,024 0,003 0 to 0,024

Ti 0,015 0 to 0,120 0,015 0 to 0,120

Cu 0,0014 to 0,250 0,001 4 to 0,250

Ni 0,005 0 to 0,090 0,005 0 to 0,090

Cr 0,004 0 to 0,015

Ba 0,002 8 to 0,035

Co 0,002 0 to 0,100

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 648, Laboratory glassware — Single-volume pipettes

ISO 1042, Laboratory glassware — One-mark volumetric flasks

ISO 2596, Iron ores — Determination of hygroscopic moisture in analytical samples — Gravimetric, Karl

Fischer and mass-loss methods

ISO 3082, Iron ores — sampling and sample preparation procedures

ISO 3696, Water for analytical laboratory use — Specification and test methods

ISO 7764, Iron ores — Preparation of predried test samples for chemical analysis

ISO 11323, Iron ore and direct reduced iron — Vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 11323 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http:// www .electropedia .org/

— ISO Online browsing platform: available at https:// www .iso .org/ obp

4 Principle

The test portion is decomposed with L-ascorbic acid, hydrofluoric acid, concentrated hydrochloric acid,

concentrated nitric acid and then evaporated to dryness. The dry mass is dissolved in hydrochloric acid

(1 + 1) and the solution is made up to 100 ml.

The solution is diluted to volume and measured on an ICP spectrometer. Final results are read from a

calibration graph prepared using standard calibration solutions.

5 Reagents

During the analysis, use only highly pure reagents of recognized analytical grade and only water that

complies with grade 2 of ISO 3696.

5.1 High-purity iron, metal, of minimum purity grade 99,99 % (mass fraction).

5.2 Hydrochloric acid, ρ 1,16 g/ml to 1,19 g/ml, diluted 1 + 1.

5.3 Nitric acid, ρ 1,38 g/ml to 1,4 g/ml

5.4 Hydrofluoric acid, ρ 1,13 g/ml to ρ 1,16 g/ml.

5.5 Sulfuric acid, p.a. grade.

5.6 L-ascorbic acid, C H O .

6 8 6

5.7 Stock solutions.

Stock solutions shall be prepared by convenient handling moisture-free high-purity salts, dried until a

constant mass and cooled in a desiccator. High-purity metals of minimum purity grade of 99,9 % (mass

fraction) can also be used to prepare vanadium, titanium, copper, nickel and chromium stock solutions.

Stock solutions may also be prepared by independent laboratories or reagent suppliers.

5.7.1 Phosphorus, 1 000 μg/ml.

Dissolve 4,393 6 g of potassium dihydrogen orthophosphate (KH PO ) in about 200 ml of water in a

2 4

1 000 ml one-mark volumetric flask. When the dissolution is complete, dilute to volume with water

and mix.

5.7.2 Vanadium, 1 000 μg/ml.

Dissolve 1,000 0 g of high-purity vanadium metal or 2,296 3 g of ammonium metavanadate (NH VO ) in

4 3

20 ml of nitric acid (5.3) in a covered tall-form beaker with heating. When dissolution is complete, cool

and transfer to a 1 000 ml one mark-volumetric flask, dilute to volume with water and mix.

2 © ISO 2017 – All rights reserved

5.7.3 Titanium, 1 000 μg/ml.

Dissolve 1,000 0 g of high-purity titanium metal in 100 ml of hydrochloric acid (5.2) in a covered tall-

form beaker with heating or 4,135 1 g of high-purity ammonium hexafluorotitanate [(NH ) TiF ] in

4 2 6

warm distilled water containing drops of hydrofluoridic acid (5.4) in a covered tall-form PTFE beaker.

When dissolution is complete, cool and transfer to a 1 000 ml one-mark volumetric flask, dilute to

volume with water and mix.

5.7.4 Copper, 1 000 μg/ml.

Dissolve 1,000 0 g of high-purity copper metal in 20 ml of nitric acid (5.3) in a covered tall-form beaker.

When dissolution is complete, add about 20 ml of water and heat to liberate oxides of nitrogen. Cool and

transfer to a 1 000 ml one-mark volumetric flask, dilute to volume with water and mix.

5.7.5 Nickel, 1 000 μg/ml.

Dissolve 1,000 0 g of high-purity nickel metal in 20 ml of nitric acid (5.3) in a covered tall-form beaker

with heating. When dissolution is complete, cool and transfer to a 1 000 ml one-mark volumetric flask,

dilute to volume with water and mix.

5.7.6 Chromium, 1 000 μg/ml.

Dissolve 1,000 0 g of high-purity chromium metal in 100 ml of nitric acid (5.3) or 7,695 8 g of

chromium (III) nitrate nonahydrate [Cr(NO ) ·9H O] in 20 ml of nitric acid (5.3) in a covered tall-form

3 3 2

beaker with heating. When dissolution is complete, cool and transfer to a 1 000 ml one-mark volumetric

flask, dilute to volume with water and mix.

5.7.7 Barium, 1 000 μg/ml.

Dissolve 1,437 0 g of high-purity barium carbonate (BaCO ) in 20 ml of nitric acid (5.3) in a covered

tall-form beaker with heating. When dissolution is complete, cool and transfer to a 1 000 ml one-mark

volumetric flask, dilute to volume with water and mix.

5.7.8 Cobalt, 1 000 μg/ml.

Dissolve 2,018 2 g of cobalt carbonate (CoCO ) in 20 ml of nitric acid (5.3) in a covered tall-form beaker

with heating. When dissolution is complete, cool and transfer to a 1 000 ml one-mark volumetric flask,

dilute to volume water and mix.

5.8 Calibration and reference solutions.

Calibration solutions are defined as the solutions required for the determination of the line peak

and background position(s) and for plotting the calibration graphs of the elements analysed. Their

concentration ranges in solution, expressed in micrograms per millilitre, are determined with reference

to the performance parameter values and the linearity response of the instrument. A minimum of five

calibration solutions is necessary to cover the concentration ranges given in Table 1. For test samples

having narrower concentration ranges, calibration solutions are prepared to cover the region of

interest.

In the case of nonlinearity, either a less sensitive line shall be used or appropriate dilutions of sample

and calibration solutions shall be carried out.

NOTE For the suggested lines shown in Table 2, the calibration solutions prepared as recommended in

Annex A will be in agreement with the performance test figures.

To comply with the requirements of similarity between the test sample and the calibration solutions, iron

and acids shall be added (see Note in Table A.1). For each calibration solution, the procedure described in

8.4.1 shall be followed, replacing the test sample with a suitable amount of high-purity iron (5.1).

In addition, to comply with the requirements of similarity, calibration solutions and test samples shall

be prepared from reagents taken from the same containers, to minimize purity differences between

batches.

6 Apparatus

Ordinary laboratory equipment, including one-mark pipettes and one-mark volumetric flasks complying

with the specifications of ISO 648 and ISO 1042 respectively, and the following.

6.1 Analytical balance, capable of weighing to the nearest 0,000 1 g.

6.2 Platinum or suitable platinum alloy crucibles, having a minimum volume of 30 ml.

6.3 Muffle furnace, to provide a minimum temperature of 1 020 °C.

6.4 ICP spectrometer.

Any conventional ICP spectrometer, with radial or axial observation path may be used, provided that

the instrument has been initially set up according to the manufacturer’s recommendations and that it

complies with the performance test (see 8.4.2.2), carried out prior to the measurements.

Suggested analytical lines are shown in Table 2. These lines are found to be relatively free of significant

interferences from the matrix elements, but they shall be carefully checked for spectral interference,

background and ionization, with appropriate corrections carried out prior to their adoption. Failure to

attain the recommended performance parameters may indicate interference.

For the analysis of samples having concentrations in the background equivalent concentration (C )

BE

region or lower, as defined in Table 3, careful assessment of the need for background correction for the

particular line chosen is recommended prior to calibration and analysis.

Table 2 — Suggested analytical lines

Element Wavelength, nm

P 178,290

V 311,071/309,311/310,230

Ti 334,941/336,120

Cu 327,396/224,700/324,75

Ni 231,604

Cr 267,716

Ba 455,405

Co 228,616/238,892

7 Sampling and samples

7.1 Laboratory sample

For analysis, use a laboratory sample of minus 100 μm which has been taken and prepared in accordance

with ISO 3082. In the case of ores having significant contents of combined water or oxidizable

compounds, use a particle size of minus 160 μm.

NOTE A guideline on significant contents of combined water and oxidizable compounds is incorporated in

ISO 7764.

4 © ISO 2017 – All rights reserved

7.2 Preparation of predried test samples

Thoroughly mix the laboratory sample and, taking multiple increments, extract a test sample in

such a manner that it is representative of the whole contents of the container. Dry the test sample at

105 °C ± 2 °C as specified in ISO 7764. (This is the predried test sample.)

For ores having significant content of combined water or oxidizable compounds, an air-equilibrated

test sample shall be prepared in accordance with ISO 2596 to determine the dry sample mass using the

hygroscopic moisture.

8 Procedure

8.1 Number of determinations

Carry out the analysis at least in duplicate in accordance with Annex C, independently, on one predried

test sample.

NOTE The expression “independently” means that the second and any subsequent result is not affected

by the previous result(s). For the particular analytical method, this condition implies that the repetition of the

procedure is carried out either by the same operator at a different time, or by a different operator, including

appropriate recalibration in either case.

8.2 Test portion

Taking several increments, weigh, to the nearest 0,000 1 g, approximately 1,0 g of the predried test

sample obtained in accordance with 7.2.

The test portion should be taken and weighed quickly to avoid re-adsorption of moisture.

8.3 Blank test and check test

In each run, one blank test and one analysis of a certified reference material of the same type of ore shall

be carried out in parallel with the analysis of the ore sample(s) under the same conditions. A predried

test sample of the certified reference material shall be prepared as specified in 7.2.

For the blank test, a suitable amount of high-purity iron (5.1) shall be used in place of the test sample.

The certified reference material shall be of the same type as the sample to be analysed and the

properties of the two materials shall be sufficiently similar to ensure that in either case no significant

changes in the analytical procedure become necessary. Where a certified reference material is not

available, a reference material may be used (see 9.4.4).

Where the analysis is carried out on several samples at the same time, the blank value may be

represented by one test, provided that the procedure is the same and the reagents used are from the

same reagent bottles.

Where the analysis is carried out on several samples of the same type of ore at the same time, the

analytical value of one certified reference material may be used.

8.4 Determination

8.4.1 Decomposition of the test portion

Transfer the weighed test portion to a 250 ml capacity PTFE Erlenmeyer flask with cover.

Add 0,5 g of L-ascorbic acid (5.6), moisten with water, 5,0 ml of hydrofluoric acid (5.4) and 30 ml of

concentrated hydrochloric acid (5.2) and take to a hotplate for 2 h. (The hotplate temperature shall be

controlled between 120 °C and 140 °C; if necessary use a thermometer inserted in a beaker containing

sulfuric acid.)

Add, after complete dissolution, concentrated nitric acid (5.3) drop by drop until complete oxidation of

the sample (approximately 10 ml) and keep heating in the hotplate for 30 min with the cover, and after

that time, remove the cover and take to complete dryness.

Recover in 20 ml of hydrochloric acid 1 + 1 (5.2), and take to the hotplate until the dissolution is

completed. Filter in white class filter paper.

Transfer the filtrate to a 100 ml volumetric flask. Make up to volume. If necessary, confirm the absence

of undecomposed material by transferring the filter to a pre-weighed platinum crucible followed by

gentle burn in a Bunsen burner, followed by ashing at 900 °C in a muffle furnace. Confirm absence of

residue by taking the difference of crucible masses, before and after the ashing operation.

Carry out also a blank test using all reagents.

8.4.2 Adjustment of spectrometer

8.4.2.1 General

The ICP spectrometer shall be initially adjusted according to the manufacturer’s recommendations and

laboratory practice for quantitative analysis.

The definition of specific ICP components such as type of plasma observation view, torch, nebulizer

as well as all instrumental parameters such as plasma power, test sample solution uptake rate, etc.,

shall be defined during the performance test optimization procedure (see 8.4.2.2), to comply with the

performance parameter figures specified in Table 3, and shall remain unchanged thereafter during

calibration and analysis.

8.4.2.2 Performance test

The performance test is devised with the purpose of optimizing the ICP spectrometer to carry out

the analysis with adequate sensitivity and precision. Target values for these figures, called method

performance parameters are listed in Table 3.

The test is based on the determination of the following three parameters:

— detection limit (L );

D

— background equivalent concentration (C );

BE

— short-term precision (σ ).

r,Nmin

The definitions of these terms and the procedure for their evaluation shall be as described in Annex B.

The procedure shall be carried out as many times as necessary, with the optimization of the instrument

parameters after each turn, until the figures obtained are equal or lower than those given in Table 3.

Table 3 — Recommended performance parameters

λ Adopted C Adopted L σ

BE D r,Nmin

Element

nm μg/ml μg/ml %

P 178,287 0,86 0,025 2

V 310,230 0,44 0,021 2

Ti 334,941 0,12 0,003 2

Cu 324,75 0,28 0,003 2

Ni 231,604 0,53 0,016 2

Cr 267,716 0,25 0,007 2

Ba 455,403 0,06 0,002 2

Co 228,616 0,30 0,020 5

6 © ISO 2017 – All rights reserved

8.4.2.3 Measurements

8.4.2.3.1 Calibration solutions

Prepare a series of at least five calibration solutions plus a blank, all containing the equivalent of

6 000 µg/ml of iron (Fe), from 0,6 g of high-purity iron (5.1) portions, following exactly the decomposition

of the test portion procedure described in 8.4.1. Add convenient amounts of each single element stock

solutions (5.7.1 to 5.7.8) to cover the required analytical range. A suggested set of calibration solutions

is given in Annex A.

Aspirate the calibration solutions in order of increasing concentration, starting with the blank (zero)

calibration solution.

Aspirate water between each solution and repeat the measurements at least twice. Take the average of

the readings.

If saturation of detector(s) occurs while running the most concentrated calibration solutions, establish

the limit of linearity range of the curve and ei

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...