ISO 15463:2003

(Main)Petroleum and natural gas industries — Field inspection of new casing, tubing and plain-end drill pipe

Petroleum and natural gas industries — Field inspection of new casing, tubing and plain-end drill pipe

ISO 15463:2003 specifies requirements and gives recommendations for field inspection and testing of oil country tubular goods (OCTG). ISO 15463:2003 covers the practices and technology commonly used in field inspection; however, certain practices may also be suitable for mill inspections. ISO 15463:2003 covers the qualification of inspection personnel, a description of inspection methods and apparatus calibration and standardization procedures for various inspection methods. The evaluation of imperfections and marking of inspected OCTG are included. ISO 15463:2003 is applicable to field inspection of OCTG and is not applicable for use as a basis for acceptance or rejection (for which the applicable purchasing specification is applicable, see 5.4.2)

Industries du pétrole et du gaz naturel — Contrôle sur parc ou sur chantier des tubes de cuvelage, des tubes de production et des tiges de forage à extrémités lisses

General Information

- Status

- Published

- Publication Date

- 03-Dec-2003

- Technical Committee

- ISO/TC 67/SC 5 - Casing, tubing and drill pipe

- Drafting Committee

- ISO/TC 67/SC 5/WG 1 - Casing, tubing and drill pipe

- Current Stage

- 9020 - International Standard under periodical review

- Start Date

- 15-Oct-2025

- Completion Date

- 15-Oct-2025

Relations

- Effective Date

- 12-Feb-2026

- Effective Date

- 28-Feb-2023

Overview

ISO 15463:2003 defines requirements and recommendations for the field inspection of new casing, tubing and plain-end drill pipe (oil country tubular goods - OCTG) used in the petroleum and natural gas industries. The standard describes field inspection practices and technologies commonly used at job sites or yards, including qualification of inspection personnel, inspection methods, calibration and standardization of apparatus, evaluation of imperfections and marking of inspected OCTG. ISO 15463:2003 applies to field inspections (some practices may suit mill inspection) but is not intended as the sole basis for contractual acceptance or rejection - purchaser specifications remain authoritative.

Key Topics and Requirements

- Scope and application: Field inspection procedures for new casing, tubing and plain-end drill pipe; repeatability and applicability of inspections.

- Personnel qualification: Written procedures, training, examinations, experience, requalification and documentation requirements for inspection staff.

- Quality assurance and documentation: Job-site documents, pre- and post-inspection records, checklists and reporting.

- Visual and dimensional inspection: Full-length visual inspection (FLVI), drift testing, thread inspection and straightness/diameter checks.

- Non-destructive testing (NDT) methods:

- Magnetic Particle Inspection (MPI) including end-area and full-length MPI procedures.

- Electromagnetic Inspection (EMI) and electromagnetic grade comparison.

- Ultrasonic Inspection (UT) for longitudinal/transverse/oblique imperfections and wall-thickness measurement.

- Gamma-ray wall thickness inspection.

- Hardness testing, residual magnetism and demagnetization procedures.

- Calibration and standardization: Equipment calibration, standardization procedures and periodic checks for NDT equipment.

- Evaluation and marking: Procedures for assessing imperfections, disposition guidance (but not contractual acceptance), and marking of inspected OCTG.

Applications

ISO 15463:2003 is used to:

- Provide consistent, repeatable field inspection methods for new OCTG at yards, well sites and storage locations.

- Guide NDT implementation and equipment calibration for field-based inspections.

- Support QA/QC workflows, documentation and traceability of inspected tubulars.

- Inform inspection training and certification programs for field inspectors.

Who Uses This Standard

- Oil & gas operators and drilling contractors

- Field inspection and NDT technicians

- Third‑party inspection agencies and yard/rig quality personnel

- OCTG manufacturers, suppliers and procurement teams

- QA/QC and HSE managers overseeing tubular integrity

Related Guidance

Refer to the purchaser’s specification for acceptance/rejection criteria (see clause 5.4.2) and to relevant industry NDT and OCTG standards and manufacturer requirements when applying ISO 15463:2003 in contractual or acceptance decisions.

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

ISO 15463:2003 is a standard published by the International Organization for Standardization (ISO). Its full title is "Petroleum and natural gas industries — Field inspection of new casing, tubing and plain-end drill pipe". This standard covers: ISO 15463:2003 specifies requirements and gives recommendations for field inspection and testing of oil country tubular goods (OCTG). ISO 15463:2003 covers the practices and technology commonly used in field inspection; however, certain practices may also be suitable for mill inspections. ISO 15463:2003 covers the qualification of inspection personnel, a description of inspection methods and apparatus calibration and standardization procedures for various inspection methods. The evaluation of imperfections and marking of inspected OCTG are included. ISO 15463:2003 is applicable to field inspection of OCTG and is not applicable for use as a basis for acceptance or rejection (for which the applicable purchasing specification is applicable, see 5.4.2)

ISO 15463:2003 specifies requirements and gives recommendations for field inspection and testing of oil country tubular goods (OCTG). ISO 15463:2003 covers the practices and technology commonly used in field inspection; however, certain practices may also be suitable for mill inspections. ISO 15463:2003 covers the qualification of inspection personnel, a description of inspection methods and apparatus calibration and standardization procedures for various inspection methods. The evaluation of imperfections and marking of inspected OCTG are included. ISO 15463:2003 is applicable to field inspection of OCTG and is not applicable for use as a basis for acceptance or rejection (for which the applicable purchasing specification is applicable, see 5.4.2)

ISO 15463:2003 is classified under the following ICS (International Classification for Standards) categories: 75.180.10 - Exploratory, drilling and extraction equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 15463:2003 has the following relationships with other standards: It is inter standard links to EN ISO 15463:2003, ISO/R 50:1957. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 15463:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 15463

First edition

2003-12-15

Petroleum and natural gas industries —

Field inspection of new casing, tubing

and plain-end drill pipe

Industries du pétrole et du gaz naturel — Contrôle sur parc ou sur

chantier des tubes de cuvelage, des tubes de production et des tiges

de forage à extrémités lisses

Reference number

©

ISO 2003

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2003

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2003 – All rights reserved

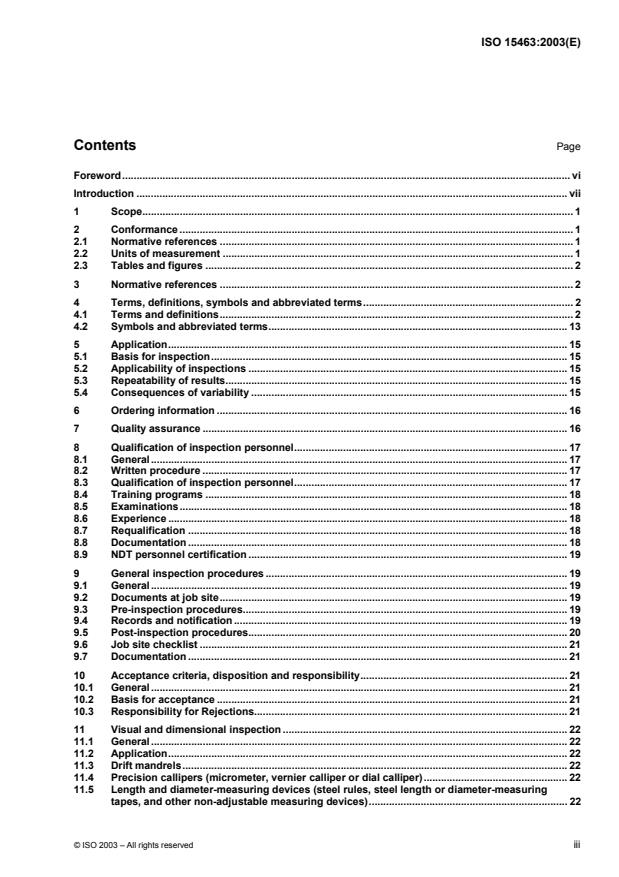

Contents Page

Foreword. vi

Introduction . vii

1 Scope. 1

2 Conformance. 1

2.1 Normative references. 1

2.2 Units of measurement . 1

2.3 Tables and figures . 2

3 Normative references. 2

4 Terms, definitions, symbols and abbreviated terms. 2

4.1 Terms and definitions. 2

4.2 Symbols and abbreviated terms. 13

5 Application. 15

5.1 Basis for inspection. 15

5.2 Applicability of inspections . 15

5.3 Repeatability of results. 15

5.4 Consequences of variability . 15

6 Ordering information. 16

7 Quality assurance. 16

8 Qualification of inspection personnel. 17

8.1 General. 17

8.2 Written procedure. 17

8.3 Qualification of inspection personnel. 17

8.4 Training programs. 18

8.5 Examinations. 18

8.6 Experience. 18

8.7 Requalification. 18

8.8 Documentation. 18

8.9 NDT personnel certification . 19

9 General inspection procedures . 19

9.1 General. 19

9.2 Documents at job site. 19

9.3 Pre-inspection procedures. 19

9.4 Records and notification. 19

9.5 Post-inspection procedures. 20

9.6 Job site checklist . 21

9.7 Documentation. 21

10 Acceptance criteria, disposition and responsibility. 21

10.1 General. 21

10.2 Basis for acceptance . 21

10.3 Responsibility for Rejections. 21

11 Visual and dimensional inspection . 22

11.1 General. 22

11.2 Application. 22

11.3 Drift mandrels. 22

11.4 Precision callipers (micrometer, vernier calliper or dial calliper). 22

11.5 Length and diameter-measuring devices (steel rules, steel length or diameter-measuring

tapes, and other non-adjustable measuring devices). 22

11.6 Depth gauges.22

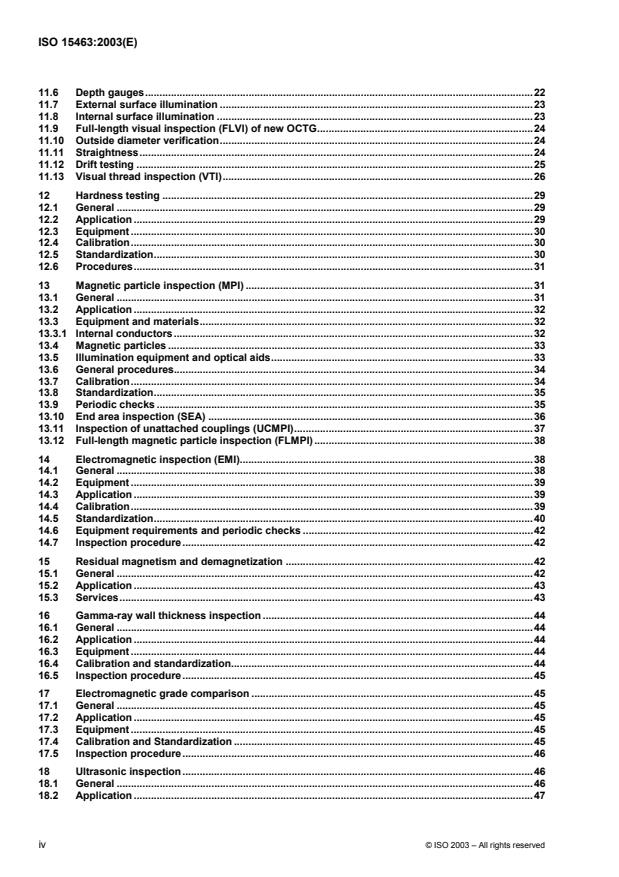

11.7 External surface illumination .23

11.8 Internal surface illumination.23

11.9 Full-length visual inspection (FLVI) of new OCTG.24

11.10 Outside diameter verification.24

11.11 Straightness.24

11.12 Drift testing.25

11.13 Visual thread inspection (VTI).26

12 Hardness testing.29

12.1 General.29

12.2 Application.29

12.3 Equipment.30

12.4 Calibration.30

12.5 Standardization.30

12.6 Procedures.31

13 Magnetic particle inspection (MPI) .31

13.1 General.31

13.2 Application.32

13.3 Equipment and materials.32

13.3.1 Internal conductors.32

13.4 Magnetic particles.33

13.5 Illumination equipment and optical aids.33

13.6 General procedures.34

13.7 Calibration.34

13.8 Standardization.35

13.9 Periodic checks.35

13.10 End area inspection (SEA) .36

13.11 Inspection of unattached couplings (UCMPI).37

13.12 Full-length magnetic particle inspection (FLMPI).38

14 Electromagnetic inspection (EMI).38

14.1 General.38

14.2 Equipment.39

14.3 Application.39

14.4 Calibration.39

14.5 Standardization.40

14.6 Equipment requirements and periodic checks .42

14.7 Inspection procedure.42

15 Residual magnetism and demagnetization .42

15.1 General.42

15.2 Application.43

15.3 Services.43

16 Gamma-ray wall thickness inspection .44

16.1 General.44

16.2 Application.44

16.3 Equipment.44

16.4 Calibration and standardization.44

16.5 Inspection procedure.45

17 Electromagnetic grade comparison .45

17.1 General.45

17.2 Application.45

17.3 Equipment.45

17.4 Calibration and Standardization .45

17.5 Inspection procedure.46

18 Ultrasonic inspection.46

18.1 General.46

18.2 Application.47

iv © ISO 2003 – All rights reserved

18.3 General procedures for calibration, standardization, and inspection. 47

18.4 Inspection for longitudinal, transverse, and oblique imperfections . 48

18.5 Standardization. 49

18.6 Procedure for the detection of longitudinal, transverse, and oblique imperfections. 49

18.7 Inspection of the body wall for wall thinning. 49

18.8 Ultrasonic inspection of longitudinal welds. 50

18.9 Manual ultrasonic thickness gauging. 52

18.10 Manual ultrasonic shear-wave inspection. 54

19 Evaluation of imperfections and deviations. 55

19.1 General. 55

19.2 Application. 55

19.3 Equipment. 55

19.4 Calibration and standardization procedures. 56

19.5 Procedure for evaluating outside-surface-breaking pipe body imperfections. 56

19.6 Procedure for evaluating inside-surface-breaking pipe body imperfections . 58

19.7 Procedure for evaluating welds. 58

19.8 Procedure for evaluating grinds. 59

19.9 Procedure for evaluating large-area wall reduction . 59

19.10 Procedure for evaluating imperfections in upsets .60

19.11 Procedure for evaluation of outside surface imperfections on couplings . 61

19.12 Procedure for evaluation of visually-located thread imperfections . 61

19.13 Procedure for triangle location and coupling makeup position . 64

19.14 Procedure for evaluating straightness . 64

19.15 Procedure for evaluating pipe diameter . 65

20 Hydrostatic pressure testing . 65

20.1 General. 65

20.2 Application. 66

20.3 Equipment, safety, and general procedures . 66

20.4 Equipment calibration. 67

20.5 Operating procedure. 67

21 Marking. 68

21.1 General. 68

21.2 Authority. 69

21.3 Guidelines. 69

21.4 Marking of prime OCTG. 70

21.5 Marking of no-drift OCTG. 70

21.6 Marking of conditioned OCTG . 70

21.7 Marking of conditionable OCTG (still to be conditioned) . 71

21.8 Marking of non-conditionable OCTG (rejects) . 71

21.9 Marking of OCTG not meeting ISO/API standards for hardness. 71

21.10 Marking of prime couplings and connectors . 72

21.11 Marking of conditioned couplings and connectors . 72

21.12 Marking of conditionable couplings and connectors (still to be conditioned). 72

21.13 Marking of non-conditionable couplings and connectors (rejects). 72

Annex A (normative) Tables in SI units. 74

Annex B (normative) Figures . 91

Annex C (normative) Tables in USC units . 96

Bibliography . 112

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 15463 was prepared by Technical Committee ISO/TC 67, Materials, equipment and offshore structures

for petroleum, petrochemical and natural gas industries, Subcommittee SC 5, Casing, tubing and drill pipe.

vi © ISO 2003 – All rights reserved

Introduction

This International Standard is provided for field inspection and testing of OCTG; it is not intended to restrict

the agency or owner from using personal judgement and supplementing the specified inspections with other

techniques, extending existing techniques, or re-inspecting certain lengths of OCTG.

Users of this International Standard should be aware that further or differing requirements might be needed for

individual applications. This International Standard is not intended to inhibit a vendor from offering, or the

purchaser from accepting, alternative equipment or engineering solutions for the individual application. This

may be particularly applicable where there is innovative or developing technology. Where an alternative is

offered, the vendor should identify any variations from this International Standard and provide details.

INTERNATIONAL STANDARD ISO 15463:2003(E)

Petroleum and natural gas industries — Field inspection of new

casing, tubing and plain-end drill pipe

1 Scope

This International Standard specifies requirements and gives recommendations for field inspection and testing

of oil country tubular goods (OCTG). This International Standard covers the practices and technology

commonly used in field inspection; however, certain practices may also be suitable for mill inspections.

This International Standard covers the qualification of inspection personnel, a description of inspection

methods and apparatus calibration and standardization procedures for various inspection methods. The

evaluation of imperfections and marking of inspected OCTG are included.

This International Standard is applicable to field inspection of OCTG and is not applicable for use as a basis

for acceptance or rejection (for which the relevant purchasing specification is applicable, see 5.4.2).

2 Conformance

2.1 Normative references

In the interests of worldwide application of this International Standard, ISO/TC 67 has decided, after detailed

technical analysis, that certain of the normative documents listed in Clause 3 and prepared by ISO/TC 67 or

other ISO Technical Committee are interchangeable in the context of the relevant requirement with the

relevant document prepared by the American Petroleum Institute (API), the American Society for Testing and

Materials (ASTM) or the American National Standards Institute (ANSI). These latter documents are cited in

the running text following the ISO reference and preceded by “or”, for example “ISO XXXX or API YYYY”.

Application of an alternative normative document cited in this manner may lead to technical results different

from the use of the preceding ISO reference. However, both results are acceptable and these documents are

thus considered interchangeable in practice.

NOTE ISO 11960 has been back-adopted by API as API Spec 5CT. Therefore, for the purposes of the provisions in

this International Standard which cite ISO 11960, API Spec 5CT is equivalent to ISO 11960.

2.2 Units of measurement

In this International Standard, data are expressed in both the International system (SI) of units and the United

States Customary (USC) system of units. For specific field inspection and testing, it is intended that only one

unit system be used, without combining data expressed in the other system.

Inspection and testing performed using either of these unit systems shall be considered equivalent and totally

interchangeable. Consequently, compliance with the requirements of the relevant Product Standard

expressed in one of the unit systems provides compliance with the requirements expressed in the other

system.

For data expressed in the SI, a comma is used as the decimal separator and a space as the thousands

separator. For data expressed in the USC system, a dot (on the line) is used as the decimal separator and a

space as the thousands separator.

In the text, data in SI units are followed by data in USC units in brackets.

2.3 Tables and figures

Separate tables for data expressed in SI units and USC units are given in Annex A and Annex C, respectively.

For a specific order item, only one unit system shall be used.

In this International Standard, cross-references are made only to the tables in Annex A; if the USC units apply

on an order, then any cross-references to tables in Annex A shall be taken to mean the equivalent table in

Annex C.

Figures (data expressed in both SI and USC units) are contained in Annex B.

3 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 10405:2000, Petroleum and natural gas industries — Care and use of casing and tubing

ISO 11960:2001 (including Technical Corrigendum 1:2002), Petroleum and natural gas industries — Steel

pipes for use as casing or tubing for wells

ISO 11961:1996, Petroleum and natural gas industries — Steel pipes for use as drill pipe — Specification

ISO 13678, Petroleum and natural gas industries — Evaluation and testing of thread compounds for use with

casing, tubing and line pipe

1)

API RP 5A3 , Thread compounds for casing, tubing and line pipe

API Spec 5B, Threading, gauging and thread inspection of casing, tubing and line pipe threads

API RP 5B1, Threading, gauging and inspection of casing, tubing, and line pipe threads

API RP 5C1:1999, Care and use of casing and tubing

API Spec 5D:2001, Specification for drill pipe

API Std 5T1, Imperfection terminology

4 Terms, definitions, symbols and abbreviated terms

4.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

4.1.1

A-scan

data presentation utilizing a horizontal base line that indicates distance, or time, and a vertical deflection from

the base line that indicates amplitude

4.1.2

AC-field

magnetic field induced by alternating current

1) American Petroleum Institute; 1220 L Street NW, Washington DC, 20005, USA

2 © ISO 2003 – All rights reserved

4.1.3

agency

entity contracted to inspect new OCTG using the methods and criteria specified

4.1.4

ampere-turn

unit of magnetomotive force which is the product of the number of turns in a coil and the quantity of amperes

of current flowing through it, representing the magnetizing strength of the coil

EXAMPLE 800 A in a 6-turn coil gives 4 800 ampere-turns.

4.1.5

arc, verb

create intense heat and light by passing an electric current across a gap

4.1.6

back-wall reflection

ultrasonic signal received from the back surface of the pipe wall

4.1.7

black-crested thread

non-full-crested thread whose original (black) mill surface has not been completely removed

4.1.8

black light

long-wave ultraviolet light (UV-A) with a wavelength between 320 nm and 400 nm

4.1.9

borescope

optical instrument with an illuminating lamp, used for inspecting the inside surface of OCTG

4.1.10

box

internally-threaded end of integral-joint OCTG, or the coupling end of threaded-and-coupled OCTG

4.1.11

calibration

comparison of an instrument with, or the adjustment of an instrument to, a known reference(s) standard that is

often traceable to a national institute such as the National Institute of Standards and Technology

4.1.12

casing

steel pipe used in oil wells to seal off fluids from the bore hole and to prevent the walls of the hole from

sloughing off or caving in

4.1.13

central conductor

conductor that is passed through the bore of OCTG in order to create a circular or circumferential magnetic

field in the OCTG

NOTE This does not imply that the current rod is necessarily centred in the bore of the OCTG.

4.1.14

chamfer

conical surface at the end of pipe having round or buttress threads

4.1.15

chatter

wavy surface of the thread flank, root, crest, or chamfer, caused by a vibrating cutter insert

4.1.16

chock

block or wedge used beneath a length of pipe so that it cannot roll

4.1.17

circular magnetic field

circumferential magnetic field

magnetic field in or surrounding a current-carrying conductor, or OCTG, such that the magnetic field is

oriented circumferentially within the wall of the OCTG

4.1.18

circular magnetization

circumferential magnetization

production of a magnetic field in a pipe wall or coupling such that the magnetic field is oriented

circumferentially

4.1.19

classification

action taken to categorize a length of new OCTG based on conformance with the contracted inspection

requirements

4.1.20

contour, verb

taper gradually by filing or grinding to remove abrupt changes in the wall thickness

4.1.21

contour-grind, verb

radius-grind

grind to remove sharp edges and/or abrupt changes in the wall thickness around imperfections or areas of

exploratory grinding

4.1.22

couplant

material (usually a liquid) used between an ultrasonic transducer and the test specimen to assist transmission

of ultrasonic sound waves between them

4.1.23

crest

top of a thread

4.1.24

cut, noun

gouge or distortion in two or more thread crests in a line, either parallel to the pipe axis or at an angle across

the threads

4.1.25

DC-field

residual or active magnetic field induced by direct current

4.1.26

defect

imperfection of sufficient magnitude or properties to warrant rejection of OCTG based on the specified

acceptance criteria

4.1.27

demagnetization

process of removing part or all of the residual magnetism from OCTG

4 © ISO 2003 – All rights reserved

4.1.28

detector

detector shoe

scanning shoe carrying one or more transducers, used to protect transducers from mechanical damage

4.1.29

discontinuity

flaw

imperfection

irregularity in the product, such as a lap, seam, pit and lamination

4.1.30

disposition

action taken in accordance with the applicable specification with regard to a defect in a length of OCTG

4.1.31

drift mandrel

cylinder, machined to specified dimensions, that is passed through a pipe to locate obstructions and/or to

assess compliance with the appropriate specifications

4.1.32

dual-element transducer

ultrasonic transducer containing two piezoelectric elements, one for transmitting and one for receiving

4.1.33

eddy current

circulating current caused to flow in the OCTG by varying magnetic fields

4.1.34

electromagnetic inspection

EMI

primarily the eddy-current and flux-leakage methods used to detect imperfections

NOTE Field electromagnetic "Inspection Systems" sometimes include equipment for performing additional

inspections or services.

4.1.35

evaluation

process of determining the severity of an imperfection which leads to determining whether the OCTG is

acceptable or rejectable against the appropriate specification

4.1.36

exploratory grind, noun

probe grind

grind performed to explore or determine the depth of an imperfection

4.1.37

external thread

thread on the outside surface of OCTG

4.1.38

false indication

NDT indication that is interpreted to be caused by a condition other than a discontinuity or imperfection

NOTE False indications are considered non-relevant.

4.1.39

false starting thread

circumferential tool mark on a round-thread chamfer that precedes the actual starting thread

4.1.40

ferromagnetic

term applied to materials that can be magnetized or strongly attracted by a magnetic field

4.1.41

field end

pipe end opposite the internally-threaded end

NOTE Mill identification is at the internally-threaded end.

4.1.42

flank

side

surface of a thread that connects the crest with the root

4.1.43

fluorescent magnetic particle inspection

magnetic particle inspection process employing a finely-divided, fluorescent, ferromagnetic inspection medium

that fluoresces when exposed to black light

4.1.44

flux density

strength of a magnetic field

NOTE In the Gaussian system, flux density is expressed in gauss.

4.1.45

flux leakage

magnetic field forced out into the air by a distortion of the field within the OCTG, caused by the presence of a

discontinuity

4.1.46

full-body inspection

inspection coverage of the entire surface area of the OCTG within the limitations of the inspection equipment

used

4.1.47

furring

build-up or bristling of dry magnetic particles at the ends of a longitudinally-magnetized length of OCTG, i.e. at

its poles

4.1.48

gain

sensitivity adjustment produced by an amplifier or circuit

4.1.49

gamma-ray

high-energy, short wavelength, electromagnetic radiation emitted by a nucleus, which is penetrating and is

best attenuated by dense material like lead or tungsten

NOTE The energy of gamma-rays is usually between 0,010 MeV and 10 MeV.

4.1.50

gauss meter

electronic magnetometer used to measure flux density

4.1.51

grind, verb

remove material from a surface by abrading, e.g. with a grinding wheel or file

6 © ISO 2003 – All rights reserved

4.1.52

handling damage

damage to the OCTG body, coupling or threads that occurred during loading, unloading, movements in transit,

etc.

EXAMPLES cuts, gouges, dents, flattened (mashed) thread crests or similar.

4.1.53

hardness

resistance of a material to indentation, measured by pressing a hardmetal ball or diamond indenter into a

smooth surface under standard conditions

4.1.54

hardness value

average of the valid readings taken in the test area for hardness

4.1.55

hydrostatic test

test performed by filling a length of OCTG with water and pressurizing it in order to verify its ability to

withstand a specified pressure without leaking or rupturing

NOTE A hydrostatic test is generally considered a method to verify the structural integrity of the pipe but not the

threaded connection.

4.1.56

imperfection

flaw

discontinuity or irregularity in the product

NOTE For more detailed definitions and illustrations of specific imperfections, see API Std 5T1.

4.1.57

indication

response or evidence from NDT

4.1.58

indicator

readout

device for displaying a condition, a current or a potential

EXAMPLES Analog and digital galvanometers, A-scan displays, warning lights, alarms.

4.1.59

induction

act of inducing a magnetic field in a ferromagnetic body

4.1.60

inspection

process of examining OCTG for possible defects or for deviation from established standards

4.1.61

inspection job

inspection of one or more lots of OCTG by an agency subject to a single contract or subcontract

4.1.62

inspection system

combination of equipment, procedures and personnel required for the detection of reference indicators

4.1.63

inspector

employee of an agency qualified and responsible for one or more of the inspections or tests specified in the

contract

4.1.64

integral joint OCTG

OCTG with one end threaded externally and the other end threaded internally

4.1.65

internal thread

thread on the inside surface of OCTG

4.1.66

interpretation

process of determining the nature or forming an opinion of an indication based on objective data

4.1.67

label 1

dimensionless designation for the size or specified outside diameter, used when ordering OCTG

4.1.68

label 2

dimensionless designation for the mass per unit length or wall thickness, used when ordering OCTG

4.1.69

leakage field

magnetic field forced out of the material into the air by distortion of the field within the material, caused by the

presence of a discontinuity

4.1.70

length

joint

complete section of pipe

4.1.71

longitudinal magnetic field

magnetic field which runs substantially parallel to the axis of the OCTG

4.1.72

longitudinal imperfection

imperfection oriented in the longitudinal or approximately longitudinal direction

4.1.73

magnetic particle field indicator

device containing artificial flaws which is used to verify the adequacy or direction, or both, of a magnetic field

4.1.74

magnetic particle

finely-divided ferromagnetic material capable of being individually magnetized and attracted to distortions in a

magnetic field

4.1.75

magnetizing force

magnetic field strength

NOTE In the Gaussian system, the symbol is H and quantities are expressed in oersteds.

s

4.1.76

magnetometer

mechanical or electronic instrument used to measure magnetic field strength

8 © ISO 2003 – All rights reserved

4.1.77

manufacturer

entity last responsible for manufacturing compliance with the applicable product specification(s)

4.1.78

marking

assorted marks on tubular products including marks made for inspection with paint sticks and stencils, and

ball-point paint tubes

4.1.79

mill end

pipe end having the coupling, box and/or mill identification

4.1.80

mill scale

iron oxide that forms on the surface of hot steel

4.1.81

no-drift

length of pipe through which a drift mandrel of specified diameter will not pass without undue force

4.1.82

non-destructive test

NDT

test used to detect internal, surface and concealed defects or imperfections in materials, using techniques that

do not damage or destroy the items being tested

4.1.83

non-full-crested thread

thread that does not have a complete thread crest

EXAMPLE Black-crested thread.

4.1.84

notch

reference indicator with specified geometry

4.1.85

oil country tubular goods

OCTG

casing, tubing, plain-end casing liners, pup joints, couplings, accessories and plain-end drill pipe

4.1.86

operator

person present throughout the inspection or testing process who is responsible for the unit, operates the

controls and observes the readout to detect imperfections

4.1.87

owner

entity having ownership of the new OCTG at the time inspection is contracted, specifying the type of

inspection or testing to be conducted and authorizing its performance

NOTE The owner might be the purchaser.

4.1.88

perfect thread length

design length from the end of pipe or couplin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...