ISO/TS 18507:2015

(Main)Surface chemical analysis — Use of Total Reflection X-ray Fluorescence spectroscopy in biological and environmental analysis

Surface chemical analysis — Use of Total Reflection X-ray Fluorescence spectroscopy in biological and environmental analysis

ISO/TS 18507:2015 provides a framework on the uses of Total Reflection X-Ray Fluorescence (TXRF) spectroscopy for elemental qualitative and quantitative analysis of biological and environmental samples. It is meant to help technicians, biologist, doctors, environmental scientists, and environmental engineers to understand the possible uses of TXRF for elemental analysis by providing the guidelines for the characterization of biological and environmental samples with TXRF spectroscopy. Measurements can be made on equipment of various configurations, from laboratory instruments to synchrotron radiation beamlines or automated systems used in industry. ISO/TS 18507:2015 provides guidelines for the characterization of biological and environmental samples with TXRF spectroscopy. It includes the following: (a) description of the relevant terms; (b) sample preparation; (c) experimental procedure; (d) discussions on data analysis and result interpretation; (e) uncertainty; (f) case studies; and (g) references.

Analyse chimique des surfaces — Utilisation de réflexion spectroscopie des rayons X de fluorescence totale dans l'analyse biologique et de l'environnement

General Information

- Status

- Published

- Publication Date

- 21-Jul-2015

- Technical Committee

- ISO/TC 201 - Surface chemical analysis

- Drafting Committee

- ISO/TC 201 - Surface chemical analysis

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 07-Nov-2023

- Completion Date

- 12-Feb-2026

Overview

ISO/TS 18507:2015 - Surface chemical analysis - Use of Total Reflection X‑ray Fluorescence spectroscopy in biological and environmental analysis - provides guidance on using Total Reflection X‑ray Fluorescence (TXRF) spectroscopy for qualitative and quantitative elemental analysis of biological and environmental samples. The Technical Specification describes relevant terms, sample preparation, instrumentation options (from laboratory instruments to synchrotron beamlines and automated industrial systems), experimental procedures, data analysis and interpretation, uncertainty assessment, and illustrative case studies.

Key SEO keywords: ISO/TS 18507:2015, TXRF spectroscopy, Total Reflection X‑ray Fluorescence, surface chemical analysis, elemental analysis, biological analysis, environmental analysis.

Key topics and technical requirements

- Instrumentation and quality control

- Requirements for X‑ray sources, monochromators, detectors, and sample stations.

- Performance checks: beam stability, spectroscopic resolution, energy calibration, and sensitivity testing.

- Sample carriers and specimen preparation

- Guidance on choice and cleaning of flat sample carriers (reflective substrates) and handling residues.

- Treatment procedures for liquid and solid samples, and preparation of internal standard solutions.

- Measurement geometry and principles

- TXRF geometry uses a glancing incident angle below the critical angle (total reflection) to enhance fluorescence yield and reduce background.

- Benefits include double excitation (primary + reflected beam) and reduced matrix effects.

- Data collection, analysis and reporting

- Procedures for data acquisition, background correction, determination of X‑ray intensities, derivation of relative sensitivities, internal‑standard quantification, and statistical treatment.

- Detailed list of experimental and procedural information required when reporting TXRF results.

- Uncertainty and validation

- Discussion of uncertainty sources and examples via case studies (environmental and biological).

- Comparative performance

- Annexes compare TXRF detection limits with techniques such as AAS and ICP‑MS and include case studies for practical contexts.

Applications and practical users

ISO/TS 18507:2015 is practical for:

- Technicians, analytical chemists, and laboratory staff

- Biologists and medical researchers (blood, serum, urine, tissue analysis)

- Environmental scientists and engineers (water, soil, aerosols, plant deposits)

- Food, pharma and forensic analysts

- Semiconductor industry for wafer contamination control

Practical advantages: multi‑element trace and ultra‑trace analysis, analysis of very small sample amounts, detection of halides, relatively short measurement times, and potentially low detection limits depending on sample and instrumentation.

Related standards

- The Technical Specification cites no normative references but includes comparisons to techniques such as AAS, GF‑AAS, ICP‑MS and discusses applicability versus conventional XRF methods.

This document is essential for labs and facilities implementing TXRF for environmental monitoring, biomedical assays, food safety, and industrial quality control, offering standardized best practices for reliable elemental analysis.

Get Certified

Connect with accredited certification bodies for this standard

ECOCERT

Organic and sustainability certification.

Eurofins Food Testing Global

Global leader in food, environment, and pharmaceutical product testing.

Intertek Bangladesh

Intertek certification and testing services in Bangladesh.

Sponsored listings

Frequently Asked Questions

ISO/TS 18507:2015 is a technical specification published by the International Organization for Standardization (ISO). Its full title is "Surface chemical analysis — Use of Total Reflection X-ray Fluorescence spectroscopy in biological and environmental analysis". This standard covers: ISO/TS 18507:2015 provides a framework on the uses of Total Reflection X-Ray Fluorescence (TXRF) spectroscopy for elemental qualitative and quantitative analysis of biological and environmental samples. It is meant to help technicians, biologist, doctors, environmental scientists, and environmental engineers to understand the possible uses of TXRF for elemental analysis by providing the guidelines for the characterization of biological and environmental samples with TXRF spectroscopy. Measurements can be made on equipment of various configurations, from laboratory instruments to synchrotron radiation beamlines or automated systems used in industry. ISO/TS 18507:2015 provides guidelines for the characterization of biological and environmental samples with TXRF spectroscopy. It includes the following: (a) description of the relevant terms; (b) sample preparation; (c) experimental procedure; (d) discussions on data analysis and result interpretation; (e) uncertainty; (f) case studies; and (g) references.

ISO/TS 18507:2015 provides a framework on the uses of Total Reflection X-Ray Fluorescence (TXRF) spectroscopy for elemental qualitative and quantitative analysis of biological and environmental samples. It is meant to help technicians, biologist, doctors, environmental scientists, and environmental engineers to understand the possible uses of TXRF for elemental analysis by providing the guidelines for the characterization of biological and environmental samples with TXRF spectroscopy. Measurements can be made on equipment of various configurations, from laboratory instruments to synchrotron radiation beamlines or automated systems used in industry. ISO/TS 18507:2015 provides guidelines for the characterization of biological and environmental samples with TXRF spectroscopy. It includes the following: (a) description of the relevant terms; (b) sample preparation; (c) experimental procedure; (d) discussions on data analysis and result interpretation; (e) uncertainty; (f) case studies; and (g) references.

ISO/TS 18507:2015 is classified under the following ICS (International Classification for Standards) categories: 71.040.40 - Chemical analysis. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/TS 18507:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 18507

First edition

2015-07-15

Surface chemical analysis — Use of

Total Reflection X-ray Fluorescence

spectroscopy in biological and

environmental analysis

Analyse chimique des surfaces — Utilisation de réflexion

spectroscopie des rayons X de fluorescence totale dans l’analyse

biologique et de l’environnement

Reference number

©

ISO 2015

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

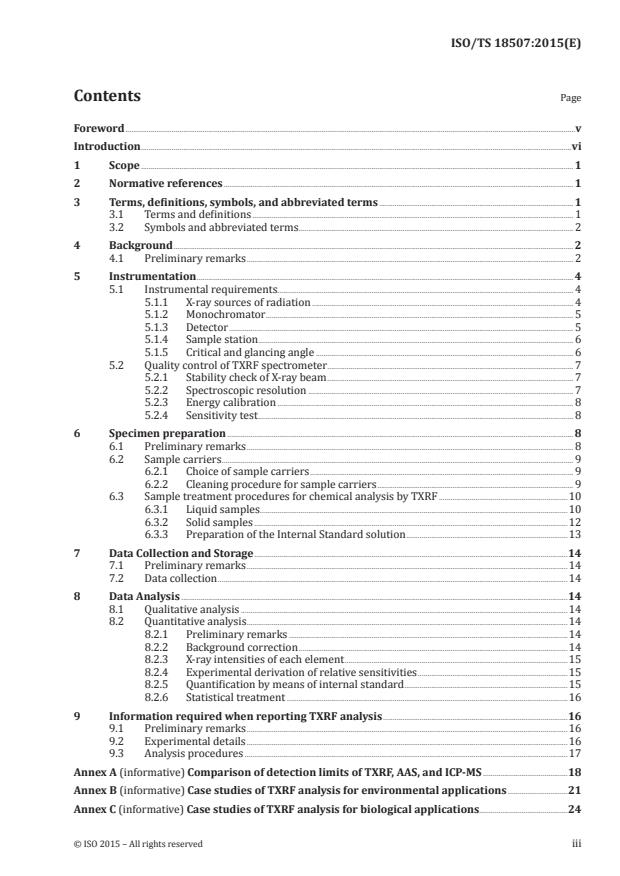

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms, definitions, symbols, and abbreviated terms . 1

3.1 Terms and definitions . 1

3.2 Symbols and abbreviated terms. 2

4 Background . 2

4.1 Preliminary remarks . 2

5 Instrumentation . 4

5.1 Instrumental requirements. 4

5.1.1 X-ray sources of radiation . 4

5.1.2 Monochromator . 5

5.1.3 Detector . 5

5.1.4 Sample station . . . 6

5.1.5 Critical and glancing angle . 6

5.2 Quality control of TXRF spectrometer . 7

5.2.1 Stability check of X-ray beam . 7

5.2.2 Spectroscopic resolution . 7

5.2.3 Energy calibration . 8

5.2.4 Sensitivity test . 8

6 Specimen preparation . 8

6.1 Preliminary remarks . 8

6.2 Sample carriers . 9

6.2.1 Choice of sample carriers . 9

6.2.2 Cleaning procedure for sample carriers . 9

6.3 Sample treatment procedures for chemical analysis by TXRF .10

6.3.1 Liquid samples .10

6.3.2 Solid samples .12

6.3.3 Preparation of the Internal Standard solution .13

7 Data Collection and Storage .14

7.1 Preliminary remarks .14

7.2 Data collection .14

8 Data Analysis .14

8.1 Qualitative analysis .14

8.2 Quantitative analysis .14

8.2.1 Preliminary remarks .14

8.2.2 Background correction .14

8.2.3 X-ray intensities of each element .15

8.2.4 Experimental derivation of relative sensitivities .15

8.2.5 Quantification by means of internal standard .15

8.2.6 Statistical treatment .16

9 Information required when reporting TXRF analysis .16

9.1 Preliminary remarks .16

9.2 Experimental details .16

9.3 Analysis procedures .17

Annex A (informative) Comparison of detection limits of TXRF, AAS, and ICP-MS .18

Annex B (informative) Case studies of TXRF analysis for environmental applications .21

Annex C (informative) Case studies of TXRF analysis for biological applications.24

Annex D (informative) Theoretical derivation of relative sensitivity factors .27

Bibliography .29

iv © ISO 2015 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT), see the following URL: Foreword — Supplementary information.

The committee responsible for this document is ISO/TC 201, Surface chemical analysis.

Introduction

Total Reflection X-Ray Fluorescence (TXRF) spectroscopy is a reliable technique for chemical analysis.

TXRF today is employed in electronic industry quality control. TXRF is also a powerful multi-elemental

method for trace and ultra-trace analysis of different kind of samples that can be grouped as follows:

environmental samples (as water, soil, aerosols, deposits, plants), geological and mineralogical samples

(as ore, crystals, mineral raw materials), technological samples (as petroleum and petroleum products,

thin films, wastes, metals, polymers), biological samples (as blood, serum, urine, human tissue), food

samples (as fish, fruit, meat, nuts, mushroom), pharma and biomedical samples (as pharmaceuticals,

cell culture media), archaeological, art, and forensic samples. Sample preparation is critical for the

quantitative analysis and depends on the sample and its aggregate state.

Because of its capability to analyse different kinds of samples, TXRF is suitable for chemical metrology

at the nanoscale, both for heavy metals and light elements in environmental and biological analysis.

The key advantages of TXRF are the following:

a) simultaneous multi-element trace analysis including halogenides;

b) analysis of very small sample amounts (lower than nanograms to microgram range depending on

sample preparation and condition);

c) simple quantification using an internal standard and possibility of reference-free quantification;

d) suitable for various sample types and applications;

e) theoretically low matrix or memory effects;

f) relatively short time is required for measurement collection;

g) high-sensitivity, low-detection limits depending on sample (elements) matrix, preparation method,

and instrumentation.

vi © ISO 2015 – All rights reserved

TECHNICAL SPECIFICATION ISO/TS 18507:2015(E)

Surface chemical analysis — Use of Total Reflection X-ray

Fluorescence spectroscopy in biological and environmental

analysis

1 Scope

This Technical Specification provides a framework on the uses of Total Reflection X-Ray Fluorescence

(TXRF) spectroscopy for elemental qualitative and quantitative analysis of biological and environmental

samples. It is meant to help technicians, biologist, doctors, environmental scientists, and environmental

engineers to understand the possible uses of TXRF for elemental analysis by providing the guidelines for

the characterization of biological and environmental samples with TXRF spectroscopy.

Measurements can be made on equipment of various configurations, from laboratory instruments to

synchrotron radiation beamlines or automated systems used in industry.

This Technical Specification provides guidelines for the characterization of biological and environmental

samples with TXRF spectroscopy. It includes the following: (a) description of the relevant terms;

(b) sample preparation; (c) experimental procedure; (d) discussions on data analysis and result

interpretation; (e) uncertainty; (f) case studies; and (g) references.

2 Normative references

No normative references cited in this document.

3 Terms, definitions, symbols, and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1.1

sample carrier

flat substrate where the specimen is deposited

Note 1 to entry: The reference surface corresponds to the flat surface of the sample carrier, where the residue

lays. The most important feature of the sample carrier is to be a reflector/mirror for X-rays. Surface roughness,

matrix, and contamination of the sample carrier have an impact on TXRF measurements.

3.1.2

residue

specimen that lays on the sample carrier to be measured

3.2 Symbols and abbreviated terms

ppm concentration in part per million range

ppb concentration in part per billion range

MW Microwave [used to describe the method of digestion (acidic MW digestion)]

APDC Ammonium pyrrolidine dithiocarbamate

MIBK Methyl isobutyl ketone

AAS Atomic Absorption Spectroscopy

GF-AAS Graphite Furnace Atomic Absorption Spectroscopy

ICP-MS inductively coupled plasma-mass spectroscopy

IS internal standard

INAA Instrumental Neutron Activation Analyses

LPME liquid phase microextraction procedure

FWHM full width at half maximum

IR infrared

QC quality control

SR Synchrotron radiation

XRT X-ray tube

XSW X-ray standing wave

4 Background

4.1 Preliminary remarks

TXRF is a surface elemental analysis technique often used for ultra-trace analysis of particles, residues,

and impurities on smooth surfaces. TXRF is currently a key tool for wafer surface contamination control

in semiconductor chip manufacturing.

In the TXRF experiment, the monochromatic X-ray beam impinges on the sample holder carrying the

sample at very small angle, causing total reflection of the beam. The glancing beam angle shall be below

the critical angle of X-ray total reflection, differently from XRF method, where both the glancing beam

[1]

and the detection angle are at 45°. Figure 1 shows XRF and TXRF geometries.

2 © ISO 2015 – All rights reserved

Key

1 X-ray generator

2 energy dispersive detector

3 irradiated sample area

Figure 1 — a. XRF conventional instrumental geometry: X-ray incident beam angle and

fluorescence detector angle are 45° with respect to the sample surface; b. TXRF instrumental

geometry: X-ray incident beam angle is near to 0° and detector position is 90° with respect to

[2]

the sample surface.

Due to the low glancing beam angle, in TXRF the detector can be arranged close to the sample leading

to a higher fluorescence yield with respect to the conventional XRF geometry. The monochromatic X-ray

beam illuminates the sample and it is totally reflected. The great inherent advantage of TXRF is the

double excitation of the sample by both the primary and the reflected beams, leading to a doubling in

the fluorescence intensity.

TXRF detection limits are comparable or better of those that can be obtained by FAAS, while the

[1]

former technique is more sensitive in terms of total sample amount. Table A.1 and Table A.2 show

the comparison of the detection limits of TXRF, AAS, and ICP analysis of environmental and biological

samples, respectively. An advantage of TXRF over AAS and ICP-OES and ICP-MS is the possibility to

detect halogenides.

TXRF can be used to perform qualitative and quantitative multi-element analysis. For quantitative

analysis, an internal standard, i.e. an element absent in the sample (for example, V, Sc, Ga, Ge, Se, Y, or

Co), is added to the sample aliquot. Reference free TXRF analysis for quantification and qualification is

technically possible and has been proposed several times and is employed at some facilities.

Resulting benefits of TXRF are significantly reduced background noise and matrix effects. In addition,

a sample preparation procedure without digestion allows more accurate analysis of some volatile

elements, as Hg, As, or Se, which can be reduced by the sample preparation. Table 1 shows a comparison

of some characteristics of TXRF, AAS, and ICP-MS.

Light elements (Z < 11) are not detected efficiently with commercial spectrometers because their

fluorescence signals are absorbed before detection. However, using the vacuum chamber spectrometer,

the proper excitation energy (e.g. Cr-Ka, Rh-L.), and the suitable detector with Ultra Thin window, the

detection down to Carbon is possible.

The detection limits for specific element depend on the X-ray tube. For example, by using Mo X-ray tube,

only the L-lines of some elements (such as Cd, Sn or Sb) can be detected. Because of the low energy of

L-lines and their possible overlapping with K-lines of Cl, K, and Ca, the quantitative analysis for these

elements is not reliable.

Table 1 — Comparison between TXRF, AAS, and ICP-MS

Property TXRF AAS ICP

Destructive technique Destructive technique

Technique used Non-destructive technique

(digestion required) (digestion required)

Single-standard Multi-standard Multi standard

Calibration

calibration (internal) calibration (external) calibration (external)

solutions, suspensions,

a a

Sample presentation solutions solutions

particles, thin films

Multi-element analysis Yes Sequential only Yes

Digestion procedure Not necessary Yes Yes

a

GF-AAS and LA-ICPMS allow the analysis of solid samples for special applications.

5 Instrumentation

5.1 Instrumental requirements

The TXRF spectrometer consists of the following:

— sources of X-ray radiation like high-voltage generator and X-ray tubes or synchrotron radiation;

— a spectral modification element like a monochromator or a cut-off reflector, if necessary;

— sample station for handling the sample carrier;

— energy-dispersive detector;

— data acquisition unit.

Wavelength, voltage, and current of the X-ray tube, the presence of a spectral modification element

(not always necessary), detector type, and glancing angle are the most relevant parameters. Today the

performances of TXRF instruments are improving due to innovative X-ray optics.

5.1.1 X-ray sources of radiation

5.1.1.1 X-ray tubes

The X-ray tube is a device for the production of X-radiation via electrons striking an anode material.

The electrons required are emitted from a heated cathode and are accelerated by a high voltage. Today,

ceramic X-ray tubes cooled by air (low-power X-ray tubes) are also available.

X-ray tube voltage is the high voltage applied to the X-ray tube that determines the relative intensities of

the characteristic X-ray lines. The maximum allowed high voltage is normally 60 kV. The optimum yield

of characteristic X-ray lines is obtained when the tube voltage (in kV) is about 3 to 4 times the energy of

the absorption edge of the anode material (in keV).

The anode material of the X-ray tube is the material that is struck by accelerated electrons. The anode

material determines not only the characteristic X-ray lines emitted by the X-ray tube but also the

intensity of the Bremsstrahlung. The latter is proportional to the atomic number of the anode material

and to the square of the applied voltage.

Types of X-ray tubes that can be used:

— Side-window tube X-ray tube from which the X-radiation is emitted perpendicular to the axis of the

tube.

— Fine-focus X-ray tube side-window tube with a fine, collimated, either point or line-shaped beam

profile.

4 © ISO 2015 – All rights reserved

— Mixed anode X-ray tube: a fine-focus X-ray tube with an anode composed of two different metals,

whose emitted spectrum consists of the spectra of the individual anode components.

The element of the XRT cannot be properly detected, and other elements (such as Cd, Sn, Sb, and Pb

when Mo tube is used) can be identified only by means of their L lines. When the quantification of these

[3]

elements is necessary, the XRT source shall be changed.

5.1.1.2 Synchrotron radiation

The use of synchrotron radiation (SR) as primary excitation source can increase the overall sensitivity

of TXRF. Compared to X-ray sources produced by electron bombarding on metal targets, SR is produced

as a natural by-product of circulating or oscillating electrons in a storage ring. It contains all the

wavelengths of the electromagnetic spectrum and is 100 or more times powerful than an X-ray generator

[4]

of a commercial instrument.

The advantages of SR are:

— High incidental flux combined with low divergence which results in higher fluorescence intensities

and so lower detection limits.

— Reduced elastic scattering of the incoming beam due to its linear polarization in the orbital plane

(Detector has to be placed in the orbital plane to make use of this).

— The spectral background, which is already reduced by total reflection, is further lowered.

— The tunability of SR allows improving the sensitivity for special elements (by increasing the photon

absorption cross section when setting the excitation energy right above the absorption edge of the

respective element).

5.1.2 Monochromator

A monochromator is a device for the selection of a narrow spectral region. A dispersive medium is the

main constituent of the monochromator. It consists of an arrangement of two multilayers which select

the X-ray radiation, according to the Bragg law. Low-pass filters can also be used as monochromator but

they are less effective. Crystal monochromators are also used with synchrontron radiation, especially if

TXRF is combined with XANES, as the high spectral resolution is required for XANES.

5.1.3 Detector

Detector is one of the key tool for TXRF analysis. It collects the characteristic X-ray radiation emitted

by the sample, according to the drift chamber principle. The following materials are usually used in

solid-state detectors: Li doped Si or Ge single crystals, high purity Ge single crystals. These detectors

are described by the following acronyms respectively: Si (Li), Ge (Li), Si-PIN, Si drift, or HPGe detectors.

Detector parameters are: energy resolution, efficiency, and dead time.

Resolution is the capability of distinguishing between two nearly equal wavelengths. The energy

resolution of a detector expressed as the full width at half maximum (FWHM) of a peak. For Silicon-

based detectors, the FWHM of Mn-Kα line at 5,9 keV is taken as reference value. Typical values for

the resolution lie in the range from 120 keV to 150 keV, depending on the size of the detector crystal.

Detector efficiency is the ratio of output signal (peak intensity) to the input signal (photon rate) at

a given energy. The detector sensitivity only accounts for the photons that reach the detector. The

overall sensitivity of system taking into consideration the system geometry is usually significantly

lower. The sensitivity varies within the range 10 % to 100 %, depending on the energy of radiation

and the type of detector. An important issue of the detector efficiency is also the absorption of the

Be window. To improve the efficiency in the low-energy range, ultra-thin windows (UTW) are used;

this allows the detection of low energy radiation of elements. Only in the high-energy regions the

thickness of the crystal influences the efficiency.

The dead time is the time period following the arrival of a photon in the detector in which the pulse

processing takes place and during which no new photons can be registered. The dead time (dead

time loss) is given as the ratio of the dead time to total time.

Depending on the detector, artificial signals and background noise might be created. Escape peaks, pile–

up peaks, shelf and tail will appear in the spectrum depending on the energy that is registered by the

detector. Thus, when a photon with definite energy escape from the detector-active region, an escape

line appears. For silicone-based detectors, the escape peak lies at an energy which is lower than the

main peak by an amount corresponding to the Si-Kα energy (1,74 keV). Pile-up peak is caused by the

simultaneous processing of two X-ray photons that the detector registers as a single event: it is a sum

peak appearing to the sum of energies of two intense lines in the X-ray spectrum. The incomplete charge

collection in the detector causes shelf and tail lines. All detector artefacts have to be considered during

the analysis and compensated for electronically or via computer operations.

5.1.4 Sample station

A sample station is used for automatic and repeated measurements of multiple samples. It also separates

the radiated measurement area from the sample interface and protects the operator.

The data acquisition unit is a stand-alone computer, which is connected to the apparatus for control of

the data acquisition, data evaluation, and storage.

5.1.5 Critical and glancing angle

The choice of the glancing angle of the X-rays beam is critical for TXRF analysis. Figure 2 shows the

reflectivity of X-rays for different glancing angles.

Figure 2 — Reflectivity curves of three different media calculated for E = 17,4 keV (Mo – Kα)

6 © ISO 2015 – All rights reserved

The critical angle of total reflection is given by Formula (1):

Z

16, 5

m

αρ= (1)

crit

E A

m

where

α is the critical angle;

crit

E is the photon energy in radiation;

Z is the mean atomic number of the medium;

m

A is the mean relative atomic weight of the medium;

m

ρ is the density of the medium.

To have total reflection, the glancing angle for TXRF experiment shall be smaller than the critical angle.

Since the critical angle depends on the substrate and the beam energy, the glancing angle might require

subsequent adjustments.

5.2 Quality control of TXRF spectrometer

5.2.1 Stability check of X-ray beam

Before starting the measurement, the stability of the X-ray beam shall be checked according to the

procedure suggested by the spectrometer producer. To operate, the main switches of the TXRF

spectrometer and the high voltage shall be on.

A generalized procedure for stability check with a specific example is reported as follows:

a). Preparation of a suitable test sample: Transfer 10 µl a standard solution (1 g/l, e.g. Ga) on TXRF

sample carrier.

b) Data acquisition: Define Region of Interest (e.g. 8,9 keV to 9,5 keV in case of a Ga standard). Run

repetitive measurements.

c) Data evaluation: Qualitative prove of the count rate in dependence of the measurement time until

the count rate reaches a stable value.

d) Required failure action: Authorized service engineer needs to be consulted in case of a deviation of

the count rate of more than 1 % after 30 min run.

5.2.2 Spectroscopic resolution

The spectroscopic resolution has a significant influence on the analytical performance of a TXRF

spectrometer. The monitoring of the parameter is performed as described in the following procedure:

A generalized procedure for monitoring the spectroscopic resolution with a specific example is reported

as follows:

a) Checking the instrument status: 60 min warm-up phase at maximum tube power.

b) Preparation of a Mn standard: Transfer 10 µl of a 1 g/l Mn solution on TXRF sample carrier and dry.

Target value for count rate is >5,000 cycles per second.

c) Data acquisition: Set measurement time (live time) to 60 s to 120 s and store acquired spectrum.

d) Data evaluation: Calculate FWHM following the specific procedure of the TXRF device and save new

value.

e) Required failure action: An authorized service engineer needs to be consulted in case of a FWHM

value with a deviation of more than 10 % compared to the delivery status.

5.2.3 Energy calibration

Energy calibration is performed with respect to the position of measured X-ray lines of the elements

of calibration samples. Energy calibration is performed by adjustment of channel/energy ratio or gain

correction of the amplifier hardware directly by software. TXRF instrument has one of the above

correction functions or both. Energy calibration should be carried out frequently enough to ensure

that the uncertainties if the analysis are not significantly increased. A set of reusable samples could be

used for the calibration of the energy. For this purpose, residue samples prepared from single or plural

element solutions, or sample carriers coated with pure metals can be employed.

A generalized procedure for the gain correction with a specific example is reported below.

a) Initial condition: Gain correction shall follow after completion of the stability check.

b) Preparation of a test sample: Transfer 10 µl of a 1 g/l standard solution on TXRF sample carrier and

dry.

c) Data acquisition: Set measurement time to 60 s to 120 s, start measurement, monitor count rate; it

shall exceed 5,000 cycles per second.

d) Calculation of new gain value: Calculate the gain factor following the specific procedure of the TXRF

device and save new value.

e) Repetition of the gain correction: During automatic measurement jobs, the gain correction should

be repeated regularly, if possible once per two hours.

f) Required failure action: Strong changes of the gain values indicate abnormal deviations for the

nominal value. In this case, a service engineer should be consulted.

g) Storage of the test sample: This test sample can be used for up to six months if it is stored safely in

a containment and does not show significant contaminations.

5.2.4 Sensitivity test

The sensitivity is determined by the measurement of single element sample and it is defined as the

detected fluorescence intensity normalized by mass, time, and tube current. The sensitivity is primarily

affected by the quality of the beam adjustment and by the deterioration of the X-ray tube. When the

sensitivity decreases below 60 % of the original value, the quality of the beam adjustment shall be

checked. If the sensitivity is still low after the adjustment, XRT shall be substituted.

6 Specimen preparation

6.1 Preliminary remarks

TXRF is used for the analysis of liquids, with or without pre-concentration treatment, and solid samples,

after decomposition, dissolution or suspension procedure, deposited on carrier with high reflectivity.

Liquid samples shall be dried before measurements. In some cases, as for aerosols, sample can be directly

collected on the sample carrier.

Detailed information on types of sample carriers and sample treatment procedures for the analysis of

liquid and solid samples in chemical analysis by TXRF are presented in this section.

8 © ISO 2015 – All rights reserved

6.2 Sample carriers

6.2.1 Choice of sample carriers

The choice of the proper sample carrier shall consider the elements to be measured, chemical resistance

of the reflector material and its spectral background. In Table 2, advantages and disadvantages of the

most commonly used sample carriers materials are given.

Table 2 — Advantages and disadvantages of commonly used sample carrier materials

Material Advantages Disadvantages

Inexpensive High background

Plexiglass

Disposable Frequently presence of S

Very hard Not stable against HF

Quartz glass Very pure Presence of Si peaks

Easy to clean Expensive

Presence of Al peaks

Chemically stable

Sapphire Very expensive

Durable

Natural material, can contain impurities

Presence of Si peaks

Silicon wafer Very pure Expensive

It should be cut and sized

Inexpensive

Soda lime glass Possible presence of impurity peaks

Disposable

The mechanical performance of sample carriers is crucial: despite the fact that the reflectors are usually

made of very hard material, they can be damaged by inappropriate handling, increasing the background.

When using non-disposable reflectors, a proper cleaning of the surface shall be ensured to avoid

contamination. Contamination on the sample carriers will result in systematic errors of both qualitative

and quantitative analysis.

6.2.2 Cleaning procedure for sample carriers

In the course of time, TXRF users have developed specific procedures for the cleaning of reflectors. The

representation of the main cleaning procedure steps is shown in Figure 3.

Figure 3 — Main steps followed for the cleaning of sample carriers

The time for each step has to be tested. Usually, to ensure the complete cleaning of sample carriers, the

whole procedure takes about 2 to 3 h.

After the cleaning procedure, a blank spectrum has to be measured for each reflector in order to ensure

the absence of contamination.

It shall be noted that the cleaning procedure and surface preparation of the carriers have impact on

the quantification procedure. In particular, the surface of sample carrier might be modified during the

cleaning and preparation procedure and this modification is not reproducible, leading to systematic

errors in the analysis. Disposable carriers might show different backgrounds. Thus it is strongly

suggested to record the background of the sample carrier before sample deposition and make the

estimation of the background signal.

In the case of aqueous samples after the drying step, non-hydrophobic carriers (i.e. quartz reflectors)

shall be coated with silicon solution and subsequently dried in order to favour the deposition of the

target sample within a small spot on the cleaned reflector.

6.3 Sample treatment procedures for chemical analysis by TXRF

The sample preparation is not important in case the quantification is performed by XSW. In the other

cases, several treatment procedures have been proposed for the analysis of liquid and solid samples by

means of TXRF. Usually, the preparation processes allow to obtain thin layer sample (thickness less than

100μm) on the reflector carrier. The choice of proper sample preparation is crucial in order to ensure

the total reflection conditions. A flow chart describing the sample preparation steps for liquid and solid

materials is shown in Figure 4.

Figure 4 — Sample preparation procedures for the analysis of liquids and solids by TXRF

Internal standardization is one of the most used strategies for quantification purposes in TXRF analysis:

it is based on the addition of a defined amount of liquid mono-element standard [internal standard

(IS)] to the sample. To select the concentration of the internal standard, one shall verify the following

conditions:

a) The IS is not present in the sample, usually Ga, Co, V, Y or some other Rare Earth Element are used;

b) The fluorescence lines of the IS do not interfere with the elements to be identified and quantified;

c) The concentration of the IS shall be in the average concentration range of the elements to be

quantified.

This procedure is applied to liquid samples, digested samples, and suspensions. The use of internal

standard reduces the inaccuracies due to sample deposition on the sample carrier.

6.3.1 Liquid samples

For liquid samples with light matrix, TXRF analysis should be performed by depositing a small volume

on suitable reflector. For the quantitative analysis, the aliquot of 500 μL to 1 000 μL of the original liquid

sample is transferred to the container with a pipette and the sample is prepared by adding the suitable

amount of internal standard solution. The mixture shall thoroughly be homogenized (automatic sample

shaker is strongly suggested) and the drop of the solution is deposited on the carrier and dried (see

Figure 5).

10 © ISO 2015 – All rights reserved

Key

1 aliquotation of some mL

2 addition of some μL of internal standard

3 homogenization by shaking

4 aliquotation of some μL

5 pipetting on a clean carrier

6 drying by evaporation

[ ]

Figure 5 — Sample preparation steps for the TXRF analysis of liquid 1

If only a small quantity of liquid is available, the internal standard (IS) can be added to the sample directly

on the carrier. However, by these procedures, homogeneous distribution of the internal standard is not

certain.

For the analysis of organic liquid samples, the IS shall be diluted in an organic solvent to guarantee the

homogeneous distribution of the IS in the sample.

Few microlitres (from 5 µL to 20 µL) of solution are needed for the sample preparation. The diameter

of the sample spot on the carrier shall be within the beam size (usually less than 10 mm) in order to

ensure the complete exposition of the drop to the X-ray beam. If a higher sensitivity for specific element

is needed, multiple droplets (from two to a maximum to be estimated with respect to the critical mass)

should be deposited sequentially on the same spot, allowing each droplet to dry before the following

deposition. The drying step should be performed in vacuum or by a dryer, with IR-lamps, laboratory

ovens, or heating plates. Contamination effects shall be excluded by testing a reference sample.

Nanodroplets or pico-droplets are suggested to attain reproducible spot and decreasing the drying time

[5]

(20 s to 170 s for 2 nL droplets). A new technique for the deposition of standard solutions in Total

Reflection X-ray Fluorescence spectrometry (TXRF) using pico-droplets generated by ink-jet printers

[6][7]

and its applicability for aerosol analysis with SR-TXRF are discussed in literature. This sample

preparation methods can be used when small quantity of the sample is available.

If in the liquid sample the concentration of salts is high, the dry spot on the carrier appears inhomogenous.

In order to comply with the thin layer condition, dilution of the liquid sample is then necessary. Dilutions

1)

by ultrapure water or diluted solutions of a commercial non-ionic detergent (i.e. Triton® X-114 ) are

suggested. Alternatively, the addition of a film-forming lubricant, e.g. polyvinyl alcohol (PVA), can be

[8]

used to facilitate homogenous sample layer formation.

If the element concentration to be quantified is lower or close to the detection limits, preconcentration

procedures can be applied. The determination of volatile elements and the attainment of element

speciation information is also possible when using specific sample treatments before TXRF analysis. For

instance, Hg, difficult to measure because of sample losses during the drying step, can be determined at

[9]

trace levels by with the help of complexing agents.

1) Triton® X-114 is an example of a suitable product available commercially. This information is given for the

convenience of users of this document and does not constitute an endorsement by ISO of this product.

6.3.1.1 Sample preconcentration

Sample preconcentration treatments are commonly used for analysis of liquid samples by means of

atomic spectroscopic techniques such as flame atomic absorption spectroscopy (FAAS) or inductively

[10]

coupled plasma atomic emission atomic spectroscopy (ICP-AES). These procedures can also be

applied for the preparation of TXRF samples.

The preconcentration procedure suggested for TXRF analysis are based on complexation and extraction

of the analytes. In Figure 6, the main steps of this procedure are shown.

Figure 6 — Main steps of preconcentration procedures based on complexation and extraction of

the analytes prior TXRF analysis

Solid-liquid extraction and liquid-liquid extraction are based on the complexation of elements under

investigation using carbamates followed by solvent extraction with an organic reagent. Then, the water-

immiscible liquid phase is collected and dried on a sample carrier before analysis.

A reduction of limits of detection can be achieved by the use of cation exchange columns to decrease

cationic metal content in the target solution. Using this approach, cation species are retained in the

cation exchange column whereas anionic species remain in the target solution and can be therefore

determined. This procedure has been already applied for selenium determination in soil leachates

[11] [12]

containing high amounts of Zn and Ca.

Since the choice of the treatment can influence the results, it is strongly suggest to test at least two

[13]

different methods for the analysis.

6.3.2 Solid samples

TXRF technique can be applied to the analysis of solid samples with or without sample treatment

procedures (i.e. dissolution, suspension, decomposition).

The direct analysis of fine powder sample entails the deposit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...