ISO 20826:2006

(Main)Automotive LPG components — Containers

Automotive LPG components — Containers

ISO 20826:2006 specifies the technical requirements for the design and the testing of automotive Liquefied Petroleum Gas (LPG) containers, to be permanently attached to a motor vehicle which uses automotive LPG as a fuel. The technical requirements cover the design criteria, the requirements on construction and workmanship, the marking and re-qualification procedures. ISO 20826:2006 also covers all tests, including their frequencies, to be carried out on autogas containers, during production and performance verification. Specific recommendations are also given on the tests to be carried out when changing the design.

Composants pour véhicules au GPL — Réservoirs

General Information

- Status

- Published

- Publication Date

- 15-Aug-2006

- Technical Committee

- ISO/TC 22/SC 41 - Specific aspects for gaseous fuels

- Current Stage

- 9020 - International Standard under periodical review

- Start Date

- 15-Oct-2025

- Completion Date

- 15-Oct-2025

Overview

ISO 20826:2006 - Automotive LPG components - Containers - sets out the technical requirements, testing and re‑qualification procedures for Liquefied Petroleum Gas (LPG) containers permanently attached to motor vehicles (autogas). The standard defines design criteria, construction and workmanship requirements, marking, production and performance verification tests (including frequencies), and recommendations for testing after design changes. It applies to both metal containers and all‑composite containers.

Key topics and technical requirements

- Scope and terms: Defines container types (cylindrical, toric), batches (max 200), and classification of metal vs all‑composite containers.

- Design pressure: 3.0 MPa design pressure for containers.

- Design temperature: Nominal range −20 °C to +65 °C; −40 °C minimum where extreme low‑temperature service is expected (and must be marked).

- Materials: Materials must be compatible with LPG; steel standards such as EN 10120 may be used. Manufacturer responsibility for material traceability, chemical and mechanical tests is required.

- Construction & workmanship: Quality control systems, welding procedures, heat treatment records, and dimensional tolerances (referencing ISO 2768‑1) are mandatory. Recommendations for out‑of‑roundness and straightness of cylindrical shells are provided.

- Openings & fittings: Requirements for filling, off‑take, pressure relief and level indication; vapour phase locations for pressure relief; threaded or flanged openings.

- Testing & test programme: Detailed test programme covering production and verification tests for both metal and all‑composite containers, plus tests after design changes. Annexes include test methods, sample location, mechanical tests and material test methods.

- Marking & re‑qualification: Marking plate requirements and procedures for periodic inspection and re‑qualification at defined intervals.

- Tolerance on capacity: Water capacity tolerance −0 % to +3 % compared to marking plate.

Practical applications

- Use ISO 20826:2006 to design and validate safe, compliant automotive LPG fuel tanks for passenger cars, commercial vehicles and special‑purpose vehicles.

- Develop manufacturing quality systems and welding/heat‑treatment procedures that meet international test and traceability expectations.

- Establish production testing, periodic inspection and re‑qualification programmes for fleet operators, converters and remanufacturers.

- Guide material selection, dimensional control, and accessory placement (valves, PRVs, off‑takes).

Who should use this standard

- Container manufacturers (metal and composite)

- Automotive OEMs and vehicle conversion companies

- Testing laboratories and inspection bodies

- Regulatory authorities and certification agencies

- Fleet operators and maintenance organizations

Related standards

ISO 20826 references several normative documents useful for implementation, including ISO 2768‑1, ISO 15614‑1 (welding qualification), ISO 17636 (radiographic testing), and fuel requirements such as EN 589.

For compliant design, production and safety assurance of autogas containers, ISO 20826:2006 is the authoritative technical reference - obtain the full standard for detailed test methods, annexes and mandatory procedures.

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

ISO 20826:2006 is a standard published by the International Organization for Standardization (ISO). Its full title is "Automotive LPG components — Containers". This standard covers: ISO 20826:2006 specifies the technical requirements for the design and the testing of automotive Liquefied Petroleum Gas (LPG) containers, to be permanently attached to a motor vehicle which uses automotive LPG as a fuel. The technical requirements cover the design criteria, the requirements on construction and workmanship, the marking and re-qualification procedures. ISO 20826:2006 also covers all tests, including their frequencies, to be carried out on autogas containers, during production and performance verification. Specific recommendations are also given on the tests to be carried out when changing the design.

ISO 20826:2006 specifies the technical requirements for the design and the testing of automotive Liquefied Petroleum Gas (LPG) containers, to be permanently attached to a motor vehicle which uses automotive LPG as a fuel. The technical requirements cover the design criteria, the requirements on construction and workmanship, the marking and re-qualification procedures. ISO 20826:2006 also covers all tests, including their frequencies, to be carried out on autogas containers, during production and performance verification. Specific recommendations are also given on the tests to be carried out when changing the design.

ISO 20826:2006 is classified under the following ICS (International Classification for Standards) categories: 43.060.40 - Fuel systems. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 20826:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 20826

First edition

2006-08-15

Automotive LPG components —

Containers

Composants pour véhicules au GPL — Réservoirs

Reference number

©

ISO 2006

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2006

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2006 – All rights reserved

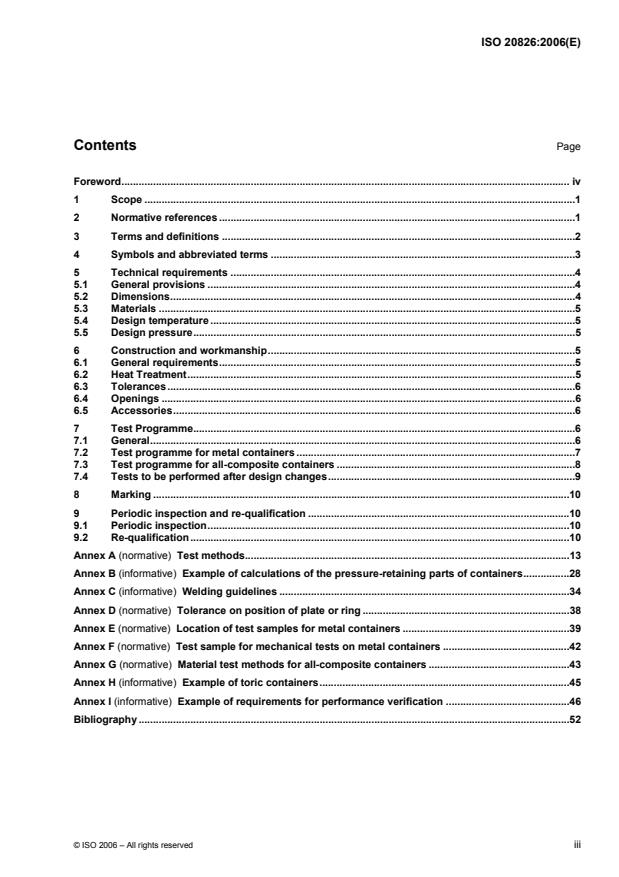

Contents Page

Foreword. iv

1 Scope.1

2 Normative references.1

3 Terms and definitions .2

4 Symbols and abbreviated terms .3

5 Technical requirements.4

5.1 General provisions .4

5.2 Dimensions.4

5.3 Materials.5

5.4 Design temperature .5

5.5 Design pressure.5

6 Construction and workmanship.5

6.1 General requirements.5

6.2 Heat Treatment.5

6.3 Tolerances.6

6.4 Openings.6

6.5 Accessories.6

7 Test Programme.6

7.1 General.6

7.2 Test programme for metal containers .7

7.3 Test programme for all-composite containers .8

7.4 Tests to be performed after design changes.9

8 Marking.10

9 Periodic inspection and re-qualification .10

9.1 Periodic inspection.10

9.2 Re-qualification.10

Annex A (normative) Test methods.13

Annex B (informative) Example of calculations of the pressure-retaining parts of containers.28

Annex C (informative) Welding guidelines .34

Annex D (normative) Tolerance on position of plate or ring .38

Annex E (normative) Location of test samples for metal containers .39

Annex F (normative) Test sample for mechanical tests on metal containers .42

Annex G (normative) Material test methods for all-composite containers .43

Annex H (informative) Example of toric containers.45

Annex I (informative) Example of requirements for performance verification .46

Bibliography .52

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 20826 was prepared by Technical Committee ISO/TC 22, Road vehicles.

iv © ISO 2006 – All rights reserved

INTERNATIONAL STANDARD ISO 20826:2006(E)

Automotive LPG components — Containers

1 Scope

This International Standard specifies the technical requirements for the design and the testing of automotive

Liquefied Petroleum Gas (LPG) containers, to be permanently attached to a motor vehicle which uses

automotive LPG as a fuel.

The technical requirements cover the design criteria, the requirements on construction and workmanship, the

marking and re-qualification procedures.

This International Standard also covers all tests, including their frequencies, to be carried out on autogas

containers, during production and performance verification. Specific recommendations are also given on the

tests to be carried out when changing the design.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 175, Plastics — Methods of test for the determination of the effects of immersion in liquid chemicals

ISO 306, Plastics — Thermoplastic materials — Determination of Vicat softening temperature (VST)

ISO 2504, Radiography of welds and viewing conditions for films — Utilization of recommended patterns of

image quality indicators (I.Q.I.)

ISO 2768-1:1989, General tolerances — Part 1: Tolerances for linear and angular dimensions without

individual tolerance indications

ISO 4136, Destructive tests on welds in metallic materials — Transverse tensile test

ISO 5173, Destructive tests on welds in metallic materials — Bend tests

ISO 6507-1:1997, Metallic materials — Vickers hardness test — Part 1: Test method

ISO 6721 (all parts), Plastics — Determination of dynamic mechanical properties

ISO 6892, Metallic materials — Tensile testing at ambient temperature

ISO 7438, Metallic materials — Bend test

ISO 7799, Metallic materials — Sheet and strip 3 mm thick or less — Reverse bend test

ISO 9328-7, Steel flat products for pressure purposes — Technical delivery conditions — Part 7: Stainless

steels

ISO 9606 (all parts), Approval testing of welders – Fusion welding

ISO 12097-2:1996, Road vehicles — Airbag components — Part 2: Testing of airbag modules

ISO 15614-1:2004, Specification and qualification of welding procedures for metallic materials — Welding

procedure test — Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys

ISO 17636, Non-destructive testing of welds — Radiographic testing of fusion-welded joints

ASTM 3039, Fibre-resin composite

ASTM D2343, Standard Test Method for Tensile Properties of Glass Fiber Strands, Yarns and Rovings Used

in Reinforced Plastics

ASTM D2344, Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and

Their Laminates

ASTM D4018.81 Carbon (tens. Prop. Continuous filament)

EN 589, Automotive fuels — LPG — Requirements and test methods

EN 10120, Steel sheet and strip for welded gas cylinders

NOTE ASTM standards are available from ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19424-2959,

USA.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

test pressure

pressure to which the container is subjected during the test procedure

3.2

design pressure

pressure on which the calculations are based

3.3

container

vessel with all its permanent support(s) and attachment(s) installed, used for the storage of automotive LPG

3.4

cylindrical container

container with a cylindrical shell and two dished ends, either torispherical or elliptical

3.5

metal container

container made only of any suitable metal

3.6

all-composite container

container made only of composite materials without a metallic liner

3.7

batch

maximum of 200 containers of the same type produced consecutively on the same production line

2 © ISO 2006 – All rights reserved

3.8

type of container

container or a group of containers where the individual container does not differ significantly with respect to

the following conditions:

⎯ the manufacturer (different trade names or marks possible);

⎯ the shape;

⎯ the openings;

⎯ the material;

⎯ the welding process (if applicable);

⎯ the heat treatment (if applicable);

⎯ the production line;

⎯ the diameter;

⎯ the height (in case of a toric container — see Annex H);

⎯ the nominal wall thickness.

3.9

longitudinal weld

weld over the full length of the shell or cylindrical part of the shell, excluding welds for fittings

3.10

re-qualification

activities such as examining and testing of the automotive LPG containers, carried out at defined intervals

3.11

parent material

material in the state after transformation necessary for the container manufacturing process

3.12

Liquefied Petroleum Gas

LPG

mixture of light hydrocarbons, gaseous under normal atmospheric conditions which can be liquefied by

increased pressure or decreased temperature, the main components of which are propane, propene, butane

and butene isomers

4 Symbols and abbreviated terms

a is the calculated minimum wall thickness of the cylindrical shell in mm,

b is the calculated wall thickness of the dished ends in mm,

C is the shape factor,

c.g is the centre of gravity,

D is the nominal outside diameter of the container in mm,

F is the force in N,

g is the gravity in m/s ,

h is the height of cylindrical part of dished end in mm,

H is the outside height of dished part of container end in mm,

H is the height of the wedge in mm,

w

L is the length of the edge in mm,

w

n is the ratio between the diameter of the mandrel of the bending test machine and the thickness of the

test sample,

P is the maximum pressure measured in the burst test in MPa,

b

P is the design pressure in MPa,

h

r is the inside knuckle radius of the dished end of the standard cylindrical container in mm,

R is the inside dish radius of the dished end of a standard cylindrical container in mm,

R is the minimum yield stress in MPa guaranteed by the manufacturer of the container, for the parent

e

material,

R is the minimum tensile strength in MPa specified by the material standard,

g

R is the actual tensile strength in MPa,

m

T is the glass transition temperature of the resin matrix, in °C,

g

V is the velocity in km/h,

z is the welding factor,

HV is the Vickers hardness,

PRD is the pressure relief device,

PRV is the pressure relief valve,

UV is Ultra-Violet.

5 Technical requirements

5.1 General provisions

The container for vehicles using automotive LPG in their propulsion system shall function in a correct and safe

way.

Any finished container, randomly chosen, shall comply with the applicable tests as prescribed in Annex A.

All necessary corrosion prevention measures shall be taken to protect the finished container.

5.2 Dimensions

For all dimensions without indication of tolerances, general tolerances of ISO 2768-1 shall apply.

4 © ISO 2006 – All rights reserved

5.3 Materials

All materials compatible with LPG, may be used provided that the container complies with the applicable tests

of this International Standard.

For steel, EN 10120 or EN 10028-7 may be used.

The container manufacturer shall ensure that all parent materials are free from defects.

Container parts and filler materials shall be compatible when welded.

For steel welds, ISO 15614-1 shall apply.

The container manufacturer shall maintain records of the results of metallurgical and mechanical tests and

analyses of parent and filler materials as described below:

⎯ for metal containers: chemical cast analysis certificates and mechanical properties for the metal used for

the construction of the parts subject to pressure;

⎯ for all-composite containers: results of tests as prescribed in Annex G.

The container manufacturer shall maintain a system to trace all parent materials for parts subject to pressure.

5.4 Design temperature

The minimum design temperature shall be −20 °C.

The maximum design temperature shall be +65 °C.

For extremely low operating temperature, a minimum design temperature of −40 °C shall be applied. This

lower design temperature shall be indicated on the marking plate.

The manufacturer shall demonstrate that the material from which the pressure-containing parts of the

container are constructed shall have properties suitable for the range of temperatures down to − 40 °C.

5.5 Design pressure

The design pressure of the container shall be 3,0 MPa.

6 Construction and workmanship

6.1 General requirements

The manufacturer shall be able to demonstrate that its quality control system ensures that the containers

produced meet the requirements of this International Standard.

The manufacturer shall maintain records of the processes, procedures, inspections and qualification that are

carried out during production.

It is recommended that the out-of-roundness of the cylindrical shell of the metal container is not more than the

difference between the maximum and minimum outside diameter of the same cross-section and is not more

than 1 % of the average of those diameters.

Unless otherwise shown on the construction drawing, it is recommended that the maximum deviation of the

cylindrical part of the shell from a straight line (straightness) does not exceed 0,3 % of the length of the

cylindrical part.

6.2 Heat treatment

The container manufacturer shall maintain records of the heat treatment procedures on container parts and

finished containers, either completely or localized, necessary to comply with the requirements of this

International Standard.

6.3 Tolerances

6.3.1 Capacity

The actual water capacity of the container, shall have a tolerance of −0 % to +3 % compared to the figure

shown on the marking plate.

6.3.2 Position

The tolerance on the position of the valve boss/plate in the container shall be plus or minus 1 degree in two

directions, transverse and twist (see Annex D).

6.4 Openings

Openings shall be provided for filling, off-take, pressure relief and level indication.

Openings for pressure relief valves shall be in the vapour phase, when the container is in its normal mounting

position.

Openings shall be taper threaded or flanged.

Openings may also be provided for power supply, pumps, etc.

Openings for valves may be either separate or combined.

An O-ring may be fitted either in the ring or in the flange, see Figure C.4.

Internal vapour off-take pipework shall be adequately supported and shall end in the vapour space of the

container as high as possible above the maximum filling level.

Internal liquid off-take pipework shall end as low as possible in the container.

6.5 Accessories

Where fitted, the marking plate shall be fixed permanently on the container shell or end. Corrosion prevention

measures shall be taken.

The accessories in and on the container shall be fitted under the responsibility of the holder of the bonfire test

approval certificate (see I.5).

It shall be possible to securely mount a gas-tight housing or other protective device over the container

accessories.

The support(s) shall be manufactured and attached to the container body in such a way as:

⎯ not to cause dangerous concentrations of stresses or be conducive to the collection of water;

⎯ to be strong enough to withstand forces of at least 30 g in all directions for at least 20 ms, to be

demonstrated by impact test or calculation.

7 Test programme

7.1 General

This clause specifies all tests and their frequencies during production and performance verification, applicable

to automotive LPG containers.

6 © ISO 2006 – All rights reserved

Tests methods are described in Annex A.

NOTE Performance verification means the demonstration to the competent authorities that the finished container

complies with the design, construction and workmanship requirements of this International Standard.

7.2 Test programme for metal containers

Table 1 — Overview of tests to be performed on metal containers

Performance

Test during Number of containers to

verification Subclause

production be tested

testing

a b

Tensile strength test 1 per batch X 2 A.1.2

b

Bend test 1 per batch X A.1.3

Burst test X 2 A.2

All containers submitted for

Pressure test Each container X A.3

performance verification

Leakage test Each container X Each container A.4

b

Hardness test X 2 A.6

Fatigue test X 3 A.7

Bonfire test X 1 A.8

Radiographic examination At least 1 per 100 % of the container

X A.9.2

of welds batch under test

Macroscopic examination

b

1 per batch X 2 A.1.4

of welds

Visual inspection of welds Each container X Each container A.9.1

Visual inspection of

Each container X Each container

container parts

During the performance verification testing, on one of the containers to be tested, the volume of the container and the

wall thickness of each part of the container shall be determined.

The number of test samples for performance verification testing shall be six; they shell be produced consecutively.

NOTE X = test required.

a

Test required.

b

These test pieces can be taken from one container.

7.3 Test programme for all-composite containers

Table 2 — Overview of tests to be performed on all-composite containers

Performance

Test during Number of containers to

verification Subclause

production be tested

testing

a

Burst test 1 per batch X 3 A.2

All containers submitted

Pressure tests Each container X for performance A.3

verification

Leakage test Each container X Each container A.4

Ambient temperature pressure

X 3 A.5.1

cycling test

High temperature pressure

X 1 A.5.2

cycling test

Permeation test X 2 A.5.3

LPG cycling test X 1 A.5.4

High temperature creep test X 1 A.5.5

Bonfire test X 1 A.8

Impact test X 1 A.10

Drop test X 2 A.11

Boss torque test X 1 A.12

Acid environment test X 1 A.13

Ultra-violet radiation test X 1 A.14

a Test required.

8 © ISO 2006 – All rights reserved

7.4 Tests to be performed after design changes

If the design of a container with recognised performance verification is changed, the performance verification

testing shall be limited to the tests listed in the Table 3.

Table 3 — Overview of tests to be performed after design changes

Design change

a

Fibre manufacturer X X

C C

Fibre material X X X X X X X X X X

C C C C C C C C C C

Resin material X X X X X X X X X X X X X

C C C C C C C C C C C C C

b

Metallic cylinder and/or filler X X X X X X

material

Plastic liner material X X X X X X X X X

C

C C C C C C C C

Nominal wall thickness X X X X X X X X X X X X X X X

C C C C C C C C C C

c

Diameter change u [20%] X X X X

C C

for toric and cylindrical

containers

c

Diameter change >[20%] X X X X X X X

C C C C

for toric and cylindrical

containers

c

Length change u [50%] X X X X

C C

for cylindrical containers

c

Length change >[50%] X X X X X X X

C C C C

for cylindrical containers

c

Height change u [50%] X X X X X

C C C

for toric containers

c

Height change > [50%] X X X X X X X X

C C C C C

for toric containers

Change of container shapes X X X X c X X X X

C C C C C C

Dome shape X X X X X

C C

Opening size X X X X

C

Coating change X X X

End boss design X X X X X

C C

Change in manuf. process X X X X X X X X X

C C C C C

Note X = test required on all types of containers.

Note X = test required only for all-composite containers.

C

a

X = test required only for all-composite containers.

C

b

X = test required on all types of containers.

c

Compliance with the permeation test requirements shall be checked by direct measure or calculation.

Burst test

Tensile strength test

Bend test

Ambient temperature

pressure cycling test

High temperature

cycling test

Fatigue

Hardness test

Permeation test

LPG cycling test

High temperature

creep test

Bonfire test

Impact test

Drop test

Boss torque test

Acid environment

UV

8 Marking

The following data shall be marked on the fitting plate or ring or marking plate:

⎯ a serial number;

⎯ the water capacity in litres;

⎯ the marking “LPG”;

⎯ hydraulic test pressure in bar: “xx bar” or MPa: “xx MPa”;

⎯ the wording: “maximum filling: 80 %”;

⎯ year and month of hydraulic testing (e.g. 2002/01);

⎯ approval mark of the country of approval and reference to this International Standard, “ISO 20826:yyyy”;

⎯ diameter (for cylindrical containers) or height (for special containers) or width x length;

NOTE 1 An example of an approval mark is shown in I.5.

⎯ the name or trade mark of the manufacturer (if not permanently marked on the container elsewhere);

⎯ when a pump is mounted in the container, the marking “pump inside” and a marking identifying the pump;

⎯ when a container is designed for temperatures lower than −40 °C, the marking “−40 °C”.

The marking plate shall have enough space to accommodate the re-qualification marks.

A reference mark shall be affixed on the container to ensure its correct orientation when installed.

9 Periodic inspection and re-qualification

9.1 Periodic inspection

The container, permanently attached to a motor vehicle, shall be externally visually inspected during each

periodic inspection of the vehicle, with specific attention to damage, deterioration and corrosion.

The inspection does not require removal of the container from the vehicle unless the inspection authority

decides that the container needs to be externally inspected or hydraulically tested (re-qualified).

9.2 Re-qualification

9.2.1 Re-qualification criteria

Each container shall be re-qualified according to the following criteria:

⎯ not more than 20 years after the year and month of the initial hydraulic test, unless a shorter time

specified by the manufacturer;

⎯ not more than 10 years after the previous re-qualification, unless a shorter time specified by the

manufacturer;

⎯ before re-installing a used container in a vehicle;

⎯ after defects detected during the periodic inspection.

10 © ISO 2006 – All rights reserved

Containers fitted in a vehicle involved in a collision shall be visually inspected for damage by a competent

person.

Containers that have been subject or exposed to fire shall be removed from further service.

9.2.2 Re-qualification procedure

The re-qualification procedure shall consist of an external visual inspection and at least one of the following

test procedures:

⎯ a hydraulic test;

⎯ an internal visual inspection.

After each re-qualification, the accessories to the container shall be replaced by new or replacement

components or officially reconditioned accessories.

The re-qualification shall be performed by a competent body, in accordance with the manufacturer’s

instructions related to the accessories.

The competent body shall keep records of the container re-qualifications in relation to the serial number of the

container.

9.2.3 Re-qualification tests

9.2.3.1 External visual inspection

9.2.3.1.1 Test procedure

The container shall be cleaned and have all loose foreign matter removed from its external surface.

The entire surface of the container shall be inspected for damage, deterioration, corrosion and readability of

the markings.

9.2.3.1.2 Interpretation

Containers showing defects shall be removed from further service.

Containers, of which the data cannot be traced, shall be removed from service.

9.2.3.2 Pressure test

The container shall be tested according to A.3.

9.2.3.3 Internal visual inspection

9.2.3.3.1 Test procedure

The containers shall be emptied of liquid and depressurized in a safe and controlled way.

At least one component fitted in or on the container shall be removed.

The container shall be inspected for any sign of corrosion or other defects.

9.2.3.3.2 Interpretation

Containers showing sign(s) of internal corrosion that may affect their integrity shall be removed from further

service.

9.2.4 Re-qualification marking

After the successful completion of the re-qualification, the container shall be legibly and durably marked with

the following information:

⎯ the symbol of the competent body that has carried out the re-qualification;

⎯ the year and month of re-qualification.

Symbols and characters shall not be less than 4 mm in height.

12 © ISO 2006 – All rights reserved

Annex A

(normative)

Test methods

All tests shall be performed at ambient temperature of 20 °C ± 5 °C, unless otherwise stated.

A.1 Destructive testing

A.1.1 General requirements

All tests for checking the properties of the parent material and welds, if any, of the container shall be carried

out on test samples taken from finished containers.

Test samples which are not flat shall be flattened by a cold process.

In test samples containing a weld, the weld shall be machined to trim the surplus.

The number and location of the test samples for the destructive tests shall be in accordance with Annex E.

A.1.2 Tensile strength test

A.1.2.1 Tensile strength test on parent material

The tensile strength test shall be carried out in accordance with ISO 6892.

The two faces of the test samples, representing the inside and the outside walls of the container respectively,

shall not be machined.

The values determined for yield stress, tensile strength and elongation during the tensile strength test of the

parent material shall comply with EN 10120 or ISO 9328-7 depending on the characteristics of the material

used.

A.1.2.2 Tensile strength test on welds

The tensile strength test perpendicular to the weld shall be carried out in accordance with ISO 4136. Test

samples shall have the dimensions as shown on Figure F.1.

The tensile strength value obtained shall meet the minimum levels required by EN 10120 or ISO 9328-7.

A.1.2.3 Retesting for a tensile strength test

If the first test fails, a second test shall be carried out on two test samples from the same container.

If both samples pass the retest, the first test shall be ignored.

Where one or both of the retests fail, the batch shall be rejected.

A.1.3 Bend test

A.1.3.1 Test procedure

The bend test shall be carried out in accordance with ISO 5173 or ISO 7438 and ISO 7799.

All bend tests shall be carried out on the inner surface in tension and the outer surface in tension.

The bend test shall be carried out transversely to the weld on test samples, with a width of 25 mm, as shown

in Figure F.2. The mandrel shall be placed in the centre of the weld.

The ratio (n) between the diameter of the mandrel and the thickness of the test sample depends on the tensile

strength of the parent material and shall not exceed the values in Table A.1.

Table A.1 — Maximum value of ratio n

Actual Tensile strength R

m

value of n

MPa

Up to 440 inclusive 2

above 440 to 520 inclusive 3

above 520 to 600 inclusive 4

above 600 to 700 inclusive 5

above 700 to 800 inclusive 6

above 800 to 900 inclusive 7

R > 900 8

m

A.1.3.2 Test interpretation

Cracks shall not appear in any of the test samples when they are bent around a mandrel, as long as the inside

edges are separated by a distance not greater than the diameter of the mandrel +3a, as shown in Figure F.3

A.1.3.3 Retesting for the bend test

If the first test fails, a second test shall be carried out on two test samples from the same container.

If both test samples pass the test, the first test shall be ignored.

Where one or both of the retests fail, the batch shall be rejected.

A.1.4 Macroscopic examination on the cross section of a weld

The macroscopic examination on a cross section of a weld to verify the properties of the parent material and

welds of the pressure containing shell of the container shall be carried out on test samples taken from finished

containers. For location of test samples, see Annex E.

The macroscopic examination of a full transverse section of the weld shall show a complete fusion on the

surface, and shall not show any welding fault or a significant inclusion or other defects.

In case of doubt, a microscopic examination shall be made of the suspect area.

14 © ISO 2006 – All rights reserved

A.2 Burst test under hydraulic pressure

A.2.1 Test conditions

The pressure shall be increased at an even rate until the container bursts and the change in pressure over

time shall be recorded. The maximum flow rate during the test shall not exceed 3 % of the capacity of the

container per minute.

A.2.2 Interpretation of test

The criteria adopted for the interpretation of the burst test are:

⎯ the burst pressure; and

⎯ examination of the tear and the shape of its edges.

A.2.3 Test acceptance conditions

The measured burst pressure P shall be at least 2,25 times the design pressure.

b

The burst test shall not cause any fragmentation of the container.

The main fracture shall not be brittle, i.e. the edges of the fracture shall not be radial but shall be at an angle

to a diametrical plane and display a reduction of area throughout their thickness.

For metal containers, the fracture shall not reveal any defects in the metal. The welds shall be at least as

strong as the original metal.

For all-composite containers, the fracture shall not reveal any defects in the structure.

A.2.4 Retesting for burst test

If the first test fails, a second burst test shall be carried out on two containers that have been produced

successively to the first container within the same batch.

If both containers pass the retest, the first test shall be ignored.

If one or both of the retests fail, the batch shall be rejected.

A.3 Hydraulic test

A.3.1 Test procedure

A finished container, without accessories but with the openings closed, shall withstand an inner pressure

equal to the design pressure without leakage or becoming permanently distorted, according to the following

requirements:

⎯ The pressure in the container shall be increased at an even rate until the final test pressure is reached.

⎯ The final test pressure shall be maintained long enough to make it possible to verify that the pressure is

not falling off and that the container is not leaking.

A.3.2 Test interpretation

The container shall not show any leakage and visible signs of permanent deformation.

A.4 Leakage test

The manufacturer shall employ such manufacturing techniques and apply such tests as will demonstrate to

the satisfaction of the inspector that the containers do not leak.

A.5 Additional hydraulic tests to be performed on all-composite containers

A.5.1 Ambient temperature pressure cycling test

A.5.1.1 Test procedure

A finished container shall be pressure cycled to a maximum of 20 000 cycles, according to the following

procedure:

a) fill the container to be tested with a non-corrosive fluid such as oil, inhibited water or glycol;

b) cycle the pressure in the container between not more than 0,3 MPa and not less than 3,0 MPa at a rate

not to exceed 10 cycles per minute. This cycle shall be performed at least 10 000 times and continued

until 20 000 times unless a leak before break appears;

The number of cycles to failure shall be recorded, along with the location and description of the failure

initiation.

A.5.1.2 Test interpretation

Before reaching 10 000 cycles, the container shall not fail or leak.

After completing 10 000 cycles, the container may leak before break.

A.5.1.3 Retesting

Retesting is permitted for the ambient temperature pressure cycling test.

A second test shall be performed on two containers that have been produced successively to the first

container within the same batch.

If the results of these tests are satisfactory, the first test shall be ignored.

In the event where one or both of the retests fail, the batch shall be rejected.

A.5.2 High temperature pressure cycling test

A.5.2.1 Test procedure

A finished container shall be cycle tested, without showing evidence of rupture, leakage or fibre unravelling, as

follows:

a) Fill the container to be tested with a non-corrosive fluid such as oil, inhibited water or glycol.

b) Condition for 48 hours at 0 MPa, 65 ºC, and 95 % or greater relative humidity.

c) Hydrostatically pressurize for 3 600 cycles not exceeding 10 cycles per minute, between not more than

0,3 MPa and not less than 3,0 MPa at 65 ºC and 95 % humidity.

Following the pressure cycling test at high temperature, the container shall be submitted to a pressure test

and then hydrostatically pressurized to failure in accordance with the burst test procedure.

16 © ISO 2006 – All rights reserved

A.5.2.2 Test interpretation

The container shall comply with the hydraulic test requirements as defined in A.3.

The container shall achieve a minimum burst pressure of 85 % of the nominal burst pressure.

A.5.2.3 Retesting

Retesting is permitted for the high temperature pressure cycling test.

A second test shall be performed on two containers that have been produced successively to the first

container within the same batch.

If the results of these tests are satisfactory, the first test shall be ignored.

In the event where one or both of the retests fail, the batch shall be rejected.

A.5.3 Permeation test

A.5.3.1 Test procedure

All the tests shall be performed at 40 °C on a container filled with commercial propane at 80 % of its water

capacity.

The test shall be held during at least 8 weeks until the steady state permeation of the structure is observed

during at least 500 hours.

Then, the rate of the container mass loss shall be measured.

The loss of mass as a function of time shall be recorded in a graph.

A.5.3.2 Test interpretation

The rate of mass loss shall be less than 0,15 g/hour maximum.

A.5.3.3 Retesting

Retesting is permitted for the permeation test.

A second test shall be performed on two containers that have been produced successively to the first

container within the same batch.

If the results of these tests are satisfactory, the first test shall be ignored. In the event where one or both of the

retests fail, the batch shall be rejected.

A.5.4 LPG cycling test

A.5.4.1 Test procedure

A container having successfully passed the permeation test shall be submitted to an ambient temperature

pressure cycling test according to the requirements of A.5.1.

The container shall be sectioned and the liner/end boss interface shall be inspected.

A.5.4.2 Test interpretation

The container shall comply with the ambient temperature pressure cycling test requirements.

Inspection of the liner/end boss interface of the container shall not reveal any evidence of deterioration, such

as fatigue cracking or electrostatic discharge.

A.5.4.3 Retesting

Retesting is permitted for the LPG cycling test.

A second test shall be performed on two containers that have been produced successively to the first

container within the same batch.

If the results of these tests are satisfactory, the first test shall be ignored.

In the event where one or both of the retests fail, the batch shall be rejected.

A.5.5 High temperature creep test

A.5.5.1 General

This test shall only be performed on all-composite containers with a resin matrix having a glass transition

temperature (T ) below the maximum design temperature.

G

A.5.5.2 Test procedure

A finished container shall be tested as follows:

a) The container shall be pressurized to the design pressure and be held at a temperature in relation to the

test duration according to Table A.2:

Table A.2 — Test temperature for the high temperature creep test

T (°C) Exposure time (hours)

100 200

95 350

90 600

85 1000

80 1800

75 3200

70 5900

65 11000

b) The container shall be submitted to a hydraulic test.

A.5.5.3 Test interpretation

The maximum allowed volume increase is 5 %.

The container shall meet the requirements of the hydraulic test as defined in A.3 and the burst test as defined

in A.2.

A.5.5.4 Retesting

Retesting is permitted for the high temperature creep test.

18 © ISO 2006 – All rights reserved

A second test shall be performed on two containers that have been produced successively to the first

container within the same batch.

If the results of these tests are satisfactory, the first test shall be ignored.

In the event where one or both of the retests fail, the batch shall be rejected.

A.6 Hardness test

The hardness of the weld and the metal around the weld of a finished container shall be determined in

accordance with ISO 6507-1.

For the test, the test force F shall be between 50 N and 300 N.

The Vickers hardness shall be determined on:

⎯ the parent metal;

⎯ the weld;

⎯ the heat-affected zone.

The Vickers hardness shall be no more than:

⎯ 100 HV for parent metal with carbon content less than or equal to 0,23 % and R less than or equal

e

to 320 N/mm ;

⎯ 150 HV for parent metal with carbon content less than or equal to 0,25 % and R less than or equal

e

to 320 N/mm .

A.7 Fatigue test

Three containers shall be subjected to the test. The containers shall be representative in respect of the

minimum wall thickness according to its design and shall be marked according to the requirements shown in

Clause 8.

The containers shall be filled with non-corrosive liquid and subjected to successive fluctuations of hydraulic

pressure, using one of the following procedures:

Procedure 1:

⎯ the upper test pressure shall be 2/3 of the design pressure;

⎯ the lower test pressure shall be not more than 10 % of the upper test pressure;

⎯ the frequency of the pressure fluctuations shall not exceed 0,25 Hz;

⎯ the container shall be subjected to 60 000 cycles;

⎯ the temperature on the outside surface of the container shall not exceed 50 °C during the test;

⎯ the pressure containing parts of the container shall not burst or leak.

Procedure 2:

⎯ the upper test pressure shall be equal to the design pressure;

⎯ the lower test pressure shall be not more than 10 % of the upper test pressure;

⎯ the frequency of the pressure fluctuations shall not exceed 0,25 Hz;

⎯ the container shall be subjected to 12 000 cycles;

⎯ the temperature on the outside surface of the container shall not exceed 50 °C during the test;

⎯ the pressure containing parts of the container shall not burst or leak.

After the fatigue test, a burst test shall be carried out on one of the containers. The burst pressure shall be at

least 1,5 times the d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...