ISO 6435:2024

(Main)Stainless steel bars for the reinforcement of concrete

Stainless steel bars for the reinforcement of concrete

This document specifies technical requirements for hot rolled stainless steel plain bars and ribbed bars used as reinforcement in concrete. It is applicable to steel delivered in the form of bars, coils and de-coiled products. It does not apply to ribbed bars produced from finished products The production process is at the discretion of the manufacturer.

Barres en aciers inoxydables pour l'armature du béton

General Information

- Status

- Published

- Publication Date

- 11-Apr-2024

- Technical Committee

- ISO/TC 17/SC 16 - Steels for the reinforcement and prestressing of concrete

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 11-Jun-2025

- Completion Date

- 12-Feb-2026

Overview - ISO 6435:2024 (Stainless steel bars for the reinforcement of concrete)

ISO 6435:2024 is the first-edition international standard that specifies technical requirements for hot‑rolled stainless steel plain bars and ribbed bars used as reinforcement in concrete. Published April 2024, the standard covers products delivered as bars, coils and de‑coiled products and clarifies that it does not apply to ribbed bars produced from finished products. The production process is left to the manufacturer’s discretion.

Key SEO terms: ISO 6435:2024, stainless steel bars, reinforcement of concrete, ribbed bars, plain bars, hot rolled.

Key topics and technical requirements

ISO 6435:2024 organizes practical requirements and test methods for stainless steel reinforcing bars. Major topics include:

- Scope and definitions - Defines stainless steel bars (≥ 10.5 % Cr, ≤ 1.2 % C) and product forms (bars, coils, de‑coiled).

- Dimensions and mass per unit length - Nominal diameters, cross‑sectional areas and tables of mass per unit length with permissible deviations for different stainless grades.

- Rib requirements - Minimum rib geometry and distribution requirements for ribbed bars (transverse ribs, at least two rows).

- Chemical composition - Cast‑analysis composition limits and rules for product analysis and permissible deviations.

- Mechanical properties - Requirements for tensile strength, proof strength, elongation, bending, rebending after ageing, and special impact requirements for duplex (austenitic‑ferritic) steels.

- Corrosion resistance & magnetic permeability - Test requirements and acceptance criteria to ensure long‑term performance in concrete.

- Testing, inspection and conformity - Specified tests (tensile, bend, rebend, impact, chemical, magnetic and corrosion tests), evaluation of production conformity and acceptance testing of deliveries.

- Designation, marking and delivery - Marking on bars, bundle identification, delivery lengths and permissible length deviations; options for manufacturer–purchaser agreement are provided.

Practical applications and users

ISO 6435:2024 is intended for anyone specifying, producing or testing stainless steel reinforcing bars for concrete applications:

- Manufacturers and steel producers - to design, manufacture and mark compliant hot‑rolled plain and ribbed bars.

- Rebar suppliers and fabricators - for ordering, identification and acceptance testing of deliveries.

- Structural and civil engineers, specifiers and contractors - to select appropriate stainless rebar grades and ensure compliance for durable reinforced concrete in aggressive or corrosive environments.

- Testing laboratories and inspection bodies - to perform tensile, bend, corrosion and magnetic permeability tests in accordance with the standard.

Typical uses include reinforced concrete for infrastructure, marine structures, bridges, tunnels, chemical plants and buildings where corrosion resistance and long service life are required.

Related standards

ISO 6435 references and complements other standards, including:

- ISO 6935‑1 / ISO 6935‑2 (steel for reinforcement - plain and ribbed bars)

- ISO 15510 (stainless steels - chemical composition)

- ISO 15630‑1 (test methods for reinforcing bars)

- ISO 148‑1 (Charpy impact test)

- EN 196‑1, EN 197‑1 (cement testing and specifications)

For procurement and specification, reference ISO 6435:2024 alongside these complementary standards to ensure complete technical coverage.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

ISO 6435:2024 is a standard published by the International Organization for Standardization (ISO). Its full title is "Stainless steel bars for the reinforcement of concrete". This standard covers: This document specifies technical requirements for hot rolled stainless steel plain bars and ribbed bars used as reinforcement in concrete. It is applicable to steel delivered in the form of bars, coils and de-coiled products. It does not apply to ribbed bars produced from finished products The production process is at the discretion of the manufacturer.

This document specifies technical requirements for hot rolled stainless steel plain bars and ribbed bars used as reinforcement in concrete. It is applicable to steel delivered in the form of bars, coils and de-coiled products. It does not apply to ribbed bars produced from finished products The production process is at the discretion of the manufacturer.

ISO 6435:2024 is classified under the following ICS (International Classification for Standards) categories: 77.140.15 - Steels for reinforcement of concrete. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 6435:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

International

Standard

ISO 6435

First edition

Stainless steel bars for the

2024-04

reinforcement of concrete

Barres en aciers inoxydables pour l'armature du béton

Reference number

© ISO 2024

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

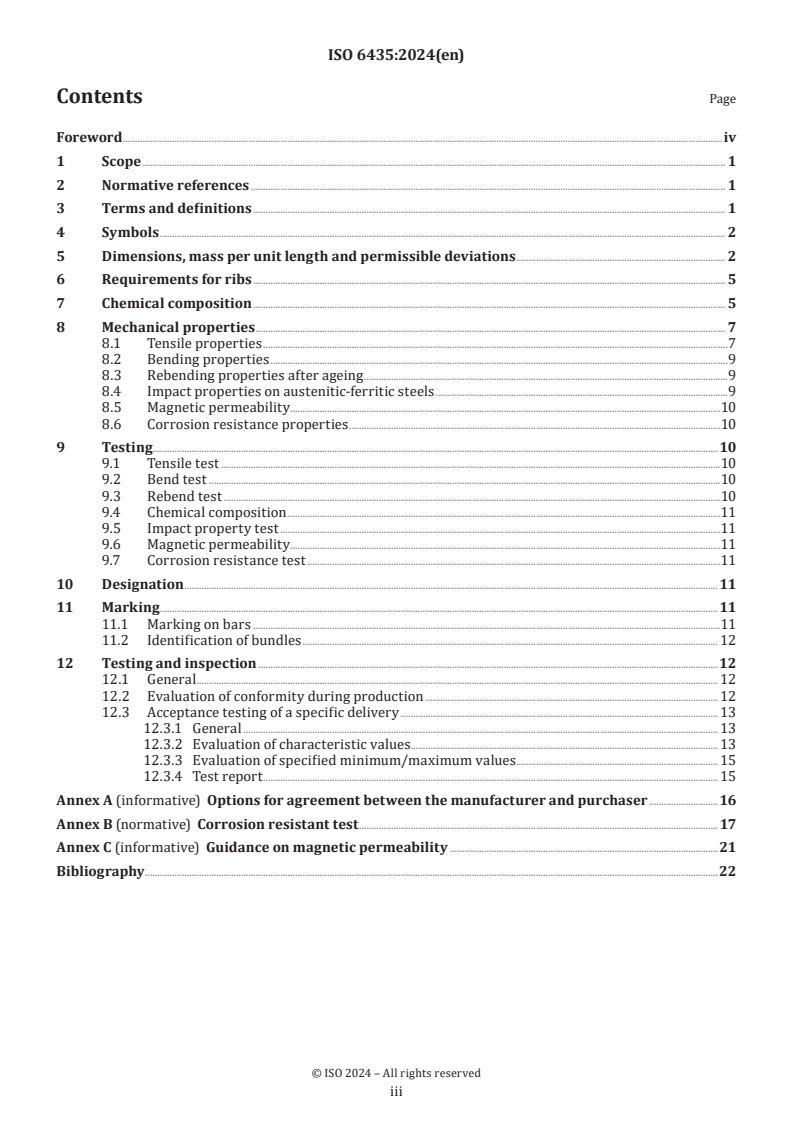

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols . 2

5 Dimensions, mass per unit length and permissible deviations . 2

6 Requirements for ribs . 5

7 Chemical composition . 5

8 Mechanical properties . 7

8.1 Tensile properties .7

8.2 Bending properties .9

8.3 Rebending properties after ageing .9

8.4 Impact properties on austenitic-ferritic steels .9

8.5 Magnetic permeability.10

8.6 Corrosion resistance properties .10

9 Testing. 10

9.1 Tensile test .10

9.2 Bend test .10

9.3 Rebend test .10

9.4 Chemical composition .11

9.5 Impact property test .11

9.6 Magnetic permeability.11

9.7 Corrosion resistance test .11

10 Designation .11

11 Marking . .11

11.1 Marking on bars .11

11.2 Identification of bundles . 12

12 Testing and inspection .12

12.1 General . 12

12.2 Evaluation of conformity during production . 12

12.3 Acceptance testing of a specific delivery . 13

12.3.1 General . 13

12.3.2 Evaluation of characteristic values . . 13

12.3.3 Evaluation of specified minimum/maximum values . 15

12.3.4 Test report . 15

Annex A (informative) Options for agreement between the manufacturer and purchaser .16

Annex B (normative) Corrosion resistant test . 17

Annex C (informative) Guidance on magnetic permeability .21

Bibliography .22

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee

has been established has the right to be represented on that committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely

with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types

of ISO document should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent

rights in respect thereof. As of the date of publication of this document, ISO had not received notice of (a)

patent(s) which may be required to implement this document. However, implementers are cautioned that

this may not represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents. ISO shall not be held responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee Technical Committee ISO/TC 17, Steel, Subcommittee

SC 16, Steels for the reinforcement and prestressing of concrete.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

International Standard ISO 6435:2024(en)

Stainless steel bars for the reinforcement of concrete

1 Scope

This document specifies technical requirements for hot rolled stainless steel plain bars and ribbed bars

used as reinforcement in concrete.

It is applicable to steel delivered in the form of bars, coils and de-coiled products. It does not apply to ribbed

bars produced from finished products

The production process is at the discretion of the manufacturer.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

ISO 148-1, Metallic materials — Charpy pendulum impact test — Part 1: Test method

ISO 6935-1, Steel for the reinforcement of concrete — Part 1: Plain bars

ISO 6935-2, Steel for the reinforcement of concrete — Part 2: Ribbed bars

ISO 14284, Steel and iron — Sampling and preparation of samples for the determination of chemical composition

ISO 15510, Stainless steels — Chemical composition

ISO 15630-1, Steel for the reinforcement and prestressing of concrete — Test methods — Part 1: Reinforcing

bars, rods and wire

EN 196-1, Methods of testing cement — Part 1: Determination of strength

EN 197-1, Cement — Part 1: Composition, specifications and conformity criteria for common cements

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 6935-1, ISO 6935-2, ISO 15510 and

the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

stainless steel bars

stainless steel bars with at least 10,5 % (mass fraction) of chromium and max. 1,2 % (mass fraction) of carbon

4 Symbols

Symbol Unit Description

A % Percentage elongation after fracture

A % Percentage total extension at maximum force

gt

S mm Nominal cross-sectional area

d mm Nominal diameter of the bar

a

R MPa Tensile strength

m

a

R MPa 0,2 % proof strength, plastic extension

p0,2

a

R MPa 7,0 % proof strength, plastic extension

7,0

a 2

1 MPa = 1 N/mm .

5 Dimensions, mass per unit length and permissible deviations

Dimensions are given in Table 1, mass per unit length and permissible deviations are given in Table 2,

Table 3 and Table 4. By agreement between the manufacturer and the purchaser, the following options shall

be applied.

— Ribbed bars and plain bars for which the nominal diameters are other than those shown in Table 2 may

be used. The permissible deviation of nominal diameters larger than 50 mm shall be ±4 %.

— The permissible deviation on mass per length of plain bars may be replaced by tolerances on diameters.

A list of options for agreement between the manufacturer and the purchaser is provided in Annex B.

Table 1 — Dimensions

a

Nominal bar diameter Nominal cross-sectional area

d S

mm mm

Ribbed bars Plain bars

6 6 28,3

8 8 50,3

10 10 78,5

12 12 113

14 14 154

16 16 201

20 20 314

22 380

25 491

28 616

32 804

40 1 257

50 1 964

a 2

S = 0,785 4 × d .

Table 2 — Mass per unit length and permissible deviations: Austenite

b

Nominal Mass per unit length Permissi-

bar diame- ble devia-

kg/m

a c

ter tion

d %

mm

4301-304- 4311-304- 4401-316- 4429-316- 4404- 4529- 4315-304- 4495-316-

R P R P

00-I 53-I 00-I 53-I 316-03-I 089-26-I 51-I 51-J

6 6 0,224 0,226 0,229 0,224 0,226 ±8 ±8

8 8 0,397 0,402 0,407 0,397 0,402 ±8 ±8

10 10 0,620 0,628 0,636 0,620 0,628 ±6 ±5

12 12 0,893 0,904 0,915 0,893 0,904 ±6 ±5

14 14 1,22 1,23 1,25 1,22 1,23 ±5 ±5

16 16 1,59 1,61 1,63 1,59 1,61 ±5 ±5

20 20 2,48 2,51 2,54 2,48 2,51 ±5 ±5

22 3,00 3,04 3,08 3,00 3,04 ±5

25 3,88 3,93 3,98 3,88 3,93 ±4

28 4,87 4,93 4,99 4,87 4,93 ±4

32 6,35 6,43 6,51 6,35 6,43 ±4

40 9,93 10,06 10,18 9,93 10,06 ±4

50 15,52 15,7 15,91 15,52 15,71 ±4

a

“R” means ribbed bars and “P” means plain bars.

b −3

Mass per unit length = Density × 10 × S .

c

Permissible deviation refers to a single bar.

Table 3 — Mass per unit length and permissible deviations: Austenite-Ferrite

b

Nominal Mass per unit length Permissi-

bar diame- ble devia-

kg/m

a c

ter tion

d %

mm

4482-320- 4462-318- 4362-323- 4460-312- 4410-327- 4501-327- 4062-322-

R P R P

01-X 03-I 04-I 00-I 50-E 60-I 02-U

6 6 0,221 ±8 ±8

8 8 0,392 ±8 ±8

10 10 0,612 ±6 ±5

12 12 0,881 ±6 ±5

14 14 1,20 ±5 ±5

16 16 1,57 ±5 ±5

20 20 2,45 ±5 ±5

22 2,96 ±5

25 3,83 ±4

28 4,80 ±4

32 6,27 ±4

40 9,80 ±4

50 15,32 ±4

a

“R” means ribbed bars and “P” means plain bars.

b −3

Mass per unit length = Density × 10 × S .

c

Permissible deviation refers to a single bar.

Table 4 — Mass per unit length and permissible deviations: Ferrite and martensite

b

Nominal Mass per unit length Permissi-

bar diame- ble devia-

kg/m

a c

ter tion

d %

Ferrite Martensite

mm

R P 4030-410-90-X 4003-410-77-I 4024-410-09-E R P

6 6 0,218 ±8 ±8

8 8 0,387 ±8 ±8

10 10 0,604 ±6 ±5

12 12 0,870 ±6 ±5

14 14 1,19 ±5 ±5

16 16 1,55 ±5 ±5

20 20 2,42 ±5 ±5

22 2,93 ±5

25 3,78 ±4

28 4,74 ±4

32 6,19 ±4

40 9,68 ±4

50 15,12 ±4

a

“R” means ribbed bars and “P” means plain bars.

b −3

Mass per unit length = Density × 10 × S .

c

Permissible deviation refers to a single bar.

The delivery length is subject to agreement between the manufacturer and purchaser.

NOTE Common delivery lengths of straight bars are 6 m, 9 m, 12 m, 15 m and 18 m.

Unless otherwise agreed, the permissible deviation on delivery lengths from the rolling mill shall be

+100,0 mm.

6 Requirements for ribs

Ribbed bars shall have transverse ribs. Longitudinal ribs may be present or not.

There shall be at least two rows of transverse ribs equally distributed around the perimeter of the bar. The

transverse ribs within each row shall be distributed uniformly over the entire length of the bar, except in

the area of marking.

Ribs shall conform to the requirements given in ISO 6935-2.

7 Chemical composition

The chemical composition of the steel, as determined by cast analysis, shall conform to Table 5, Table 6 and

Table 7.

The elements not listed in Table 5, Table 6 and Table 7 shall not be intentionally added without agreement

between manufacturer and purchaser. Precautionary measures shall be taken to avoid unintentional

chemical elements which would impair mechanical properties.

In cases where product analysis is required, it shall be agreed at the time of enquiry and order.

The permissible deviation of the product analysis relative to the cast analysis as specified in Table 5, Table 6

and Table 7 are given in Table 8.

Table 5 — Chemical composition based on cast analysis — Maximum values of mass fractions, in

percentage: Austenite

a c d

ISO number C Si Mn P S Cr Mo Ni N Others

b

4301-304-00-I 0,07 1,00 2,00 0,045 0,030 17,5 to 19,5 - 8,0 to 10,5 0,10 -

4311-304-534 0,030 1,00 2,00 0,045 0,030 17,5 to 19,5 - 8,0 to 11,0 0,12 to 0,22 -

4401-316-00-I 0,08 1,00 2,00 0,045 0,030 16,0 to 18,0 2,00 to 3,0 10,0 to 13,0 0,10 -

4429-316-53-I 0,030 1,00 2,00 0,045 0,030 16,5 to 18,5 2,50 to 3,0 10,5 to 13,0 0,12 to 0,22 -

4404-316-03-I 0,030 1,00 2,00 0,045 0,030 16,5 to 18,5 2,00 to 3,0 10,0 to 13,0 0,10 -

4529-089-26-I 0,020 0,75 2,00 0,035 0,015 19,0 to 21,0 6,0 to 7,0 24,0 to 26,0 0,15 to 0,25 Cu: 0,50 to 1,50

4315-304-51-I 0,08 1,00 2,50 0,045 0,030 18,0 to 20,0 - 7,0 to 10,5 0,10 to 0,30 -

4495-316-51-J 0,08 1,00 2,00 0,045 0,030 16,0 to 18,0 2,00 to 3,0 10,0 to 14,0 0,10 to 0,22 -

4406-316-53-I 0,030 1,00 2,00 0,045 0,030 16,5 to 18,5 2,00 to 3,0 10,0 to12,5 0,12 to 0,22

4571-316-35-I 0,08 1,00 2,00 0,045 0,030 16,5 to 18,5 2,00 to 2,50 10,5 to 13,5 - Ti : 5xC to 0,70

a

The ISO numbers and chemical compositions are referenced in ISO 15510.

b

Particular ranges of sulphur mass fraction can provide improvement of particular properties. For machinability, a controlled sulphur mass fraction between

0,015 % to 0,030 % is recommended.

c

For special purposes (e.g. hot workability), the maximum nickel mass fraction can be increased by the following amounts to minimize ferrite content:

— by 0,50 % for 4301-304-00-I;

— by 1,00 % for 4401-316-00-I and 4429-316-53-I;

— by 1,50 % for 4404-316-03-I.

d

Nb can be added up to 0,15 %.

Table 6 — Chemical composition based on cast analysis — Maximum values of mass fractions, in

percentage: Austenite-Ferrite

a

ISO number C Si Mn P S Cr Mo Ni N Others

4482-320-01-X 0,030 1,00 4,0 to 0,035 0,030 19,5 to 21,5 0,10 to 0,60 1,50 to 3,50 0,05 to 0,20 Cu: 1,00

6,0

b

4462-318-03-I 0,030 1,00 2,00 0,035 0,015 21,0 to 23,0 2,50 to 3,5 4,5 to 6,5 0,10 to 0,22 -

4362-323-04-I 0,030 1,00 2,00 0,035 0,015 22,0 to 24,5 0,10 to 0,60 3,5 to 5,5 0,05 to 0,20 Cu: 0,10 to 0,60

4460-312-00-I 0,050 1,00 2,00 0,035 0,030a 25,0 to 28,0 1,30 to 2,00 4,5 to 6,5 0,05 to 0,20 -

4410-327-50-E 0,030 1,00 2,00 0,035 0,015 24,0 to 26,0 3,0 to 4,5 6,0 to 8,0 0,24 to 0,35 -

Cu: 0,50 to 1,00

4501-327-60-I 0,030 1,00 1,00 0,030 0,010 24,0 to 26,0 3,0 to 4,0 6,0 to 8,0 0,20 to 0,30

W: 0,50 to 1,00

4062-322-02-U 0,030 1,00 2,00 0,040 0,010 21,5 to 24,0 0,45 1,00 to 2,80 0,18 to 0,26 -

4,0 to

4162-321-01-E 0,040 1,00 0,040 0,015 21,0to22,0 0,10to0,80 1,35to1,70 0,20to0,25 Cu: 0,10 to 0,80

6,0

a

The ISO numbers and chemical compositions are referenced in ISO 15510.

b

For special applications, the lower limits of N, Cr, and Mo can be limited to 0,14 %, 22,0 %, and 3,0 %.

Table 7 — Chemical composition based on cast analysis — Maximum values of mass fractions, in

percentage: Ferrite and martensite

a

ISO number C Si Mn P S Cr Mo Ni N Others

4030-410-90-X 0,030 1,00 1,00 0,040 0,030 11,00 to 13,50 - - -

-

4003-410-77-I 0,030 1,00 2,00 0,040 0,015 10,5 to12,5 - 0,30 to1,10 0,030

4024-410-09-E 0,12 to 0,17 1,00 1,00 0,040 0,015 12,0 to 14,0 - - - -

a

The ISO numbers and chemical compositions are referenced in ISO 15510.

Table 8 — Permissible deviations of chemical compositions

a

Specified limits, cast analysis Permissible deviation

Element

% (mass fraction) % (mass fraction)

≤0,010 +0,002

C

>0,010 ≤0,03 +0,005

(Carbon)

>0,030 ≤0,17 ±0,01

Si

≤1,00 +0,05

(Silicon)

≤1,00 +0,03

Mn

(Manganese)

>1,00 ≤2,50 +0,04

≤0,040 +0,005

P

(Phosphorus)

>0,040 ≤0,045 +0,01

S

≤0,030 +0,005

(Sulphur)

≥11,0 ≤15,0 ±0,10

Cr

>15,0 ≤20,00 ±0,15

(Chromium)

>20,0 ≤28,0 ±0,20

>0,20 ≤0,60 ±0,03

Mo

>0,60 ≤2,00 ±0,05

(Molybdenum)

>2,00 ≤7,0 ±0,10

≥3,5 ≤5,0 ±0,07

>5,0 ≤10,0 ±0,10

Ni

(Nickel)

>10,0 ≤20,0 ±0,15

>20,0 ≤26,0 ±0,20

≥0,05 ≤0,19 ±0,01

N

>0,19 ≤0,25 ±0,02

(Nitrogen)

>0,25 ≤0,35 ±0,03

≤0,50 ±0,03

Cu

(Copper)

>0,50 ≤1,00 ±0,05

W

≤1,00 ±0,03

(Tungsten)

a

± means that in one cast, the deviation can occur over the upper value or under the lower value of the specified range in Table 9, but not both at the same time.

8 Mechanical properties

8.1 Tensile properties

The tensile test shall be performed in accordance with 9.1.

The bars shall conform to the requirements in Table 9.

In the context of this document, the characteristic value is (unless otherwise indicated) the lower or upper

limit of the statistical tolerance interval at which there is a 90 % probability (1 − t = 0,90) that 95 % (p =

0,95) of the values are at or above this lower limit, or are at or below this upper limit, respectively. This

definition refers to the long-term quality level of production.

Table 9 — Tensile properties

Specified characteristic Ductility properties

value of

Specified characteris- Specified characteristic

b

0,2 proof strength d

tic value of value of elongation

Ductility

a

Steel grade

R

b

Class

p0,2 R /R %

m p0,2

c

MPa

e A

Minimum Maximum A

gt

SB400AR 400 — —

SB450AR 450 — —

SB500AR 500 —

A SB550AR 550 — ≥1,05 — ≥2,5

SB600AR 600 — —

SB700AR 700 — —

SB750AR 750 — —

SB300BR —

300 ≥16

SB300BP

SB400BR 400 — ≥14

SB450BR 450 — —

SB500BR 500 — ≥14

B ≥1,08 ≥5

SB550BR 550 — —

SB600BR 600 — —

SB700BR 700 — —

SB750BR 750 — —

SB400CR 400 — —

SB450CR 450 — —

SB500CR 500 — —

f

C SB550CR 550 — ≥ 1,15 and ˂1,35 — ≥7,5

SB600CR 600 — —

SB700CR 700 — —

SB750CR 750 — —

a Reinforcement can be classified according to the specified characteristic values of yield strength. The first “SB” means

"Stainless steel Bars for the reinforcement of concrete". The next 3 digits represent the specified characteristic value of yield

strength. The sixth “A”, “B”, “C” and "D" means each ductility class. And last "R" and "P" mean Ribbed bar and Plain bar.

b The maximum actual proof strength R , shall not exceed (1,3 x R ), where R is the characteristic value.

p0,2 p0,2 p0,2

c If the total extension at maximum force (A ) is below the minimum value specified in Table 9, this shall not be the cause for

gt

non-conformity, provided the minimum percentage elongation after fracture is met as in Table 9.

d By agreement between the manufacturer and purchaser, the type of elongation shall be selected between A and A . If the

gt

type of elongation is not specified by agreement, A shall be used.

gt

e For steel bars with a nominal diameter equal to or higher than 32 mm in ductility class D, the minimum specified

characteristic value for A may be de

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...