ISO 15031-5:2006

(Main)Road vehicles — Communication between vehicle and external equipment for emissions-related diagnostics — Part 5: Emissions-related diagnostic services

Road vehicles — Communication between vehicle and external equipment for emissions-related diagnostics — Part 5: Emissions-related diagnostic services

ISO 15031-5:2006 specifies diagnostic services and functionally addressed request/response messages required to be supported by motor vehicles and external test equipment for diagnostic purposes which pertain to motor vehicle emission-related data. Any external test equipment meeting the requirements of ISO 15031-4 use these messages to retrieve emissions-related information from the vehicle. Each section of ISO 15031-5:2006, which specifies additional detail to existing sections of ISO 9141-2, ISO 14230-4, SAE J1850, and ISO 15765-4, supersedes those specifications.

Véhicules routiers — Communications entre un véhicule et un équipement externe pour le diagnostic relatif aux émissions — Partie 5: Services de diagnostic relatif aux émissions

General Information

- Status

- Withdrawn

- Publication Date

- 08-Jan-2006

- Withdrawal Date

- 08-Jan-2006

- Technical Committee

- ISO/TC 22 - Road vehicles

- Drafting Committee

- ISO/TC 22 - Road vehicles

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 12-Apr-2011

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 15-Apr-2008

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

ISO 15031-5:2006 is a standard published by the International Organization for Standardization (ISO). Its full title is "Road vehicles — Communication between vehicle and external equipment for emissions-related diagnostics — Part 5: Emissions-related diagnostic services". This standard covers: ISO 15031-5:2006 specifies diagnostic services and functionally addressed request/response messages required to be supported by motor vehicles and external test equipment for diagnostic purposes which pertain to motor vehicle emission-related data. Any external test equipment meeting the requirements of ISO 15031-4 use these messages to retrieve emissions-related information from the vehicle. Each section of ISO 15031-5:2006, which specifies additional detail to existing sections of ISO 9141-2, ISO 14230-4, SAE J1850, and ISO 15765-4, supersedes those specifications.

ISO 15031-5:2006 specifies diagnostic services and functionally addressed request/response messages required to be supported by motor vehicles and external test equipment for diagnostic purposes which pertain to motor vehicle emission-related data. Any external test equipment meeting the requirements of ISO 15031-4 use these messages to retrieve emissions-related information from the vehicle. Each section of ISO 15031-5:2006, which specifies additional detail to existing sections of ISO 9141-2, ISO 14230-4, SAE J1850, and ISO 15765-4, supersedes those specifications.

ISO 15031-5:2006 is classified under the following ICS (International Classification for Standards) categories: 13.040.50 - Transport exhaust emissions; 43.040.10 - Electrical and electronic equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 15031-5:2006 has the following relationships with other standards: It is inter standard links to ISO 15031-5:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 15031-5:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 15031-5

First edition

2006-01-15

Road vehicles — Communication

between vehicle and external equipment

for emissions-related diagnostics —

Part 5:

Emissions-related diagnostic services

Véhicules routiers — Communications entre un véhicule et un

équipement externe pour le diagnostic relatif aux émissions —

Partie 5: Services de diagnostic relatif aux émissions

Reference number

©

ISO 2006

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2005

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2006 – All rights reserved

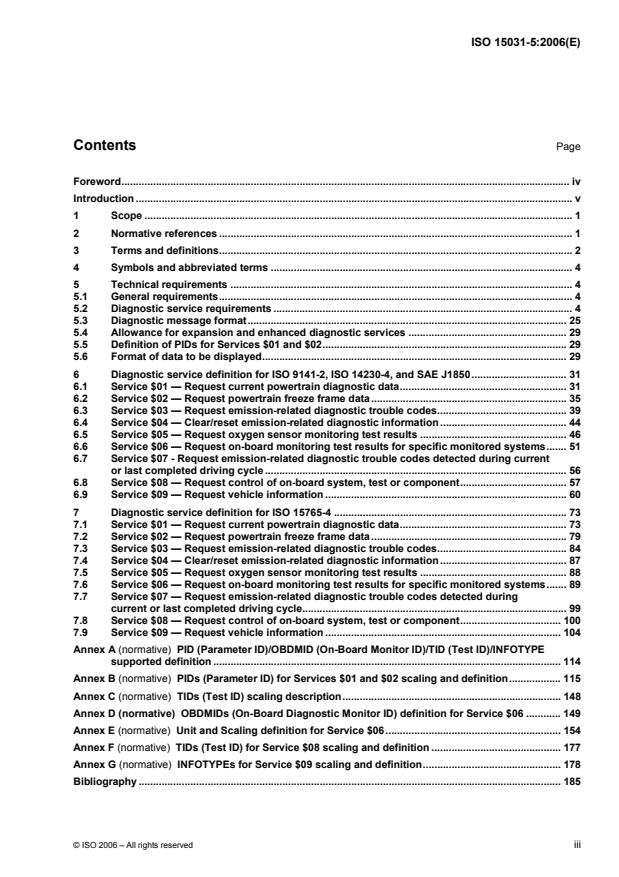

Contents Page

Foreword. iv

Introduction . v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions. 2

4 Symbols and abbreviated terms . 4

5 Technical requirements . 4

5.1 General requirements. 4

5.2 Diagnostic service requirements . 4

5.3 Diagnostic message format. 25

5.4 Allowance for expansion and enhanced diagnostic services . 29

5.5 Definition of PIDs for Services $01 and $02.29

5.6 Format of data to be displayed. 29

6 Diagnostic service definition for ISO 9141-2, ISO 14230-4, and SAE J1850. 31

6.1 Service $01 — Request current powertrain diagnostic data. 31

6.2 Service $02 — Request powertrain freeze frame data. 35

6.3 Service $03 — Request emission-related diagnostic trouble codes. 39

6.4 Service $04 — Clear/reset emission-related diagnostic information . 44

6.5 Service $05 — Request oxygen sensor monitoring test results . 46

6.6 Service $06 — Request on-board monitoring test results for specific monitored systems. 51

6.7 Service $07 - Request emission-related diagnostic trouble codes detected during current

or last completed driving cycle . 56

6.8 Service $08 — Request control of on-board system, test or component. 57

6.9 Service $09 — Request vehicle information . 60

7 Diagnostic service definition for ISO 15765-4 . 73

7.1 Service $01 — Request current powertrain diagnostic data. 73

7.2 Service $02 — Request powertrain freeze frame data. 79

7.3 Service $03 — Request emission-related diagnostic trouble codes. 84

7.4 Service $04 — Clear/reset emission-related diagnostic information . 87

7.5 Service $05 — Request oxygen sensor monitoring test results . 88

7.6 Service $06 — Request on-board monitoring test results for specific monitored systems. 89

7.7 Service $07 — Request emission-related diagnostic trouble codes detected during

current or last completed driving cycle. 99

7.8 Service $08 — Request control of on-board system, test or component. 100

7.9 Service $09 — Request vehicle information . 104

Annex A (normative) PID (Parameter ID)/OBDMID (On-Board Monitor ID)/TID (Test ID)/INFOTYPE

supported definition . 114

Annex B (normative) PIDs (Parameter ID) for Services $01 and $02 scaling and definition. 115

Annex C (normative) TIDs (Test ID) scaling description. 148

Annex D (normative) OBDMIDs (On-Board Diagnostic Monitor ID) definition for Service $06 . 149

Annex E (normative) Unit and Scaling definition for Service $06. 154

Annex F (normative) TIDs (Test ID) for Service $08 scaling and definition . 177

Annex G (normative) INFOTYPEs for Service $09 scaling and definition. 178

Bibliography . 185

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 15031-5 was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 3,

Electrical and electronical equipment.

ISO 15031 consists of the following parts, under the general title Road vehicles — Communication between

vehicle and external equipment for emissions-related diagnostics:

⎯ Part 1: General information

⎯ Part 2: Terms, definitions, abbreviations and acronyms

⎯ Part 3: Diagnostic connector and related electrical circuits, specification and use

⎯ Part 4: External test equipment

⎯ Part 5: Emissions-related diagnostic services

⎯ Part 6: Diagnostic trouble code definitions

⎯ Part 7: Data link security

iv © ISO 2006 – All rights reserved

Introduction

ISO 15031 consists of a number of parts which, taken together, provide a coherent self-consistent set of

specifications to facilitate emissions-related diagnostics. Parts 2 through 7 are based on SAE recommended

practices. This part is based on SAE J1979 SEP97 (E/E Diagnostic Test Modes).

ISO 15031-1 provides an introduction to the series of International Standards.

This part of ISO 15031 is based on the Open Systems Interconnection (OSI) Basic Reference Model in

accordance with ISO/IEC 7498 and ISO/IEC 10731, which structures communication systems into seven

layers as shown in the table below.

Table 1 — Applicability and relationship between documents

Applicability OSI 7 layer Emissions-related diagnostics

ISO 11898,

Physical (layer 1) ISO 9141-2 ISO 14230-1 SAE J1850

ISO 15765-4

ISO 11898,

Data link (layer 2) ISO 9141-2 ISO 14230-2 SAE J1850

ISO 15765-4

Seven layer

ISO 15765-2,

according to

Network (layer 3) — — —

ISO 15765-4

ISO/IEC 7498

and

Transport (layer 4) — — — —

ISO/IEC 10731

Session (layer 5) — — — ISO 15765-4

Presentation (layer 6) — — — —

Application (layer 7) ISO 15031-5 ISO 15031-5 ISO 15031-5 ISO 15031-5

INTERNATIONAL STANDARD ISO 15031-5:2006(E)

Road vehicles — Communication between vehicle and external

equipment for emissions-related diagnostics —

Part 5:

Emissions-related diagnostic services

1 Scope

This part of ISO 15031 specifies diagnostic services and functionally addressed request/response messages

required to be supported by motor vehicles and external test equipment for diagnostic purposes which pertain

to motor vehicle emission-related data. Any external test equipment meeting the requirements of ISO 15031-4

use these messages to retrieve emissions-related information from the vehicle.

Each section of this part of ISO 15031, which specifies additional detail to existing sections of ISO 9141-2,

ISO 14230-4, SAE J1850, and ISO 15765-4 supersede those specifications.

NOTE This part of ISO 15031 provides the mechanism to satisfy the requirements included in the country-specific

regulations and not all capabilities included in this document are required by the country-specific regulations. This part of

ISO 15031 also is not considered a final authority for interpretation of the regulations, so readers should determine the

applicability of capabilities defined in this document for their specific needs.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 9141-2, Road vehicles — Diagnostic systems — Part 2: CARB requirements for interchange of digital

information

ISO 9141-2/Amendment 1, Road vehicles — Diagnostic systems — Part 2: CARB requirements for

interchange of digital information

ISO 14230-4, Road vehicles — Diagnostic systems — Keyword Protocol 2000 — Part 4: Requirements for

emission-related systems

ISO 15031-1, Road vehicles — Communication between vehicle and external equipment for emissions-related

diagnostics — Part 1: General information

ISO/TS 15031-2, Road vehicles — Communication between vehicle and external equipment for emissions-

related diagnostics — Part 2: Terms, definitions, abbreviations and acronyms

ISO 15031-3, Road vehicles — Communication between vehicle and external equipment for emissions-related

diagnostics — Part 3: Diagnostic connector and related electrical circuits, specification and use

ISO 15031-4, Road vehicles — Communication between vehicle and external equipment for emissions-related

diagnostics — Part 4: External test equipment

ISO 15031-6, Road vehicles — Communication between vehicle and external equipment for emissions-related

diagnostics — Part 6: Diagnostic trouble code definitions

ISO 15765-2, Road vehicles — Diagnostics on Controller Area Networks (CAN) — Part 2: Network layer

services

ISO 15765-4, Road vehicles — Diagnostics on Controller Area Networks (CAN) — Part 4: Requirements for

emissions-related systems

SAE J1850: MAY2001,Class B Data Communications Network Interface

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 15031-2 and the following apply.

3.1

absolute throttle position sensor

value intended to represent the throttle opening

NOTE For systems where the output is proportional to the input voltage, this value is the percent of maximum input

signal. For systems where the output is inversely proportional to the input voltage, this value is 100 % minus the percent of

maximum input signal. Throttle position at idle usually indicates greater than 0 %, and throttle position at wide open throttle

usually indicates less than 100 %.

3.2

bank

specific group of cylinders sharing a common control sensor, bank 1 always containing cylinder number 1,

bank 2 the opposite bank

NOTE If there is only one bank, bank #1 DTCs is used, and the word bank may be omitted. With a single “bank”

system utilising multiple sensors, bank #1 DTCs is used identifying the sensors as #1, #2, #3 in order as they move further

away from the cylinder(s).

3.3

base fuel schedule

the fuel calibration schedule programmed into the Powertrain Control Module or PROM when manufactured or

when updated by some off-board source, prior to any learned on-board correction

3.4

Calculated Load Value

for spark ignition engines, typically an indication of the current airflow divided by peak airflow at wide open

throttle as a function of rpm, where airflow is corrected for altitude and ambient temperature

NOTE 1 This definition provides a unit-less number, and provides the service technician with an indication of the

percent engine capacity that is being used.

NOTE 2 For diesel applications, the calculated load value shall be determined by substituting fuelflow in place of

airflow in the calculation.

3.5

client

function that is part of the tester and that makes use of the diagnostic services

NOTE A tester normally makes use of other functions such as data base management, specific interpretation,

man-machine interface.

3.6

continuous monitoring

sampling at a rate no less than two samples per second

2 © ISO 2006 – All rights reserved

3.7

convention

Cvt

column integrated in each message table which marks each parameter included

NOTE The following conventions are used: C = Conditional: the parameter marked “C” in a request/response

message is present only under a condition specified in the bottom row of the message table. M = Mandatory: the

parameter marked “M” in a request/response message table is always present. U = User optional: the parameter marked

“U” in a request/response message table is or is not supplied, depending on dynamic usage by the manufacturer. The

convention recommends a mnemonic, which might be used for implementation. In no case is the specified mnemonic a

mandatory requirement for any implementation.

3.8

Electronic Control Unit

ECU

generic term for any electronic control unit

3.9

Fuel Trim

FT

feedback adjustments to the base fuel schedule

NOTE Short-term fuel trim refers to dynamic or instantaneous adjustments. Long-term fuel trim refers to much more

gradual adjustments to the fuel calibration schedule than short-term trim adjustments. These long-term adjustments

compensate for vehicle differences and gradual changes that occur over time.

3.10

negative numbers

signed binary, the most significant bit (MSB) of the binary number used to indicate positive (0) / negative (1)

NOTE 1 2s complement: negative numbers are represented by complementing the binary number and then adding 1.

EXAMPLE – 0,99 = 8001 hex = 1000 0000 0000 0001 binary

0 = 0000 hex = 0000 0000 0000 0000 binary

+ 0,99 = 7FFF hex = 0111 1111 1111 1111 binary

NOTE 2 (– 0,99) + (+ 0,99) = 0.

3.11

number

expressed by this symbol “#”

3.12

P2, P3 timing parameter

application timing parameters for the ECU(s) and the external test equipment

3.13

server

function that is part of an electronic control unit that provides the diagnostic services

NOTE This part of ISO 15031 differentiates between the server (i.e. the function) and the electronic control unit so

that this document remains independent from the implementation.

3.14

service

information exchange initiated by a client (external test equipment) in order to require diagnostic information

from a server (ECU) and/or to modify its behaviour for diagnostic purpose

NOTE This is also the equivalent of test mode or mode.

4 Symbols and abbreviated terms

CVN Calibration Verification Number

ECM Engine Control Module

ISR Interrupt Service Routine

LSB Least Significant Bit

MSB Most Significant Bit

NRC Negative Response Code

PCM Powertrain Control Module

SI International System of Units

TCM Transmission Control Module

5 Technical requirements

5.1 General requirements

The requirements specified in this clause are necessary to ensure proper operation of both the external test

equipment and the vehicle during diagnostic procedures. External test equipment, when using messages

specified, shall not affect normal operation of the emission control system.

5.2 Diagnostic service requirements

5.2.1 Multiple responses to a single data request

The request messages are functional messages, which means the external test equipment will request data

without knowledge of which ECU(s) on the vehicle will respond. In some vehicles, multiple ECUs may respond

with the information requested. Any external test equipment requesting information shall therefore have

provisions for receiving multiple responses.

IMPORTANT — All emissions-related OBD ECUs which at least support one of the services defined in

this part of ISO 15031 shall support service $01 and PID $00. Service $01 with PID $00 is defined as the

universal “initialization/keep alive/ping” message for all emissions-related OBD ECUs.

5.2.2 Application timing parameter definition

5.2.2.1 Overview

The definition of P2 and P3 is included in this clause. A subscript is added to each timing parameter to identify

the protocol:

⎯ P2 P3 : P2, P3 for ISO 9141-2 and ISO 14230-4 protocols

K-line, K-line

⎯ P2 : P2 for SAE J1850 protocol

J1850

⎯ P2 : P2 for ISO 15765-4 protocol

CAN

IMPORTANT — It is the vehicle manufacturer’s responsibility to specify a shorter P2 timing window

than specified in this part of ISO 15031 for each emission-related server/ECU in the vehicle to make

sure that network topology delays of the vehicle architecture are considered.

4 © ISO 2006 – All rights reserved

5.2.2.2 Definition for ISO 9141-2

For ISO 9141-2 interfaces, Data Link Layer response time requirements (P1, P4) are specified in ISO 9141-2.

Table 2 specifies the application timing parameter values for P2 and P3.

Table 2 — Definition ISO 9141-2 application timing parameter values

Parameter Minimum Maximum Description

value value (ms)

(ms)

Time between external test equipment request message and the successful

P2 25 50

K-line

transmission of the ECU(s) response message(s). Each OBD ECU shall start

Key Bytes:

sending its response message within P2 after the request message has been

K-line

$08 $08

correctly received. Subsequent response messages shall also be transmitted

within P2 of the previous response message for multiple message responses.

K-line

Time between external test equipment request message and the successful

P2 0 50

K-line

transmission of the ECU response message(s). The OBD ECU shall start sending

Key Bytes:

its response message within P2 after the request message has been

K-line

$94 $94

correctly received. Subsequent response messages shall also be transmitted

within P2 of the previous response message for multiple message responses.

K-line

Time between the end of an ECU(s) successful transmission of response

P3 55 5000

K-line

message(s) and start of new external test equipment request message. The

external test equipment may send a new request message if all response

messages related to the previously sent request message have been received

and if P3 minimum time expired.

K-line

ECU implementation guideline: TX (transmit) and RX (receive) line are connected.

Each transmitted byte is read back by the receiver in the ECU. Upon the reception

of a received byte, e.g. last byte of a request message (checksum) from the

tester, the ECU shall reset the P3 timer value to zero. If the ECU supports the

request message, it will start transmitting the response message within the P2

timing window. Each transmitted byte will cause the P3 timer value to be reset. If

the ECU does not support the request and does not send a response message

then in a single OBD ECU system the P3 is started with the last byte received of

the request message. In a multiple OBD ECU system a response message by any

one or more ECUs shall cause the P3 timer value to be reset in all ECUs including

any ECU not supporting the request message.

5.2.2.3 Definition for ISO 14230-4

For ISO 14230-4 interfaces, Data Link Layer response time requirements are specified in ISO 14230-4.

Table 3 specifies the application timing parameter values for P2 and P3.

Table 3 — Definitions of ISO 14230-4 application timing parameter values

Parameter Minimum Maximum Description

value value

(ms) (ms)

P2 25 50 Time between external test equipment request message and the successful

K-line

transmission of the ECU(s) response message(s). Each OBD ECU shall start

sending its response message within P2 after the request message has been

K-line

correctly received. Subsequent response messages shall also be transmitted

within P2 of the previous response message for multiple message responses.

K-line

P3 55 5000 Time between the end of an ECU(s) successful transmission of response

K-line

message(s) and start of new external test equipment request message. The

external test equipment may send a new request message if all response

messages related to the previously sent request message have been received

and if P3 minimum time expired.

K-line

ECU implementation guideline: TX (transmit) and RX (receive) line are connected.

Each transmitted byte is read back by the receiver in the ECU. Upon the reception

of a received byte, e.g. last byte of a request message (checksum) from the

tester, the ECU shall reset the P3 timer value to zero. If the ECU supports the

request message, it will start transmitting the response message within the P2

timing window. Each transmitted byte will cause the P3 timer value to be reset. If

the ECU does not support the request and does not send a response message,

then in a single OBD ECU system the P3 is started with the last byte received of

the request message. In a multiple OBD ECU system, a response message by

any one or more ECUs shall cause the P3 timer value to be reset in all ECUs

including any ECU not supporting the request message.

5.2.2.4 Implementation guidance example for ISO 9141-2 and ISO 14230-4 protocols

This subclause provides an implementation example for client/external test equipment and server/ECU. It is

assumed that the client (external test equipment) communicates to a vehicle with two (2) emission-related

OBD servers (ECUs). The client requests a CVN, which is only supported by server #1 (ECU #1) with two (2)

response messages. Server #2 (ECU #2) is not flash programmable. Figure 1 graphically depicts the timing

handling in the client and two (2) servers for a functionally addressed request message. A description follows

the figure that references the points marked in Figure 1.

From a server point of view, there is no difference in the timing handling compared to a physically addressed

request message. The server shall reset the P3 timer value on each received byte regardless of whether

K-line

the byte is part of a request message or a response message from any another server or an echo from its

transmit line. There are several methods of how a server could implement the timing handling. The

implementation of timing parameters is not part of this International Standard but an important system supplier

responsibility. Some general server timing parameter implementation guidelines are described in this

subclause. The server time stamps each receiver interrupt event and restarts/resets the P3 timer or

K-line_server

timing value, e.g. ISR time stamps received byte, and processing of the received information is performed

outside the ISR. For simplification of the diagram, the Figure 1 only shows a P3 restart after the

K-line_server

reception of the first byte and last byte (checksum) of a received message. The P3 restart is

K-line_server

required on each received byte. The received message can be either a request message from the client or a

response message from any other server connected and initialized by the 33 hex address. If the server has

received a complete message, it compares the target address with the 33 hex address.

6 © ISO 2006 – All rights reserved

Figure 1 — ISO 9141-2 and ISO 14230-4 protocol client and server timing behaviour

Figure 1 shows the client and two (2) initialized servers connected via K-line (either ISO 9141-2 or

ISO 14230-4 protocol). The relevant events for the client and both servers are marked and described.

a) The diagnostic application of the client starts the transmission of a functionally addressed request

message by issuing a DL_Data.request to its data link layer. The data link layer transmits the request

message to the servers.

b) Both servers and the client receive a byte of a message via a receive interrupt by the UART. The ISR

(Interrupt Service Routine) either restarts the P2 /P3 timers or time stamps the received byte.

K-line K-line

c) The completion of the request message is indicated in the client with DL_Data.confirmation. When

receiving the DL_Data.confirmation, the client starts its P2 and P3 timer, using the default reload

K-line K-line

values P2 and P3 .

K-line_max K-line_max

d) If the last message byte is received, each server checks whether the received message includes a target

address which matches the 33 hex address. If the result is a match (server #1 and #2), then the

completion of the request message is indicated in the servers via DL_Data.indication and each server

determines whether it supports the request and has a message available to respond with. If a server

determines that the address in the received message is different from 33 hex, or if the address is a match

but no response needs to be sent (server #2), the P2 timer is stopped. Since the P3 timer has

K-line

already been restarted, no further action is required. If a response message is available and has to be

sent (server #1, but not server #2), then the transmission of the response message shall be started after

P2 timing is expired.

K-line_min

e) Server #1 starts the response message by indicating a DL_Data.request from the application to the data

link layer and at the same time stops its P2 timer.

K-line

f) Both servers and the client receive a byte of a message via a receive interrupt by the UART. The ISR

(Interrupt Service Routine) restarts the P2 /P3 timers or time stamps the received byte and the

K-line K-line

client issues a DL_Data_FB.indication to the application layer.

g) The completion of the response message is indicated in the client with DL_Data.indication. When

receiving the DL_Data.indication, the client starts its P2 and P3 timer, using the default reload

K-line K-line

values P2 and P3 .

K-line_max K-line_max

h) Both servers have received the last byte of a message via a receive interrupt by the UART. The ISR

(Interrupt Service Routine) either resets the P2 /P3 timers or time stamps the received byte. The

K-line K-line

completion of the response message (e.g. length and checksum check) is indicated in server #1 via

DL_Data.confirmation. If server #1 does not want to send further response messages, it stops its P2 timer.

In server #2 the message is received and the P3 timer is restarted, but no DL_Data.indication is

K-line

forwarded to the application because the target address does not match the 33 hex (target address of this

message is the tester address F1 hex).

i) The client application detects a P2 timeout, which indicates that all response messages from all

K-line_max

servers are received.

j) The client application indicates that P3 is reached and that the P3 timing window is now

K-line_min K-line

open to send a new request message [see a)].

5.2.2.5 Definition for SAE J1850

For SAE J1850 network interfaces, the on-board systems shall respond to a request within P2 of a

J1850

request or a previous response message. With multiple response messages possible from a single request

message, this allows as much time as is necessary for all ECUs to access the data link and transmit their

response message(s). If there is no response message within this time period, the external test equipment

can either assume no response message will be received, or if a response message has already been

received, that no more response messages will be received. The application timing parameter value P2 is

J1850

specified in Table 4.

Table 4 — Definition of SAE J1850 application timing parameter values

Parameter Minimum Maximum Description

value value

(ms) (ms)

P2 0 100 Time between external test equipment request message and the successful

J1850

transmission of the ECU(s) response message(s). Each OBD ECU shall

attempt to send its response message (or at least the first of multiple response

messages) within P2 after the request message has been correctly

J1850

received. Subsequent response messages shall also be transmitted within

P2 of the previous response message for multiple message responses.

J1850

8 © ISO 2006 – All rights reserved

5.2.2.6 Definition for ISO 15765-4

For CAN bus systems based on ISO 15765-4, the (all) responding ECU(s) of the on-board system shall

respond to a request message within P2 . The table below specifies the application timing parameter

CAN

values for P2.

Table 5 — Definition of ISO 15765-4 application timing parameter values

Parameter Minimum Maximum Description

value value

(ms) (ms)

P2 0 50 Time between external test equipment request message and the receipt of all

CAN

unsegmented response messages and all first frames of segmented response

message(s).

In case the vehicle’s network architecture uses a gateway to report emissions-

related diagnostic data, all unsegmented response messages and all first

frames of segmented response message(s) shall be received by the external

test equipment within P2 .

CAN

P2* 0 5000 Time between the successful reception of a negative response message with

CAN

response code $78 and the next response message (positive or negative

message).

A negative response message with NRC 78 hex shall not be used as a

response message to a service $01 request.

5.2.2.7 Implementation guidance example for ISO 15765-4 protocol

5.2.2.7.1 Functional OBD communication during defaultSession

Figure 2 graphically depicts the timing handling in the client and two (2) servers for a functionally addressed

request message during the default session. A description follows the figure that references the points marked

in Figure 2.

Figure 2 — Functional OBD communication: Default response timing

From a server point of view, there is no difference in the timing handling compared to a physically addressed

request message, but the client shall handle the timing differently compared with physical communication.

a) The diagnostic application of the client starts the transmission of a functionally addressed request

message by issuing an N_USData.req to its network layer. The network layer transmits the request

message to the servers. A functionally addressed request message shall only be a single-frame message.

b) The completion of the request message is indicated in the client via N_USData.con. When receiving the

N_USData.con, the client starts its P2 timer, using the default reload value P2 . For simplicity,

CAN CAN

Figure 2 assumes that the client and the server are located on the same network.

c) The completion of the request message is indicated in the servers via N_USData.ind.

d) The functionally addressed servers are required to start with their response messages within P2 after

CAN

the reception of N_USData.ind. This means that in case of multi-frame response messages, the

FirstFrame shall be sent within P2 and, for single-frame response messages, that the SingleFrame

CAN

shall be sent within P2 .

CAN

e) In case of a multi-frame response message, the reception of the FirstFrame from any server is indicated

in the client via the N_USDataFF.ind of the network layer. A single-frame response message is indicated

via N_USData.ind.

f) When receiving the FirstFrame/SingleFrame indication of an incoming response message, the client

either stops its P2 in case it knows the servers to be expected to respond and all servers have

CAN

responded, or keeps the P2 running if the client does not know the servers to be expected to respond

CAN

(client awaits the start of further response messages). The network layer of the client will generate a final

N_USData.ind in case the complete message is received or an error occurred during the reception. The

reception of a final N_USData.ind of a multi-frame message in the client will not have any influence on the

P2 timer.

CAN

10 © ISO 2006 – All rights reserved

g) The completion of the transmission of the response message will also be indicated in the servers via

N_USData.con.

5.2.2.7.2 Functional OBD communication during defaultSession with enhanced response timing

Figure 3 graphically depicts the timing handling in the client and two (2) servers for a functionally addressed

request message during the default session, where one server requests an enhanced response timing via a

negative response message including response code 78 hex. A description follows the figure that references

the points marked in Figure 3.

Figure 3 — Functional OBD communication – enhanced response timing

From a server point of view, there is no difference in the timing handling compared to a physically addressed

request message that requires enhanced response timing, but the client shall handle the timing differently

compared with physical communication.

a) The diagnostic application of the client starts the transmission of the functionally addressed request

message by issuing a N_USData.req to its network layer. The network layer transmits the request

message to the servers. A functionally addressed request message shall only be a single-frame message.

b) The completion of the request message is indicated in the client via N_USData.con. When receiving

N_USData.con, the client starts its P2 timer, using the default reload value P2 . For the response

CAN CAN

message, the value of the P2 timer shall consider any latency that is involved based on the vehicle

CAN

network design (e.g. communication over gateways, bus bandwidth, etc.). For simplicity, the figure

assumes that the client and the server are located on the same network.

c) The completion of the request message is indicated in the servers via N_USData.ind.

d) The functionally addressed servers shall start with their response messages within P2 after the

CAN

reception of N_USData.ind. This means that in case of a multi-frame response messages, the FirstFrame

shall be sent within P2 and for single-frame response messages, that the SingleFrame shall be sent

CAN

within P2 . In case any of the addressed servers cannot provide the requested information within the

CAN

P2 response timing, it can request an enhanced response-timing window by sending a negative

CAN

response message including response code 78 hex (this is not allowed for service $01).

e) Upon the reception of the negative response message within the client, the client network layer generates

a N_USData.ind. The reception of a negative response message with response code 78 hex causes the

client to continue its P2 timer in order to observe other servers to respond within P2 . In addition,

CAN CAN

the client establishes an enhanced P2* timer for observation of further server #1 response(s). The

CAN

client shall store a server identification in a list of pending response messages. Once a server that is

stored as pending in the client starts with its final response message (positive response message or

negative response message including a response code other than 78 hex), it is deleted from the list of

pending response messages. For simplicity, Figure 5 only shows a single negative response message

including response code 78 hex from server #1.

f) Server #2 transmits a FirstFrame of a multi-frame response message within P2* . The reception of the

CAN

FirstFrame is indicated in the client network layer by a N_USDataFF.ind. Figure 5 shows when the client

receives the start of the response message of the second server.

g) Server #1 previously indicated to the client (e) enhanced response timing. Once server #1 can provide

the requested information, it starts with its final response message by issuing a N_USData.req to its

network layer. If server #1 can still not provide the requested information within the enhanced P2* ,

CAN

then a further negative response message including response code 78 hex can be sent. This will cause

the client to reload its P2* timer value again. A negative response message including response code

CAN

78 hex from a server that is already stored in the list of pending response messages has no affect to the

client internal list of pending response message.

h) Server #1 transmits a FirstFrame of a multi-frame response message within P2* . The reception of the

CAN

FirstFrame is indicated in the client network layer by a N_USDataFF.ind. Figure 5 shows when the client

receives the start of the response message of the server #1. The client removes server #1 from the

internal list of pending response messages.

i) The client network layer will generate a N_USData.ind.

j) The server network layer will generate a N_USData.con based on the completion of the transmission.

5.2.3 Minimum time between requests from external test equipment

5.2.3.1 ISO 9141-2, ISO 14230-4 — Minimum time between requests from external test equipment

For ISO 9141-2 (K-line) interfaces, the required times between request messages are specified in ISO 9141-2.

12 © ISO 2006 – All rights reserved

For ISO 14230-4 (K-line) interfaces, the required times between request messages are specified in

ISO 14230-4. Figure 4 shows an example of a request message followed by four (4) response messages and

another request message.

Figure 4 — ISO 9141-2 (Key Bytes: $08 $08) and ISO 14230-4 application timing parameter overview

5.2.3.2 SAE J1850 — Minimum time between requests from external test equipment

For SAE J1850 network interfaces, an external test equipment shall always wait for a response message from

the previous request, or “no response” time-out before sending another request message. If the number of

response messages is known and all response messages have been received, then the external test

equipment is permitted to send the next request message immediately. If the number of response messages

is not known, then the external test equipment shall wait at least P2 maximum time.

J1850

Figure 5 shows an example of a request message followed by four (4) response messages and another

request message.

Figure 5 — SAE J1850 application timing parameter overview

5.2.3.3 ISO 15765-4 — Minimum time between requests from external test equipment

For ISO 15765-4 network interfaces, the external test equipment may send a new request message

immediately after it has determined that all responses related to the previously sent request message have

been received. If the external test equipment does not know whether it has received all response messages,

(e.g. after sending the initial OBD request message: Service $01, PID $00), it shall wait (P2 maximum)

CAN

after the last request (if no responses are sent) or the last response message. The timer P2 of the external

CAN

test equipment starts with the confirmation of a successful transmission of the request message.

Figure 6 shows an example of a request message followed by three (3) single-frame response messages and

another request message.

14 © ISO 2006 – All rights reserved

Figure 6 — ISO 15765-4 application timing parameter (Single Frame Response Messages) overview

Figure 7 shows an example of a request message followed by two (2) single frames, one (1) multiple frame

response message and another request message. The next request message can be sent immediately by the

external test equipment after completion of all response messages in case the transmission of the response

messages takes longer than P2 even if the external test equipment does not know the number of

CAN

responding ECUs.

Figure 7 — ISO 15765-4 application timing parameter (Single and Multiple Frame Response Messages

not finished within P2 ) overview

CAN

NOTE The Network Layer timing parameters for the multiple frame response are not shown. Network Layer timing

requirements for legislated diagnostic messages are sp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...