ISO 13256-1:2021

(Main)Water-source heat pumps — Testing and rating for performance — Part 1: Water-to-air and brine-to-air heat pumps

Water-source heat pumps — Testing and rating for performance — Part 1: Water-to-air and brine-to-air heat pumps

1.1 This document establishes performance testing and rating criteria for factory-made residential, commercial and industrial, electrically-driven, mechanical- compression type, water-to-air and brine-to-air heat pumps. The requirements for testing and rating contained in this document are based on the use of matched assemblies. 1.2 Equipment designed for rating at one liquid temperature range under this document may not be suitable at all liquid temperature ranges covered in this document. 1.3 This document does not apply to the testing and rating of individual assemblies for separate use, nor to the testing and rating of heat pumps covered in ISO 5151, ISO 13253 or ISO 13256‑2.

Pompes à chaleur à eau — Essais et détermination des caractéristiques de performance — Partie 1: Pompes à chaleur eau-air et eau glycolée-air

General Information

- Status

- Published

- Publication Date

- 06-May-2021

- Technical Committee

- ISO/TC 86/SC 6 - Testing and rating of air-conditioners and heat pumps

- Current Stage

- 6060 - International Standard published

- Start Date

- 07-May-2021

- Due Date

- 12-Dec-2020

- Completion Date

- 07-May-2021

Relations

- Effective Date

- 23-Apr-2020

Overview - ISO 13256-1:2021 (water-source heat pumps)

ISO 13256-1:2021 defines standardized testing and rating methods for water-to-air and brine-to-air heat pumps. It applies to factory-made, electrically driven, mechanical‑compression heat pumps used in residential, commercial, and industrial HVAC systems. The standard is based on testing matched assemblies and establishes uniform conditions and procedures to determine cooling and heating performance, power inputs and published ratings.

Key topics and technical requirements

- Scope and applicability

- Covers water‑to‑air and brine‑to‑air (refrigerant-to-water/brine) heat pumps; excludes individual assemblies and equipment covered by ISO 5151, ISO 13253 or ISO 13256‑2.

- Notes that equipment rated for one liquid temperature range may not be suitable across all source temperature ranges.

- Rating and test conditions

- Defines rating conditions for net capacities, fan and pump power inputs, airflow and liquid flow rates, and test liquids.

- Introduces High/Medium/Low source temperature ranges to support broader operating maps and interpolation for energy modelling.

- Performance requirements and tests

- Specifies maximum/minimum operating condition tests, enclosure condensate/sweat tests, and steady‑state cooling/heating capacity tests.

- Harmonized measurement uncertainties and tolerances aligned with modern ISO testing practice.

- Test methods and data

- Procedures for equipment installation, reconditioning, data collection, and calculation of net cooling/heating capacity.

- Annexes provide methods for airflow measurement, indoor/ refrigerant/liquid enthalpy tests, condensate measurements and corrections for fan/pump power.

- Marking and publication

- Nameplate and published rating requirements so manufacturers can communicate certified performance.

Practical applications and who uses this standard

- Manufacturers - to develop, test and publish certified performance data for water‑source heat pumps and for product development across source temperature ranges.

- Independent test laboratories - to perform repeatable, ISO‑compliant HVAC performance testing.

- HVAC designers and specifiers - to compare product performance, select equipment for systems using groundwater, looped water or antifreeze/brine sources, and for accurate energy modelling.

- Regulatory bodies, procurement and certification schemes - to verify claims, support efficiency labeling, and ensure consistent test reporting.

- Energy modelers - use the High/Medium/Low ratings to interpolate performance for building simulation.

Related standards

- ISO 13256 series (other parts)

- ISO 13256-2 (other heat pump types)

- ISO 5151, ISO 13253 (air conditioners and other heat pumps)

- ISO 817 (refrigerant designation and safety)

Keywords: ISO 13256-1, water-source heat pumps, water-to-air heat pump testing, brine-to-air, heat pump performance rating, HVAC testing standard.

Buy Documents

ISO 13256-1:2021 - Water-source heat pumps -- Testing and rating for performance

ISO 13256-1:2021 - Water-source heat pumps — Testing and rating for performance — Part 1: Water-to-air and brine-to-air heat pumps Released:5/7/2021

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

ISO 13256-1:2021 is a standard published by the International Organization for Standardization (ISO). Its full title is "Water-source heat pumps — Testing and rating for performance — Part 1: Water-to-air and brine-to-air heat pumps". This standard covers: 1.1 This document establishes performance testing and rating criteria for factory-made residential, commercial and industrial, electrically-driven, mechanical- compression type, water-to-air and brine-to-air heat pumps. The requirements for testing and rating contained in this document are based on the use of matched assemblies. 1.2 Equipment designed for rating at one liquid temperature range under this document may not be suitable at all liquid temperature ranges covered in this document. 1.3 This document does not apply to the testing and rating of individual assemblies for separate use, nor to the testing and rating of heat pumps covered in ISO 5151, ISO 13253 or ISO 13256‑2.

1.1 This document establishes performance testing and rating criteria for factory-made residential, commercial and industrial, electrically-driven, mechanical- compression type, water-to-air and brine-to-air heat pumps. The requirements for testing and rating contained in this document are based on the use of matched assemblies. 1.2 Equipment designed for rating at one liquid temperature range under this document may not be suitable at all liquid temperature ranges covered in this document. 1.3 This document does not apply to the testing and rating of individual assemblies for separate use, nor to the testing and rating of heat pumps covered in ISO 5151, ISO 13253 or ISO 13256‑2.

ISO 13256-1:2021 is classified under the following ICS (International Classification for Standards) categories: 27.080 - Heat pumps. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 13256-1:2021 has the following relationships with other standards: It is inter standard links to ISO 13256-1:1998. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 13256-1:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 13256-1

Second edition

2021-05

Water-source heat pumps — Testing

and rating for performance —

Part 1:

Water-to-air and brine-to-air heat

pumps

Pompes à chaleur à eau — Essais et détermination des

caractéristiques de performance —

Partie 1: Pompes à chaleur eau-air et eau glycolée-air

Reference number

©

ISO 2021

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

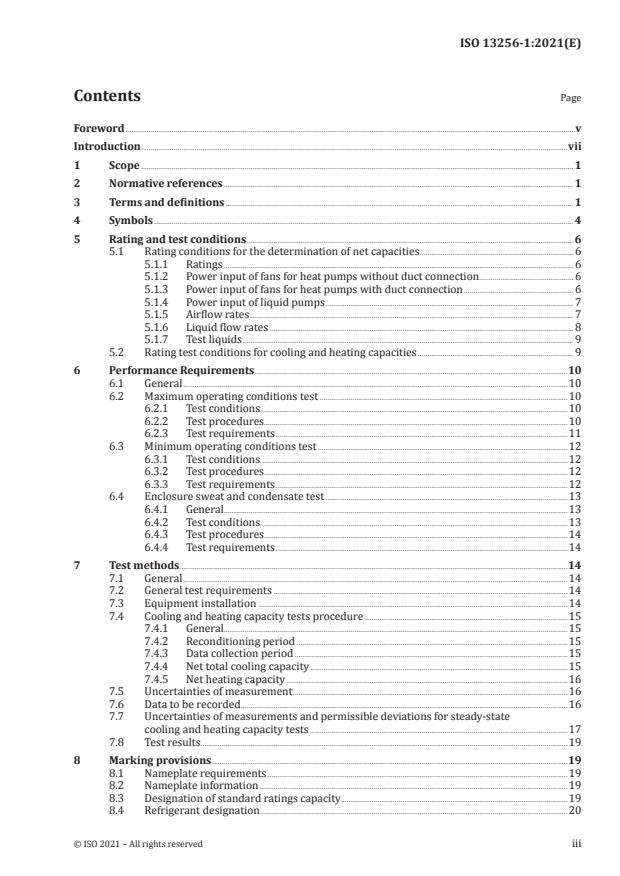

Contents Page

Foreword .v

Introduction .vii

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols . 4

5 Rating and test conditions . 6

5.1 Rating conditions for the determination of net capacities . 6

5.1.1 Ratings . 6

5.1.2 Power input of fans for heat pumps without duct connection . 6

5.1.3 Power input of fans for heat pumps with duct connection . 6

5.1.4 Power input of liquid pumps . 7

5.1.5 Airflow rates . 7

5.1.6 Liquid flow rates . 8

5.1.7 Test liquids . 9

5.2 Rating test conditions for cooling and heating capacities . 9

6 Performance Requirements.10

6.1 General .10

6.2 Maximum operating conditions test .10

6.2.1 Test conditions.10

6.2.2 Test procedures.10

6.2.3 Test requirements .11

6.3 Minimum operating conditions test .12

6.3.1 Test conditions.12

6.3.2 Test procedures.12

6.3.3 Test requirements .12

6.4 Enclosure sweat and condensate test .13

6.4.1 General.13

6.4.2 Test conditions.13

6.4.3 Test procedures.14

6.4.4 Test requirements .14

7 Test methods .14

7.1 General .14

7.2 General test requirements .14

7.3 Equipment installation .14

7.4 Cooling and heating capacity tests procedure .15

7.4.1 General.15

7.4.2 Reconditioning period .15

7.4.3 Data collection period .15

7.4.4 Net total cooling capacity .15

7.4.5 Net heating capacity .16

7.5 Uncertainties of measurement .16

7.6 Data to be recorded .16

7.7 Uncertainties of measurements and permissible deviations for steady-state

cooling and heating capacity tests .17

7.8 Test results.19

8 Marking provisions .19

8.1 Nameplate requirements .19

8.2 Nameplate information .19

8.3 Designation of standard ratings capacity.19

8.4 Refrigerant designation .20

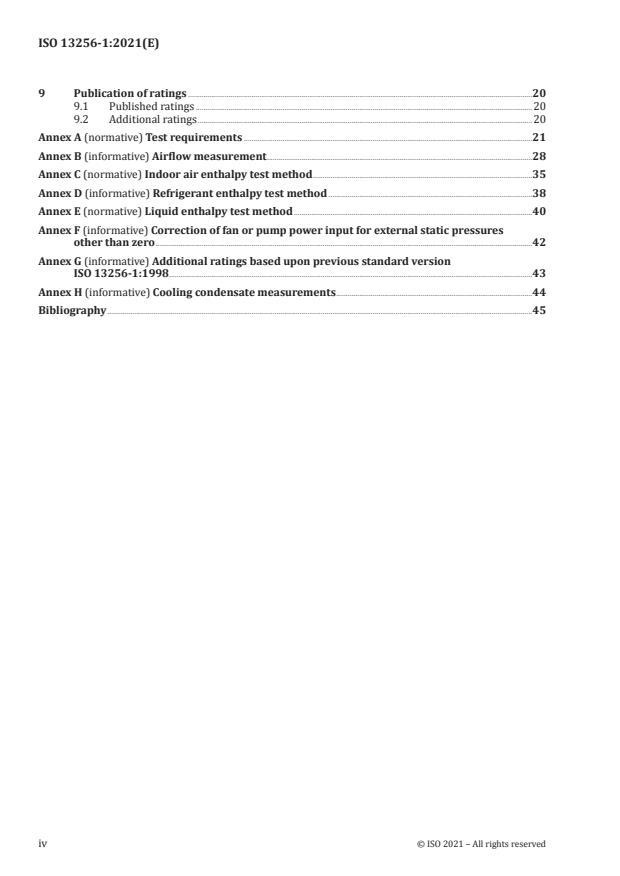

9 Publication of ratings .20

9.1 Published ratings .20

9.2 Additional ratings .20

Annex A (normative) Test requirements .21

Annex B (informative) Airflow measurement .28

Annex C (normative) Indoor air enthalpy test method .35

Annex D (informative) Refrigerant enthalpy test method .38

Annex E (normative) Liquid enthalpy test method .40

Annex F (informative) Correction of fan or pump power input for external static pressures

other than zero .42

Annex G (informative) Additional ratings based upon previous standard version

ISO 13256-1:1998.43

Annex H (informative) Cooling condensate measurements .44

Bibliography .45

iv © ISO 2021 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 86, Refrigeration and air-conditioning,

Subcommittee SC 6, Testing and rating of air-conditioners and heat pumps.

This second edition cancels and replaces the first edition (ISO 13256-1:1998), which has been technically

revised.

The main changes compared to the previous edition are as follows:

— Significant updates to the formatting, symbols, and terms and definitions, have been included to

more closely align with other pertinent ISO standards and the latest ISO requirements.

— The original water loop heat pump (WLHP), ground water heat pump (GWHP) and ground loop

heat pump (GLHP) application rating designations, specifying entering liquid source rating test

conditions, have been replaced with High, Medium, and Low source temperature range conditions to

represent a wider operating map at both standard and partially loaded application rating conditions.

It is now possible, when all three (High, Medium and Low) temperature ranges are specified by the

manufacturer for energy modelling programs to interpolate performance at other entering water

temperatures than those used in the standard.

— Specific antifreeze solution composition requirements have been removed to eliminate prescriptive

language and promote industry innovation of novel and improved antifreeze solutions.

— Airflow testing requirements have been updated to align with the complexities of testing more

sophisticated constant airflow electronically commutated fan motors.

— Testing tolerances and uncertainties have been harmonized with other pertinent ISO standards.

— Annexes have been added and/or significantly updated that harmonize with other pertinent ISO

standards.

A list of all parts in the ISO 13256 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

vi © ISO 2021 – All rights reserved

Introduction

This document covers heating and cooling systems which are generally referred to as “water-source

heat pumps.” These systems generally include an indoor coil with air-moving means, a compressor, and

a refrigerant-to-water or refrigerant-to-brine heat exchanger. A system may provide both heating and

cooling, cooling-only, or heating-only functions.

INTERNATIONAL STANDARD ISO 13256-1:2021(E)

Water-source heat pumps — Testing and rating for

performance —

Part 1:

Water-to-air and brine-to-air heat pumps

1 Scope

1.1 This document establishes performance testing and rating criteria for factory-made residential,

commercial and industrial, electrically-driven, mechanical- compression type, water-to-air and brine-to-

air heat pumps. The requirements for testing and rating contained in this document are based on the use

of matched assemblies.

1.2 Equipment designed for rating at one liquid temperature range under this document may not be

suitable at all liquid temperature ranges covered in this document.

1.3 This document does not apply to the testing and rating of individual assemblies for separate use,

nor to the testing and rating of heat pumps covered in ISO 5151, ISO 13253 or ISO 13256-2.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 817, Refrigerants — Designation and safety classification

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

water-to-air heat pump

brine-to-air heat pump

heat pump which consists of one or more factory-made assemblies which normally include an indoor

conditioning coil with air-moving means, compressor(s), and refrigerant-to-water or refrigerant-to-

brine heat exchanger(s), including means to provide both cooling and heating, cooling-only, or heating-

only functions

Note 1 to entry: When such equipment is provided in more than one assembly, the separated assemblies should

be designed to be used together.

Note 2 to entry: Such equipment may also provide functions of sanitary water heating, air cleaning, dehumidifying,

and humidifying.

3.2

water-loop heat pump

water-to-air heat pump using liquid circulating in a common piping loop functioning as a heat source in

`heating mode and/or heat sink in cooling mode

Note 1 to entry: The temperature of the liquid loop is usually within a range of 10 °C to 30 °C.

3.3

ground-water heat pump

water-to-air heat pump using water pumped from a well, lake, or stream functioning as a heat source in

heating mode and/or heat sink in cooling mode

Note 1 to entry: The temperature of the water is related to the climatic conditions and is generally constant

within the range from 5 °C to 25 °C for deep wells.

3.4

ground-loop heat pump

brine-to-air heat pump using a brine solution circulating through a subsurface piping loop functioning

as a heat source in heating mode and/or heat sink in cooling mode

Note 1 to entry: The heat exchange loop may be placed in horizontal trenches or vertical bores, or be submerged

in a body of surface water.

Note 2 to entry: The temperature of the brine is related to the heat exchange load and climatic conditions and is

generally within a range from –5 °C to 40 °C.

3.5

total cooling capacity

amount of sensible and latent heat that the equipment can remove from the conditioned space in a

defined interval of time

Note 1 to entry: Expressed in units of watts.

3.6

net total cooling capacity

total cooling capacity with fan power adjustment

Note 1 to entry: Expressed in units of watts.

3.7

heating capacity

amount of heat that the equipment can add to the conditioned space in a defined interval of time

Note 1 to entry: Expressed in units of watts.

3.8

net heating capacity

heating capacity with fan power adjustment

Note 1 to entry: Expressed in units of watts.

3.9

rated voltage

voltage shown on the nameplate of the equipment

Note 1 to entry: Expressed in units of volts.

3.10

rated frequency

frequency shown on the nameplate of the equipment

Note 1 to entry: Expressed in units of Hz.

2 © ISO 2021 – All rights reserved

3.11

energy efficiency ratio

EER

ratio of the net total cooling capacity to the effective power input at any given set of rating conditions

Note 1 to entry: Expressed in units of watt per watt.

3.12

coefficient of performance

COP

ratio of the net heating capacity to the effective power input of the equipment at any given set of rating

conditions

Note 1 to entry: Expressed in units of watt per watt.

3.13

standard air

dry air at 20,0 °C and at a standard barometric pressure of 101,325 kPa, having a mass density of

1,204 kg/m

3.14

effective power input

average electrical power input to the equipment within a defined interval of time; i.e. the sum of:

— the power input for operation of the compressor excluding additional electrical heating devices,

— the power input of all control and safety devices of the equipment, and

— the proportional power input of the conveying devices for the transport of the heat transfer media

through the heat pump only (e.g. fans, pumps, whether internal or external, whether provided with

the equipment or not)

Note 1 to entry: Expressed in units of watts.

3.15

latent cooling capacity

amount of latent heat that the equipment can remove from the conditioned space in a defined

interval of time

Note 1 to entry: Expressed in units of watts.

3.16

sensible cooling capacity

amount of sensible heat that the equipment can remove from the conditioned space in a defined

interval of time

Note 1 to entry: Expressed in units of watts.

3.17

brine

heat transfer liquid that has a freezing point lower than the freezing point of water

3.18

external static pressure difference

∆

pe

pressure difference measured between the air (or water/brine) outlet section and the air (or water/

brine) inlet section of the unit, which is available for overcoming the pressure drop of any additional

ducted air (or water/brine) circuit

Note 1 to entry: Expressed in units of pascals.

3.19

internal static pressure difference

∆

pi

pressure difference measured between the air (or water/brine) outlet section and the air (or water/

brine) inlet section of the unit, which corresponds to the total pressure drop of all components on the

air (or water/brine) side of the unit.

Note 1 to entry: Expressed in units of pascals.

3.20

fixed capacity heat pump

equipment which does not have possibility to change its capacity

Note 1 to entry: This definition applies to each cooling and heating operation individually.

3.21

two-stage capacity heat pump

equipment where the capacity is varied by two steps

Note 1 to entry: This definition applies to each cooling and heating operation individually.

3.22

multi-stage capacity heat pump

equipment where the capacity is varied by three or four steps

Note 1 to entry: This definition applies to each cooling and heating operation individually.

3.23

variable capacity heat pump

equipment where the capacity is varied by five or more steps to represent continuously variable

capacity

Note 1 to entry: This definition applies to each cooling and heating operation individually.

3.24

standard rating conditions

operating conditions while establishing the standard rating net cooling and/or heating capacities

Note 1 to entry: These conditions correspond to an operation of the heat pump at full capacity, in relation to the

source side.

3.25

application rating conditions

operating conditions while establishing additional cooling and/or heating capacities

Note 1 to entry: These conditions correspond to an operation of the heat pump at reduced capacity, in relation to

the source side.

3.26

standard rating capacity

net cooling and/or heating capacity measured at standard rating conditions

4 Symbols

Symbol Description and Units

A nozzle area, m

n

α pressure ratio

C nozzle discharge coefficient

d

c specific heat of dry air entering indoor side, J/kg·K

pa1

4 © ISO 2021 – All rights reserved

Symbol Description and Units

c specific heat of dry air leaving indoor side, J/kg·K

pa2

c specific heat of liquid, J/kg·K

pf

D nozzle throat diameter, mm

n

Δ measured internal static pressure difference, Pa

pi

Δ measured external static pressure difference, Pa

pe

h specific enthalpy of air entering indoor air-side, J/kg of dry air

a1

h specific enthalpy of air leaving indoor air-side, J/kg of dry air

a2

h specific enthalpy of refrigerant entering indoor side, J/kg

r1

h specific enthalpy of refrigerant leaving indoor side, J/kg

r2

K latent heat of vaporization of water, J/kg (2,47 x 10 , J/kg at 15 °C)

η representative efficiency

P power input to indoor-side compartment, W

i

p pressure, at nozzle throat, kPa absolute

n

p velocity pressure at nozzle throat or static pressure difference across nozzle, Pa

v

ϕ total power input

c

ϕ fan power adjustment, W

fa

ϕ latent cooling capacity, (indoor air-side data), W

lci

ϕ net cooling capacity, W

nc

ϕ net heating capacity, W

nh

ϕ sensible cooling capacity, (air-side data), W

sci

ϕ total cooling capacity, (airside data), W

tci

ϕ total cooling capacity, (liquid side data), W

tco

ϕ total heating capacity, (air-side data), W

thi

ϕ total heating capacity, (liquid side data), W

tho

q measured volumetric flow rate, l/s

q measured airflow rate at standard air conditions, m /s

a

q air mass flow rate, kg/s

m

q refrigerant and oil mixture flow rate, m /s

ro

q air volume flow rate, standard air, m /s

s

q air-volume flow rate, calculated, m /s

V

q air volume flow rate, measured, m /s

Vi

q flow rate, liquid condensate (steam), kg/s

wc

Re Reynolds number

t temperature, air entering indoor side, dry bulb, °C

a1

t temperature, air leaving indoor side, dry bulb, °C

a2

t temperature, liquid entering equipment, °C

f3

t temperature, liquid leaving equipment, °C

f4

v kinematic viscosity of air

v specific volume of dry air at conditions existing at nozzle at standard barometric pressure, m /kg

n

specific volume of air at nozzle, m /kg of air-water vapour mixture

v

n

W mass of cylinder and bleeder assembly, empty, g

W mass of cylinder and bleeder assembly, with sample, g

W mass of cylinder and bleeder assembly, with oil from sample, g

w Liquid mass flow rate, kg/s

f

w specific humidity, air entering indoor side, kg/kg of dry air

i1

Symbol Description and Units

w specific humidity, air leaving indoor side, kg/kg of dry air

i2

W specific humidity at nozzle inlet, kg/kg of dry air

n

X concentration of oil to refrigerant-oil mixture

X mass ratio, refrigerant to refrigerant-oil mixture

r

Y expansion factor

5 Rating and test conditions

5.1 Rating conditions for the determination of net capacities

5.1.1 Ratings

Ratings shall be established at the test conditions specified in 5.2, using the test procedures described

in Clause 7. Ratings relating to cooling and heating capacities shall be net values (see 7.4.4 and 7.4.5),

including the effects of circulating-fan heat (see 7.4.4 and 7.4.5), but excluding any supplementary heat.

Energy efficiency ratios shall be based on the effective power input as defined in 3.11.

5.1.2 Power input of fans for heat pumps without duct connection

In the case of heat pumps which are not designed for duct connection and which are equipped with

an integral fan, all power consumed by the fans shall be included in the effective power input to the

heat pump.

5.1.3 Power input of fans for heat pumps with duct connection

5.1.3.1 If no fan is provided with the heat pump, a fan power adjustment is to be included in the

effective power input to the heat pump, using Formula (1):

q × Δ

()

api

φ = (1)

fa

η

where

ϕ is the fan power adjustment, in W;

fa

η = 0,3 by convention;

∆ is the absolute value of the measured internal static pressure difference, in Pa;

pi

q is the airflow rate at standard air conditions, in m /s.

a

This value shall be added to the heating capacity and subtracted from the cooling capacity.

5.1.3.2 If a fan is an integral part of a heat pump, only the portion of the fan power required to overcome

the internal resistance shall be included in the effective power input to the heat pump. The fraction which

is to be excluded from the total power consumed by the fan shall be calculated using Formula (2):

q ×Δ

ape

φ = (2)

fa

η

where

6 © ISO 2021 – All rights reserved

ϕ is the fan power adjustment, in W;

fa

η = 0,3 by convention;

∆ is the measured external static pressure difference, in Pa;

pe

q is the airflow rate at standard air conditions, in m /s.

a

This value shall be subtracted from the heating capacity and added to the cooling capacity.

5.1.4 Power input of liquid pumps

5.1.4.1 If no liquid pump is provided with the heat pump, a pump power adjustment is to be included

in the effective power consumed by the heat pump, using Formula (3):

q× Δ

()

pi

φ = (3)

pa

η

where

ϕ is the pump power adjustment, in W;

pa

η = 0,3 by convention;

Δ is the absolute value of the measured internal static pressure difference, in Pa;

pi

q is the measured volumetric fluid flow rate, in m /s.

5.1.4.2 If a liquid pump is an integral part of the heat pump, only the portion of the pump power

required to overcome the internal resistance shall be included in the effective power input to the

heat pump. The fraction which is to be excluded from the total power consumed by the pump shall be

calculated using Formula (4):

q×Δ

pe

φ = (4)

pa

η

where:

ϕ is the pump power adjustment, in W;

pa

η = 0,3 by convention;

Δ is the measured external static pressure difference, in Pa;

pe

q is the measured volumetric fluid flow rate, in m /s.

5.1.5 Airflow rates

5.1.5.1 All standard ratings shall be determined at airflow rates as described below. All airflow rates

shall be expressed as cubic meters per second of standard air as defined in 3.10.

5.1.5.2 The manufacturer shall specify a single airflow rate for all tests required in this document

unless automatic adjustment of airflow rate is provided by the equipment. A separate control signal

output for each step of airflow rate shall be considered as an automatic adjustment.

5.1.5.3 For ducted heat pumps which have integral, non-constant airflow, single or multi-speed fans

the airflow rate shall be set as specified by the manufacturer. The external static pressure shall not be less

than the value defined by Table 1. If the unit is unable to attain specified airflow and has an adjustable

speed, it shall be adjusted to the lowest speed that provides at least the external static defined in Table 1

at the specified airflow rate. If the external static at the rated airflow rate is less than the value defined by

Table 1, then the test shall be run at the airflow achieved at the minimum external static pressure.

5.1.5.4 Ducted heat pumps which have integral constant airflow fan shall be tested at the manufacturers'

specified airflow and external static pressure. Specified external static shall not be less than specified in

Table 1. If the external static at the rated airflow rate is less than the value defined by Table 1, then the

test shall be run at the airflow achieved at the minimum external static pressure.

Table 1 — External static pressure requirement

Standard capacity Minimum external static

a

ratings pressure

kW Pa

0 < Q < 8 25

8 ≤ Q < 12 37

12 ≤ Q < 20 50

20 ≤ Q < 30 62

30 ≤ Q < 45 75

45 ≤ Q < 82 100

82 ≤ Q < 117 125

117 ≤ Q < 147 150

Q > 147 175

a

For equipment tested without an air filter installed, the minimum external static

pressure shall be increased by 10 Pa.

5.1.5.5 Ducted heat pumps which do not have integral fans but which are rated for general use with

a variety of air moving devices, shall be tested at the airflow rates specified by the manufacturer in the

published ratings. However, the pressure drop across the indoor coil assembly and the recommended

enclosures and attachment means shall not exceed 75 Pa.

5.1.5.6 If the air enthalpy method is used, non-ducted heat pumps shall be tested at the airflow rates

obtained at zero external static pressure difference.

5.1.6 Liquid flow rates

5.1.6.1 General

All standard ratings shall be determined at a liquid flow rate described below, expressed as cubic

meters per second.

5.1.6.2 Source side flowrate

The manufacturer shall specify a flow rate for all of the tests performed unless automatic adjustment

of the liquid flow rate is provided by the equipment. A separate control signal output for each step of

liquid flow rate will be considered as an automatic adjustment.

5.1.6.3 Heat pumps with integral liquid pumps shall be tested at the liquid flow rate specified by

the manufacturer or that is obtained at zero external static pressure difference (within the tolerance

specified in Table 11), whichever provides the lower liquid flow rate.

5.1.6.4 Heat pumps without integral liquid pumps shall be tested at the flow rate specified by the

manufacturer.

8 © ISO 2021 – All rights reserved

5.1.7 Test liquids

5.1.7.1 The test liquid for all tests except low temperature heating tests shall be water or brine of a

composition and concentration specified by the manufacturer.

5.1.7.2 The test liquid for low temperature heating tests (H1) shall be brine of a composition and

concentration specified by the manufacturer.

5.1.7.3 The test liquid shall be sufficiently free of gas to ensure that the measured result is not

influenced by the presence of gas.

5.2 Rating test conditions for cooling and heating capacities

5.2.1 The test conditions for the determination of cooling capacities are specified in Table 2. The test

conditions for determination of heating capacities are specified in Table 3.

NOTE Previous rating conditions can be found in Annex G, Tables G.1 and G.2

5.2.2 Fixed capacity heat pumps shall be rated at standard rating conditions for one or several cooling

and/or heating conditions defined by Table 2 and 3.

5.2.3 Two stage and multi-stage capacity heat pumps shall be rated at maximum capacity at standard

rating conditions and at minimum capacity at application rating conditions for one or several cooling

and/or heating conditions as defined by Table 2 and 3. Additional ratings may be applied at application

rating conditions with different capacity levels using Tables 2 and 3.

5.2.4 Variable capacity heat pumps shall be rated at the maximum continuous capacity allowed

by the controls at standard rating conditions and at the minimum capacity allowed by the controls at

application rating conditions. Additional ratings may be applied at application rating conditions with

different capacity levels using Tables 2 and 3.

Table 2 — Rating test conditions for the determination of cooling capacity

C3 C2 C1

high source tem- medium source tem- Low source tem-

perature perature perature

Air entering load side 27 27 27

— dry bulb, °C 19 19 19

— wet bulb, °C

Air surrounding unit installed indoor 27 27 27

— dry bulb, °C 19 19 19

— wet bulb, °C

Standard rating conditions 30 20 10

Source side entering temperature, °C

Application rating conditions 25 15 5

Source side entering temperature, °C

a

Frequency Rated Rated Rated

b

Voltage Rated Rated Rated

a

Equipment with dual-rated frequencies shall be tested at each frequency.

b

Equipment with dual-rated voltages shall be tested at both voltages or at the lower of the two voltages if only a single

rating is published.

Table 3 — Rating test conditions for the determination of heating capacity

H3 H2 H1

high source tem- medium source tem- low source tem-

perature perature perature

Air entering load side 20 20 20

— dry bulb, °C 15 15 15

— wet bulb, °C (maximum)

Air surrounding unit installed indoor 20 20 20

— dry bulb, °C_ 15 15 15

— wet bulb, °C (maximum)

Standard rating 20 10 0

Conditions

Source side entering temperature, °C

Application rating conditions 25 15 5

Source side entering temperature, °C

a

Frequency Rated Rated Rated

b

Voltage Rated Rated Rated

a

Equipment with dual-rated frequencies shall be tested at each frequency.

b

Equipment with dual-rated voltages shall be tested at both voltages or at the lower of the two voltages if only a single

rating is published.

6 Performance Requirements

6.1 General

6.1.1 To comply with this document, water-to-air and brine-to-air heat pumps shall meet the applicable

requirements of this document.

6.1.2 For heat pumps with capacity control, the performance requirements tests shall be conducted at

the maximum capacity as determined in standard rating conditions.

6.2 Maximum operating conditions test

6.2.1 Test conditions

For maximum operating conditions tests, a single heating and/or cooling test when applicable shall be

conducted at the test conditions established for the specific rating temperature range (see 5.2) specified

in Tables 4 and 5.

6.2.2 Test procedures

The equipment shall be operated continuously for one hour after the specified conditions have been

established at each specified voltage level.

The 110 % voltage test shall be conducted prior to the 90 % voltage test.

All power to the equipment shall be cut off for 3 min. at the conclusion of the one hour test at the 90 %

voltage level and then restored for one hour.

10 © ISO 2021 – All rights reserved

6.2.3 Test requirements

Heat pumps shall meet the following requirements when operating at the conditions specified in

Tables 4 and 5.

During the entire test, the equipment shall operate without any indication of damage.

During the test period specified in 6.2.2., the motor overload protective device may trip only during the

first 5 min of operation after the shutdown period of 3 min. During the remainder of the test period, no

motor overload protective device shall trip. For those models so designed that resumption of operation

does not occur within the first 5 min after the initial trip, the equipment may remain out of operation

for no longer than 30 min. It shall then operate continuously for the remainder of the test period.

Table 4 — Maximum cooling test conditions

Rated Temperature Range: C3 C2 C1

high source tem- medium source tem- low source temper-

perature perature ature

Air entering load side 32 32 32

— dry bulb, °C 23 23 23

— wet bulb, °C

Air surrounding unit 32 32 32

— dry bulb, °C

Source side entering temperature, °C 40 40 40

a

Frequency Rated Rated Rated

b

Voltage 1) 90 % and 110 % 1) 90 % and 110 % 1) 90 % and 110 %

of rated voltage of rated voltage of rated voltage

for equipment for equipment for equipment

with a single with a single with a single

nameplate rating, nameplate rating, nameplate rating,

2) 90 % of 2) 90 % of 2) 90 % of

minimum minimum minimum

voltage and voltage and voltage and

110 % of 110 % of 110 % of

maximum maximum maximum

voltage for voltage for voltage for

equipment with equipment with equipment with

dual nameplate dual nameplate dual nameplate

voltage. voltage. voltage.

a

Equipment with dual-rated frequencies shall be tested at each frequency.

b

Equipment with dual-rated voltages shall be tested at both voltages or at the lower of the two voltages if only a single

rating is published.

Table 5 — Maximum heating test conditions

Rating Temperature Range: H3 H2 H1

high source tem- medium source tem- low source temper-

perature perature ature

Air entering load side 27 27 27

— dry bulb, °C

a

Equipment with dual-rated frequencies shall be tested at each frequency.

b

Equipment with dual-rated voltages shall be tested at both voltages or at the lower of the two voltages if only a single

rating is published.

Table 5 (continued)

Rating Temperature Range: H3 H2 H1

high source tem- medium source tem- low source temper-

perature perature ature

Air surrounding unit 27 27 27

— dry bulb, °C

Source side entering temperature, °C 30 30 30

a

Frequency Rated Rated Rated

b

Voltage 1) 90 % and 110 % 1) 90 % and 110 % 1) 90 % and 110 %

of rated voltage of rated voltage of rated voltage

for equipment for equipment for equipment

with a single with a single with a single

nameplate rating, nameplate rating, nameplate rating,

2) 90 % of 2) 90 % of 2) 90 % of

minimum minimum minimum

voltage and voltage and voltage and

110 % of 110 % of 110 % of

maximum maximum maximum

voltage for voltage for voltage for

equipment with equipment with equipment with

dual nameplate dual nameplate dual nameplate

voltage. voltage. voltage.

a

Equipment with dual-rated frequencies shall be tested at each frequency.

b

Equipment with dual-rated voltages shall be tested at both voltages or at the lower of the two voltages if only a single

rating is published.

6.3 Minimum operating conditions test

6.3.1 Test conditions

For minimum operating conditions test, a single heating and/or cooling test when applicable shall be

conducted at the test conditions established for the specific applications (see 5.2.) specified in Tables 6

and 7. Heat pumps intended for use in two or more source temperature conditions shall be tested at the

most stringent set of conditions specified in Tables 6 and 7.

6.3.2 Test procedures

For the minimum operating cooling test, the heat pump shall be operated continuously for a period of

no less than 30 min after the specified temperature conditions have been established. For the minimum

operating heating test, the heat pump shall soak for 10 min with liquid at the specified temperature

circulating through the coil. The equipment shall then be started and operated continuously for 30 min.

6.3.3 Test requirements

No protective device shall trip during these tests and no damage shall occur to the equipment.

12 © ISO 2021 – All rights reserved

Table 6 — Minimum cooling test conditions

Rating Temperature Range: C3 C2 C1

high temperature medium tempera- low temperature

ture

Air entering load side 21 21 21

— dry bulb, °C 15 15 15

— maximum wet bulb, °C

Air surrounding unit 21 21 21

— dry bulb, °C

Source side ent

...

INTERNATIONAL ISO

STANDARD 13256-1

Second edition

2021-05

Water-source heat pumps — Testing

and rating for performance —

Part 1:

Water-to-air and brine-to-air heat

pumps

Pompes à chaleur à eau — Essais et détermination des

caractéristiques de performance —

Partie 1: Pompes à chaleur eau-air et eau glycolée-air

Reference number

©

ISO 2021

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

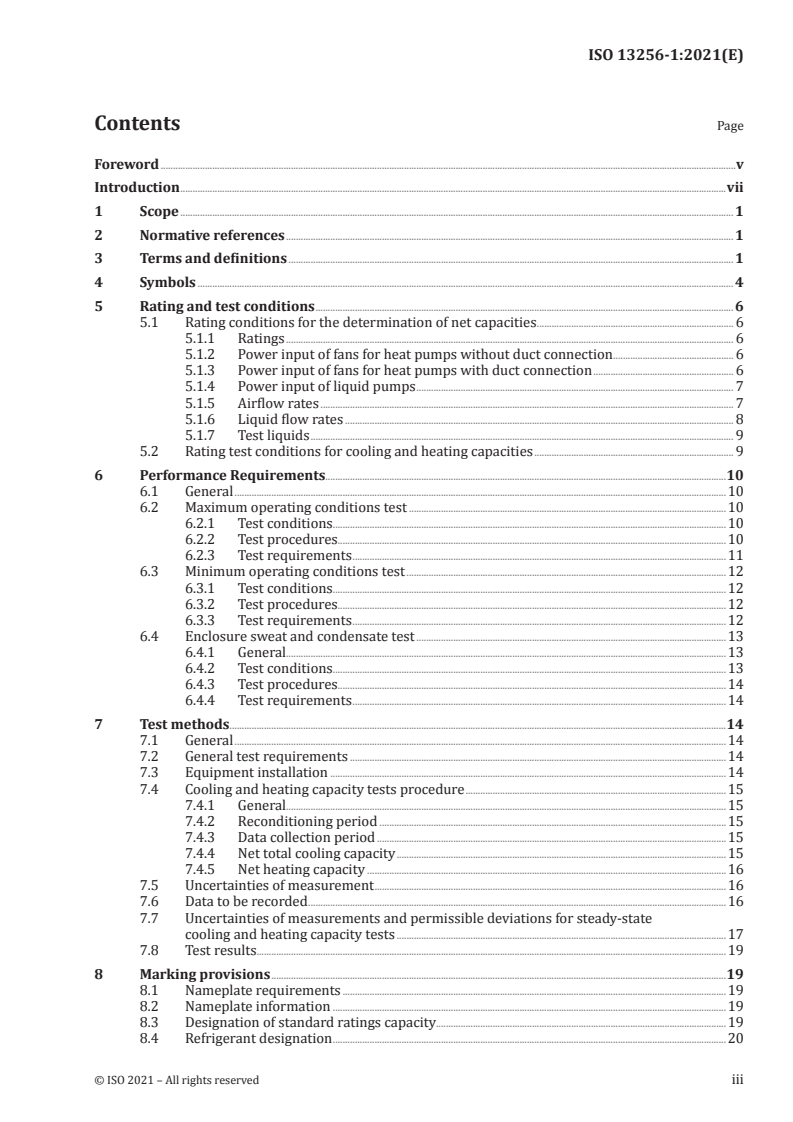

Contents Page

Foreword .v

Introduction .vii

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols . 4

5 Rating and test conditions . 6

5.1 Rating conditions for the determination of net capacities . 6

5.1.1 Ratings . 6

5.1.2 Power input of fans for heat pumps without duct connection . 6

5.1.3 Power input of fans for heat pumps with duct connection . 6

5.1.4 Power input of liquid pumps . 7

5.1.5 Airflow rates . 7

5.1.6 Liquid flow rates . 8

5.1.7 Test liquids . 9

5.2 Rating test conditions for cooling and heating capacities . 9

6 Performance Requirements.10

6.1 General .10

6.2 Maximum operating conditions test .10

6.2.1 Test conditions.10

6.2.2 Test procedures.10

6.2.3 Test requirements .11

6.3 Minimum operating conditions test .12

6.3.1 Test conditions.12

6.3.2 Test procedures.12

6.3.3 Test requirements .12

6.4 Enclosure sweat and condensate test .13

6.4.1 General.13

6.4.2 Test conditions.13

6.4.3 Test procedures.14

6.4.4 Test requirements .14

7 Test methods .14

7.1 General .14

7.2 General test requirements .14

7.3 Equipment installation .14

7.4 Cooling and heating capacity tests procedure .15

7.4.1 General.15

7.4.2 Reconditioning period .15

7.4.3 Data collection period .15

7.4.4 Net total cooling capacity .15

7.4.5 Net heating capacity .16

7.5 Uncertainties of measurement .16

7.6 Data to be recorded .16

7.7 Uncertainties of measurements and permissible deviations for steady-state

cooling and heating capacity tests .17

7.8 Test results.19

8 Marking provisions .19

8.1 Nameplate requirements .19

8.2 Nameplate information .19

8.3 Designation of standard ratings capacity.19

8.4 Refrigerant designation .20

9 Publication of ratings .20

9.1 Published ratings .20

9.2 Additional ratings .20

Annex A (normative) Test requirements .21

Annex B (informative) Airflow measurement .28

Annex C (normative) Indoor air enthalpy test method .35

Annex D (informative) Refrigerant enthalpy test method .38

Annex E (normative) Liquid enthalpy test method .40

Annex F (informative) Correction of fan or pump power input for external static pressures

other than zero .42

Annex G (informative) Additional ratings based upon previous standard version

ISO 13256-1:1998.43

Annex H (informative) Cooling condensate measurements .44

Bibliography .45

iv © ISO 2021 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 86, Refrigeration and air-conditioning,

Subcommittee SC 6, Testing and rating of air-conditioners and heat pumps.

This second edition cancels and replaces the first edition (ISO 13256-1:1998), which has been technically

revised.

The main changes compared to the previous edition are as follows:

— Significant updates to the formatting, symbols, and terms and definitions, have been included to

more closely align with other pertinent ISO standards and the latest ISO requirements.

— The original water loop heat pump (WLHP), ground water heat pump (GWHP) and ground loop

heat pump (GLHP) application rating designations, specifying entering liquid source rating test

conditions, have been replaced with High, Medium, and Low source temperature range conditions to

represent a wider operating map at both standard and partially loaded application rating conditions.

It is now possible, when all three (High, Medium and Low) temperature ranges are specified by the

manufacturer for energy modelling programs to interpolate performance at other entering water

temperatures than those used in the standard.

— Specific antifreeze solution composition requirements have been removed to eliminate prescriptive

language and promote industry innovation of novel and improved antifreeze solutions.

— Airflow testing requirements have been updated to align with the complexities of testing more

sophisticated constant airflow electronically commutated fan motors.

— Testing tolerances and uncertainties have been harmonized with other pertinent ISO standards.

— Annexes have been added and/or significantly updated that harmonize with other pertinent ISO

standards.

A list of all parts in the ISO 13256 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

vi © ISO 2021 – All rights reserved

Introduction

This document covers heating and cooling systems which are generally referred to as “water-source

heat pumps.” These systems generally include an indoor coil with air-moving means, a compressor, and

a refrigerant-to-water or refrigerant-to-brine heat exchanger. A system may provide both heating and

cooling, cooling-only, or heating-only functions.

INTERNATIONAL STANDARD ISO 13256-1:2021(E)

Water-source heat pumps — Testing and rating for

performance —

Part 1:

Water-to-air and brine-to-air heat pumps

1 Scope

1.1 This document establishes performance testing and rating criteria for factory-made residential,

commercial and industrial, electrically-driven, mechanical- compression type, water-to-air and brine-to-

air heat pumps. The requirements for testing and rating contained in this document are based on the use

of matched assemblies.

1.2 Equipment designed for rating at one liquid temperature range under this document may not be

suitable at all liquid temperature ranges covered in this document.

1.3 This document does not apply to the testing and rating of individual assemblies for separate use,

nor to the testing and rating of heat pumps covered in ISO 5151, ISO 13253 or ISO 13256-2.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 817, Refrigerants — Designation and safety classification

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

water-to-air heat pump

brine-to-air heat pump

heat pump which consists of one or more factory-made assemblies which normally include an indoor

conditioning coil with air-moving means, compressor(s), and refrigerant-to-water or refrigerant-to-

brine heat exchanger(s), including means to provide both cooling and heating, cooling-only, or heating-

only functions

Note 1 to entry: When such equipment is provided in more than one assembly, the separated assemblies should

be designed to be used together.

Note 2 to entry: Such equipment may also provide functions of sanitary water heating, air cleaning, dehumidifying,

and humidifying.

3.2

water-loop heat pump

water-to-air heat pump using liquid circulating in a common piping loop functioning as a heat source in

`heating mode and/or heat sink in cooling mode

Note 1 to entry: The temperature of the liquid loop is usually within a range of 10 °C to 30 °C.

3.3

ground-water heat pump

water-to-air heat pump using water pumped from a well, lake, or stream functioning as a heat source in

heating mode and/or heat sink in cooling mode

Note 1 to entry: The temperature of the water is related to the climatic conditions and is generally constant

within the range from 5 °C to 25 °C for deep wells.

3.4

ground-loop heat pump

brine-to-air heat pump using a brine solution circulating through a subsurface piping loop functioning

as a heat source in heating mode and/or heat sink in cooling mode

Note 1 to entry: The heat exchange loop may be placed in horizontal trenches or vertical bores, or be submerged

in a body of surface water.

Note 2 to entry: The temperature of the brine is related to the heat exchange load and climatic conditions and is

generally within a range from –5 °C to 40 °C.

3.5

total cooling capacity

amount of sensible and latent heat that the equipment can remove from the conditioned space in a

defined interval of time

Note 1 to entry: Expressed in units of watts.

3.6

net total cooling capacity

total cooling capacity with fan power adjustment

Note 1 to entry: Expressed in units of watts.

3.7

heating capacity

amount of heat that the equipment can add to the conditioned space in a defined interval of time

Note 1 to entry: Expressed in units of watts.

3.8

net heating capacity

heating capacity with fan power adjustment

Note 1 to entry: Expressed in units of watts.

3.9

rated voltage

voltage shown on the nameplate of the equipment

Note 1 to entry: Expressed in units of volts.

3.10

rated frequency

frequency shown on the nameplate of the equipment

Note 1 to entry: Expressed in units of Hz.

2 © ISO 2021 – All rights reserved

3.11

energy efficiency ratio

EER

ratio of the net total cooling capacity to the effective power input at any given set of rating conditions

Note 1 to entry: Expressed in units of watt per watt.

3.12

coefficient of performance

COP

ratio of the net heating capacity to the effective power input of the equipment at any given set of rating

conditions

Note 1 to entry: Expressed in units of watt per watt.

3.13

standard air

dry air at 20,0 °C and at a standard barometric pressure of 101,325 kPa, having a mass density of

1,204 kg/m

3.14

effective power input

average electrical power input to the equipment within a defined interval of time; i.e. the sum of:

— the power input for operation of the compressor excluding additional electrical heating devices,

— the power input of all control and safety devices of the equipment, and

— the proportional power input of the conveying devices for the transport of the heat transfer media

through the heat pump only (e.g. fans, pumps, whether internal or external, whether provided with

the equipment or not)

Note 1 to entry: Expressed in units of watts.

3.15

latent cooling capacity

amount of latent heat that the equipment can remove from the conditioned space in a defined

interval of time

Note 1 to entry: Expressed in units of watts.

3.16

sensible cooling capacity

amount of sensible heat that the equipment can remove from the conditioned space in a defined

interval of time

Note 1 to entry: Expressed in units of watts.

3.17

brine

heat transfer liquid that has a freezing point lower than the freezing point of water

3.18

external static pressure difference

∆

pe

pressure difference measured between the air (or water/brine) outlet section and the air (or water/

brine) inlet section of the unit, which is available for overcoming the pressure drop of any additional

ducted air (or water/brine) circuit

Note 1 to entry: Expressed in units of pascals.

3.19

internal static pressure difference

∆

pi

pressure difference measured between the air (or water/brine) outlet section and the air (or water/

brine) inlet section of the unit, which corresponds to the total pressure drop of all components on the

air (or water/brine) side of the unit.

Note 1 to entry: Expressed in units of pascals.

3.20

fixed capacity heat pump

equipment which does not have possibility to change its capacity

Note 1 to entry: This definition applies to each cooling and heating operation individually.

3.21

two-stage capacity heat pump

equipment where the capacity is varied by two steps

Note 1 to entry: This definition applies to each cooling and heating operation individually.

3.22

multi-stage capacity heat pump

equipment where the capacity is varied by three or four steps

Note 1 to entry: This definition applies to each cooling and heating operation individually.

3.23

variable capacity heat pump

equipment where the capacity is varied by five or more steps to represent continuously variable

capacity

Note 1 to entry: This definition applies to each cooling and heating operation individually.

3.24

standard rating conditions

operating conditions while establishing the standard rating net cooling and/or heating capacities

Note 1 to entry: These conditions correspond to an operation of the heat pump at full capacity, in relation to the

source side.

3.25

application rating conditions

operating conditions while establishing additional cooling and/or heating capacities

Note 1 to entry: These conditions correspond to an operation of the heat pump at reduced capacity, in relation to

the source side.

3.26

standard rating capacity

net cooling and/or heating capacity measured at standard rating conditions

4 Symbols

Symbol Description and Units

A nozzle area, m

n

α pressure ratio

C nozzle discharge coefficient

d

c specific heat of dry air entering indoor side, J/kg·K

pa1

4 © ISO 2021 – All rights reserved

Symbol Description and Units

c specific heat of dry air leaving indoor side, J/kg·K

pa2

c specific heat of liquid, J/kg·K

pf

D nozzle throat diameter, mm

n

Δ measured internal static pressure difference, Pa

pi

Δ measured external static pressure difference, Pa

pe

h specific enthalpy of air entering indoor air-side, J/kg of dry air

a1

h specific enthalpy of air leaving indoor air-side, J/kg of dry air

a2

h specific enthalpy of refrigerant entering indoor side, J/kg

r1

h specific enthalpy of refrigerant leaving indoor side, J/kg

r2

K latent heat of vaporization of water, J/kg (2,47 x 10 , J/kg at 15 °C)

η representative efficiency

P power input to indoor-side compartment, W

i

p pressure, at nozzle throat, kPa absolute

n

p velocity pressure at nozzle throat or static pressure difference across nozzle, Pa

v

ϕ total power input

c

ϕ fan power adjustment, W

fa

ϕ latent cooling capacity, (indoor air-side data), W

lci

ϕ net cooling capacity, W

nc

ϕ net heating capacity, W

nh

ϕ sensible cooling capacity, (air-side data), W

sci

ϕ total cooling capacity, (airside data), W

tci

ϕ total cooling capacity, (liquid side data), W

tco

ϕ total heating capacity, (air-side data), W

thi

ϕ total heating capacity, (liquid side data), W

tho

q measured volumetric flow rate, l/s

q measured airflow rate at standard air conditions, m /s

a

q air mass flow rate, kg/s

m

q refrigerant and oil mixture flow rate, m /s

ro

q air volume flow rate, standard air, m /s

s

q air-volume flow rate, calculated, m /s

V

q air volume flow rate, measured, m /s

Vi

q flow rate, liquid condensate (steam), kg/s

wc

Re Reynolds number

t temperature, air entering indoor side, dry bulb, °C

a1

t temperature, air leaving indoor side, dry bulb, °C

a2

t temperature, liquid entering equipment, °C

f3

t temperature, liquid leaving equipment, °C

f4

v kinematic viscosity of air

v specific volume of dry air at conditions existing at nozzle at standard barometric pressure, m /kg

n

specific volume of air at nozzle, m /kg of air-water vapour mixture

v

n

W mass of cylinder and bleeder assembly, empty, g

W mass of cylinder and bleeder assembly, with sample, g

W mass of cylinder and bleeder assembly, with oil from sample, g

w Liquid mass flow rate, kg/s

f

w specific humidity, air entering indoor side, kg/kg of dry air

i1

Symbol Description and Units

w specific humidity, air leaving indoor side, kg/kg of dry air

i2

W specific humidity at nozzle inlet, kg/kg of dry air

n

X concentration of oil to refrigerant-oil mixture

X mass ratio, refrigerant to refrigerant-oil mixture

r

Y expansion factor

5 Rating and test conditions

5.1 Rating conditions for the determination of net capacities

5.1.1 Ratings

Ratings shall be established at the test conditions specified in 5.2, using the test procedures described

in Clause 7. Ratings relating to cooling and heating capacities shall be net values (see 7.4.4 and 7.4.5),

including the effects of circulating-fan heat (see 7.4.4 and 7.4.5), but excluding any supplementary heat.

Energy efficiency ratios shall be based on the effective power input as defined in 3.11.

5.1.2 Power input of fans for heat pumps without duct connection

In the case of heat pumps which are not designed for duct connection and which are equipped with

an integral fan, all power consumed by the fans shall be included in the effective power input to the

heat pump.

5.1.3 Power input of fans for heat pumps with duct connection

5.1.3.1 If no fan is provided with the heat pump, a fan power adjustment is to be included in the

effective power input to the heat pump, using Formula (1):

q × Δ

()

api

φ = (1)

fa

η

where

ϕ is the fan power adjustment, in W;

fa

η = 0,3 by convention;

∆ is the absolute value of the measured internal static pressure difference, in Pa;

pi

q is the airflow rate at standard air conditions, in m /s.

a

This value shall be added to the heating capacity and subtracted from the cooling capacity.

5.1.3.2 If a fan is an integral part of a heat pump, only the portion of the fan power required to overcome

the internal resistance shall be included in the effective power input to the heat pump. The fraction which

is to be excluded from the total power consumed by the fan shall be calculated using Formula (2):

q ×Δ

ape

φ = (2)

fa

η

where

6 © ISO 2021 – All rights reserved

ϕ is the fan power adjustment, in W;

fa

η = 0,3 by convention;

∆ is the measured external static pressure difference, in Pa;

pe

q is the airflow rate at standard air conditions, in m /s.

a

This value shall be subtracted from the heating capacity and added to the cooling capacity.

5.1.4 Power input of liquid pumps

5.1.4.1 If no liquid pump is provided with the heat pump, a pump power adjustment is to be included

in the effective power consumed by the heat pump, using Formula (3):

q× Δ

()

pi

φ = (3)

pa

η

where

ϕ is the pump power adjustment, in W;

pa

η = 0,3 by convention;

Δ is the absolute value of the measured internal static pressure difference, in Pa;

pi

q is the measured volumetric fluid flow rate, in m /s.

5.1.4.2 If a liquid pump is an integral part of the heat pump, only the portion of the pump power

required to overcome the internal resistance shall be included in the effective power input to the

heat pump. The fraction which is to be excluded from the total power consumed by the pump shall be

calculated using Formula (4):

q×Δ

pe

φ = (4)

pa

η

where:

ϕ is the pump power adjustment, in W;

pa

η = 0,3 by convention;

Δ is the measured external static pressure difference, in Pa;

pe

q is the measured volumetric fluid flow rate, in m /s.

5.1.5 Airflow rates

5.1.5.1 All standard ratings shall be determined at airflow rates as described below. All airflow rates

shall be expressed as cubic meters per second of standard air as defined in 3.10.

5.1.5.2 The manufacturer shall specify a single airflow rate for all tests required in this document

unless automatic adjustment of airflow rate is provided by the equipment. A separate control signal

output for each step of airflow rate shall be considered as an automatic adjustment.

5.1.5.3 For ducted heat pumps which have integral, non-constant airflow, single or multi-speed fans

the airflow rate shall be set as specified by the manufacturer. The external static pressure shall not be less

than the value defined by Table 1. If the unit is unable to attain specified airflow and has an adjustable

speed, it shall be adjusted to the lowest speed that provides at least the external static defined in Table 1

at the specified airflow rate. If the external static at the rated airflow rate is less than the value defined by

Table 1, then the test shall be run at the airflow achieved at the minimum external static pressure.

5.1.5.4 Ducted heat pumps which have integral constant airflow fan shall be tested at the manufacturers'

specified airflow and external static pressure. Specified external static shall not be less than specified in

Table 1. If the external static at the rated airflow rate is less than the value defined by Table 1, then the

test shall be run at the airflow achieved at the minimum external static pressure.

Table 1 — External static pressure requirement

Standard capacity Minimum external static

a

ratings pressure

kW Pa

0 < Q < 8 25

8 ≤ Q < 12 37

12 ≤ Q < 20 50

20 ≤ Q < 30 62

30 ≤ Q < 45 75

45 ≤ Q < 82 100

82 ≤ Q < 117 125

117 ≤ Q < 147 150

Q > 147 175

a

For equipment tested without an air filter installed, the minimum external static

pressure shall be increased by 10 Pa.

5.1.5.5 Ducted heat pumps which do not have integral fans but which are rated for general use with

a variety of air moving devices, shall be tested at the airflow rates specified by the manufacturer in the

published ratings. However, the pressure drop across the indoor coil assembly and the recommended

enclosures and attachment means shall not exceed 75 Pa.

5.1.5.6 If the air enthalpy method is used, non-ducted heat pumps shall be tested at the airflow rates

obtained at zero external static pressure difference.

5.1.6 Liquid flow rates

5.1.6.1 General

All standard ratings shall be determined at a liquid flow rate described below, expressed as cubic

meters per second.

5.1.6.2 Source side flowrate

The manufacturer shall specify a flow rate for all of the tests performed unless automatic adjustment

of the liquid flow rate is provided by the equipment. A separate control signal output for each step of

liquid flow rate will be considered as an automatic adjustment.

5.1.6.3 Heat pumps with integral liquid pumps shall be tested at the liquid flow rate specified by

the manufacturer or that is obtained at zero external static pressure difference (within the tolerance

specified in Table 11), whichever provides the lower liquid flow rate.

5.1.6.4 Heat pumps without integral liquid pumps shall be tested at the flow rate specified by the

manufacturer.

8 © ISO 2021 – All rights reserved

5.1.7 Test liquids

5.1.7.1 The test liquid for all tests except low temperature heating tests shall be water or brine of a

composition and concentration specified by the manufacturer.

5.1.7.2 The test liquid for low temperature heating tests (H1) shall be brine of a composition and

concentration specified by the manufacturer.

5.1.7.3 The test liquid shall be sufficiently free of gas to ensure that the measured result is not

influenced by the presence of gas.

5.2 Rating test conditions for cooling and heating capacities

5.2.1 The test conditions for the determination of cooling capacities are specified in Table 2. The test

conditions for determination of heating capacities are specified in Table 3.

NOTE Previous rating conditions can be found in Annex G, Tables G.1 and G.2

5.2.2 Fixed capacity heat pumps shall be rated at standard rating conditions for one or several cooling

and/or heating conditions defined by Table 2 and 3.

5.2.3 Two stage and multi-stage capacity heat pumps shall be rated at maximum capacity at standard

rating conditions and at minimum capacity at application rating conditions for one or several cooling

and/or heating conditions as defined by Table 2 and 3. Additional ratings may be applied at application

rating conditions with different capacity levels using Tables 2 and 3.

5.2.4 Variable capacity heat pumps shall be rated at the maximum continuous capacity allowed

by the controls at standard rating conditions and at the minimum capacity allowed by the controls at

application rating conditions. Additional ratings may be applied at application rating conditions with

different capacity levels using Tables 2 and 3.

Table 2 — Rating test conditions for the determination of cooling capacity

C3 C2 C1

high source tem- medium source tem- Low source tem-

perature perature perature

Air entering load side 27 27 27

— dry bulb, °C 19 19 19

— wet bulb, °C

Air surrounding unit installed indoor 27 27 27

— dry bulb, °C 19 19 19

— wet bulb, °C

Standard rating conditions 30 20 10

Source side entering temperature, °C

Application rating conditions 25 15 5

Source side entering temperature, °C

a

Frequency Rated Rated Rated

b

Voltage Rated Rated Rated

a

Equipment with dual-rated frequencies shall be tested at each frequency.

b

Equipment with dual-rated voltages shall be tested at both voltages or at the lower of the two voltages if only a single

rating is published.

Table 3 — Rating test conditions for the determination of heating capacity

H3 H2 H1

high source tem- medium source tem- low source tem-

perature perature perature

Air entering load side 20 20 20

— dry bulb, °C 15 15 15

— wet bulb, °C (maximum)

Air surrounding unit installed indoor 20 20 20

— dry bulb, °C_ 15 15 15

— wet bulb, °C (maximum)

Standard rating 20 10 0

Conditions

Source side entering temperature, °C

Application rating conditions 25 15 5

Source side entering temperature, °C

a

Frequency Rated Rated Rated

b

Voltage Rated Rated Rated

a

Equipment with dual-rated frequencies shall be tested at each frequency.

b

Equipment with dual-rated voltages shall be tested at both voltages or at the lower of the two voltages if only a single

rating is published.

6 Performance Requirements

6.1 General

6.1.1 To comply with this document, water-to-air and brine-to-air heat pumps shall meet the applicable

requirements of this document.

6.1.2 For heat pumps with capacity control, the performance requirements tests shall be conducted at

the maximum capacity as determined in standard rating conditions.

6.2 Maximum operating conditions test

6.2.1 Test conditions

For maximum operating conditions tests, a single heating and/or cooling test when applicable shall be

conducted at the test conditions established for the specific rating temperature range (see 5.2) specified

in Tables 4 and 5.

6.2.2 Test procedures

The equipment shall be operated continuously for one hour after the specified conditions have been

established at each specified voltage level.

The 110 % voltage test shall be conducted prior to the 90 % voltage test.

All power to the equipment shall be cut off for 3 min. at the conclusion of the one hour test at the 90 %

voltage level and then restored for one hour.

10 © ISO 2021 – All rights reserved

6.2.3 Test requirements

Heat pumps shall meet the following requirements when operating at the conditions specified in

Tables 4 and 5.

During the entire test, the equipment shall operate without any indication of damage.

During the test period specified in 6.2.2., the motor overload protective device may trip only during the

first 5 min of operation after the shutdown period of 3 min. During the remainder of the test period, no

motor overload protective device shall trip. For those models so designed that resumption of operation

does not occur within the first 5 min after the initial trip, the equipment may remain out of operation

for no longer than 30 min. It shall then operate continuously for the remainder of the test period.

Table 4 — Maximum cooling test conditions

Rated Temperature Range: C3 C2 C1

high source tem- medium source tem- low source temper-

perature perature ature

Air entering load side 32 32 32

— dry bulb, °C 23 23 23

— wet bulb, °C

Air surrounding unit 32 32 32

— dry bulb, °C

Source side entering temperature, °C 40 40 40

a

Frequency Rated Rated Rated

b

Voltage 1) 90 % and 110 % 1) 90 % and 110 % 1) 90 % and 110 %

of rated voltage of rated voltage of rated voltage

for equipment for equipment for equipment

with a single with a single with a single

nameplate rating, nameplate rating, nameplate rating,

2) 90 % of 2) 90 % of 2) 90 % of

minimum minimum minimum

voltage and voltage and voltage and

110 % of 110 % of 110 % of

maximum maximum maximum

voltage for voltage for voltage for

equipment with equipment with equipment with