ISO 12135:2016

(Main)Metallic materials — Unified method of test for the determination of quasistatic fracture toughness

Metallic materials — Unified method of test for the determination of quasistatic fracture toughness

ISO 12135:2016 specifies methods for determining fracture toughness in terms of K, δ, J and R-curves for homogeneous metallic materials subjected to quasistatic loading. Specimens are notched, precracked by fatigue and tested under slowly increasing displacement. The fracture toughness is determined for individual specimens at or after the onset of ductile crack extension or at the onset of ductile crack instability or unstable crack extension. In some cases in the testing of ferritic materials, unstable crack extension can occur by cleavage or ductile crack initiation and growth, interrupted by cleavage extension. The fracture toughness at crack arrest is not covered by this document. In cases where cracks grow in a stable manner under ductile tearing conditions, a resistance curve describing fracture toughness as a function of crack extension is measured. In most cases, statistical variability of the results is modest and reporting the average of three or more test results is acceptable. In cases of cleavage fracture of ferritic materials in the ductile-to-brittle transition region, variability can be large and additional tests may be required to quantify statistical variability. Special testing requirements and analysis procedures are necessary when testing weldments and these are described in ISO 15653 which is complementary to this document. When fracture occurs by cleavage or when cleavage is preceded by limited ductile crack extension, it may be useful to establish the reference temperature for the material by conducting testing and analysis in accordance with ASTM E1921.[2]

Matériaux métalliques — Méthode unifiée d'essai pour la détermination de la ténacité quasi statique

General Information

- Status

- Withdrawn

- Publication Date

- 08-Nov-2016

- Withdrawal Date

- 08-Nov-2016

- Technical Committee

- ISO/TC 164/SC 4 - Fatigue, fracture and toughness testing

- Drafting Committee

- ISO/TC 164/SC 4 - Fatigue, fracture and toughness testing

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 27-Jul-2021

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 23-Apr-2020

- Effective Date

- 12-Nov-2011

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

ISO 12135:2016 is a standard published by the International Organization for Standardization (ISO). Its full title is "Metallic materials — Unified method of test for the determination of quasistatic fracture toughness". This standard covers: ISO 12135:2016 specifies methods for determining fracture toughness in terms of K, δ, J and R-curves for homogeneous metallic materials subjected to quasistatic loading. Specimens are notched, precracked by fatigue and tested under slowly increasing displacement. The fracture toughness is determined for individual specimens at or after the onset of ductile crack extension or at the onset of ductile crack instability or unstable crack extension. In some cases in the testing of ferritic materials, unstable crack extension can occur by cleavage or ductile crack initiation and growth, interrupted by cleavage extension. The fracture toughness at crack arrest is not covered by this document. In cases where cracks grow in a stable manner under ductile tearing conditions, a resistance curve describing fracture toughness as a function of crack extension is measured. In most cases, statistical variability of the results is modest and reporting the average of three or more test results is acceptable. In cases of cleavage fracture of ferritic materials in the ductile-to-brittle transition region, variability can be large and additional tests may be required to quantify statistical variability. Special testing requirements and analysis procedures are necessary when testing weldments and these are described in ISO 15653 which is complementary to this document. When fracture occurs by cleavage or when cleavage is preceded by limited ductile crack extension, it may be useful to establish the reference temperature for the material by conducting testing and analysis in accordance with ASTM E1921.[2]

ISO 12135:2016 specifies methods for determining fracture toughness in terms of K, δ, J and R-curves for homogeneous metallic materials subjected to quasistatic loading. Specimens are notched, precracked by fatigue and tested under slowly increasing displacement. The fracture toughness is determined for individual specimens at or after the onset of ductile crack extension or at the onset of ductile crack instability or unstable crack extension. In some cases in the testing of ferritic materials, unstable crack extension can occur by cleavage or ductile crack initiation and growth, interrupted by cleavage extension. The fracture toughness at crack arrest is not covered by this document. In cases where cracks grow in a stable manner under ductile tearing conditions, a resistance curve describing fracture toughness as a function of crack extension is measured. In most cases, statistical variability of the results is modest and reporting the average of three or more test results is acceptable. In cases of cleavage fracture of ferritic materials in the ductile-to-brittle transition region, variability can be large and additional tests may be required to quantify statistical variability. Special testing requirements and analysis procedures are necessary when testing weldments and these are described in ISO 15653 which is complementary to this document. When fracture occurs by cleavage or when cleavage is preceded by limited ductile crack extension, it may be useful to establish the reference temperature for the material by conducting testing and analysis in accordance with ASTM E1921.[2]

ISO 12135:2016 is classified under the following ICS (International Classification for Standards) categories: 77.040.10 - Mechanical testing of metals. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 12135:2016 has the following relationships with other standards: It is inter standard links to ISO 12135:2021, ISO 12135:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 12135:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 12135

Second edition

2016-11-15

Metallic materials — Unified method

of test for the determination of

quasistatic fracture toughness

Matériaux métalliques — Méthode unifiée d’essai pour la

détermination de la ténacité quasi statique

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

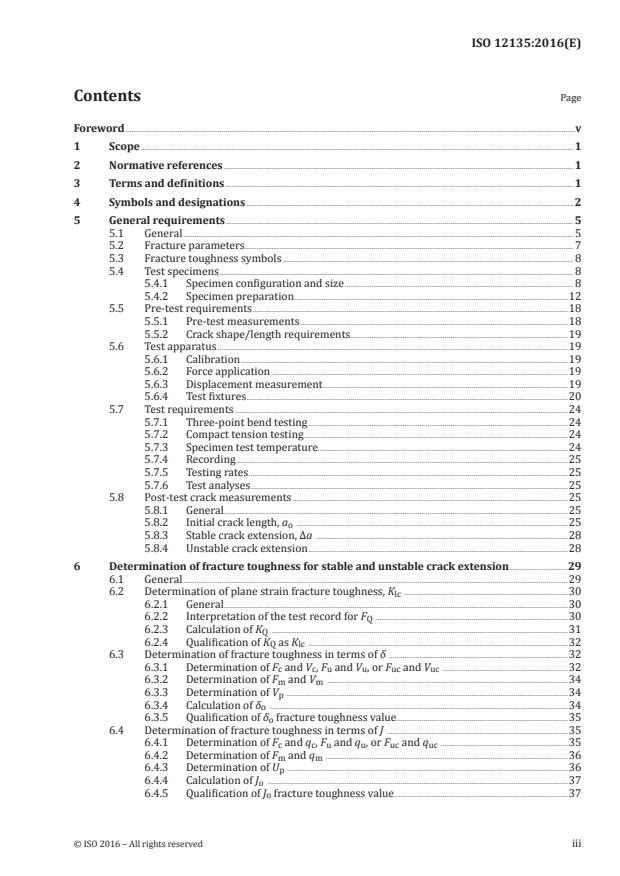

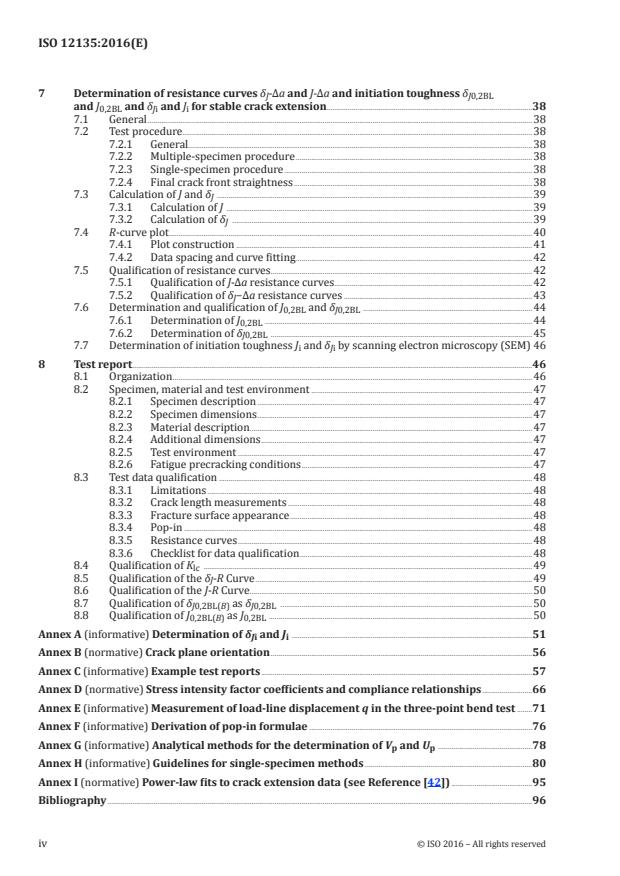

Contents Page

Foreword .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols and designations . 2

5 General requirements . 5

5.1 General . 5

5.2 Fracture parameters. 7

5.3 Fracture toughness symbols . 8

5.4 Test specimens . 8

5.4.1 Specimen configuration and size . 8

5.4.2 Specimen preparation .12

5.5 Pre-test requirements .18

5.5.1 Pre-test measurements .18

5.5.2 Crack shape/length requirements .19

5.6 Test apparatus .19

5.6.1 Calibration .19

5.6.2 Force application .19

5.6.3 Displacement measurement .19

5.6.4 Test fixtures .20

5.7 Test requirements .24

5.7.1 Three-point bend testing .24

5.7.2 Compact tension testing .24

5.7.3 Specimen test temperature.24

5.7.4 Recording .25

5.7.5 Testing rates .25

5.7.6 Test analyses .25

5.8 Post-test crack measurements .25

5.8.1 General.25

5.8.2 Initial crack length, a .25

o

5.8.3 Stable crack extension, Δa .28

5.8.4 Unstable crack extension .28

6 Determination of fracture toughness for stable and unstable crack extension .29

6.1 General .29

6.2 Determination of plane strain fracture toughness, K .30

lc

6.2.1 General.30

6.2.2 Interpretation of the test record for F .30

Q

6.2.3 Calculation of K .31

Q

6.2.4 Qualification of K as K .32

Q lc

6.3 Determination of fracture toughness in terms of δ .32

6.3.1 Determination of F and V , F and V , or F and V .32

c c u u uc uc

6.3.2 Determination of F and V .34

m m

6.3.3 Determination of V .34

p

6.3.4 Calculation of δ .34

ο

6.3.5 Qualification of δ fracture toughness value .35

ο

6.4 Determination of fracture toughness in terms of J .35

6.4.1 Determination of F and q , F and q , or F and q .35

c c u u uc uc

6.4.2 Determination of F and q .36

m m

6.4.3 Determination of U .36

p

6.4.4 Calculation of J .37

o

6.4.5 Qualification of J fracture toughness value .37

o

7 Determination of resistance curves δ -Δa and J-Δa and initiation toughness δ

J J0,2BL

and J and δ and J for stable crack extension .38

0,2BL Ji i

7.1 General .38

7.2 Test procedure .38

7.2.1 General.38

7.2.2 Multiple-specimen procedure .38

7.2.3 Single-specimen procedure .38

7.2.4 Final crack front straightness .38

7.3 Calculation of J and δ .39

J

7.3.1 Calculation of J .39

7.3.2 Calculation of δ .39

J

7.4 R-curve plot .40

7.4.1 Plot construction .41

7.4.2 Data spacing and curve fitting .42

7.5 Qualification of resistance curves .42

7.5.1 Qualification of J-Δa resistance curves .42

7.5.2 Qualification of δ −Δa resistance curves .43

J

7.6 Determination and qualification of J and δ .44

0,2BL J0,2BL

7.6.1 Determination of J .44

0,2BL

7.6.2 Determination of δ .45

J0,2BL

7.7 Determination of initiation toughness J and δ by scanning electron microscopy (SEM) 46

i Ji

8 Test report .46

8.1 Organization .46

8.2 Specimen, material and test environment .47

8.2.1 Specimen description .47

8.2.2 Specimen dimensions .47

8.2.3 Material description . .47

8.2.4 Additional dimensions .47

8.2.5 Test environment .47

8.2.6 Fatigue precracking conditions .47

8.3 Test data qualification .48

8.3.1 Limitations .48

8.3.2 Crack length measurements .48

8.3.3 Fracture surface appearance .48

8.3.4 Pop-in .48

8.3.5 Resistance curves .48

8.3.6 Checklist for data qualification .48

8.4 Qualification of K .49

lc

8.5 Qualification of the δ -R Curve .49

J

8.6 Qualification of the J-R Curve .50

8.7 Qualification of δ as δ .50

J0,2BL(B) J0,2BL

8.8 Qualification of J as J .50

0,2BL(B) 0,2BL

Annex A (informative) Determination of δ and J .51

Ji i

Annex B (normative) Crack plane orientation .56

Annex C (informative) Example test reports .57

Annex D (normative) Stress intensity factor coefficients and compliance relationships .66

Annex E (informative) Measurement of load-line displacement q in the three-point bend test .71

Annex F (informative) Derivation of pop-in formulae .76

Annex G (informative) Analytical methods for the determination of V and U .78

p p

Annex H (informative) Guidelines for single-specimen methods .80

Annex I (normative) Power-law fits to crack extension data (see Reference [42]) .95

Bibliography .96

iv © ISO 2016 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment,

as well as information about ISO’s adherence to the World Trade Organization (WTO) principles in the

Technical Barriers to Trade (TBT) see the following URL: www.iso.org/iso/foreword.html.

The committee responsible for this document is ISO/TC 164, Mechanical testing of metals, Subcommittee

SC 4, Toughness testing — Fracture (F), Pendulum (P), Tear (T).

This second edition cancels and replaces the first edition (ISO 12135:2002), which has been technically

revised. It also incorporates the Technical Corrigendum ISO 12135:2002/Cor 1:2008.

INTERNATIONAL STANDARD ISO 12135:2016(E)

Metallic materials — Unified method of test for the

determination of quasistatic fracture toughness

1 Scope

This document specifies methods for determining fracture toughness in terms of K, δ, J and R-curves

for homogeneous metallic materials subjected to quasistatic loading. Specimens are notched,

precracked by fatigue and tested under slowly increasing displacement. The fracture toughness is

determined for individual specimens at or after the onset of ductile crack extension or at the onset of

ductile crack instability or unstable crack extension. In some cases in the testing of ferritic materials,

unstable crack extension can occur by cleavage or ductile crack initiation and growth, interrupted by

cleavage extension. The fracture toughness at crack arrest is not covered by this document. In cases

where cracks grow in a stable manner under ductile tearing conditions, a resistance curve describing

fracture toughness as a function of crack extension is measured. In most cases, statistical variability of

the results is modest and reporting the average of three or more test results is acceptable. In cases of

cleavage fracture of ferritic materials in the ductile-to-brittle transition region, variability can be large

and additional tests may be required to quantify statistical variability. Special testing requirements

and analysis procedures are necessary when testing weldments and these are described in ISO 15653

which is complementary to this document.

When fracture occurs by cleavage or when cleavage is preceded by limited ductile crack extension,

it may be useful to establish the reference temperature for the material by conducting testing and

[2]

analysis in accordance with ASTM E1921.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3785, Metallic materials — Designation of test specimen axes in relation to product texture

ISO 7500-1, Metallic materials — Calibration and verification of static uniaxial testing machines — Part 1:

Tension/compression testing machines — Calibration and verification of the force-measuring system

ISO 9513, Metallic materials — Calibration of extensometer systems used in uniaxial testing

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

stress intensity factor

K

magnitude of the elastic stress-field singularity for a homogeneous, linear-elastic body

Note 1 to entry: The stress intensity factor is a function of applied force, crack length, specimen size and specimen

geometry.

3.2

crack-tip opening displacement

δ

relative displacement of the crack surfaces normal to the original

(undeformed) crack plane at the tip of the fatigue precrack, evaluated using the rotation point formula

3.3

crack-tip opening displacement

δ

J

estimate of the crack-tip opening displacement, obtained from J

3.4

J-integral

line or surface integral that encloses the crack front from one crack surface to the other and

characterizes the local stress-strain field at the crack tip

3.5

J

loading parameter, equivalent to the J-integral, specific values of which, experimentally determined by

this method of test (J , J , J ,…), characterize fracture toughness under elastic-plastic conditions

c i u

3.6

stable crack extension

crack extension which stops or would stop when the applied displacement is held constant as a test

progresses under displacement control

3.7

unstable crack extension

abrupt crack extension occurring with or without prior stable crack extension

3.8

pop-in

abrupt discontinuity in the force versus displacement record, featured as a sudden increase in

displacement and, generally, a decrease in force followed by an increase in force

Note 1 to entry: Displacement and force subsequently increase beyond their values at pop-in.

Note 2 to entry: When conducting tests by this method, pop-ins may result from unstable crack extension in the

plane of the precrack and are to be distinguished from discontinuity indications arising from: i) delaminations

or splits normal to the precrack plane; ii) roller or pin slippage in bend or compact specimen load trains,

respectively; iii) improper seating of displacement gauges in knife edges; iv) ice cracking in low-temperature

testing; v) electrical interference in the instrument circuitry of force and displacement measuring and recording

devices.

3.9

crack extension resistance curves

R-curves

variation in δ or J with stable crack extension

J

4 Symbols and designations

See Table 1.

2 © ISO 2016 – All rights reserved

Table 1 — Symbols and their designations

Symbol Unit Designation

a mm Nominal crack length (for the purposes of fatigue precracking, an assigned value less

than a )

o

a mm Final crack length (a + Δa)

f o

a mm Instantaneous crack length

i

a mm Length of machined notch

m

a mm Initial crack length

o

A J Plastic component of the area under the force vs. notch opening displacement diagram

p

(Figure 17)

Δa mm Stable crack extension including blunting

Δa mm Crack extension limit for δ or J controlled crack extension

max

B mm Specimen thickness

B mm Specimen net thickness between side grooves

N

C m/N Specimen elastic compliance

E GPa Modulus of elasticity at the pertinent temperature

F kN Applied force

F kN Applied force at the onset of unstable crack extension or pop-in when Δa is less than

c

0,2 mm offset from the construction line (Figure 2)

F kN Force value corresponding to the intersection of the test record with the secant line

d

(Figure 16)

F kN Maximum fatigue precracking force

f

F kN Maximum force for a test which exhibits a maximum force plateau preceding fracture

m

with no significant prior pop-ins (Figure 2)

F kN Provisional force value used for the calculation of K

Q Q

F kN Applied force at the onset of unstable crack extension or pop-in when Δa is equal to or

u

greater than than 0,2 mm offset from the construction line (Figure 2)

J MJ/m Experimental equivalent to the J-integral

J MJ/m Size sensitive fracture resistance J at onset of unstable crack extension or pop-in when

c(B)

stable crack extension is less than 0,2 mm offset from the construction line (B = speci-

men thickness in mm)

J MJ/m J at upper limit of J-controlled crack extension

g

J MJ/m Size-insensitive fracture resistance J at initiation of stable crack extension

i

J MJ/m Size sensitive fracture resistance J at the first attainment of a maximum force plateau

m(B)

for fully plastic behaviour (B = specimen thickness in mm)

J MJ/m Limit of J-R material behaviour defined by this method of test

max

J MJ/m Size sensitive fracture resistance J at the onset of unstable crack extension or pop-in

u(B)

when the event is preceded by stable crack extension equal to or greater than 0,2 mm

offset from the construction line (B = specimen thickness in mm)

J MJ/m Size sensitive fracture resistance J at the onset of unstable crack extension or pop-in

uc(B)

when stable crack extension cannot be measured (B = specimen thickness in mm)

J MJ/m J uncorrected for stable crack extension

o

J MJ/m Size insensitive fracture resistance J at 0,2 mm stable crack extension offset from the

0,2BL

construction line

J MJ/m Size sensitive fracture resistance J at 0,2 mm stable crack extension offset from the

0,2BL(B)

construction line (B = specimen thickness in mm)

NOTE 1 This is not a complete list of parameters. Only the main parameters are given here, other parameters are referred

to in the text.

NOTE 2 The values of all parameters used in calculations are assumed to be those measured or calculated for the

temperature of the test, unless otherwise specified.

Table 1 (continued)

Symbol Unit Designation

K Stress intensity factor

MPa m

K Maximum value of K during the final stages of fatigue precracking

f

MPa m

K Plane strain linear elastic fracture toughness

lc

MPa m

K Plane strain linear elastic fracture toughness equivalent to J

J0,2BL 0,2BL

MPa m

K A provisional value of K

Q lc

MPa m

q mm Load-point displacement

R MPa Ultimate tensile strength perpendicular to crack plane at the test temperature

m

R MPa 0,2 % offset yield strength perpendicular to crack plane at the test temperature

p0,2

S mm Span between outer loading points in a three-point bend test

T °C Test temperature

U J Area under plot of force F versus specimen load-point displacement q at the load-line

U J Elastic component of U

e

U J Plastic component of U

p

V mm Notch-opening displacement

V mm Elastic component of V

e

V mm Plastic component of V

p

W mm Width of the test specimen

z mm For bend and straight-notch compact specimens, the initial distance of the notch opening

gauge measurement position from the notched edge of the specimen, either further from

the crack tip [+z in Figure 8 b)] or closer to the crack tip (−z); or, for a stepped-notch

compact specimen, the initial distance of the notch opening gauge measurement position

either beyond (+z) or before (−z) the initial load-line

δ mm Crack-tip opening displacement (CTOD) evaluated using the rotation point formula

δ mm Crack-tip opening displacement (CTOD) evaluated from J

J

δ mm Size sensitive fracture resistance δ at the onset of unstable crack extension or pop-in

c(B)

when stable crack extension is less than 0,2 mm crack offset from the construction line

(B = specimen thickness in mm)

δ mm δ at the limit of δ-controlled crack extension

g

δ mm Fracture resistance δ at initiation of stable crack extension

Ji J

δ mm Size sensitive fracture resistance δ at the first attainment of a maximum force plateau

m(B)

for fully plastic behaviour (B = specimen thickness in mm)

δ mm Limit of δ -R defined by this method of test

J,max J

δ mm Size sensitive fracture resistance δ at the onset of unstable crack extension or pop-in

u(B)

when the event is preceded by stable crack extension equal to or greater than 0,2 mm

offset from the construction line (B = specimen thickness in mm)

δ mm Size sensitive fracture resistance δ at the onset of unstable crack extension or pop-in

uc(B)

when stable crack extension Δa cannot be measured (B = specimen thickness in mm)

δ mm δ uncorrected for stable crack extension

o

NOTE 1 This is not a complete list of parameters. Only the main parameters are given here, other parameters are referred

to in the text.

NOTE 2 The values of all parameters used in calculations are assumed to be those measured or calculated for the

temperature of the test, unless otherwise specified.

4 © ISO 2016 – All rights reserved

Table 1 (continued)

Symbol Unit Designation

δ mm Size insensitive fracture resistance δ at 0,2 mm crack extension offset from construc-

J0,2BL J

tion line

δ mm Size sensitive fracture resistance δ at 0,2 mm stable crack extension offset from con-

J0,2BL(B) J

struction line (B = specimen thickness in mm)

ν — Poisson’s ratio

NOTE 1 This is not a complete list of parameters. Only the main parameters are given here, other parameters are referred

to in the text.

NOTE 2 The values of all parameters used in calculations are assumed to be those measured or calculated for the

temperature of the test, unless otherwise specified.

5 General requirements

5.1 General

The fracture toughness of metallic materials can be characterized in terms of either specific (single

point) values (see Clause 6), or a continuous curve relating fracture resistance to crack extension over

a limited range of crack extension (see Clause 7). The procedures and parameters used to determine

fracture toughness vary depending upon the level of plasticity realized in the test specimen during

the test. Under any given set of conditions, however, any one of the fatigue-precracked test specimen

configurations specified in this method may be used to measure any of the fracture toughness

parameters considered. In all cases, tests are performed by applying slowly increasing displacements

to the test specimen and measuring the forces and displacements realized during the test. The

forces and displacements are then used in conjunction with certain pre-test and post-test specimen

measurements to determine the fracture toughness that characterizes the material’s resistance to

crack extension. Details of the test specimens and general information relevant to the determination

of all fracture parameters are given in this method. A flow-chart illustrating the way this method can

be used is presented in Figure 1. Characteristic types of force versus displacement records obtained in

fracture toughness tests are shown in Figure 2.

Figure 1 — General flowchart showing how to use the standard method of test

6 © ISO 2016 – All rights reserved

Key

a

Fracture.

b

Pop-in.

NOTE 1 F , F and F correspond to either δ , δ and δ respectively, or J , J and J respectively.

c u m c u m c u m

NOTE 2 Pop-in behaviour is a function of the testing machine/specimen compliance and the recorder response rate.

Figure 2 — Characteristics types of force versus displacement records in fracture tests

5.2 Fracture parameters

Specific (point) values of fracture toughness are determined from individual specimens to define the

onset of unstable crack extension or describe stable crack extension.

NOTE K characterizes the resistance to extension of a sharp crack so that i) the state of stress near the

lc

crack front closely approximates plane strain, and ii) the crack tip plastic zone is small compared with the

specimen crack size, thickness and ligament ahead of the crack.

K is considered a size-insensitive measurement of fracture toughness under the above conditions.

lc

Certain test criteria shall be met in order to qualify measurements of K .

lc

The parameters δ , J , δ , J , δ and J also characterize the resistance of a material to unstable

c c u u uc uc

extension of a sharp crack. However, these measurements are regarded as size-sensitive and as such

characterize only the specimen thickness tested. The specimen thickness is thus noted in millimetre

units in parentheses appended to the parameter symbol when reporting a test result.

When stable crack extension is extensive, test procedure and fracture toughness measurement shall

be performed as specified in Clause 7. Stable crack extension is characterized either in terms of crack

tip opening displacement δ and fracture toughness J parameters, or of a continuous δ - and

J0,2BL 0,2BL J

J-resistance curve. The values δ and J , regarded as specimen size insensitive, are engineering

J0,2BL 0,2BL

estimates of the onset of stable crack extension, not to be confused with the actual initiation toughness

δ and J Measurement of δ and J is described in Annex A.

Ji i. Ji i

Two procedures are available for determining δ and J . The multiple specimen procedure

0,2BL 0,2BL

requires several nominally identical specimens to be monotonically loaded, each to different amounts

of displacement. Measurements of force and displacement are made and recorded. Specimen crack

fronts are marked (e.g. by heat tinting or post-test fatiguing) after testing, thus enabling measurement

of stable crack extension on the specimen halves after each specimen is broken open. Post-test cooling

of ferritic material specimens to ensure brittle behaviour may be helpful in preserving crack front

markings prior to breaking open the specimens.

A minimum of six specimens is required by the multiple-specimen method. When material availability

is limited, a single-specimen procedure based on either unloading compliance or the potential drop

technique may be used. There is no restriction on the single-specimen procedure providing sufficient

accuracy can be demonstrated. In all cases, certain criteria are to be met before δ or J values

J0,2BL 0,2BL

and δ - or J-resistance curves are qualified by this standard method of test.

J

5.3 Fracture toughness symbols

Fracture toughness symbols identified in this document are given in Table 2.

Table 2 — Fracture toughness symbols

Size sensitive quantities

Qualifying limits

Parameter Size insensitive quantities (specific to thickness

to R-curves

B tested)

K

lc

K

K

J0,2BL

δ

c(B)

δ

Ji

δ, δ δ δ , δ (Δa )

J J0,2BL(B) J,g J,g max

δ

J0,2BL

δ , δ , δ

u(B) uc(B) m(B)

J

c(B)

J

i

J J J J (Δa )

0,2BL(B) g, g max

J

0,2BL

J , J , J

u(B) uc(B) m(B)

5.4 Test specimens

5.4.1 Specimen configuration and size

Dimensions and tolerances of specimens shall conform to Figures 3 to 5.

8 © ISO 2016 – All rights reserved

Surface roughness values in micrometres

Key

a

See Figures 6 to 8 and 5.4.2.3.

NOTE 1 Integral or attachable knife edges for clip gauge attachment may be used (see Figures 8 and 9).

NOTE 2 For starter notch and fatigue crack configuration, see Figure 6.

NOTE 3 1,0 ≤ W/B ≤ 4,0 (W/B = 2 preferred).

NOTE 4 0,45 ≤ a/W ≤ 0,70. For K determination, 0,45 ≤ a/W ≤ 0,55.

lc

The intersection of the crack starter notch tips with the two specimen surfaces shall be equally distant from the top

and bottom edges of the specimen to within 0,005 W.

Figure 3 — Proportional dimensions and tolerances for bend specimen

Surface roughness values in micrometres

Key

a

See Figures 6 to 8 and 5.4.2.3.

NOTE 1 Integral or attachable knife edges for clip gauge attachment may be used (see Figures 8 and 9).

NOTE 2 For starter notch and fatigue crack configuration, see Figure 6.

NOTE 3 0,8 ≤ W/B ≤ 4,0 (W/B = 2 preferred).

NOTE 4 0,45 ≤ a/W ≤ 0,70. For K determination, 0,45 ≤ a/W ≤ 0,55.

lc

+0,004 W

NOTE 5 Alternative pin hole diameter, ∅ 0,188 W .

The intersection of the crack starter notch tips with the two specimen surfaces shall be equally distant from the top

and bottom edges of the specimen to within 0,005 W.

Figure 4 — Proportional dimensions and tolerances for straight-notch compact specimen

10 © ISO 2016 – All rights reserved

Surface roughness values in micrometres

Key

a

See Figures 6 to 8.

NOTE 1 Integral or attachable knife edges for clip gauge attachment may be used (see Figures 8 and 9).

NOTE 2 For starter notch and fatigue crack configuration, see Figure 6.

NOTE 3 0,8 ≤ W/B ≤ 4,0 (W/B = 2 preferred).

NOTE 4 0,45 ≤ a/W ≤ 0,70. For K determination, 0,45 ≤ a/W ≤ 0,55.

lc

NOTE 5 Second step may not be necessary for some clip gauges; configuration optional providing fatigue crack

starter notch and fatigue crack fit within the envelope represented in Figure 6.

+0,004 W

Alternative pin hole diameter, ∅ 0,188 W . When this pin size in used, notch opening may be

NOTE 6

increased to 0,21 W maximum.

The intersection of the crack starter notch tips with the two specimen surfaces shall be equally distant from the top

and bottom edges of the specimen to within 0,005 W.

Figure 5 — Proportional dimensions and tolerances for stepped-notch compact specimen

The choice of specimen design shall take into consideration the likely outcome of the test (see Figure 1),

any preference for δ or J fracture toughness values, the crack plane orientation of interest (Annex B)

and the quantity and condition of test material available.

NOTE 1 All specimen designs (Figures 3 to 5) are suitable for determining K , δ and J values, although there

lc

are special procedural requirements for J values calculated from measurements made away from the load line.

Table 3 provides guidance on specimen size for K measurement.

lc

Table 3 — Minimum recommended thickness for K testing

lc

B

R

p02,

mm

E

≥0,005 0 <0,005 7 75

≥0,005 7 <0,006 2 63

≥0,006 2 <0,006 5 50

≥0,006 5 <0,006 8 44

≥0,006 8 <0,007 1 38

≥0,007 1 <0,007 5 32

≥0,007 5 <0,008 0 25

≥0,008 0 <0,008 5 20

≥0,008 5 <0,010 0 13

≥0,010 0 7

NOTE 2 When notch opening displacement V is measured on the load line, V = q for the stepped-notch compact

specimen (see Figure 5). The stepped-notch specimen is thus equally useful for the determination of values of K ,

lc

δ and J.

NOTE 3 For both the bend and compact configurations, a specimen width-to-thickness ratio (W/B) of 2 is

preferred, but values ranging from 1 to 4 for bend specimens and 0,8 to 4 for compact specimens are allowed.

Evidence suggests that specimen proportions of W/B = 4 yield slightly higher R-curves than the lesser proportions

of W/B = 2.

5.4.2 Specimen preparation

5.4.2.1 Material condition

Specimens shall be machined from material in the final heat treated and/or mechanically worked

condition.

NOTE 1 In the exceptional circumstance where a material cannot be machined in its final heat treated condition,

such final heat treatment may be carried out after machining provided that the specimen’s required dimensions

and tolerances, shape, and surface finishes are met, and full account is taken of the effects of specimen dimensions

on the metallurgical condition induced by certain heat treatments, for example, water quenching of steels.

NOTE 2 Residual stresses can influence the measurement of quasistatic fracture toughness. The effect can be

significant when test coupons are taken from material that characteristically embodies residual stress fields;

e.g. weldments, complex shapes, such as die forgings, stepped extrusions, castings where full stress relief is

not possible, or parts with intentionally-induced residual stresses. Specimens taken from such products that

contain residual stresses will likewise themselves contain residual stress. While extraction of the specimen in

itself partially relieves and redistributes the pattern of residual stress, the remaining magnitude can affect the

test result. Residual stress is superimposed on applied stress and results in actual crack-tip stress intensity that

is different from that based solely on externally applied forces or displacements. Distortion during specimen

machining, specimen configuration d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...