ISO 6722:2006

(Main)Road vehicles — 60 V and 600 V single-core cables — Dimensions, test methods and requirements

Road vehicles — 60 V and 600 V single-core cables — Dimensions, test methods and requirements

ISO 6722:2006 specifies the dimensions, test methods, and requirements for single-core 60 V cables intended for use in road vehicle applications where the nominal system voltage is equal to or less than (60 V d.c. or 25 V a.c.). It also specifies additional test methods and/or requirements for 600 V cables intended for use in road vehicle applications where the nominal system voltage is greater than (60 V d.c. or 25 V a.c.) to equal to or less than (600 V d.c. or 600 V a.c.). It also applies to individual cores in multi-core cables.

Véhicules routiers — Câbles monoconducteurs de 60 V et 600 V — Dimensions, méthodes d'essai et exigences

General Information

- Status

- Withdrawn

- Publication Date

- 25-Jul-2006

- Withdrawal Date

- 25-Jul-2006

- Technical Committee

- ISO/TC 22 - Road vehicles

- Drafting Committee

- ISO/TC 22 - Road vehicles

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 06-Oct-2011

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 12-Dec-2009

- Effective Date

- 15-Apr-2008

- Effective Date

- 15-Apr-2008

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

ISO 6722:2006 is a standard published by the International Organization for Standardization (ISO). Its full title is "Road vehicles — 60 V and 600 V single-core cables — Dimensions, test methods and requirements". This standard covers: ISO 6722:2006 specifies the dimensions, test methods, and requirements for single-core 60 V cables intended for use in road vehicle applications where the nominal system voltage is equal to or less than (60 V d.c. or 25 V a.c.). It also specifies additional test methods and/or requirements for 600 V cables intended for use in road vehicle applications where the nominal system voltage is greater than (60 V d.c. or 25 V a.c.) to equal to or less than (600 V d.c. or 600 V a.c.). It also applies to individual cores in multi-core cables.

ISO 6722:2006 specifies the dimensions, test methods, and requirements for single-core 60 V cables intended for use in road vehicle applications where the nominal system voltage is equal to or less than (60 V d.c. or 25 V a.c.). It also specifies additional test methods and/or requirements for 600 V cables intended for use in road vehicle applications where the nominal system voltage is greater than (60 V d.c. or 25 V a.c.) to equal to or less than (600 V d.c. or 600 V a.c.). It also applies to individual cores in multi-core cables.

ISO 6722:2006 is classified under the following ICS (International Classification for Standards) categories: 43.040.10 - Electrical and electronic equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 6722:2006 has the following relationships with other standards: It is inter standard links to ISO 6722-2:2013, ISO 6722:2002, ISO 6722-1:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 6722:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 6722

Second edition

2006-08-01

Road vehicles — 60 V and 600 V

single-core cables — Dimensions, test

methods and requirements

Véhicules routiers — Câbles monoconducteurs de 60 V et 600 V —

Dimensions, méthodes d'essai et exigences

Reference number

©

ISO 2006

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2006

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2006 – All rights reserved

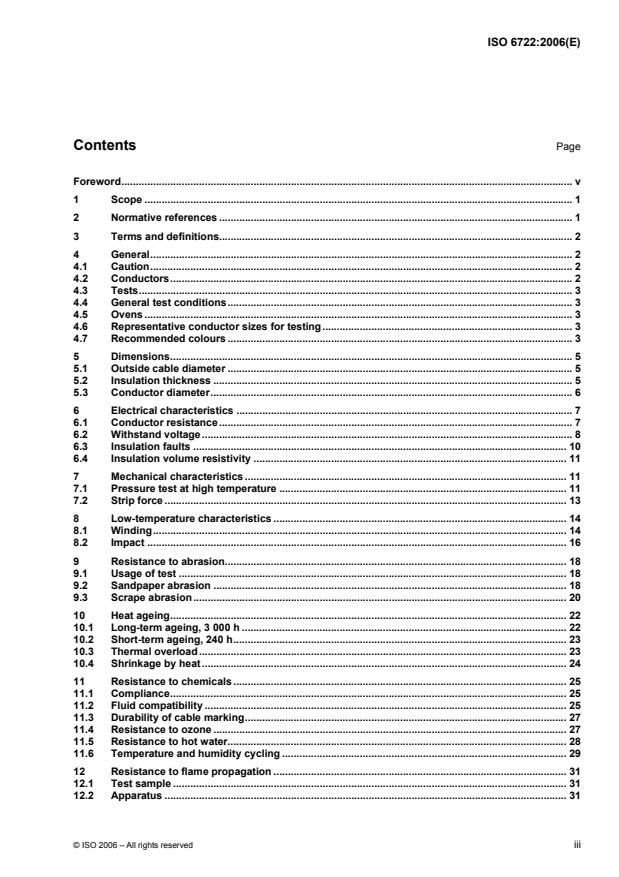

Contents Page

Foreword. v

1 Scope. 1

2 Normative references. 1

3 Terms and definitions. 2

4 General. 2

4.1 Caution. 2

4.2 Conductors. 2

4.3 Tests. 3

4.4 General test conditions. 3

4.5 Ovens. 3

4.6 Representative conductor sizes for testing. 3

4.7 Recommended colours . 3

5 Dimensions. 5

5.1 Outside cable diameter . 5

5.2 Insulation thickness . 5

5.3 Conductor diameter. 6

6 Electrical characteristics. 7

6.1 Conductor resistance. 7

6.2 Withstand voltage. 8

6.3 Insulation faults . 10

6.4 Insulation volume resistivity . 11

7 Mechanical characteristics. 11

7.1 Pressure test at high temperature . 11

7.2 Strip force. 13

8 Low-temperature characteristics. 14

8.1 Winding. 14

8.2 Impact. 16

9 Resistance to abrasion. 18

9.1 Usage of test . 18

9.2 Sandpaper abrasion . 18

9.3 Scrape abrasion. 20

10 Heat ageing. 22

10.1 Long-term ageing, 3 000 h . 22

10.2 Short-term ageing, 240 h. 23

10.3 Thermal overload. 23

10.4 Shrinkage by heat. 24

11 Resistance to chemicals . 25

11.1 Compliance. 25

11.2 Fluid compatibility . 25

11.3 Durability of cable marking. 27

11.4 Resistance to ozone . 27

11.5 Resistance to hot water. 28

11.6 Temperature and humidity cycling . 29

12 Resistance to flame propagation . 31

12.1 Test sample. 31

12.2 Apparatus. 31

12.3 Procedure. 31

12.4 Requirement. 31

Annex A (informative) Conductors . 32

Annex B (informative) Recommended colours. 33

Annex C (informative) High-volume cable constructions . 34

Annex D (informative) Sources for reference materials . 36

Bibliography . 37

iv © ISO 2006 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 6722 was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 3, Electrical

and electronic equipment.

This second edition cancels and replaces the first edition (ISO 6722:2002) which has been technically revised.

INTERNATIONAL STANDARD ISO 6722:2006(E)

Road vehicles — 60 V and 600 V single-core cables —

Dimensions, test methods and requirements

1 Scope

This International Standard specifies the dimensions, test methods, and requirements for single-core 60 V

cables intended for use in road vehicle applications where the nominal system voltage is u (60 V d.c. or

25 V a.c.). It also specifies additional test methods and/or requirements for 600 V cables intended for use in

road vehicle applications where the nominal system voltage is > (60 V d.c. or 25 V a.c.) to u (600 V d.c. or

600 V a.c.). It also applies to individual cores in multi-core cables.

Eight temperature classes are defined in Table 1.

Table 1 — Temperature class rating

Class Temperature

A − 40 °C to 85 °C

B – 40 °C to 100 °C

C − 40 °C to 125 °C

D − 40 °C to 150 °C

E − 40 °C to 175 °C

F − 40 °C to 200 °C

G − 40 °C to 225 °C

H − 40 °C to 250 °C

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 1817, Rubber, vulcanized — Determination of the effect of liquids

ISO 6931-1, Stainless steels for springs — Part 1: Wire

IEC 60757, Code for designation of colours

IEC 60811-2-1, Common test methods for insulating and sheathing materials of electrical and optical

cables — Part 2-1: Methods specific to elastomeric compounds — Ozone resistance, hot set and mineral oil

immersion tests

ASTM B1, Standard Specification for Hard-Drawn Copper Wire

ASTM B3, Standard Specification for Soft or Annealed Copper Wire

ASTM B33, Standard Specification for Tinned Soft or Annealed Copper Wire for Electrical Purposes

ASTM B298, Standard Specification for Silver-Coated Soft or Annealed Copper Wire

ASTM B355, Standard Specification for Nickel-Coated Soft or Annealed Copper Wire

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

60 Volt (V) cable

cable intended for use in road vehicle applications where the nominal system voltage is equal to or less than

60 V d.c. or 25 V a.c.

3.2

600 Volt (V) cable

cable intended for use in road vehicle applications where the nominal system voltage is greater than

(60 V d.c. or 25 V a.c.) and less than (600 V d.c. or 600 V a.c.)

NOTE a.c. tests are performed at 50 Hz or 60 Hz. Applications at higher frequencies may require additional testing.

3.3

cable family

group with multiple conductor sizes having the same conductor strand coating, insulation formulation and

wall-thickness type

3.4

nominal (value)

suitable approximate value used to designate or identify a component

4 General

4.1 Caution

Special care shall be taken with cables used with voltages above (60 V d.c. or 25 V a.c.) to protect them from

mechanical stress in order to avoid shock hazard. Regardless of wall thickness, 600 V cables shall meet the

“resistance to abrasion” requirements for thick wall cable.

4.2 Conductors

The conductors shall consist of plain or coated copper strands as shown in Table 2. Conductor sizes

W 0,5 mm shall consist of soft annealed copper or annealed compressed/compacted wires. Conductor sizes

< 0,5 mm shall consist of soft annealed copper, soft annealed compressed/compacted copper, hard

unannealed copper or a copper alloy. The specifications for the conductors shall be completed by material

specifications. Elongation requirements shall be established by agreement between customer and supplier.

The finished cable shall meet the resistance requirements of 6.1 for all conductors except alloys. When an

alloy is used, the resistance requirement shall be established by agreement between customer and supplier.

NOTE Examples of strandings are shown in Table A.1. These strandings highlight examples of conceptual

configurations and are not intended to reflect any preferred constructions. Other strandings' configurations may be used

provided they meet the requirements shown above and are agreed upon between customer and supplier.

2 © ISO 2006 – All rights reserved

Table 2 — Conductor specifications

ASTM B1 Hard-drawn copper wire

ASTM B3 Soft or annealed copper wire

ASTM B33 Tinned soft or annealed copper wire

ASTM B298 Silver-coated soft or annealed copper wire

ASTM B355 Nickel-coated soft or annealed copper wire

NOTE Silver- and nickel-coated conductors are intended for use

with high “temperature class ratings”.

4.3 Tests

The cables shall be submitted to the tests as specified in Table 3.

4.4 General test conditions

Test samples for all tests except those in Clause 5 and in 6.1 and 6.3 shall be preconditioned for at least 16 h

at a room temperature of (23 ± 5) °C. Unless otherwise specified, all tests other than “in-process” tests shall

be conducted at this same temperature. Where no tolerance is specified, all values shall be considered to be

approximate.

4.5 Ovens

Unless otherwise specified, when an oven is required, it shall be a hot air oven. The air contained in the oven

shall be completely changed at least eight (8) times but not more than twenty (20) times per hour at the

specified temperature.

4.6 Representative conductor sizes for testing

When a test is required, all combinations of conductor size, wall thickness and insulation formulation shall

meet the appropriate requirements. However, if representative conductor sizes for testing are permitted,

compliance for a cable family may be demonstrated by testing examples of large and small conductor sizes

only. Permission to show compliance for a cable family by testing “representative conductor sizes” shall be

established by agreement between customer and supplier.

4.7 Recommended colours

A list of recommended colours is shown in Table B.1

Table 3 — Tests

c

In-process Certification If required

Clause Test description

a b b

Initial Initial

tests Periodic Periodic

5 Dimensions

5.1 Outside cable diameter — × × — —

5.2 Insulation thickness — × × — —

5.3 Conductor diameter — — — × ×

6 Electrical characteristics

6.1 Conductor resistance — × × — —

d d

6.2 Withstand voltage — — —

d

6.3 Insulation faults — — — —

6.4 Insulation volume resistivity — — — × ×

7 Mechanical characteristics

7.1 Pressure test at high temperature — × × — —

7.2 Strip force — — — × ×

8 Low-temperature characteristics

8.1 Winding — × × — —

8.2 Impact — — — × ×

e e

9 Resistance to abrasion

— — —

9.2 Sandpaper abrasion — — — — —

9.3 Scrape abrasion — — — — —

10 Heat ageing

10.1 Long-term ageing, 3 000 h — × — — —

10.2 Short-term ageing, 240 h — × × — —

10.3 Thermal overload — — — × ×

10.4 Shrinkage by heat — — —

× ×

11 Resistance to chemicals

f, g f, g

11.2 Fluid compatibility — — —

g g

11.3 Durability of cable marking — — —

g

11.4 Resistance to ozone — — — —

g

11.5 Resistance to hot water — — — —

g

11.6 Temperature and humidity cycling — — — —

12 Resistance to flame propagation — × × — —

"X" To be applied.

"—" Not applicable.

a

A test made on all cables during or after manufacture.

b

The frequency of periodic testing shall be established by agreement between customer and supplier.

c

The usage of "if required” tests shall be established by agreement between customer and supplier.

d

Some cables are rated at 60 V and others at 600 V. See 6.2 and 6.3 for details.

e

See Clause 9.

f

Some fluids are for “certification” and others are “if required”. See 11.2 for details.

g

Compliance for a cable family may be demonstrated by testing examples of large and small conductor sizes only. See 4.6 for

details.

4 © ISO 2006 – All rights reserved

5 Dimensions

5.1 Outside cable diameter

5.1.1 Test Sample

Prepare a test sample 3 m in length.

5.1.2 Apparatus

Use a measuring device with an accuracy of ± 0,01 mm. The device shall not cause deformation.

5.1.3 Procedure

Take three sets of measurements at positions separated by 1 m and record the highest and lowest outside

cable diameter at each position.

5.1.4 Requirement

All measurements shall be within the limits of the appropriate maximum and minimum “outside cable

diameter” specified in Table 4 and Table C.1. The values in Table 4 are normative. Since the values in

Table C.1 are informative, they are not required; however, they may be applied by agreement between

customer and supplier.

5.2 Insulation thickness

5.2.1 Test samples

Prepare three test samples from a cable sample 3 m in length. Take the test samples at 1 m intervals. Strip

the insulation from the cable. A test sample consists of a thin cross section of insulation. Take care not to

deform the test sample during the preparation process. If cable marking causes indentation of the insulation,

take the first test sample through this indentation.

5.2.2 Apparatus

Use a measuring device with an accuracy of ± 0,01 mm. The device shall not cause deformation.

5.2.3 Procedure

Place the test sample under the measuring equipment with the plane of the cut perpendicular to the optical

axis. Determine the minimum “insulation thickness”.

5.2.4 Requirement

No single value shall be less than the appropriate minimum insulation thickness specified in Table 4.

Table 4 — Dimensions

ISO conductor Thick wall Thin wall Ultra-thin wall

Outside Outside Outside

Insulation Insulation Insulation

Size Diameter cable cable cable

thickness thickness thickness

diameter diameter diameter

mm mm mm mm mm mm mm mm

max. nominal min. max. nominal min. max. nominal min. max.

0,13 0,55 — — — 0,25 0,20 1,05 0,20 0,16 0,95

0,22 0,70 — — — 0,25 0,20 1,20 0,20 0,16 1,05

a

0,35 0,90 — — — 0,25 0,20 0,20 0,16 1,20

1,40

0,50 1,10 0,60 0,48 2,30 0,28 0,22 1,60 0,20 0,16 1,40

0,75 1,30 0,60 0,48 2,50 0,30 0,24 1,90 0,20 0,16 1,60

1 1,50 0,60 0,48 2,70 0,30 0,24 2,10 0,20 0,16 1,75

1,5 1,80 0,60 0,48 3,00 0,30 0,24 2,40 0,20 0,16 2,10

2 2,00 0,60 0,48 3,30 0,35 0,28 2,80 0,25 0,20 2,40

2,5 2,20 0,70 0,56 3,60 0,35 0,28 3,00 0,25 0,20 2,70

3 2,40 0,70 0,56 4,10 0,40 0,32 3,40 — — —

4 2,80 0,80 0,64 4,40 0,40 0,32 3,70 — — —

5 3,10 0,80 0,64 4,90 0,40 0,32 4,20 — — —

6 3,40 0,80 0,64 5,00 0,40 0,32 4,30 — — —

10 4,50 1,00 0,80 6,50 0,60 0,48 6,00 — — —

16 6,30 1,00 0,80 8,30 0,65 0,52 7,90 — — —

25 7,80 1,30 1,04 10,40 0,65 0,52 9,40 — — —

35 9,00 1,30 1,04 11,60 — — — — — —

50 10,50 1,50 1,20 13,50 — — — — — —

70 12,50 1,50 1,20 15,50 — — — — — —

95 14,80 1,60 1,28 18,00 — — — — — —

120 16,50 1,60 1,28 19,70 — — — — — —

NOTE Outside cable diameter minimum values for high-volume cable constructions are shown in Table C.1. Since the values in

Table C.1 are informative, they are not required; however, they may be applied by agreement between customer and supplier.

a 2

The outside cable diameter for conductor size 0,35 mm with 7 strands shall be a maximum of 1,30 mm.

5.3 Conductor diameter

5.3.1 Test samples

The usage of this test shall be established by agreement between customer and supplier. In case of disputed

results, a refereeing method is provided.

Referee test samples: in case of a dispute, prepare three test samples from a cable sample 3 m in length.

Take the test samples at 1 m intervals. A test sample consists of a 20 mm length of cable. Take care not to

deform the test sample. Immerse the test samples in a casting resin. After hardening, take a section

perpendicular to the axis of the test sample.

6 © ISO 2006 – All rights reserved

5.3.2 Apparatus

Carry out this test on the same apparatus used for the measurement of the insulation thickness (see 5.2).

Referee apparatus: in case of a dispute, the measuring device shall be capable of at least 10 × linear

magnification.

5.3.3 Procedure

Check the conductor diameter by measuring the inside diameter of the samples used in 5.2 and recording the

maximum inside diameter for each test sample.

Referee procedure: in case of a dispute, measure the conductor diameter using the “referee test samples”

and the “referee apparatus”. Record the maximum conductor diameter for each test sample.

5.3.4 Requirement

The measured value shall not exceed the maximum value, specified in Table 4. This measured value is also

required in 6.4.

6 Electrical characteristics

6.1 Conductor resistance

6.1.1 Test samples

Prepare a test sample 1 m in length plus the length necessary for connections. Other lengths may be used

providing that the resistance reading is adjusted using the method shown in 6.1.3. The ends of the test sample

may be soldered.

6.1.2 Apparatus

Use a resistance-measuring device with an accuracy of ± 0,5 % of the measured value and a thermometer

with an accuracy of ± 0,5 °C.

6.1.3 Procedure

Measure the temperature of the test sample and the unsoldered length. Take care to ensure that connections

are secure. Measure the resistance of the test sample. Correct the measured value using the following

equation:

R

t

R =

⎡⎤

Lt1+−0,003 93 20

()

⎣⎦

where

R is the corrected conductor resistance at the reference temperature of 20 °C, expressed in milliohms

per metre;

R is the conductor resistance measured at the conductor temperature, expressed in milliohms;

t

L is the unsoldered conductor length, expressed in metres;

t is the conductor temperature at the time of measuring, expressed in degrees centigrade.

NOTE The value of 0,003 93 is the temperature coefficient for copper with 100 % conductivity at a temperature of

20 °C. For coated wires or alloys, the correction factor shall be established by agreement between customer and supplier.

6.1.4 Requirement

The corrected value shall not exceed the appropriate maximum resistance specified in Table 5.

Conductors produced from silver-coated strands shall not exceed the maximum conductor resistance per

length for plain copper.

6.2 Withstand voltage

6.2.1 Test sample

Prepare a test sample of a minimum length of 350 mm, strip 25 mm of insulation from each end and twist the

ends together to form a loop.

6.2.2 Apparatus

Partially fill an electrically non-conductive vessel with salt water (aqueous solution of 3 % by mass of NaCl)

with the ends of the test sample emerging above the bath as shown in Figure 1. Use a 50 Hz or 60 Hz a.c.

voltage source.

6.2.3 Procedure

6.2.3.1 60 V cable

Immerse the test sample in the bath, as shown in Figure 1, for 4 h and then apply a test voltage of 1 kV

(r.m.s.) for 30 min between the conductor and the bath. Then increase the voltage at a rate of 500 V/s until the

following value is reached:

⎯ 3 kV (r.m.s.) for cables < 0,5 mm ;

⎯ 5 kV (r.m.s.) for cables W 0,5 mm .

6.2.3.2 600 V cable

After completing the procedure for a 60 V cable, hold the 3 kV or 5 kV for a further 5 min.

6.2.4 Requirement

Breakdown shall not occur.

8 © ISO 2006 – All rights reserved

Table 5 — Conductor resistance

Maximum conductor resistance per length

ISO conductor

mΩ/m at 20 °C

Size Plain copper Sn-plated copper Ni-plated copper

mm

0,13 136 140 142

0,22 84,8 86,5 87,9

0,35 54,4 55,5 56,8

0,50 37,1 38,2 38,6

0,75 24,7 25,4 25,7

1 18,5 19,1 19,3

1,5 12,7 13,0 13,2

2 9,42 9,69 9,82

2,5 7,60 7,82 7,92

3 6,15 6,36 6,41

4 4,71 4,85 4,91

5 3,94 4,02 4,11

6 3,14 3,23 3,27

10 1,82 1,85 1,90

16 1,16 1,18 1,21

25 0,743 0,757 0,774

35 0,527 0,538 0,549

50 0,368 0,375 0,383

70 0,259 0,264 0,270

95 0,196 0,200 0,204

120 0,153 0,156 0,159

NOTE Conductor resistance, minimum values for high-volume cable constructions are shown in Table C.2.

Since the values in Table C.2 are informative, they are not required; however, they may be applied by agreement

between customer and supplier.

Key

1 test voltage (terminals)

2 non-conductive vessel

3 electrode

4 test sample

5 salt-water bath

Figure 1 — Apparatus for withstand voltage test

6.3 Insulation faults

6.3.1 Test sample

All cable-produced.

6.3.2 Apparatus

Use a sinusoidal voltage source set at the value shown in Table 6. The test electrode may consist of metal

ball chains, metal brushes or any other type of suitable electrodes. Choose the electrode length and frequency

considering the speed of the cable running through the field of the electrode so that each point of the cable is

loaded by at least nine voltage cycles.

Table 6 — Insulation faults

Voltage rating

ISO

conductor size

kV (r.m.s.)

60 V cables 600 V cables

mm

3 6

< 0,5

W 0,5 5 8

6.3.3 Procedure

This test shall be carried out under production conditions. Subject all cables to this test. Other methods of test

may be used provided that insulation faults are detected with the same certainty.

10 © ISO 2006 – All rights reserved

6.3.4 Requirement

No breakdown shall occur when the earthed cable is drawn through the test electrode.

6.4 Insulation volume resistivity

6.4.1 Usage of test

The usage of this test shall be agreed between customer and supplier.

6.4.2 Test sample

Prepare a test sample of 5 m length and remove 25 mm of insulation from each end.

6.4.3 Apparatus

Partially fill an electrically non-conductive vessel with tap water at a temperature of (70 ± 2) °C. Use a

resistance-measuring device with a d.c. voltage of 500 V. Voltages between 100 V and 500 V are allowed;

however, if a dispute arises, the referee apparatus shall be a resistance-measuring device with a d.c. voltage

of 500 V.

6.4.4 Procedure

Immerse the test sample for 2 h with each end emerging from the bath by 250 mm. Apply the d.c. voltage

between the conductor and the bath. Measure the insulation resistance 1 min after application of the voltage.

Calculate the insulation volume resistivity using the following formula:

L× R

ρ=×2,725

D

lg

d

where

ρ is the insulation volume resistivity, expressed in ohm millimetres;

L is the immersed length of the test sample in millimetres;

R is the measured insulation resistance in ohms;

D is the outside cable diameter in millimetres according to 5.1;

d is the conductor diameter in millimetres according to 5.3;

lg is logarithm to the base 10.

6.4.5 Requirement

The insulation volume resistivity shall not be less than 10 Ω·mm.

7 Mechanical characteristics

7.1 Pressure test at high temperature

7.1.1 Test samples

Prepare three test samples, each of 600 mm length.

7.1.2 Apparatus

The test temperature for the oven is given in Table 7 and the apparatus is shown in Figure 2. Ensure that the

apparatus is free from vibrations. Apply the force, F, by the blade to the test sample as given by the formula:

F=−0,8iD2 i

()

where

F is the total vertical force exerted on the test sample in newtons;

0,8 is a coefficient which carries the dimension in newtons per millimetre;

D is the appropriate “outside cable diameter maximum” in millimetres according to Table 4;

i is the appropriate nominal value of the “insulation thickness” in millimetres according to Table 4.

The calculated force may be rounded off at the lower digit, but not beyond 3 %.

Table 7 — Pressure test at high temperature

a

Test temperature

Class

°C

A

85 ± 2

B 100 ± 2

C

125 ± 3

D 150 ± 3

E

175 ± 3

F 200 ± 3

G

225 ± 4

H 250 ± 4

a

Upper value of temperature class rating (see Table 1).

7.1.3 Procedure

Place a test sample as shown in Figure 2. Attach the test sample to the support so as not to bend it under the

pressure of the blade. The load and the blade of the apparatus shall be perpendicular to the test-sample axis

and applied in the middle of the test sample. Place the test sample under load, not preheated, for 4 h in the

oven. Then cool the test sample within 10 s by immersion in cold water. Repeat the procedure for the other

test samples. After immersion, subject the test samples to the withstand voltage test and make the following

changes to the procedure in 6.2.

⎯ Immerse the test samples in the salt-water bath for a minimum of 10 min prior to the application of the

voltage.

⎯ Apply the 1 kV (r.m.s.) voltage for 1 min.

⎯ Do not “ramp up” the voltage after the application of the 1 kV (r.m.s.) voltage.

12 © ISO 2006 – All rights reserved

Dimensions in millimetres

Key

1 test frame

2 test sample

3 support

F Applied force.

a

Sharp edge with a max. radius of 0,005 mm.

Figure 2 — Apparatus for pressure test at high temperature

7.1.4 Requirement

Breakdown shall not occur during the withstand voltage test.

7.2 Strip force

7.2.1 Usage of test

The usage of this test shall be agreed between customer and supplier. This test is applicable to cables with a

conductor size u 6 mm .

7.2.2 Test samples

Prepare three test samples of 100 mm from a cable sample 3 m in length. Take the test samples at 1 m

intervals. Cut at least 25 mm of insulation cleanly and strip it carefully from one end of the conductor (see

Figure 3, length AB). Then cut the test samples leaving a 50 mm section (B-C) undisturbed.

7.2.3 Apparatus

Use a test fixture similar to the one shown in Figure 3. A metal plate is provided with a round hole equal to the

appropriate conductor diameter. Use a tensile machine with a speed of 250 mm/min. Ensure that the

apparatus is capable of pulling the test samples without friction between the conductor and the apparatus.

Dimensions in millimetres

Figure 3 — Apparatus for strip force

7.2.4 Procedure

Place a test sample in the test fixture. Pull the test sample without friction between the conductor and the

apparatus at a speed of 250 mm/min and record the force, F. Repeat the procedure for the other test samples.

If the 50 mm section of insulation B-C buckles when sliding, prepare new test samples with the length B-C

equal to 25 mm and repeat this procedure.

7.2.5 Requirement

The measured force shall be within the values agreed between customer and supplier.

8 Low-temperature characteristics

8.1 Winding

8.1.1 Test samples

Prepare two test samples of 600 mm and remove 25 mm of insulation from each end.

8.1.2 Apparatus

Use a freezing chamber at (−40 ± 2) °C [(−25 ± 2) °C may be used for thick wall cables when agreed to

between customer and supplier]. Either a rotatable or a stationary mandrel may be used. See Table 8 for

mandrel diameter.

Rotatable mandrel: when a rotatable mandrel is used, it shall be in accordance with Figure 4. See Table 8 for

mass.

Stationary mandrel: when a stationary mandrel is used, no mass is used.

14 © ISO 2006 – All rights reserved

Table 8 — Winding

ISO conductor size Mandrel diameter

Number

Mass Winding speed

of turns

a

mm

Reference: Reference:

2 −1

kg min.

mm s

8.1, 10.2, 11.2, 11.4, 11.5 10.1, 10.3, 11.6

a u 0,75

0,5 1 3

0,75 < a u 1,5

2,5 1 3

1,5 < a u 6

5 1 2

u 1,5 × outside

u 5 × outside cable

6 < a u 10 cable diameter

8 0,5 0,5

diameter maximum

maximum

10 < a u 25

10 0,5 0,5

25 < a u 35

20 0,5 0,5

35 < a u 120

30 0,2 0,5

Key

1 mandrel

2 test sample(s)

3 mass(es)

Figure 4 — Apparatus for winding

8.1.3 Procedure

The test samples and mandrel shall be conditioned for a minimum of 4 h in the freezing chamber.

Rotatable mandrel: when a rotatable mandrel is used, the test samples shall be fixed on the mandrel as

shown in Figure 4. The free ends are loaded with the mass. Position the mandrel with the test samples

hanging vertically.

Stationary mandrel: when a stationary mandrel is used, a test sample shall be wrapped around the mandrel

by hand. Repeat the procedure for the other test sample.

Wind the test sample for at least the “minimum number of turns” around the mandrel within the freezing

chamber and at winding speed as specified in Table 8. Ensure that there is continuous contact between the

test samples and the mandrel.

After the cold winding, allow the test samples to return to room temperature, and make a visual examination of

the insulation. If no exposed conductor is visible, perform the withstand voltage test; however, make the

following changes to the procedure in 6.2:

⎯ immerse the test sample in the salt-water bath for a minimum of 10 min prior to the application of the

voltage;

⎯ apply the 1 kV (r.m.s.) voltage for 1 min;

⎯ do not “ramp up” the voltage after the application of the 1 kV (r.m.s.) voltage.

8.1.4 Requirement

After winding, no conductor shall be visible. During the withstand voltage test, breakdown shall not occur.

8.2 Impact

8.2.1 Usage of test

The usage of this test shall be agreed between customer and supplier.

8.2.2 Test samples

Prepare three test samples, each of 1,2 m length and remove 25 mm of insulation from each end.

8.2.3 Apparatus

The apparatus shown in Figure 5 is positioned on a foam rubber pad of 40 mm thickness. The mass of the

hammer is specified in Table 9. Set the freezing chamber temperature to (−15 ± 2) °C.

8.2.4 Procedure

Perform the “impact test” in the middle of the test sample. Place the apparatus, positioned on the foam rubber

pad, together with the test samples, in the freezing chamber for at least 16 h. If the apparatus is pre-cooled, a

freezing time of 4 h is sufficient, providing that the test samples have reached the specified temperature. At

the end of this period, place a test sample parallel to the steel base. The hammer is then allowed to fall from a

height of 100 mm. Repeat the procedure for the remaining test samples. After the impact, allow the test

samples to return to room temperature, and make a visual examination of the insulation. If no exposed

conductor is visible, perform the withstand voltage test; however, make the following changes to the

procedure in 6.2:

⎯ immerse the test samples in the salt-water bath for a minimum of 10 min prior to the application of the

voltage;

⎯ apply the 1 kV (r.m.s.) voltage for 1 min;

⎯ do not “ramp up” the voltage after the application of the 1 kV (r.m.s.) voltage.

16 © ISO 2006 – All rights reserved

8.2.5 Requirement

After impact, no conductor shall be visible. During the withstand voltage test according to 6.2, breakdown shall

not occur.

Dimensions in millimetres

Key

1 hammer

2 steel intermediate piece, 100 g

3 test sample

4 steel base, mass 10 kg

5 foam rubber pad

Figure 5 — Apparatus for impact test

Table 9 — Impact

ISO conductor size Mass of the hammer

a g

mm Thick wall cable Thin wall cable Ultra-thin wall cable

a u 0,5

— N/A

N/A

0,5 < a u 2,5

100 100

2,5 < a u 4

4 < a u 10

200 200

10 < a u 25 —

25 < a u 50

—

50 < a u 120

“N/A” Not applicable.

“—” Cable type does not exist.

9 Resistance to abrasion

9.1 Usage of test

This test is only applicable to cables with a conductor size u 6 mm , for which either 9.2 (sandpaper abrasion)

or 9.3 (scrape abrasion) shall be used. The customer and supplier shall define which test shall be used. No

abrasion test is required for conductor sizes > 6 mm .

9.2 Sandpaper abrasion

9.2.1 Test sample

Prepare a test sample of 1 m length and remove 25 mm of insulation from each end.

9.2.2 Apparatus

Measure the “resistance to sandpaper abrasion” using 150 J garnet sandpaper tape with 10 mm conductive

strips perpendicular to the edge of the sandpaper spaced a maximum of every 75 mm. Mount a suitable

bracket to the pivoting arm (see Figure 6) to maintain the test-sample position over an unused portion of the

sandpaper abrasion tape. Exert a force of (0,63 ± 0,05) N on the test sample by the combination of the

bracket, support rod and pivoting arm. The total vertical force exerted on the test sample shall be the

combination of the force exerted by the bracket, pivoting arm, support rod and additional mass. The additional

mass shall be according to Table 10.

9.2.3 Procedure

Mount the test sample taut, without stretching, in a horizontal position using an area of the sandpaper

abrasion tape not previously used. Place the additional mass and bracket on top of the test sample. Draw the

sandpaper abrasion tape under the test sample at a rate of (100 ± 75) mm/min and record the length of

sandpaper abrasion tape necessary to expose the conductor. Move the test sample 50 mm and rotate the test

sample clockwise 90°. Repeat the procedure for a total of four readings. The mean of the readings shall

determine the resistance to sandpaper abrasion.

18 © ISO 2006 – All rights reserved

Key

1 support rod 5 bracket

2 additional mass 6 tape supporting pin, diameter = 6,9 mm

3 pivoting arm 7 150 J, garnet sandpaper abrasion tape

4 test sample

Figure 6 — Apparatus for sandpaper abrasion test

9.2.4 Requirement

The resistance to sandpaper abrasion shall meet or exceed the minimum length of sandpaper requirements

according to Table 10.

Table 10 — Sandpaper abrasion

60 V thick wall 60 V thin wall 60 V ultra-thin wall 600 V

ISO

Minimum Minimum Minimum Minimum

conductor

Additional Additional Additional Additional

length of length of length of length of

size

mass mass mass mass

sandpaper sandpaper sandpaper sandpaper

mm kg mm kg mm kg mm kg mm

0,13 200 150

0,22 225 — — 0,1 0,05 175

0,35 250 200

0,5 400 300 175

0,5

0,75 410 350 200 410

1 420 0,5 0,2 400 0,1 225 420

1,5 430 450 250 430

2 450 500 275 450

2,5 280 250 0,2 125 280

3 330 300 330

4 400 1,5 0,5 350 1,5 400

— —

5 450 430 450

6 500 500 500

NOTE The total vertical force exerted on the test sample is the combination of the force exerted by the bracket, pivoting arm,

support rod and additional mass.

9.3 Scrape abrasion

9.3.1 Test sample

Prepare a test sample of 1 m length and remove 25 mm of insulation from one end.

9.3.2 Apparatus

Use a “resistance to scrape abrasion” apparatus according to Figure 7. It consists of a device designed to

abrade the surface of the insulation in both directions along the longitudinal axis of the test sample and a

counter for recording the numbers of cycles to failure. It shall be controlled in such a way that when the needle

abrades through the insulation and makes contact with the conductor, the machine shall stop operating. The

characteristics of a suitable apparatus shall be as follows:

⎯ diameter of needle: (0,25 ± 0,01) mm or (0,45 ± 0,01) mm as agreed between customer and supplier;

⎯ type of needle: spring wire (polished) material in accordance with ISO 6931-1;

⎯ frequency: (55 ± 5) cycles/min (one cycle consists of one reciprocating movement);

⎯ displacement of the needle: (20 ± 1) mm;

⎯ length of abrasion: (15,5 ± 1) mm;

⎯ type of movement: design details shall not influence the test result;

⎯ mass (position, value, design details): the vertical force on the test sample shall be constant under

dynamic conditions;

⎯ test sample mounting force: the test sample shall not move during the test; if fixing is necessary, the

tension applied on the conductor shall not exceed 100 MPa (N/mm );

⎯ stability of equipment: the apparatus shall be so stable that the results shall not be affected.

9.3.3 Procedure

Apply a total vertical force of (7 ± 0,05) N to the test sample. Determine the number of cycles by taking four

measurements at a temperature of (23 ± 1) °C. After each reading, move the test sample 100 mm and rotate it

clockwise 90°. Change the needle after each reading.

9.3.4 Requirement

The number of cycles shall be agreed between customer and supplier

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...