ISO 21561-2:2016

(Main)Styrene-butadiene rubber (SBR) — Determination of the microstructure of solution-polymerized SBR — Part 2: FTIR with ATR method

Styrene-butadiene rubber (SBR) — Determination of the microstructure of solution-polymerized SBR — Part 2: FTIR with ATR method

ISO 21561-2:2016 specifies procedures for the quantitative determination of the microstructure of the butadiene and the content of styrene in solution-polymerized SBR (S-SBR) by Fourier Transform Infrared Spectrometry (FTIR) with Attenuated Total Reflection (ATR) method. The styrene content is expressed in mass % relative to the whole polymer. The vinyl, trans and cis contents are expressed in mol % relative to the butadiene content. This method is only applicable to raw rubbers. NOTE 1 Precision as shown in Annex A may not be obtained for S-SBRs containing polystyrene block or styrene content more than 45 mass %. NOTE 2 Only "vinyl", "trans" and "cis", are used in this part of ISO 21561. However, the expression of vinyl, trans and cis mean as follows in general: - vinyl: vinyl unit, vinyl bond, 1,2-unit, 1,2-bond, 1,2-vinyl-unit or 1,2-vinyl-bond; - trans: 1,4-trans unit, 1,4-trans bond, trans-1,4 unit or trans1,4 bond; - cis: 1,4-cis unit, 1,4-cis bond, cis-1,4 unit or cis-1,4 bond.

Caoutchouc styrène-butadiène (SBR) — Détermination de la microstructure du SBR polymérisé en solution — Partie 2: Méthode FTIR avec ATR

General Information

- Status

- Withdrawn

- Publication Date

- 07-Mar-2016

- Drafting Committee

- ISO/TC 45/SC 3/WG 5 - Synthetic and reclaimed rubber

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 15-Aug-2024

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 03-Sep-2022

- Effective Date

- 10-May-2014

- Effective Date

- 10-May-2014

Overview

ISO 21561-2:2016 specifies a standardized laboratory method for quantitative determination of the microstructure of solution‑polymerized styrene‑butadiene rubber (S‑SBR) using Fourier Transform Infrared Spectrometry (FTIR) with an Attenuated Total Reflection (ATR) accessory. The method reports styrene content as mass % of the whole polymer and butadiene microstructures (vinyl, trans, cis) as mol % relative to the butadiene fraction. It applies only to raw rubbers and is intended for industrial quality control, R&D and material characterization.

Key topics and technical requirements

- Principle: Measure ATR‑FTIR absorbances at characteristic wavenumbers and calculate component contents using regression formulae derived from reference S‑SBR samples.

- Sampling: Prepare test pieces in accordance with ISO 1795 (raw rubber sampling and preparative procedures).

- Apparatus:

- FTIR with DTGS or TGS detector, typically 32 scans, 2 cm−1 resolution, spectral range about 600–1 800 cm−1.

- Single‑bounce ATR (diamond crystal), 45° incidence, and a sample pressure clamp (preferably torque‑controlled).

- Measurement:

- Record background and sample ATR spectra under consistent atmospheric conditions to avoid CO2 interference.

- Measure absorbance peaks for styrene, cis, vinyl and trans at specified wavenumber ranges (examples: styrene ~695–761 cm−1; vinyl ~905–996 cm−1; trans ~962–967 cm−1; baseline at 1 200 cm−1). Note: cis peaks can be weak or hidden when styrene content is high.

- Calculations:

- Apply baseline corrections and compute normalized absorbance ratios.

- Use specified regression equations to obtain styrene and microstructure contents in mass %. Convert vinyl/trans/cis to mol % of butadiene using the provided formulae.

- Limitations: Precision shown in Annex A may not be achieved for S‑SBRs containing polystyrene blocks or with styrene > ~45 mass %.

- Reporting: Test report must include sample details, reference to ISO 21561‑2, number of test pieces, results (rounded to one decimal %), test procedures used and test dates.

Applications and users

- Polymer producers: incoming quality control of S‑SBR batches and process monitoring.

- Tire and rubber product manufacturers: verifying polymer microstructure for performance (wear, wet grip, hysteresis).

- Analytical laboratories and R&D: routine characterization and comparative studies of S‑SBR formulation and synthesis routes.

- Regulatory/standards labs: ensuring traceable, repeatable microstructure data for material specifications.

Related standards

- ISO 21561‑1 - Part 1: H‑NMR and FTIR with cast‑film method (alternative microstructure determination methods).

- ISO 1795 - Sampling and preparative procedures for raw rubber.

- See Annex A and B of ISO 21561‑2 for precision data and regression equation acquisition details.

Keywords: ISO 21561‑2:2016, SBR microstructure, solution‑polymerized SBR, FTIR ATR method, styrene content, vinyl cis trans, raw rubber testing, polymer characterization.

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

ISO 21561-2:2016 is a standard published by the International Organization for Standardization (ISO). Its full title is "Styrene-butadiene rubber (SBR) — Determination of the microstructure of solution-polymerized SBR — Part 2: FTIR with ATR method". This standard covers: ISO 21561-2:2016 specifies procedures for the quantitative determination of the microstructure of the butadiene and the content of styrene in solution-polymerized SBR (S-SBR) by Fourier Transform Infrared Spectrometry (FTIR) with Attenuated Total Reflection (ATR) method. The styrene content is expressed in mass % relative to the whole polymer. The vinyl, trans and cis contents are expressed in mol % relative to the butadiene content. This method is only applicable to raw rubbers. NOTE 1 Precision as shown in Annex A may not be obtained for S-SBRs containing polystyrene block or styrene content more than 45 mass %. NOTE 2 Only "vinyl", "trans" and "cis", are used in this part of ISO 21561. However, the expression of vinyl, trans and cis mean as follows in general: - vinyl: vinyl unit, vinyl bond, 1,2-unit, 1,2-bond, 1,2-vinyl-unit or 1,2-vinyl-bond; - trans: 1,4-trans unit, 1,4-trans bond, trans-1,4 unit or trans1,4 bond; - cis: 1,4-cis unit, 1,4-cis bond, cis-1,4 unit or cis-1,4 bond.

ISO 21561-2:2016 specifies procedures for the quantitative determination of the microstructure of the butadiene and the content of styrene in solution-polymerized SBR (S-SBR) by Fourier Transform Infrared Spectrometry (FTIR) with Attenuated Total Reflection (ATR) method. The styrene content is expressed in mass % relative to the whole polymer. The vinyl, trans and cis contents are expressed in mol % relative to the butadiene content. This method is only applicable to raw rubbers. NOTE 1 Precision as shown in Annex A may not be obtained for S-SBRs containing polystyrene block or styrene content more than 45 mass %. NOTE 2 Only "vinyl", "trans" and "cis", are used in this part of ISO 21561. However, the expression of vinyl, trans and cis mean as follows in general: - vinyl: vinyl unit, vinyl bond, 1,2-unit, 1,2-bond, 1,2-vinyl-unit or 1,2-vinyl-bond; - trans: 1,4-trans unit, 1,4-trans bond, trans-1,4 unit or trans1,4 bond; - cis: 1,4-cis unit, 1,4-cis bond, cis-1,4 unit or cis-1,4 bond.

ISO 21561-2:2016 is classified under the following ICS (International Classification for Standards) categories: 83.060 - Rubber. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 21561-2:2016 has the following relationships with other standards: It is inter standard links to ISO 21561-2:2024, ISO 21561:2005/Amd 1:2010, ISO 21561:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 21561-2:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 21561-2

First edition

2016-03-01

Styrene-butadiene rubber (SBR) —

Determination of the microstructure

of solution-polymerized SBR —

Part 2:

FTIR with ATR method

Caoutchouc styrène-butadiène (SBR) — Détermination de la

microstructure du SBR polymérisé en solution —

Partie 2: Méthode FTIR avec ATR

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

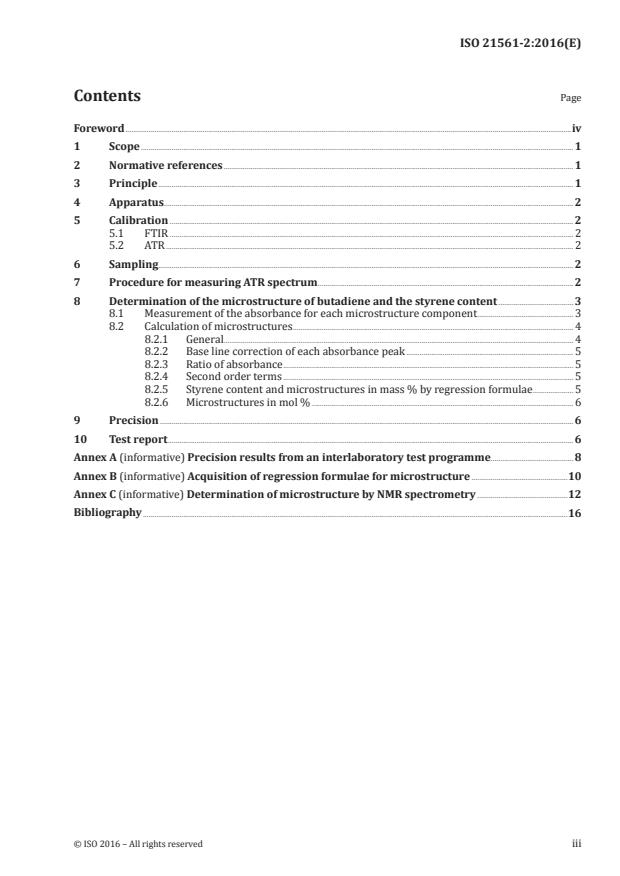

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Principle . 1

4 Apparatus . 2

5 Calibration . 2

5.1 FTIR . 2

5.2 ATR . 2

6 Sampling . 2

7 Procedure for measuring ATR spectrum . 2

8 Determination of the microstructure of butadiene and the styrene content .3

8.1 Measurement of the absorbance for each microstructure component . 3

8.2 Calculation of microstructures . 4

8.2.1 General. 4

8.2.2 Base line correction of each absorbance peak . 5

8.2.3 Ratio of absorbance . 5

8.2.4 Second order terms . 5

8.2.5 Styrene content and microstructures in mass % by regression formulae . 5

8.2.6 Microstructures in mol % . 6

9 Precision . 6

10 Test report . 6

Annex A (informative) Precision results from an interlaboratory test programme .8

Annex B (informative) Acquisition of regression formulae for microstructure .10

Annex C (informative) Determination of microstructure by NMR spectrometry .12

Bibliography .16

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 45, Rubber and rubber products, Subcommittee

SC 2, Testing and analysis.

This first edition of ISO 21561-2 cancels and replaces ISO 21561:2005, which has been technically

revised. It also incorporates Amendment ISO 21561:2005/Amd.1:2010.

ISO 21561 consists of the following parts, under the general title Styrene-butadiene rubber (SBR) —

Determination of the microstructure of solution-polymerized SBR:

— Part 1: H-NMR and IR with cast-film method

— Part 2: FTIR with ATR method

iv © ISO 2016 – All rights reserved

INTERNATIONAL STANDARD ISO 21561-2:2016(E)

Styrene-butadiene rubber (SBR) — Determination of the

microstructure of solution-polymerized SBR —

Part 2:

FTIR with ATR method

WARNING — Persons using this part of ISO 21561 should be familiar with normal laboratory

practice. This part of ISO 21561 does not purport to address all the safety problems, if any,

associated with its use. It is the responsibility of the user to establish appropriate safety and

health practices and to ensure compliance with any national regulatory conditions.

CAUTION — Certain procedures specified in this part of ISO 21561 might involve the use or

generation of substances, or the generation of waste, that could constitute a local environmental

hazard. Reference should be made to appropriate documentation on safe handling and disposal

after use.

1 Scope

This part of ISO 21561 specifies procedures for the quantitative determination of the microstructure

of the butadiene and the content of styrene in solution-polymerized SBR (S-SBR) by Fourier Transform

Infrared Spectrometry (FTIR) with Attenuated Total Reflection (ATR) method. The styrene content is

expressed in mass % relative to the whole polymer. The vinyl, trans and cis contents are expressed in

mol % relative to the butadiene content. This method is only applicable to raw rubbers.

NOTE 1 Precision as shown in Annex A may not be obtained for S-SBRs containing polystyrene block or

styrene content more than 45 mass %.

NOTE 2 Only “vinyl”, “trans” and “cis”, are used in this part of ISO 21561. However, the expression of vinyl,

trans and cis mean as follows in general:

— vinyl: vinyl unit, vinyl bond, 1,2-unit, 1,2-bond, 1,2-vinyl-unit or 1,2-vinyl-bond;

— trans: 1,4-trans unit, 1,4-trans bond, trans-1,4 unit or trans1,4 bond;

— cis: 1,4-cis unit, 1,4-cis bond, cis-1,4 unit or cis-1,4 bond.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 1795, Rubber, raw natural and raw synthetic — Sampling and further preparative procedures

3 Principle

The IR spectrum of the S-SBR sample is measured by FTIR with ATR. The absorbances that are

characteristic of each microstructure component and styrene at the specified wavelengths are used

to determine the content of each component by using the specific formulae presented in this part of

ISO 21561.

4 Apparatus

4.1 FTIR, of the following specifications:

— Detector: Deuterium Tri-Glycine Sulfate (DTGS) or Tri-Glycine Sulfate (TGS);

— Number of scans: 32;

−1

— Resolution: 2 cm ;

−1 −1

— Range of wavelength: 600 cm to 1 800 cm .

4.2 ATR, of the following specifications:

— Type: Single bounce ATR;

— Crystal: Diamond;

— Angle of incidence: 45°;

— Sample pressure clamp: A concave or a flat-shaped clamp which is capable of maintaining a constant

pressure on the sample. The use of a torque wrench is preferable.

5 Calibration

5.1 FTIR

Adjust the optical bench alignment of FTIR spectrometer according to the manufacturer’s

instruction manual.

5.2 ATR

Set ATR in the sample chamber of FTIR and adjust the optical alignment of ATR according to the

manufacturer’s instruction manual.

6 Sampling

6.1 Prepare the test sample in accordance with ISO 1795.

NOTE The extraction of ordinary extender oils by solvent is not necessary.

6.2 Cut out a test piece from the test sample. The test piece shall have a flat surface to give good contact

with the ATR crystal and be approximately the same size as the crystal, usually a few square millimetres.

7 Procedure for measuring ATR spectrum

7.1 Set up FTIR according to the manufacturer’s instruction manual.

7.2 Set ATR in a sample chamber of FTIR.

7.3 Measure the background spectrum with the conditions shown in 4.1.

7.4 Put the test piece on the ATR crystal and contact it as completely as possible to the crystal surface,

preferably using the clamp specified in 4.2. The contact between the test piece and the crystal affects the

absorbance of ATR spectra.

2 © ISO 2016 – All rights reserved

7.5 Measure the sample spectrum with the conditions shown in 4.1.

7.6 The atmosphere of the sample chamber for FTIR shall be kept consistent during the background and

−1 −1

test piece measurements in order to avoid the influences of absorbance at 668 cm and 723 cm by CO .

8 Determination of the microstructure of butadiene and the styrene content

8.1 Measurement of the absorbance for each microstructure component

Measure the absorbance values at the wave numbers corresponding to the microstructure components

as specified in Table 1. For cis, the absorption peaks are weak and the wave number of the peaks is

affected by the styrene content of the polymer.

Table 1 — Measurement of absorbances for each microstructure component of S-SBR

Notation for Microstructure

Remarks

absorbance component

−1 −1

A10 Styrene Measure the absorbance at the peak maximum from 695 cm to 700 cm .

The wave number at this peak maximum is affected by the nature of the

polymer, such as the styrene content. When the peak maximum is visible,

−1 −1

read off the absorbance at the peak maximum from 720 cm to 730 cm .

A20 Cis

If the styrene content is over 30 %, the peak of the cis bond is hidden

−1

between the two large styrene absorptions at around 758 cm and

−1 −1

around 698 cm . In this case, measure the absorbance value at 726 cm .

−1 −1

A30 Styrene Measure the absorbance at the peak maximum from 755 cm to 761 cm .

−1 −1

A40 Vinyl Measure the absorbance at the peak maximum from 905 cm to 912 cm .

−1 −1

A50 Trans Measure the absorbance at the peak maximum from 962 cm to 967 cm .

−1 −1

A60 Vinyl Measure the absorbance at the peak maximum from 991 cm to 996 cm .

−1

A70 Base line Measure the absorbance at 1 200 cm as zero point of each absorbance.

Key

−1

X wave number (cm )

Y absorbance

Figure 1 — ATR spectrum of a typical S-SBR

8.2 Calculation of microstructures

8.2.1 General

The microstructure of S-SBR is calculated by using regression formulae and the measured absorbance

values of the ATR spectra of each sample. The regression formulae were derived from a statistical study

on the ATR spectra of various S-SBR samples with known microstructures. After adjusting the baseline

of the ATR spectra, the absorbance ratio values of respective absorptions are obtained as the parameter

value for microstructure calculation. The microstructure results are calculated by substituting these

parameter values in the regression formulae.

4 © ISO 2016 – All rights reserved

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...