ISO 5348:1987

(Main)Mechanical vibration and shock — Mechanical mounting of accelerometers

Mechanical vibration and shock — Mechanical mounting of accelerometers

Vibrations et chocs mécaniques — Fixation mécanique des accéléromètres

General Information

Relations

Standards Content (Sample)

Foreword

IS0 (the International Organization for Standardization) is a worldwide federation of

national standards bodies (IS0 member bodies). The work of preparing International

Standards is normally carried out through IS0 technical committees. Each member

body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, govern-

mental and non-governmental, in liaison with ISO, also take part in the work.

Draft International Standards adopted by the technical committees are circulated to

the member bodies for approval before their acceptance as International Standards by

the IS0 Council. They are approved in accordance with IS0 procedures requiring at

least 75 % approval by the member bodies voting.

IS0 5348 was prepared by Technical Committee ISO/TC 108,

International Standard

Mechanical vibration and shock.

Users should note that all International Standards undergo revision from time to time

and that any reference made herein to any other International Standard implies its

latest edition, unless otherwise stated.

0 International Organization for Standardization, 1987 O

Printed in Switzerland

---------------------- Page: 1 ----------------------

INTERNATIONAL STANDARD IS0 5348 : 1987 (E)

Mechanical vibration and shock - Mechanical

mounting of accelerometers

The information desired is the vi

O Introduction

structure S.

The method most commonly used for determining the vibratory

motion, vs, of a structure or body S is that using an electro-

The electric signal, U, g

mechanical transducer T.

it would have

from what

VS, of the structure,

Vibration monitoring transducers fall into two broad classes:

m S to the sensitive

contacting and non-contacting transducers. Non-contacting

structural response transducers are placed in close proximity to

the structure and include such generic types as eddy current

Deviations may also occur owing to misalignment of the sen-

probes and optical proximity probes. Contacting transducers

sitive axis of the transducer, base bending, temperature tran-

are placed in mechanical contact with the structural system and

sients, mounting torque, and cable whip.

include such generic types as piezoelectric and piezoresistive

accelerometers and seismic velocity transducers. This Inter-

The mechanical mounting will change the useful frequency

national Standard is concerned with contacting type ac-

range for a given accuracy with regard to amplitude as well as

celerometers which enjoy wide current popularity. The concern

phase response (see 5.4.5).

with using such transducers is that the mechanical connection

between the accelerometer and the test structure alters the

response of the structure. This International Standard attempts

to isolate parameters of concern in the selection of a method to

1 Scope and field of application

mount the accelerometer to the structure.

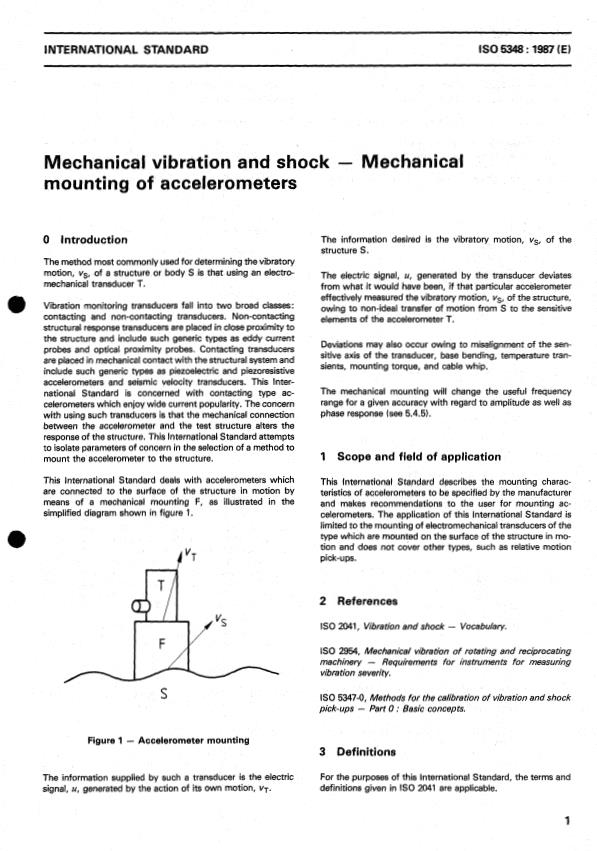

This International Standard deals with accelerometers which

This International Standard describes the mounting charac-

are connected to the surface of the structure in motion by

teristics of accelerometers to be specified by the manufacturer

means of a mechanical mounting F, as il

and makes recommendations to the user for mounting ac-

simplified diagram shown in figure 1.

celerometers. The application of this International Standard is

limited to the mounting of electromechanical transducers of the

type which are mounted on the surface of the structure in mo-

tion and does not cover other types, such as relative motion

pick-ups.

2 References

IS0 2041, Vibration and shock - Vocabulary.

IS0 2954, Mechanical vibration of rotating and reciprocating

machinery - Requirements for instruments for measuring

vibration severity.

S

IS0 5347-0, Methods for the calibration of vib

pick-ups - Part O : Basic concepts.

Figure 1 - Accelerometer mounting

3 Definitions

The information supplied by such a transducer is the electric For the purposes of this International Standard, the terms and

definitions given in IS0 2041 are applicable.

signal, U, generated by the action of its own motion, VT.

1

---------------------- Page: 2 ----------------------

IS0 5348 : 1W (E)

5 Considerations in the selection of a

4 Characteristics to be specified by

mounting method

manufacturers of accelerometers

5.1 General considerations

The manufacturer shall specify the following characteristics:

A contact accelerometer will achieve optimal performance only

a) the mounting surface and flatness tolerance of the

accelerometer to which

b) the geometrical dimensions of the accelerometer,

including:

celerometer attachment;

- the position of the centre of gravity for the

b) the motion of the structure shall be changed as little as

accelerometer as a whole,

possible by the addition of the accelerometer;

-

the position of the centre of gravity for the seismic

c) the ratio of the signal from the accelerometer to the mo-

mass of the accelerometer;

tion of the accelerometer shall not be distorted by operating

too near to its mounted fundamental resonance frequency.

c) the mounting technique ed during calibration;

In order to achieve these ideal conditions, it is necessary to

d) the normal and maximum (i.e. for less than 2 % change

ensure that

in the useful frequency range) mounting torque;

a) the accelerometer and its mounting are as rigid and firm

e) temperature limitation f the accelerometer and as possible (the mounting surfaces shall be as clean and flat

,

fastening device; as possible);

bl the mounting introduces minimum distorting motions

f) pertinent mechanical characteristics:

of its own (for example, simple symmetrical mountings are

best);

- total mass,

c) the mass of the accelerometer and mounting are small

- material of base,

in comparison with that of the structure under test (see

IS0 2954).

- the unmounted fundamental frequency of the ac-

celerometer,

- the frequency response characteristic under well-

5.2 Specific considerations

defined mounting conditions, describing the object on

which the transducer is mounted in terms of mass, 5.2.1 Frequency range of operation

material and dimensions,

The accelerometer shall be used well below its fundamental

- the maximum transverse sensitivity, and the fre- resonance frequency. If it is possible to use the manufacturers’

recommended mounting, then operation at frequencies not

quency at which it was determined;

greater than 20 % of their quoted mounted resonance should,

in the case of undamped accelerometers, ensure in most cases

g) a description of the various fastening devices provided

that errors of only a few per cent on the amplitude response oc-

for the accelerometer, i.e.

cur. If an estimate of the approximate error is required, it may

be made on the basis of an equivalent linear spring-mass

- diameter,

system with a given value of damping.

NOTE - For single shock measurements, one may expect errors of

- thread,

less than a few per cent if the mounted fundamental resonance fre-

quency is ten times greater than the inverse of the pulse duration.

- material;

5.2.2 Mounting torque

h) the frequency response curves of the accelerometer

with the type of mechanical mounting recommended by the

When screw thread mounting is used, the mounting torque

manufacturer and the effect of special mounting devices

shall be as recommended by the manufacturer.

supplied with the accelerometer, in particular :

- axial stiffness, with account taken of the state of

5.2.3 Cables

the surface of the structure in contact with the ac-

Loose cables may introduce tribo-electric effects. Stiff cables

celerometer and the tightening torque of the ac-

celerometer, can cause case strain when used with accelerometers with axial

connectors. Careful clamping of the cables is required to avoid

- transverse deflection stiffness, on the same basis. such problems (see figure 2).

2

---------------------- Page: 3 ----------------------

IS0 534û : 1987 (E)

5.4 Recommendations for particular types

5.3 Determination of the mounted fundamental

of mountings

resonance frequency

It is very useful, though at times difficult in practice, to deter-

5.4.1 General

mine accurately the mounted fundamental resonance fre

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.