ISO 20730-1:2021

(Main)Road vehicles — Vehicle interface for electronic Periodic Technical Inspection (ePTI) — Part 1: Application and communication requirements

Road vehicles — Vehicle interface for electronic Periodic Technical Inspection (ePTI) — Part 1: Application and communication requirements

This document is applicable to road vehicles, where the electronic vehicle interface is used to perform a test method that is part of a periodic technical inspection (ePTI). This document describes use cases and specifies technical requirements in order to support the ePTI-relevant vehicle safety system(s) checks during the periodic technical inspection via the electronic interface. This document references the ISO 14229 series, the unified diagnostic services implemented on diagnostic communication over controller area network (DoCAN) and the Internet protocol (DoIP) along with the required provision of data definitions. The technical requirements of diagnostic services and data definitions of emissions-related systems are specified in other International Standards, for example, ISO 15031 and ISO 27145. Other environmental systems' ePTI use cases and technical requirements can be considered in the future. This document defines: — all requirements describing the vehicle-communication functionality via the diagnostic link connector related to ePTI, for example: 1) discovery of the ePTI data link; 2) discovery of the ePTI-relevant systems; 3) query of ePTI-relevant systems’ information, including software identification, software integrity, current and/or stored values; 4) query of ePTI-relevant systems’ error information; 5) activation of ePTI-relevant systems’ actuators or routines; — the use cases about the individual vehicle communication functionality, for example, query identification information, command functional test method. This document does not directly specify any type of test method or pass/fail criteria of the ePTI-relevant system during a PTI, but provides data, which may support PTI test methods. The document specifies: — terminology; — communication establishment between the ePTI external test equipment and the vehicle's ePTI-relevant systems; — usage of a credentials-based authentication and authorisation mechanism between the ePTI external test equipment and the vehicle; — protection against tampering of the defined ePTI methods; — definition of ePTI-relevant use cases: — ePTI external test equipment discovers available data identifier as specified in ISO 20730-3; — ePTI external test equipment queries the ePTI-relevant system’s information, including software numbers, software integrity information, current and/or stored values, self-test completion status, system status, and error information (e.g. DTC and/or DID information); — ePTI external test equipment activates the ePTI-relevant system’s actuators or routines; — definition of ePTI-relevant technical requirements; — ePTI external test equipment minimum requirements. This document excludes: — process definitions for performing the PTI check; — process and data definitions for off-board data provision; — standardised data exchange formats; — validation and verification of vehicle safety systems according to vehicle manufacturer specifications.

Véhicules routiers — Interface de véhicule pour contrôle technique périodique électronique (ePTI) — Partie 1: Exigences d’application et de communication

General Information

- Status

- Published

- Publication Date

- 20-Apr-2021

- Technical Committee

- ISO/TC 22/SC 31 - Data communication

- Drafting Committee

- ISO/TC 22/SC 31/WG 7 - Electronic periodic technical inspection (ePTI)

- Current Stage

- 6060 - International Standard published

- Start Date

- 21-Apr-2021

- Completion Date

- 21-Apr-2021

Overview

ISO 20730-1:2021 specifies the application and communication requirements for an electronic Periodic Technical Inspection (ePTI) vehicle interface. It applies to road vehicles where an electronic vehicle interface is used to support one or more PTI test methods. The standard defines use cases, message flows and technical requirements for diagnostic communication between ePTI external test equipment and vehicle ECUs via the diagnostic link connector using DoCAN (diagnostic communication over CAN) and DoIP (diagnostic communication over IP). It enables consistent access to vehicle data needed to support ePTI checks while constraining system access through credentials, authentication and tamper-protection measures.

Key technical topics and requirements

- Use cases and inspection modules (IM-1 … IM-6) covering:

- Discovery of the ePTI data link and ePTI-relevant systems

- Authentication and authorization flows between test equipment and vehicle ECUs

- Querying supported data identifiers, routines and input/output controls

- Reading VIN, odometer, software identification, software integrity and stored/current values

- Querying self-test completion, system status and error information (e.g., DTC/DID)

- Activating routines or actuators for functional tests

- Communication protocols and layers: references and constraints on UDS/ISO 14229 functionality, application/session layer behavior, and DoCAN/DoIP link setup.

- Security requirements: credentials-based authentication, ECU authentication, and tamper-protection to preserve test integrity.

- Minimum requirements for ePTI external test equipment to interoperate with compliant vehicles.

- Scope limits: ISO 20730-1 provides data and interfaces to support PTI methods but does not define specific PTI pass/fail criteria, off-board data processes, or vehicle manufacturer validation procedures.

Practical applications and who uses it

- Vehicle manufacturers (OEMs) - implement compliant diagnostic interfaces and expose ePTI-relevant DIDs/routines.

- Diagnostic tool and test equipment vendors - design ePTI external test equipment that follows the minimum requirements, authentication flows and message sequences.

- PTI stations, regulators and inspection authorities - adopt consistent electronic inspection workflows and integrate secure ePTI systems into inspection programs.

- System integrators and cybersecurity teams - assess tamper protection, credential management and secure access for roadworthiness checks.

Related standards

- ISO 14229 series (UDS / unified diagnostic services) - primary diagnostic services referenced.

- ISO 20730-3 - data identifier specifications for ePTI.

- ISO 15031 and ISO 27145 - emissions-related diagnostic services and data definitions.

Keywords: ISO 20730-1, ePTI, electronic Periodic Technical Inspection, vehicle interface, DoCAN, DoIP, UDS, ISO 14229, diagnostic link connector, VIN, odometer, DTC, authentication.

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

ISO 20730-1:2021 is a standard published by the International Organization for Standardization (ISO). Its full title is "Road vehicles — Vehicle interface for electronic Periodic Technical Inspection (ePTI) — Part 1: Application and communication requirements". This standard covers: This document is applicable to road vehicles, where the electronic vehicle interface is used to perform a test method that is part of a periodic technical inspection (ePTI). This document describes use cases and specifies technical requirements in order to support the ePTI-relevant vehicle safety system(s) checks during the periodic technical inspection via the electronic interface. This document references the ISO 14229 series, the unified diagnostic services implemented on diagnostic communication over controller area network (DoCAN) and the Internet protocol (DoIP) along with the required provision of data definitions. The technical requirements of diagnostic services and data definitions of emissions-related systems are specified in other International Standards, for example, ISO 15031 and ISO 27145. Other environmental systems' ePTI use cases and technical requirements can be considered in the future. This document defines: — all requirements describing the vehicle-communication functionality via the diagnostic link connector related to ePTI, for example: 1) discovery of the ePTI data link; 2) discovery of the ePTI-relevant systems; 3) query of ePTI-relevant systems’ information, including software identification, software integrity, current and/or stored values; 4) query of ePTI-relevant systems’ error information; 5) activation of ePTI-relevant systems’ actuators or routines; — the use cases about the individual vehicle communication functionality, for example, query identification information, command functional test method. This document does not directly specify any type of test method or pass/fail criteria of the ePTI-relevant system during a PTI, but provides data, which may support PTI test methods. The document specifies: — terminology; — communication establishment between the ePTI external test equipment and the vehicle's ePTI-relevant systems; — usage of a credentials-based authentication and authorisation mechanism between the ePTI external test equipment and the vehicle; — protection against tampering of the defined ePTI methods; — definition of ePTI-relevant use cases: — ePTI external test equipment discovers available data identifier as specified in ISO 20730-3; — ePTI external test equipment queries the ePTI-relevant system’s information, including software numbers, software integrity information, current and/or stored values, self-test completion status, system status, and error information (e.g. DTC and/or DID information); — ePTI external test equipment activates the ePTI-relevant system’s actuators or routines; — definition of ePTI-relevant technical requirements; — ePTI external test equipment minimum requirements. This document excludes: — process definitions for performing the PTI check; — process and data definitions for off-board data provision; — standardised data exchange formats; — validation and verification of vehicle safety systems according to vehicle manufacturer specifications.

This document is applicable to road vehicles, where the electronic vehicle interface is used to perform a test method that is part of a periodic technical inspection (ePTI). This document describes use cases and specifies technical requirements in order to support the ePTI-relevant vehicle safety system(s) checks during the periodic technical inspection via the electronic interface. This document references the ISO 14229 series, the unified diagnostic services implemented on diagnostic communication over controller area network (DoCAN) and the Internet protocol (DoIP) along with the required provision of data definitions. The technical requirements of diagnostic services and data definitions of emissions-related systems are specified in other International Standards, for example, ISO 15031 and ISO 27145. Other environmental systems' ePTI use cases and technical requirements can be considered in the future. This document defines: — all requirements describing the vehicle-communication functionality via the diagnostic link connector related to ePTI, for example: 1) discovery of the ePTI data link; 2) discovery of the ePTI-relevant systems; 3) query of ePTI-relevant systems’ information, including software identification, software integrity, current and/or stored values; 4) query of ePTI-relevant systems’ error information; 5) activation of ePTI-relevant systems’ actuators or routines; — the use cases about the individual vehicle communication functionality, for example, query identification information, command functional test method. This document does not directly specify any type of test method or pass/fail criteria of the ePTI-relevant system during a PTI, but provides data, which may support PTI test methods. The document specifies: — terminology; — communication establishment between the ePTI external test equipment and the vehicle's ePTI-relevant systems; — usage of a credentials-based authentication and authorisation mechanism between the ePTI external test equipment and the vehicle; — protection against tampering of the defined ePTI methods; — definition of ePTI-relevant use cases: — ePTI external test equipment discovers available data identifier as specified in ISO 20730-3; — ePTI external test equipment queries the ePTI-relevant system’s information, including software numbers, software integrity information, current and/or stored values, self-test completion status, system status, and error information (e.g. DTC and/or DID information); — ePTI external test equipment activates the ePTI-relevant system’s actuators or routines; — definition of ePTI-relevant technical requirements; — ePTI external test equipment minimum requirements. This document excludes: — process definitions for performing the PTI check; — process and data definitions for off-board data provision; — standardised data exchange formats; — validation and verification of vehicle safety systems according to vehicle manufacturer specifications.

ISO 20730-1:2021 is classified under the following ICS (International Classification for Standards) categories: 43.180 - Diagnostic, maintenance and test equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 20730-1:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 20730-1

First edition

2021-04

Road vehicles — Vehicle interface

for electronic Periodic Technical

Inspection (ePTI) —

Part 1:

Application and communication

requirements

Véhicules routiers — Interface de véhicule pour contrôle technique

périodique électronique (ePTI) —

Partie 1: Exigences d’application et de communication

Reference number

©

ISO 2021

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

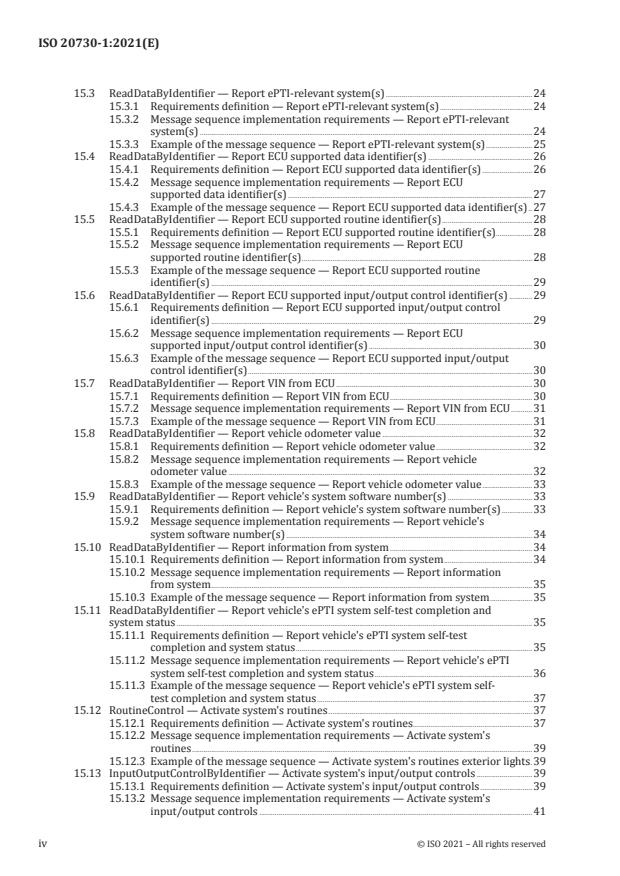

Contents Page

Foreword .vi

Introduction .vii

1 Scope . 1

2 Normative references . 2

3 Terms and definitions . 3

4 Symbols and abbreviated terms . 5

5 How to read this document . 5

5.1 Layout of the document . 5

5.2 Use case structure explanation . 6

5.3 Requirements statement structure . 6

5.4 ePTI application example . 7

6 ePTI inspection modules and use cases overview and principles .8

6.1 Basic principles. 8

6.2 ePTI inspection modules . 9

7 IM-1 – Discover ePTI data link and ePTI-relevant system(s) . 9

7.1 UC 1.1 – Discover ePTI data link . 9

7.2 UC 1.2 – Discover ePTI-relevant system(s) .10

8 IM-2 – Authentication, authorisation .10

8.1 UC 2.1 – ePTI external test equipment authentication .10

8.2 UC 2.2 – Vehicle ECU authentication .11

9 IM-3 – Query available ePTI identifier(s) .11

9.1 UC 3.1 – Query supported data identifier(s) .11

9.2 UC 3.2 – Query supported routine identifier(s) .12

9.3 UC 3.3 – Query supported input/output control identifier(s) .12

10 IM-4 – Query ePTI system information .13

10.1 UC 4.1 – Query vehicle identification number .13

10.2 UC 4.2 – Query vehicle odometer value .13

10.3 UC 4.3 – Query system's software number .13

10.4 UC 4.4 – Identify installed system's software integrity information .14

10.5 UC 4.5 – Query information from system .14

11 IM-5 – Query system's self-test completion and error information .15

11.1 UC 5.1 – Query system's self-test completion status .15

11.2 UC 5.2 – Query system status and error information .15

12 IM-6 – Activate system's routines, input/output control(s) .16

12.1 UC 6.1 – Activate system's routine(s) .16

12.2 UC 6.2 – Activate system's input/output control(s) .16

13 Overview of vehicle system requirements .17

13.1 ePTI external test equipment and vehicle message exchange sequence .17

13.2 Technical requirements and use case coverage .17

14 Application (APP) .18

14.1 Setup vehicle's DoCAN data link framework .18

14.2 Setup vehicle's DoIP data link framework .20

14.3 Choice of DoCAN and DoIP data link in the vehicle .22

15 Application layer (AL) .22

15.1 Applicable ISO 14229-1 UDS functionality .22

15.2 Authentication .23

15.2.1 Requirements definition — ePTI external test equipment authentication .23

15.2.2 Requirements definition — ECU authentication .24

15.3 ReadDataByIdentifier — Report ePTI-relevant system(s) .24

15.3.1 Requirements definition — Report ePTI-relevant system(s) .24

15.3.2 Message sequence implementation requirements — Report ePTI-relevant

system(s) .24

15.3.3 Example of the message sequence — Report ePTI-relevant system(s) .25

15.4 ReadDataByIdentifier — Report ECU supported data identifier(s) .26

15.4.1 Requirements definition — Report ECU supported data identifier(s) .26

15.4.2 Message sequence implementation requirements — Report ECU

supported data identifier(s) .27

15.4.3 Example of the message sequence — Report ECU supported data identifier(s) .27

15.5 ReadDataByIdentifier — Report ECU supported routine identifier(s) .28

15.5.1 Requirements definition — Report ECU supported routine identifier(s).28

15.5.2 Message sequence implementation requirements — Report ECU

supported routine identifier(s) .28

15.5.3 Example of the message sequence — Report ECU supported routine

identifier(s) .29

15.6 ReadDataByIdentifier — Report ECU supported input/output control identifier(s) .29

15.6.1 Requirements definition — Report ECU supported input/output control

identifier(s) .29

15.6.2 Message sequence implementation requirements — Report ECU

supported input/output control identifier(s) .30

15.6.3 Example of the message sequence — Report ECU supported input/output

control identifier(s) .30

15.7 ReadDataByIdentifier — Report VIN from ECU .30

15.7.1 Requirements definition — Report VIN from ECU .30

15.7.2 Message sequence implementation requirements — Report VIN from ECU .31

15.7.3 Example of the message sequence — Report VIN from ECU .31

15.8 ReadDataByIdentifier — Report vehicle odometer value .32

15.8.1 Requirements definition — Report vehicle odometer value .32

15.8.2 Message sequence implementation requirements — Report vehicle

odometer value .32

15.8.3 Example of the message sequence — Report vehicle odometer value .33

15.9 ReadDataByIdentifier — Report vehicle's system software number(s) .33

15.9.1 Requirements definition — Report vehicle's system software number(s) .33

15.9.2 Message sequence implementation requirements — Report vehicle's

system software number(s) .34

15.10 ReadDataByIdentifier — Report information from system .34

15.10.1 Requirements definition — Report information from system .34

15.10.2 Message sequence implementation requirements — Report information

from system .35

15.10.3 Example of the message sequence — Report information from system .35

15.11 ReadDataByIdentifier — Report vehicle's ePTI system self-test completion and

system status .35

15.11.1 Requirements definition — Report vehicle's ePTI system self-test

completion and system status .35

15.11.2 Message sequence implementation requirements — Report vehicle's ePTI

system self-test completion and system status .36

15.11.3 Example of the message sequence — Report vehicle's ePTI system self-

test completion and system status .37

15.12 RoutineControl — Activate system's routines .37

15.12.1 Requirements definition — Activate system's routines .37

15.12.2 Message sequence implementation requirements — Activate system's

routines .39

15.12.3 Example of the message sequence — Activate system's routines exterior lights .39

15.13 InputOutputControlByIdentifier — Activate system's input/output controls .39

15.13.1 Requirements definition — Activate system's input/output controls .39

15.13.2 Message sequence implementation requirements — Activate system's

input/output controls .41

iv © ISO 2021 – All rights reserved

15.13.3 Example of the message sequence — Activate system's input/output controls .41

16 Session layer (SL) .41

Bibliography .42

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 31,

Data communication.

A list of all parts in the ISO 20730 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

vi © ISO 2021 – All rights reserved

Introduction

Roadworthiness testing is a part of a wider regime designed to ensure that road vehicles are kept

in a safe and environmentally acceptable condition during their use. This regime covers periodic

roadworthiness testing of vehicles and technical roadside inspections of vehicles used for commercial

road transport activities and provides a vehicle registration procedure allowing for the suspension of

a vehicle’s authorisation to be used in road traffic where the vehicle constitutes an immediate risk to

road safety. Periodic testing is the main tool to ensure roadworthiness. Technical roadside inspections

of commercial vehicles are merely complementary to periodic testing.

An ePTI system list, which is defined in ISO 20730-3, summarises ePTI-relevant systems and specifies

a defined name (system), a unique identifier (ePTI system identifier) and a description for each ePTI

system. All the definitions in this document refer to this ePTI system list.

The ISO 20730 series is based on the Open Systems Interconnection (OSI) basic reference model

specified in ISO/IEC 7498-1 and ISO/IEC 10731, which structures communication systems into seven

layers. When mapped on this model, the application protocol and data link framework requirements

specified/referenced in the ISO 20730 series are structured according to Figure 1.

Figure 1 illustrates a standard-based documentation concept, which consists of the following main

clusters:

— vehicle diagnostic communication framework: covers all relevant basic vehicle diagnostic

communication specifications of OSI layers 7, 6 and 5;

— vehicle diagnostic communication use case framework: covers the master specification, which

specifies the use cases and requirements of the subject matter of OSI layer 7;

— presentation layer framework: covers all data relevant specifications of OSI layer 6;

— conformance test plan: covers the conformance test plan requirements of the use cases and

communication requirements of OSI layers 7, 6 and 5;

— lower OSI layer framework: covers all vehicle diagnostic protocol standards of OSI layers 4, 3, 2 and

1, which are relevant and referenced by the use case specific standard.

Figure 1 — ePTI document reference according to OSI model

viii © ISO 2021 – All rights reserved

INTERNATIONAL STANDARD ISO 20730-1:2021(E)

Road vehicles — Vehicle interface for electronic Periodic

Technical Inspection (ePTI) —

Part 1:

Application and communication requirements

1 Scope

This document is applicable to road vehicles, where the electronic vehicle interface is used to perform a

test method that is part of a periodic technical inspection (ePTI).

This document describes use cases and specifies technical requirements in order to support the ePTI-

relevant vehicle safety system(s) checks during the periodic technical inspection via the electronic

interface. This document references the ISO 14229 series, the unified diagnostic services implemented

on diagnostic communication over controller area network (DoCAN) and the Internet protocol (DoIP)

along with the required provision of data definitions.

The technical requirements of diagnostic services and data definitions of emissions-related systems are

specified in other International Standards, for example, ISO 15031 and ISO 27145. Other environmental

systems' ePTI use cases and technical requirements can be considered in the future.

This document defines:

— all requirements describing the vehicle-communication functionality via the diagnostic link

connector related to ePTI, for example:

1) discovery of the ePTI data link;

2) discovery of the ePTI-relevant systems;

3) query of ePTI-relevant systems’ information, including software identification, software

integrity, current and/or stored values;

4) query of ePTI-relevant systems’ error information;

5) activation of ePTI-relevant systems’ actuators or routines;

— the use cases about the individual vehicle communication functionality, for example, query

identification information, command functional test method.

This document does not directly specify any type of test method or pass/fail criteria of the ePTI-

relevant system during a PTI, but provides data, which may support PTI test methods.

The document specifies:

— terminology;

— communication establishment between the ePTI external test equipment and the vehicle's ePTI-

relevant systems;

— usage of a credentials-based authentication and authorisation mechanism between the ePTI

external test equipment and the vehicle;

— protection against tampering of the defined ePTI methods;

— definition of ePTI-relevant use cases:

— ePTI external test equipment discovers available data identifier as specified in ISO 20730-3;

— ePTI external test equipment queries the ePTI-relevant system’s information, including software

numbers, software integrity information, current and/or stored values, self-test completion

status, system status, and error information (e.g. DTC and/or DID information);

— ePTI external test equipment activates the ePTI-relevant system’s actuators or routines;

— definition of ePTI-relevant technical requirements;

— ePTI external test equipment minimum requirements.

This document excludes:

— process definitions for performing the PTI check;

— process and data definitions for off-board data provision;

— standardised data exchange formats;

— validation and verification of vehicle safety systems according to vehicle manufacturer specifications.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 11898-1, Road vehicles — Controller area network (CAN) — Part 1: Data link layer and physical

signalling

ISO 11898-2, Road vehicles — Controller area network (CAN) — Part 2: High-speed medium access unit

ISO 13400-2, Road vehicles — Diagnostic communication over Internet Protocol (DoIP) — Part 2: Transport

protocol and network layer services

ISO 13400-3, Road vehicles — Diagnostic communication over Internet Protocol (DoIP) — Part 3: Wired

vehicle interface based on IEEE 802.3

ISO 13400-4, Road vehicles — Diagnostic communication over Internet Protocol (DoIP) — Part 4: Ethernet-

based high-speed data link connector

ISO 14229-1, Road vehicles — Unified diagnostic services (UDS) — Part 1: Application layer

ISO 14229-2, Road vehicles — Unified diagnostic services (UDS) — Part 2: Session layer services

ISO 14229-3, Road vehicles — Unified diagnostic services (UDS) — Part 3: Unified diagnostic services on

CAN implementation (UDSonCAN)

ISO 14229-5, Road vehicles — Unified diagnostic services (UDS) — Part 5: Unified diagnostic services on

Internet Protocol implementation (UDSonIP)

ISO 15031-3, Road vehicles — Communication between vehicle and external equipment for emissions-

related diagnostics — Part 3: Diagnostic connector and related electrical circuits: Specification and use

ISO 15765-2, Road vehicles — Diagnostic communication over Controller Area Network (DoCAN) — Part 2:

Transport protocol and network layer services

2 © ISO 2021 – All rights reserved

1)

ISO 15765-5 , Road vehicles — Diagnostic communication over Controller Area Network (DoCAN) —

Part 5: Specification for an in-vehicle network connected to the diagnostic link connector

ISO 19689, Motorcycles and mopeds — Communication between vehicle and external equipment for

diagnostics — Diagnostic connector and related electrical circuits, specification and use

2)

ISO 20730-3 , Road vehicles — Vehicle interface for electronic Periodic Technical Inspection (ePTI) —

Part 3: Data definitions

SAE J1939-13, Off-Board Diagnostic Connector

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 14229-1 and the following

apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

credentials

data that are transferred to establish the claimed identity of an entity

[SOURCE: ISO/IEC 2382:2015, 2126254, modified — The notes to entry have been deleted.]

3.2

electronic periodic technical inspection

ePTI

standardised communication functionality utilising the electronic vehicle communication interface

supporting the PTI (3.8)

3.3

ePTI external test equipment

test system external to the vehicle's diagnostic link connector, which uses serial communication to

perform ePTI-relevant system (3.4) assessments, measurements and control functions

3.4

ePTI-relevant system

system which is able to perform a function required to be tested during the PTI (3.8)

Note 1 to entry: The ePTI system list (3.6), which is defined in ISO 20730-3, summarises safety-relevant systems

which may be part of a PTI test.

Note 2 to entry: An ePTI-relevant system (3.4) consists of one or multiple ECUs with dedicated sensors and

actuators.

3.5

ePTI inspection module

container of one or more use cases related to the same subject

1) Under preparation. Stage at the time of publication: ISO/FDIS 15765-5:2021.

2) Under preparation. Stage at the time of publication: ISO/DIS 20730-3:2021.

3.6

ePTI system list

list of ePTI-relevant systems (3.4)

Note 1 to entry: It contains a basis of defined electronic systems to be tested via the electronic vehicle interface

as part of the PTI (3.8). The ePTI system list (3.6) specifies a defined name (system), a unique ID (ePTI system ID)

and a description for each ePTI-relevant system.

3.7

ePTI system identifier

unique identifier for an ePTI-relevant system (3.4)

3.8

periodic technical inspection

PTI

roadworthiness testing at predefined intervals and authorized test facilities

Note 1 to entry: Roadworthiness testing is part of a wider regime designed to ensure that vehicles are kept in a

safe and environmentally acceptable condition during their use.

[SOURCE: DIRECTIVE 2014/45/EC]

3.9

safety-relevant system

vehicle systems and components, that when not operating to their design criteria, affect the safety of

the vehicle

3.10

system self-test completion status

finalised status of the on-board diagnosis of the ePTI-relevant system(s) (3.4)

3.11

technical classification

indication of the relevance of the use case related to the communication between the

vehicle’s ePTI-relevant system(s) (3.4) and the ePTI external test equipment (3.3) as specified in this

document

3.12

use case

description of a system’s behaviour as it responds to a request that originates from outside that system

[SOURCE: ISO 15118-1:2019, 3.1.71, modified — The notes to entry have been deleted.]

3.13

conditional

mandatory if a certain criterion is met

3.14

mandatory

keyword indicating an item that is required to be implemented as defined in this document to claim

compliance with this document

[SOURCE: ISO/IEC 14776-113:2002, 3.3.3, modified — The word “standard” has been replaced by

“document”.]

3.15

optional

keyword indicating that the referenced item is not required to claim compliance with this document

Note 1 to entry: Implementation of an optional item should be as defined in this document.

4 © ISO 2021 – All rights reserved

[SOURCE: ISO/IEC 15205:2000, 2.1.23, modified — The wording “keyword indicating that” has been

added; the word “standard” has been replaced by “document”; the last sentence in the definition has

been moved to Note 1 to entry.]

4 Symbols and abbreviated terms

For the purposes of this document, the abbreviated terms given in ISO 14229-1 and the following apply.

BP basic principle

CANID CAN identifier

DID data identifier

ePTI electronic periodic technical inspection

ECU electronic control unit

ETE external test equipment

IM inspection module

MsgParam message parameter

N/A not applicable

NRC negative response code

PDU protocol data unit

PTI periodic technical inspection

PosRspMsgParam positive response message parameter

REQ requirement

ReqMsgParam request message parameter

RID routine identifier

RMI repair and maintenance information

SEQ sequence

SF subFunction

UC use case

VIN vehicle identification number

VM vehicle manufacturer

5 How to read this document

5.1 Layout of the document

This subclause provides an overview about the structuring of the content of this document. Table 1

describes the layout of the main clauses in the document.

Table 1 — Layout of the document

Overview of vehicle system requirements Clause/Subclause

Definition of ePTI inspection modules (IM) and basic principles (BP) Clause 6

Definition of use cases (UC) Clauses 7 to 12

Technical requirements versus use cases coverage matrix Clause 13

Technical requirement statements to setup the vehicle data links Clause 14

ePTI application layer requirements related to diagnostic services with message se- Clause 15

quence implementation and examples

5.2 Use case structure explanation

Table 2 provides an overview about the use case structure and the elements accompanied by an

example.

Table 2 — Use case structure

Title Use case number – Use case name

EXAMPLE UC 4.1 – Query vehicle identification number.

Actor Entity in charge of performing the operation in the use case

EXAMPLE ePTI external test equipment.

Goal Definition of the purpose and objective of the use case

EXAMPLE UC 4.1 – Query vehicle identification number.

Input Definition of input information required to start the purpose and objective of the use case

EXAMPLE VIN data identifier.

Output Definition of output information expected to achieve the purpose and objective of the use

case

EXAMPLE VIN data.

Description Detailed description of the sequence of steps to be performed to achieve the purpose and

objective of the use case

EXAMPLE The ePTI external test equipment requests the VIN. The vehicle responds with

the VIN.

Technical Indication of the relevance of the use case related to communication between the vehicle’s

classification ePTI-relevant system(s) and the ePTI external test equipment (mandatory/conditional/op-

tional).

5.3 Requirements statement structure

A requirement statement is indicated by the following notation:

— REQ: requirement statement indication;

— X = main requirement statement number;

— Y = sub requirement statement number.

NOTE 1 A requirement statement table does not have a table title.

6 © ISO 2021 – All rights reserved

REQ X.Y Clause/subclause reference – Category (optional) – Individual requirement statement name

The requirement statement description (one or multiple sentences) shall always include the word 'shall' and

uniquely specify what is required by whom. A reference to a document is included as a "NOTE #" by using the

description "… is defined in …".

Only one requirement statement shall be stated in the requirement statement description.

EXAMPLE The DID (SupportedePTISystems) parameter shall be used to request the supported

ePTISystemIdentifier.

NOTE 2 The DID (SupportedePTISystems) parameter is defined in ISO 20730-3.

5.4 ePTI application example

Figure 2 shows an ePTI application example from ISO 20730-1. The three columns illustrate the

— PTI step,

— method, and

— information/data.

The step "Prepare" describes the process of providing off-board information necessary for performing

ePTI on a VIN-based access or other unequivocal identification method. Such information is required

to prepare the vehicle for PTI testing, for example, preconditions for ePTI self-tests, preconditions for

ePTI routines of activations, etc.

The step "Proceed" covers the standardised interface and the data definition for ePTI checks. Such

definitions are specified in this document or in the vehicle manufacturer-specific documentation

and are required to establish and perform communication between the external test equipment and

the vehicle, for example, communication requirements, authentication, standardised data, vehicle

manufacturer-specific data, etc.

The step "Compare" describes the process for providing the reference values for ePTI checks, which

requires data to perform a comparison between the read-out data from the vehicle and the reference

values provided by an external information source, for example, list of ePTI systems installed end of

line, software/variant references, thresholds, ePTI-relevant errors, etc.

The step "Decide" describes the method for deciding, whether to approve or reject the vehicle based on

the test, for example, pass/fail criteria, list of additional tests (manual/visual) to confirm the decision,

etc.

Key

1 information required to prepare the vehicle to the PTI

2 information required to establish and perform communication between the external test equipment and the

vehicle

3 standardised data required to collect and interpret ePTI information from the vehicle with the external test

equipment

4 vehicle manufacturer-specific data required to collect and interpret ePTI information from the vehicle with the

external test equipment

5 data required to perform a comparison between the read-out data from the vehicle and the reference values

provided by an external information source

6 data required for deciding, whether the vehicle fails

NOTE Information/data of Key 1, 5, and 6 are not within the scope of the ISO 20730 series.

Figure 2 — ePTI application example

6 ePTI inspection modules and use cases overview and principles

6.1 Basic principles

Basic principles have been established as a guideline to develop this document.

— BP1: ePTI use cases describe the interaction between the ePTI external test equipment with an ePTI

application and the vehicle's ePTI-relevant system(s) utilising the vehicle's communication interface

at the diagnostic link connector.

— BP2: ePTI use cases of the same subject are combined in one ePTI inspection module.

— BP3: ePTI use cases are described from an external test equipment and vehicle point of view.

— BP4: ePTI use cases are described independently of the vehicle system group, for example, safety

systems.

— BP5: All communication messages are compatible with the ISO 14229 series.

— BP6: All data definitions are compatible with the ISO 14229 series.

8 © ISO 2021 – All rights reserved

— BP7: Sensors, internal signals, current and stored values, input/output controls and routines, which

are available in the vehicle via the diagnostic communication interface as specified in this document

and are assigned to a standardised identifier (DID, RID) in ISO 20730-3, are mandatory for applicable

use cases and interface requirements as specified in this document unless otherwise noted.

— BP8: For DIDs, Routines and Input/Output controls as specified in ISO 20730-3, the defined format

shall not cause a change to the sensor(s)/actuator(s) range and resolution. The conversion is used

by the ePTI external test equipment to convert the data sent in the response message into a physical

value and is not a requirement on the actual sensor.

— BP9: Requirements inherit the classification of the corresponding use cases.

— BP10: A "REQ X.Y" requirement specifies a single requirement (not multiple).

— BP11: Only diagnostic services and data that are within the scope of the ISO 20730 series are

guaranteed to work in the context of ePTI.

— BP12: This document specifies the support of periodic technical inspection of safety-relevant

systems in road vehicles.

6.2 ePTI inspection modules

Table 3 provides an overview of the main ePTI inspection modules and associated use cases.

Table 3 — ePTI inspection modules and associated use cases

Main title of the inspection

# Use case reference

module (IM)

1 IM-1 – Discover ePTI data link and UC 1.1 – Discover ePTI data link

ePTI-relevant system(s)

UC 1.2 – Discover ePTI-relevant system(s)

2 IM-2 – Authentication, authorisation UC 2.1 – ePTI external test equipment authentication

UC 2.2 – Vehicle ECU authentication

3 IM-3 – Query available ePTI identifi- UC 3.1 – Query supported data identifier(s)

er(s)

UC 3.2 – Query supported routine identifier(s)

UC 3.3 – Query supported input/output control identifier(s)

4 IM-4 – Query ePTI system informa- UC 4.1 – Query vehicle identification number

tion

UC 4.2 – Query vehicle odometer value

UC 4.3 – Query system's software number

UC 4.4 – Identify installed system's software integrity information

UC 4.5 – Query information from system

5 IM-5 – Query system's self-test com- UC 5.1 – Query system's self-test completion status

pletion and error information

UC 5.2 – Query system status and error information

6 IM-6 – Activate system's routines, UC 6.1 – Activate system's routine(s)

input/output control(s)

UC 6.2 – Activate system's input/output control(s)

7 IM-1 – Discover ePTI data link and ePTI-relevant system(s)

7.1 UC 1.1 – Discover ePTI data link

Table 4 defines the UC 1.1 – Discover ePTI data link.

Table 4 — UC 1.1 – Discover ePTI data link

Title UC 1.1 – Discover ePTI data link

Actor ePTI external test equipment

Goal Discover the standardised ePTI data link supported by the vehicle utilising the vehicle‘s

standardised diagnostic link connector according to either ISO 15031-3, ISO 13400-4,

ISO 19689 or SAE J1939-13.

Input The ePTI external test equipment tries to discover the data link according to this document.

Output The ePTI external test equipment has identified the data link according to this document.

The ePTI external test equipment displays an error message in case the ePTI data link

initialisation procedure failed as specified in this document.

Description The ePTI external test equipment is connected to the vehicle‘s diagnostic connector.

The ePTI external test equipment starts the ePTI data link discovery procedure as

referenced in this document.

The ePTI external test equipment displays an error message in case the ePTI data link

discovery procedure failed.

Technical Mandatory

classification

7.2 UC 1.2 – Discover ePTI-relevant system(s)

Table 5 defines the UC 1.2 – Discover ePTI-relevant system(s).

Table 5 — UC 1.2 – Discover ePTI-relevant system(s)

Title UC 1.2 – Discover ePTI-relevant system(s)

Actor ePTI external test equipment

Goal Discover vehicle's ePTI-relevant systems' identifiers via the electronic interface in the vehicle

as defined in ISO 20730-3 to determine relevant inspection modules for the vehicle under

test.

Input ePTI-relevant system data identifier as defined in ISO 20730-3

Output Discovered ePTI-relevant system identifier(s) and associated ECUs, which are required for

ePTI communication from each installed ePTI-relevant system. ePTI-relevant systems

installed in the vehicle identify themselves using the IDs defined in ISO 20730-3.

Description The ePTI external test equipment uses the standardised ePTI-relevant system data identifier

as defined in ISO 20730-3 to request from the vehicle the reporting of the currently

supported ePTI-relevant system identifier(s) and associated ECUs.

Technical Mandatory

classification

8 IM-2 – Authentication, authorisation

8.1 UC 2.1 – ePTI external test equipment authentication

Table 6 defines the UC 2.1 – ePTI external test equipment authentication.

10 © ISO 2021 – All rights reserved

Table 6 — UC 2.1 – ePTI external test equipment authentication

Title UC 2.1 – ePTI external test equipment authentication

Actor ePTI external test equipment

Goal Authenticate the ePTI external test equipment against at least one ECU.

Input Valid credentials sent by the ePTI external test equipment to at least one ECU of the ePTI-

relevant system(s)

Output At least one ECU of the ePTI-relevant system(s) sends the result of the authentication to the

ePTI external test equipment.

A positive authentication response message confirms the authenticity.

Description The ePTI external test equipment uses credentials to authenticate against at least one of the

vehicle’s ECUs.

At least one ECU of the vehicle's ePTI-relevant system(s) respond with the result of the au-

thentication and if successful, grant access rights to all diagnostic services and data

necessary to fulfil the use cases specified in this document.

Technical Optional

classification

8.2 UC 2.2 – Vehicl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...