ISO/CD 15338

(Main)Surface chemical analysis — Glow-discharge mass spectrometry (GD-MS) — Introduction to use

Surface chemical analysis — Glow-discharge mass spectrometry (GD-MS) — Introduction to use

Analyse chimique des surfaces — Spectrométrie de masse à décharge luminescente (GD-MS) — Introduction à l'utilisation

General Information

- Status

- Withdrawn

- Technical Committee

- ISO/TC 201/SC 8 - Glow discharge spectroscopy

- Drafting Committee

- ISO/TC 201/SC 8 - Glow discharge spectroscopy

- Current Stage

- 3098 - Project deleted

- Start Date

- 04-Jul-2007

- Completion Date

- 14-Feb-2026

Buy Documents

ISO/CD 15338 - Surface chemical analysis — Glow-discharge mass spectrometry (GD-MS) — Introduction to use Released:4/8/2005

Get Certified

Connect with accredited certification bodies for this standard

ECOCERT

Organic and sustainability certification.

Eurofins Food Testing Global

Global leader in food, environment, and pharmaceutical product testing.

Intertek Bangladesh

Intertek certification and testing services in Bangladesh.

Sponsored listings

Frequently Asked Questions

ISO/CD 15338 is a draft published by the International Organization for Standardization (ISO). Its full title is "Surface chemical analysis — Glow-discharge mass spectrometry (GD-MS) — Introduction to use". This standard covers: Surface chemical analysis — Glow-discharge mass spectrometry (GD-MS) — Introduction to use

Surface chemical analysis — Glow-discharge mass spectrometry (GD-MS) — Introduction to use

ISO/CD 15338 is classified under the following ICS (International Classification for Standards) categories: 71.040.40 - Chemical analysis. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/CD 15338 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

DRAFT INTERNATIONAL STANDARD ISO/DIS 15338

ISO/TC 201/SC 8 Secretariat: JISC

Voting begins on: Voting terminates on:

2005-04-11 2005-09-12

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION • МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ • ORGANISATION INTERNATIONALE DE NORMALISATION

Surface chemical analysis — Glow-discharge mass

spectrometry (GD-MS) — Introduction to use

Analyse chimique des surfaces — Spectromètrie de masse à décharge luminescente (GD-MS) — Introduction

à l'utilisation

ICS 71.040.40

In accordance with the provisions of Council Resolution 15/1993 this document is circulated in

the English language only.

Conformément aux dispositions de la Résolution du Conseil 15/1993, ce document est distribué

en version anglaise seulement.

To expedite distribution, this document is circulated as received from the committee secretariat.

ISO Central Secretariat work of editing and text composition will be undertaken at publication

stage.

Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.

THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.

© International Organization for Standardization, 2005

ISO/DIS 15338

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall

not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the

unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

Copyright notice

This ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user's country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, photocopying,

recording or otherwise, without prior written permission being secured.

Requests for permission to reproduce should be addressed to either ISO at the address below or ISO's

member body in the country of the requester.

ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

©

ii ISO 2005 – All rights reserved

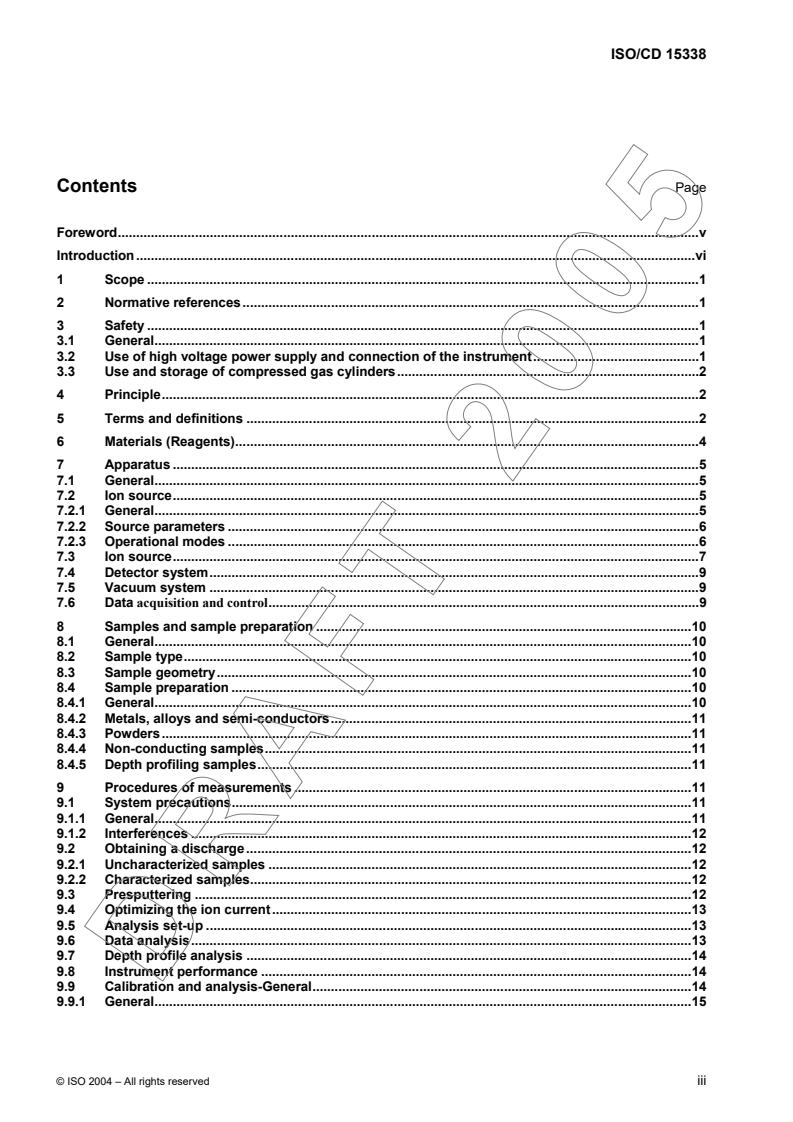

Contents Page

Foreword.v

Introduction.vi

1 Scope .1

2 Normative references.1

3 Safety .1

3.1 General.1

3.2 Use of high voltage power supply and connection of the instrument.1

3.3 Use and storage of compressed gas cylinders.2

4 Principle.2

5 Terms and definitions .2

6 Materials (Reagents).4

7 Apparatus .5

7.1 General.5

7.2 Ion source.5

7.2.1 General.5

7.2.2 Source parameters .6

7.2.3 Operational modes .6

7.3 Ion source.7

7.4 Detector system.9

7.5 Vacuum system .9

7.6 Data acquisition and control.9

8 Samples and sample preparation .10

8.1 General.10

8.2 Sample type.10

8.3 Sample geometry.10

8.4 Sample preparation .10

8.4.1 General.10

8.4.2 Metals, alloys and semi-conductors.11

8.4.3 Powders.11

8.4.4 Non-conducting samples.11

8.4.5 Depth profiling samples.11

9 Procedures of measurements .11

9.1 System precautions.11

9.1.1 General.11

9.1.2 Interferences .12

9.2 Obtaining a discharge.12

9.2.1 Uncharacterized samples .12

9.2.2 Characterized samples.12

9.3 Presputtering .12

9.4 Optimizing the ion current.13

9.5 Analysis set-up .13

9.6 Data analysis.13

9.7 Depth profile analysis .14

9.8 Instrument performance .14

9.9 Calibration and analysis-General.14

9.9.1 General.15

DRAFT 2005

9.9.2 Measurement using relative sensitive factor.15

9.9.3 Measurement using a matrix corrected relative sensitivity factors.18

9.10 Calibration and analysis criteria .19

9.10.1 Number of determinations.19

9.10.2 Calibration standard samples .19

9.10.3 Calibration verification.21

9.10.4 Acceptance of results .21

10 Test report.21

iv © ISO 2004 – All rights reserved

DRAFT 2005

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 15338 was prepared by Technical Committee ISO/TC 201, Surface Chemical analysis, Subcommittee

SC 8, Glow discharge spectroscopy.

DRAFT 2005

COMMITTEE DRAFT ISO/CD 15338

Surface chemical analysis — Glow-discharge mass

spectrometry (GD-MS) — Introduction to use

1 Scope

This Standard is a guide to the operation and recommendations for the use of glow discharge mass

spectrometry (GD-MS).

Note: This Standard should be read in conjunction with the instrument manufacturer’s manuals and recommendations.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 18115:2001/PDAM 1, Surface chemical analysis — Vocabulary — Supplement

ISO 5725-1:1994, Accuracy (trueness and precision) of measurement methods and results — Part 1: General

principles and definitions.

ISO 5725-2:1994, Accuracy (trueness and precision) of measurement methods and results — Part 2: Basic

method for the determination of repeatability and reproducibility of a standard measurement method.

ISO 5725-6:1994, Accuracy (trueness and precision) of measurement methods and results — Part 6: Use in

practice of accuracy values.

ISO/DIS 18115, Surface chemical analysis — Vocabulary

1 Safety

3.1 General

The following precautions should be taken to ensure the safety of operators and their environment, during

operation of glow discharge mass spectrometry:

(a) Use of high voltage power supply and connection of the instrument.

(b) Use and storage of compressed gas cylinders.

(c) Handling of cryogenic materials.

3.2 Use of high voltage power supply and connection of the instrument

Electrical connection should comply with the regulations in force. Particular care should be taken to ensure

that connection of the instrument to ground/earth is correct, and the efficiency of the ground/earth connection

should be checked.

DRAFT 2005

3.3 Use and storage of compressed gas cylinders

The compressed gas cylinders should be regularly tested by the appropriate authorities. Preferably, cylinders

should not be stored or used inside the laboratory. Rather, they should be located outside the laboratory in a

place that is well ventilated, away from direct heat, and accessible to service and safety personnel. The

cylinders should be provided with suitable pressure reducing valves. If more than one cylinder is to be used or

stored in close proximity, it is advisable to indicate in some way which cylinder or cylinders are currently in use.

3.4 Handling of cryogenic materials

The installation of vessels of cryogenic materials shall be located so as to minimize the risk to personnel. Area

where cryogenic liquids are stored and used shall be ventilated to prevent the accumulation of gas or vapour

which could evaporate from the liquid. It is good practice to keep areas where cryogenic liquids are used very

clean. All transfer operation shall be in accordance with statutory requirement. When a cryogenic liquids is

being transferred from one vessel to another, precautions shall be taken to minimize any spills and splashing.

The requirement of the relevant regulatory authority shall also be met.

4 Principle

In a glow discharge source electrical power is supplied between the sample (cathode) and the anode by a

power supply typically operated in direct current (dc) at 0.5 to 2 kV and 1 to 30 mA. Argon (or other inert gas

such as neon, krypton or helium) is introduced into the discharge cell. The pressure inside the discharge cell

is typically a few hundred Pascals (Pa). The potential difference between the cathode and the anode is

applied and a glow discharge (plasma) is established. Sample material (single atoms and/or clusters) which

are sputtered by ions and neutrals diffuse into the plasma.

Ions formed in the glow discharge are extracted from the cell and pass into a mass analyzer. The mass

analyzer is used to transmit ions of given mass to charge ratio to the detector(s). The ions reaching the

detector(s) are measured directly as ion current or counted by a counting system. Information is stored in a

computer system. Elemental mass fractions are typically calculated by the instrument software using the ion

currents of isotopes, by normalizing the signal to the signal of a matrix element and subsequently comparing

the normalized signals with those arising from the corresponding elements in calibration samples.

5 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

5.1

Abundance sensitivity

ratio of the maximum ion current recorded at a mass m to the ion current arising from the same species

recorded at an adjacent mass (m ± 1).

5.2

Accuracy of measurement

the closeness of the agreement between a test result and the accepted reference value.

5.3

Anode

more positively charged electrode in a glow discharge device.

5.4

Cathode

more negatively charged electrode in a glow discharge device.

2 © ISO 2004 – All rights reserved

DRAFT 2005

5.5

Chemical specie

atom, molecule, ion or functional group.

5.6

Detection limit (DL)

smallest amount of an element or compound that can be measured under specified analytical conditions.

5.7

Elemental intensity

the amount of ion current recorded for a particular element.

5.8

Flat cell

a sample cell used for the analysis of flat samples.

5.9

Glow discharge, abnormal

glow discharge operated in a current/voltage regime for which an increase in current is accompanied by an

increase in voltage.

5.10

Glow discharge, normal

glow discharge operated in a current/voltage regime for which an increase in current is accompanied by little

or no detectible change in voltage.

5.11

Ion beam ratio (IBR)

the signal intensity of the analyte ion divided by the intensity of the matrix ion(s), both corrected for isotopic

abundance.

5.12

Intensity, peak

measure of signal intensity for a constituent spectral peak.

5.13

Intensity, signal

strength of a measured signal at a spectrometer detector or after some defined processing.

5.14

Interference signal

signal measured at the position of mass of interest due to another, undesired, species.

5.15

Mass to charge ratio

mass of an ion divided by the number of electrons added to or removed from it to form an ion.

5.16

Pin cell

sample cell used for the analysis of wire and rod samples.

5.17

Plasma

gas consisting of ions, electrons, and neutral particles.

5.18

Preburn

period during which preburning occurs, i.e. period when plasma is on before analysis.

DRAFT 2005

5.19

Presputtering period

process of sputtering, prior to signal registration, employed to allow steady state sputtering to be established

and analytical signals to stabilise.

5.20

Precision of measurements

the closeness of the agreement between independent test results obtained under stipulated conditions,

normally reported as a standard deviation.

5.21

Reference material

material or substance one or more of whose property values are sufficiently homogeneous and well

established to be used for the calibration of an apparatus, the assessment of measured methods, or for

assigning value to materials.

5.22

Reference material, certified

reference material, accompanied by a certificate, one or more of whose property values are certified by a

procedure which establishes its traceability to an accurate realization of the unit in which the property values

are expressed, and for which each certified values is accompanied by an uncertainty at a stated level of

confidence.

5.23

Resolution of spectrometer

contribution of the spectrometer to the measured full width at half maximum (FWHM) or at 10% height of

maximum intensities of spectral peaks above their local backgrounds.

5.24

Resolving power of a spectrometer

ratio of the mass to the resolution of the spectrometer at that mass.

5.25

Pin, rod and wire sample

a sample with cylindrical or square cross section of nominal length typically 20 mm and not normally

exceeding 10 mm across.

5.26

Secondary cathode

electrically conductive mask, containing an aperture, used to enable sputtering of an electrically

nonconductive sample surface in a direct glow discharge device.

5.27

Sensitivity factor, relative (RSF)

coefficient for an element with which the measured intensity of a mass peak for that element, divided by the

measured intensity of a mass peak of a matrix element, is multiplied to yield the mass fraction of that element

in the sample divided by the mass fraction of the matrix element.

NOTE RSF values for some other techniques are sometimes calculated as the inverse of the definition used here for GD-

MS.

5.28

Transmission

a ratio of the number of ions reaching the detector relative to the number of ions entering the mass analyzer.

6 Materials (Reagents)

Water- deionized water, 18 M ohm or better.

4 © ISO 2004 – All rights reserved

DRAFT 2005

Argon gas (Ar) - Of purity at least 99.9995% argon (or other gases of high purity)

Liquid nitrogen (LN2) - For cryogenic cooling of discharge cell.

Compressed air - To operate pneumatic valves.

7 Apparatus

7.1 General

A glow discharge mass spectrometer typically consists of the following parts:

(a) Ion source

(b) Mass analyzer

(c) Detector system

(d) Data acquisition and control

7.2 Ion source

7.2.1 General

A glow discharge ion source consists of a glow discharge cell and a power supply. The ion source also may

contain a series of focusing plates, external to the cell, whose function is to extract ions from the cell and

focus these ions into the mass spectrometer.

Typically the body of the discharge cell is connected to the anode output of the power supply. The sample

serves in the glow discharge cell as a cathode and is connected to the cathode output of the power supply.

The discharge cells have been designed to accommodate samples in the geometries recommended in 8.3

and examples of the discharge cells are illustrated with the appropriate sample holders in Figures 1a and 1b.

IInnsulsulaatotorr

IoIonn

ExExitit

SlSlitit

SampleSample

AnodAnodee

PlatPlatee

SampleSample Holder Holder

CatCathhodeode

PlatePlate

Figure 1a — Example of a cell used for the analysis of pin samples

DRAFT 2005

InInsusullaattoorr

CeCellll B Booddyy

SprinSpringg

IoIonn

ExExitit

SlitSlit

AnAnodode e

PlatPlatee

SampleSample

(Ca(Catthodhode)e)

Figure 1b — Example of a cell used for the analysis of flat samples

7.2.2 Source parameters

The source parameters are as follows:

(a) Electrical

a. Potential difference

b. Current

c. Power

(b) Geometrical

a. Dimension of sample exposed to plasma

b. Anode to sample distance

c. Cathode dimension

d. Mask dimension, where appropriate

(c) Gas type and pressure

(d) Cell temperature

(e) Type of sample

1.1.1 Operational modes

The direct current source may be operated in different modes, including:

6 © ISO 2004 – All rights reserved

DRAFT 2005

(a) Constant current with potential difference selected by adjusting the plasma gas pressure.

(b) Constant potential difference with current selected by adjusting the plasma gas pressure.

The discharge pressure may be regulated using a mass flow controller or a needle valve. For some types of

GD-MS instruments, the high accelerating voltages encountered require a capillary in the gas line to prevent

electrical breakdown through the gas line. Radio frequency powered GD sources are also being developed for

GD-MS.

7.3 Ion source

There are two types of mass analyzers commonly used for glow discharge mass spectrometry: magnetic

sector and quadrupole instruments. Other types like time-of-flight instruments are also becoming more

common.

(a) Magnetic sector - This type of instrument (see Figure 2a) typically utilizes an electro-magnet and an

electrostatic analyzer (ESA). The magnet achieves mass separation, and as the magnetic field is

increased, ions with a greater mass to charge ratio are transmitted. The ESA acts as an energy filter and

transmits only those ions with the appropriate energies.

This arrangement permits high transmission and high resolution operation, giving accurate mass

information advantageous in complex sample matrices where there is an increased possibility of

interferences. A resolving power of 4000 is sufficient to overcome most common interferences.

Figure 2a—Schematic diagram of a magnetic sector mass analyzer

(b) Quadrupole - Ions of increasing mass are transmitted as an increasing direct current bias is imposed

using a radio frequency (rf) potential applied to four parallel rods (see Figure 2b). The mass to charge

ratio is used to filter the elements such that only those selected emerge.

DRAFT 2005

Whilst a quadrupole does not have the high resolution of a magnetic sector instrument, typically it has a

resolving power of less than 200, it has a much faster scanning speed, is compact and is able to achieve

low detection limits if interferences are kept low.

Figure 2b—Schematic diagram of a quadrupole mass analyzer

(c) TOF (time-of-flight mass spectrometers) – An ensemble of ions are accelerated simultaneously by an

electric field and then allowed to drift a certain distance before impinging onto an ion detector(see Figure

2c). In the accelerating field all ions receive a similar E/z (energy per charge). Therefore, ions with low m/z

will arrive at the detector earlier than ions with higher m/z. By measuring the arrival time of ions the, m/z of

those ions can be determined.

Whilst quadrupoles and sector instruments are m/z filters, TOFs do not have to scan in order to record a

mass spectrum and therefore have the potential for higher duty cycle. TOFs intrinsically have a large

mass range and good mass accuracy. They also have reasonably good resolvin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...