ISO 1920-13:2018

(Main)Testing of concrete — Part 13: Properties of fresh self compacting concrete

Testing of concrete — Part 13: Properties of fresh self compacting concrete

This document specifies procedures for testing fresh self-compacting concrete. It specifies the following test methods: determination of consistence (slump flow test), V funnel test, L box test, sieve segregation test, J-ring test and self-compactability test.

Essais du béton — Partie 13: Titre manque

General Information

- Status

- Published

- Publication Date

- 14-Jun-2018

- Technical Committee

- ISO/TC 71/SC 1 - Test methods for concrete

- Drafting Committee

- ISO/TC 71/SC 1 - Test methods for concrete

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 28-Nov-2023

- Completion Date

- 12-Feb-2026

Relations

- Consolidated By

ISO 23371:2022 - Anaesthetic and respiratory equipment — Cuff pressure indication, control and regulation devices - Effective Date

- 06-Jun-2022

Overview

ISO 1920-13:2018 - "Testing of concrete - Part 13: Properties of fresh self compacting concrete" specifies standardized procedures for testing the fresh properties of self‑compacting concrete (SCC). The document covers laboratory and site test methods used to evaluate fresh SCC performance characteristics such as flowability, viscosity, passing ability and segregation resistance. It is intended for use in quality control, mix development and conformity assessment of SCC.

Key topics and test methods

This part of the ISO 1920 series defines procedures and reporting requirements for the following test methods:

Slump‑flow test

- Measures the spread (slump‑flow) and the time to reach a specified spread (t500). Indicates flowability in the absence of obstructions and provides information on yield stress and relative viscosity. (Note: the slump‑flow test is not suitable when maximum aggregate size exceeds 40 mm.)

V‑funnel test

- Used to assess flow time/viscosity of SCC under flow conditions.

L‑box test

- Evaluates the passing ability of SCC - its capacity to flow through tight openings (e.g., congested reinforcement) without blocking.

Sieve segregation test

- Determines segregation resistance, i.e., the ability of fresh concrete to remain homogeneous and not separate.

J‑ring test

- Assesses both passing ability and flow spread; the standard includes expressions of results such as passing ability (PJ), flow spread (SF) and flow time (t500).

Drop‑and‑fill (self‑compactability) test

- Measures the capability of SCC to fill formwork and flow around obstacles; includes filling time and filling height metrics.

The standard also defines key terms (e.g., self‑compacting concrete, passing ability, segregation resistance, slump‑flow, viscosity), apparatus, sampling and reporting requirements, and discusses repeatability and reproducibility for each method.

Practical applications and who uses ISO 1920-13

ISO 1920-13:2018 is used by:

- Concrete laboratories and quality control technicians for routine acceptance testing of SCC.

- Mix designers and material suppliers to validate SCC mixes and optimize admixture dosages.

- Contractors and site engineers to confirm that SCC will fill formwork and pass reinforcement without vibration.

- Research institutions and standards bodies for method comparison and development.

- Specifiers and clients to set performance requirements in construction contracts and technical specifications.

Typical applications include precast production, heavily reinforced structural elements, complex formwork, and projects where vibration is undesirable or impractical.

Related standards

- ISO 1920-1 - Testing of concrete - Part 1: Sampling of fresh concrete

- ISO 1920-2 - Testing of concrete - Part 2: Properties of fresh concrete (slump test referenced)

- ISO 3310-2 - Test sieves - Technical requirements (for sieve segregation test)

Keywords: ISO 1920-13, self‑compacting concrete testing, SCC testing methods, slump‑flow test, V‑funnel, L‑box, J‑ring, sieve segregation test, self‑compactability test.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

ISO 1920-13:2018 is a standard published by the International Organization for Standardization (ISO). Its full title is "Testing of concrete — Part 13: Properties of fresh self compacting concrete". This standard covers: This document specifies procedures for testing fresh self-compacting concrete. It specifies the following test methods: determination of consistence (slump flow test), V funnel test, L box test, sieve segregation test, J-ring test and self-compactability test.

This document specifies procedures for testing fresh self-compacting concrete. It specifies the following test methods: determination of consistence (slump flow test), V funnel test, L box test, sieve segregation test, J-ring test and self-compactability test.

ISO 1920-13:2018 is classified under the following ICS (International Classification for Standards) categories: 91.100.30 - Concrete and concrete products. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 1920-13:2018 has the following relationships with other standards: It is inter standard links to ISO 23371:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 1920-13:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 1920-13

First edition

2018-06

Testing of concrete —

Part 13:

Properties of fresh self compacting

concrete

Essais du béton —

Partie 13: Titre manque

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

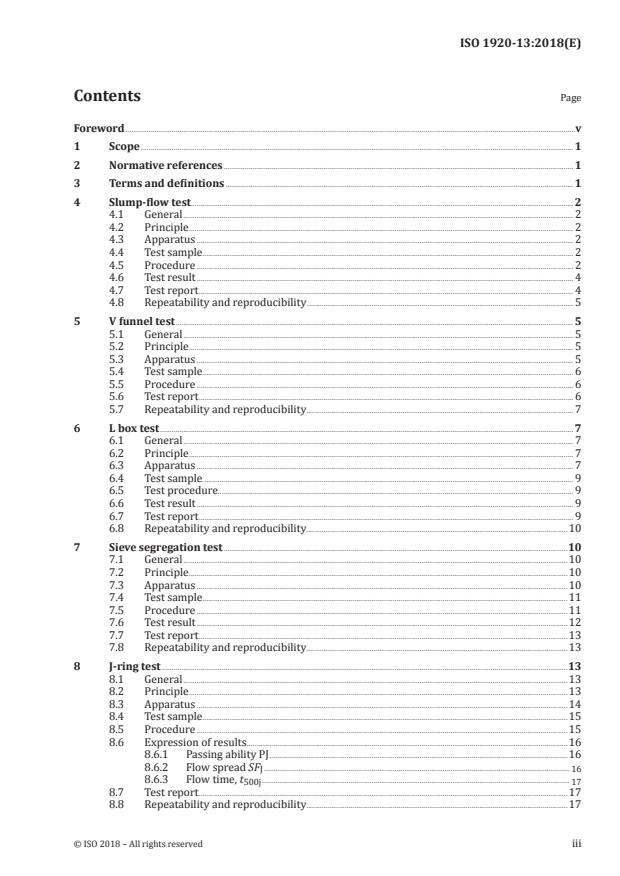

Contents Page

Foreword .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Slump-flow test. 2

4.1 General . 2

4.2 Principle . 2

4.3 Apparatus . 2

4.4 Test sample . 2

4.5 Procedure . 2

4.6 Test result . 4

4.7 Test report . 4

4.8 Repeatability and reproducibility. 5

5 V funnel test . 5

5.1 General . 5

5.2 Principle . 5

5.3 Apparatus . 5

5.4 Test sample . 6

5.5 Procedure . 6

5.6 Test report . 6

5.7 Repeatability and reproducibility. 7

6 L box test . 7

6.1 General . 7

6.2 Principle . 7

6.3 Apparatus . 7

6.4 Test sample . 9

6.5 Test procedure . 9

6.6 Test result . 9

6.7 Test report . 9

6.8 Repeatability and reproducibility.10

7 Sieve segregation test .10

7.1 General .10

7.2 Principle .10

7.3 Apparatus .10

7.4 Test sample .11

7.5 Procedure .11

7.6 Test result .12

7.7 Test report .13

7.8 Repeatability and reproducibility.13

8 J-ring test .13

8.1 General .13

8.2 Principle .13

8.3 Apparatus .14

8.4 Test sample .15

8.5 Procedure .15

8.6 Expression of results .16

8.6.1 Passing ability PJ .16

8.6.2 Flow spread SF .

J 16

8.6.3 Flow time, t .

500j 17

8.7 Test report .17

8.8 Repeatability and reproducibility.17

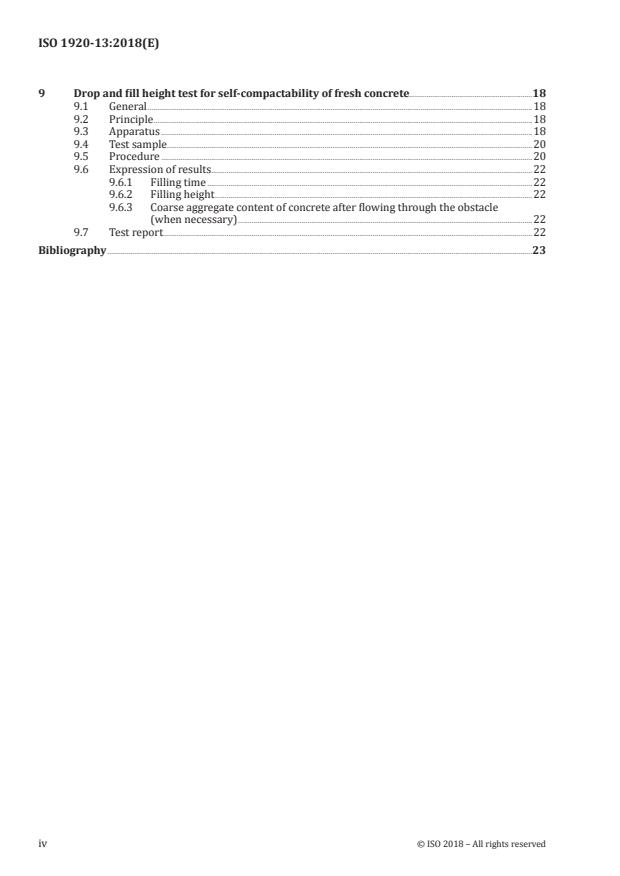

9 Drop and fill height test for self-compactability of fresh concrete.18

9.1 General .18

9.2 Principle .18

9.3 Apparatus .18

9.4 Test sample .20

9.5 Procedure .20

9.6 Expression of results .22

9.6.1 Filling time .22

9.6.2 Filling height .22

9.6.3 Coarse aggregate content of concrete after flowing through the obstacle

(when necessary) .22

9.7 Test report .22

Bibliography .23

iv © ISO 2018 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 71, Concrete, reinforced concrete and pre-

stressed concrete, Subcommittee SC 1, Test methods for concrete.

A list of all parts in the ISO 1920 series can be found on the ISO website.

INTERNATIONAL STANDARD ISO 1920-13:2018(E)

Testing of concrete —

Part 13:

Properties of fresh self compacting concrete

1 Scope

This document specifies procedures for testing fresh self-compacting concrete. It specifies the following

test methods: determination of consistence (slump flow test), V funnel test, L box test, sieve segregation

test, J-ring test and self-compactability test.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1920-1, Testing of concrete — Part 1: Sampling of fresh concrete

ISO 1920-2, Testing of concrete — Part 2: Properties of fresh concrete

ISO 3310-2, Test sieves — Technical requirements and testing — Part 2: Test sieves of perforated metal plate

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at http: //www .electropedia .org/

3.1

self-compacting concrete

SCC

innovative concrete that does not require vibration for placing and compaction because it is able to flow

under its own weight, completely filing formwork and achieving full compaction, even in the presence

of congested reinforcement

3.2

passing ability

ability of fresh concrete to flow through tight openings such as spaces between steel reinforcing bars

without segregation or blocking

3.3

segregation resistance

ability of fresh concrete to remain homogeneous in composition while in its fresh state

3.4

slump flow

mean diameter of the spread of fresh concrete from a standardized slump cone

3.5

viscosity

resistance to flow of fresh concrete once flow has started

4 Slump-flow test

4.1 General

This test specifies the procedure for determining the slump-flow and t time for self-compacting

concrete. The test is not suitable when the maximum size of the aggregate exceeds 40 mm.

4.2 Principle

The slump-flow test is an indication of the flowability of self-compacting concrete in the absence of

obstructions. It is based on the slump test described in ISO 1920-2. The flowability is evaluated by

measuring the spreading maximum diameter, d , and the time it reaches the spreading diameter of

max

500 mm, t . The d of spreading is a measure of the self-compacting concrete flow range when

500 max

subjected to load from its own weight. It is an indication of the yield stress of the self-compacting

concrete. The t time is a measure of the speed of flow and an indication of the relative viscosity of the

self-compacting concrete. The result is an indication of the filling ability of self-compacting concrete.

The fresh concrete is poured into a cone as specified for the ISO 1920-2 slump test. When the cone is

withdrawn upwards, the time from commencing upward movement of the cone to when the concrete

has flowed to a diameter of 500 mm is measured; this is the t time. The largest diameter of the flow

spread of the concrete and the diameter of the spread at right angles to it are then measured and the

mean is the slump-flow.

4.3 Apparatus

4.3.1 Mould, in accordance with ISO 1920-2:2016, 4.3.2.1 (see Figure 1).

4.3.2 Rule or measuring tape, of minimum length 1 000 mm and having sub-divisions not greater

than 5 mm along its entire length.

4.3.3 Stop watch, capable of measuring to 0,1 s.

4.3.4 Spirit level, for checking horizontality of base plate prior to commencing the test.

4.3.5 Container, to hold the test sample and having a volume of at least 10 l.

4.3.6 Collar, (optional) having a mass of at least 9 kg (see Figure 2).

NOTE The collar allows the test to be carried out by one person.

4.4 Test sample

The sample shall be obtained in accordance with ISO 1920-1.

4.5 Procedure

Place the baseplate on a flat and horizontal surface free from external vibration or shock. Check the top

surface for horizontality using the spirit level. Clean the table and the cone and dampen immediately

prior to testing, but keep free from excess moisture.

Fit the collar to the cone if being used.

2 © ISO 2018 – All rights reserved

Place the cone centrally within the 200 mm circle on the baseplate and hold in position by standing on

the foot pieces (or use the collar), ensuring that no concrete can leak from under the cone.

Fill the cone in one operation without any agitation or mechanical compaction, and strike off surplus

from the top of the cone. Allow the filled cone to stand for not more than 30 s; during this time remove

any spilled concrete from the baseplate.

Lift the cone vertically in 1 s to 3 s in one movement without interfering with the flow of concrete. If the

t time has been requested, start the stop watch immediately the cone ceases to be in contact with the

baseplate and record the time taken to the nearest 0,1 s for the concrete to first touch the 500 mm circle

After the flow of concrete has stabilized without disturbing the baseplate or concrete, measure the

largest diameter of the flow spread and record as d to the nearest 10 mm. Then measure the diameter

of the flow spread at right angles to d to the nearest 10 mm and record as d to the nearest 10 mm. If the

1 2

difference between d and d is greater than 50 mm another sample shall be taken and the procedure

1 2

repeated.

If two consecutive tests show the difference between d and d to be greater than 50 mm, the concrete

1 2

lacks the necessary flowability for the slump-flow test to be suitable.

Check the concrete spread for signs of segregation and report under item 4.6, f) in a qualitative way, e.g.

no indication of segregation, strong indication of segregation.

NOTE Signs of segregation include a ring of cement paste/mortar and segregated coarse aggregate in the

central area.

Dimensions in millimetres

Figure 1 — Baseplate

Dimensions in millimetres

Figure 2 — Example of dimensions of a steelwighted collar

4.6 Test result

The slump-flow, SF, is the mean of d and d , expressed to the nearest 10 mm, given by Formula (1).

1 2

dd+

()

SF = (1)

where

SF is the slump-flow, in millimetres;

d is the largest diameter of flow spread, in millimetres;

d is the flow spread at 90° to d , in millimetres.

2 1

The t time is reported to the nearest 0,5 s.

4.7 Test report

The test report shall include:

a) the identification of the test sample;

b) the location where the test was performed;

c) the date and time of test;

d) the slump-flow, SF, to the nearest 5 mm;

e) the t time, to the nearest 0,1 s (when requested);

f) any indication of segregation of the concrete;

g) any deviation from the standard test method;

h) a declaration by the person technically responsible for the test that it was carried out in accordance

with this document, except as noted in g).

The report may include:

— the temperature of the concrete at the time of test;

4 © ISO 2018 – All rights reserved

— the age of concrete at time of test (if known).

4.8 Repeatability and reproducibility

The repeatability, r, and reproducibility, R, have been determined by a programme including eight

laboratories, 16 operators and two replicates, and interpreted in accordance with ISO 5725-2.

The resulting values for r and R are given in Tables 1 and 2.

Table 1 — Repeatability and reproducibility for typical values of Slump-flow

Slump-flow, SF

<600 600–750 >750

mm

Repeatability, r n/a 42 22

Reproducibility, R n/a 43 28

Table 2 — Repeatability and reproducibility for typical values of t times

t time

<3,5 3,5–6,0 >6,0

seconds

Repeatability, r 0,66 1,18 n/a

Reproducibility, R 0,88 1,18 n/a

5 V funnel test

5.1 General

This test specifies the procedure for determining the V-funnel flow time for self-compacting concrete.

The test is not suitable when the maximum size of the aggregate exceeds 25 mm.

5.2 Principle

The relative viscosity is indicated by the time the concrete to flow out of the funnel. And the filling

ability is assessed by the time the concrete takes, under the action of its own weight, to flow through

section variation of mold. A V-shaped funnel is filled with fresh concrete and the time taken for the

concrete to flow out of the funnel is measured and recorded as the V-funnel flow time.

5.3 Apparatus

5.3.1 V-funnel, made to the internal dimensions and tolerances (see Figure 3), fitted with a quick

release, watertight hinged or sliding gate at its base and supported by a frame so that the top of the

funnel is horizontal with sufficient clearance beneath the gate to place the container underneath.

The V-funnel shall be made from metal not prone to be readily attacked by cement paste or be liable to

rusting; the surfaces shall be smooth, and not readily attacked by cement paste or be liable to rusting.

If the funnel is made from other materials, in-use performance test data shall be available which

demonstrates long-term equivalence with metal.

The funnels specified in national standards may be used where applicable.

5.3.2 Container, to hold the test sample and having a volume not less than 12 l.

5.3.3 Stop watch, capable of measuring to 0,1 s.

5.3.4 Straight edge, for striking off concrete level with the top of the funnel.

Dimensions in millimetres

Key

1 hinged or sliding gate

Figure 3 — V-funnel

5.4 Test sample

A sample of at least 12 l shall be obtained in accordance with ISO 1920-1.

5.5 Procedure

Clean the funnel and bottom gate, then dampen all the inside surface including the gate. Close the gate

and pour the sample of concrete into the funnel in one operation, without any agitation or mechanical

compaction, then strike off the top with the straight edge so that the concrete is level with the top of the

funnel. Place the container under the funnel in order to collect the concrete. After a delay of (10 ± 2) s

from filling the funnel, open the gate quickly and measure the time, t , to 0,1 s, from opening the gate to

v

when it is possible to see vertically through the funnel into the container below for the first time. The

time t is the V-funnel flow time.

v

The flow of concrete from the funnel shall be continuous. If a blockage occurs, the test shall be

repeated. If a second blockage occurs, the concrete lacks the necessary viscosity and filling ability of

self-compacting concrete. Report if a blockage has occurred.

5.6 Test report

The test report shall include:

a) the identification of the test sample;

b) the location where the test was performed;

c) the date and time of test;

d) the V-funnel flow time, t , to the nearest 0,5 s;

v

e) any deviation from the standard test method;

f) a declaration by the person technically responsible for the test that it was carried out in accordance

with this document, except as noted in e).

6 © ISO 2018 – All rights reserved

The report may include:

— the temperature of the concrete at the time of test;

— the age of concrete at time of test (if known).

5.7 Repeatability and reproducibility

The repeatability, r, and reproducibility, R, have been determined by a programme including

10 laboratories, 20 operators and two replicates, and interpreted in accordance with ISO 5725-2.

The resulting values for r and R are given in Table 3.

Table 3 — Repeatability and reproducibility for typical values of V-funnel flow time

V-funnel flow time, t

v

3,0 5,0 8,0 12,0 >15,0

seconds

Repea

...

© ISO 2018 – All rights reserved

ISO 1920‐13:2018(E)

ISO TC 71/SC 01/WG 2

Secretariat: SII

Testing of concrete —Part 13: Properties of fresh self‐compacting concrete

Deleted:

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or

utilized otherwise in any form or by any means, electronic or mechanical, including photocopying,

or posting on the internet or an intranet, without prior written permission. Permission can be

requested from either ISO at the address below or ISO’s member body in the country of the

requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH‐1214 Vernier, Geneva, Switzerland

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

copyright@iso.org

www.iso.org

2 © ISO 2018 – All rights reserved

Contents

Foreword . Error! Bookmark not defined. Deleted: ¶

Introduction. Error! Bookmark not defined.

1 Scope . Error! Bookmark not defined.

2 Normative references . Error! Bookmark not defined.

3 Terms and definitions . Error! Bookmark not defined.

4 Slump-flow test . Error! Bookmark not defined.

4.1 General . Error! Bookmark not defined.

4.2 Principle . Error! Bookmark not defined.

4.3 Apparatus . Error! Bookmark not defined.

4.3.1 Baseplate . Error! Bookmark not defined.

4.3.2 Rule or measuring tape . Error! Bookmark not defined.

4.3.3 Stop watch . Error! Bookmark not defined.

4.3.4 Spirit level . Error! Bookmark not defined.

4.3.5 Container . Error! Bookmark not defined.

4.3.6 Collar (optional) . Error! Bookmark not defined.

4.4 Test sample . Error! Bookmark not defined.

4.5 Procedure . Error! Bookmark not defined.

4.6 Test result . Error! Bookmark not defined.

4.7 Test report . Error! Bookmark not defined.

4.8 Repeatability and reproducibility . Error! Bookmark not defined.

5 V funnel test . Error! Bookmark not defined.

5.1 General . Error! Bookmark not defined.

5.2 Principle . Error! Bookmark not defined.

5.3 Apparatus . Error! Bookmark not defined.

5.3.1 V-funnel . Error! Bookmark not defined.

5.3.2 Container . Error! Bookmark not defined.

5.3.3 Stop watch . Error! Bookmark not defined.

5.3.4 Straight edge . Error! Bookmark not defined.

5.4 Test sample . Error! Bookmark not defined.

5.5 Procedure . Error! Bookmark not defined.

5.6 Test report . Error! Bookmark not defined.

5.7 Repeatability and reproducibility . Error! Bookmark not defined.

6 L box test . Error! Bookmark not defined.

6.1 General . Error! Bookmark not defined.

6.2 Principle . Error! Bookmark not defined.

6.3 Apparatus . Error! Bookmark not defined.

6.3.1 L box . Error! Bookmark not defined.

6.3.2 Rule or measuring tape . Error! Bookmark not defined.

6.3.3 Containers . Error! Bookmark not defined.

6.3.4 Spirit level . Error! Bookmark not defined.

6.3.5 Straight edge . Error! Bookmark not defined.

6.4 Test sample . Error! Bookmark not defined.

6.5 Test procedure . Error! Bookmark not defined.

6.6 Test result . Error! Bookmark not defined.

6.7 Test report . Error! Bookmark not defined.

6.8 Repeatability and reproducibility . Error! Bookmark not defined.

© ISO 2018 – All rights reserved 3

Deleted:

7 Sieve segregation test . Error! Bookmark not defined.

7.1 General . Error! Bookmark not defined.

7.2 Principle . Error! Bookmark not defined.

7.3 Apparatus . Error! Bookmark not defined.

7.3.1 Perforated plate sieve . Error! Bookmark not defined.

7.3.2 Balance . Error! Bookmark not defined.

7.3.3 Sample container . Error! Bookmark not defined.

7.3.4 Timer . Error! Bookmark not defined.

7.3.5 Thermometer . Error! Bookmark not defined.

7.4 Test sample . Error! Bookmark not defined.

7.5 Procedure . Error! Bookmark not defined.

7.6 Test result . Error! Bookmark not defined.

7.7 Test report . Error! Bookmark not defined.

7.8 Repeatability and reproducibility . Error! Bookmark not defined.

8 J-ring test . Error! Bookmark not defined.

8.1 General . Error! Bookmark not defined.

8.2 Principle . Error! Bookmark not defined.

8.3 Apparatus . Error! Bookmark not defined.

8.3.1 General . Error! Bookmark not defined.

8.3.2 Narrow gap J-ring . Error! Bookmark not defined.

8.3.3 Wide gap J-ring . Error! Bookmark not defined.

8.3.4 Straight edge . Error! Bookmark not defined.

8.4 Test sample . Error! Bookmark not defined.

8.5 Procedure . Error! Bookmark not defined.

8.6 Expression of results . Error! Bookmark not defined.

8.6.1 Passing ability PJ . Error! Bookmark not defined.

8.6.2 Flow spread SF . Error! Bookmark not defined.

J

low time t . Error! Bookmark not defined.

8.6.3 F 500j

8.7 Test report . Error! Bookmark not defined.

8.8 Repeatability and reproducibility . Error! Bookmark not defined.

9 Drop and fill height test for self-compactability of fresh concreteError! Bookmark not defined.

9.1 General . Error! Bookmark not defined.

9.2 Principle . Error! Bookmark not defined.

9.3 Apparatus . Error! Bookmark not defined.

9.4 Test sample . Error! Bookmark not defined.

9.5 Procedure . Error! Bookmark not defined.

9.6 Expression of results . Error! Bookmark not defined.

9.6.1 Filling time . Error! Bookmark not defined.

9.6.2 Filling height . Error! Bookmark not defined.

Deleted: Fill

9.6.3 Coarse aggregate content of concrete after flowing through the obstacle (when

necessary) . Error! Bookmark not defined.

9.7 Test report . Error! Bookmark not defined.

Bibliography . Error! Bookmark not defined.

4 © ISO 2018 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national

standards bodies (ISO member bodies). The work of preparing International Standards is normally

carried out through ISO technical committees. Each member body interested in a subject for which a

technical committee has been established has the right to be represented on that committee.

International organizations, governmental and non‐governmental, in liaison with ISO, also take part in

the work. ISO collaborates closely with the International Electrotechnical Commission (IEC) on all

matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 71, Concrete, reinforced concrete and pre-

stressed concrete, Subcommittee SC 1, Test methods for concrete.

A list of all parts in the ISO 1920 series can be found on the ISO website.

© ISO 2018 – All rights reserved 5

Testing of concrete — Part 13: Properties of fresh self‐compacting

concrete

1 Scope

This document specifies procedures for testing fresh self‐compacting concrete. It specifies the following

test methods: determination of consistence (slump flow test), V funnel test, L box test, sieve segregation Deleted: Sieve

test, J‐ring test and self‐compactability test.

Deleted:

Deleted: Self

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1920‐1, Testing of concrete — Part 1: Sampling of fresh concrete

ISO 1920‐2, Testing of concrete — Part 2: Properties of fresh concrete

ISO 3310‐2, Test sieves — Technical requirements and testing — Part 2: Test sieves of perforated metal

plate

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

Deleted: https://www.electropedi

a.org/

3.1

self-compacting concrete

SCC

innovative concrete that does not require vibration for placing and compaction because it is able to flow

under its own weight, completely filing formwork and achieving full compaction, even in the presence

of congested reinforcement

3.2

passing ability

ability of fresh concrete to flow through tight openings such as spaces between steel reinforcing bars

without segregation or blocking

3.3

segregation resistance

ability of fresh concrete to remain homogeneous in composition while in its fresh state

3.4

slump flow

mean diameter of the spread of fresh concrete from a standardized slump cone

3.5

© ISO 2018 – All rights reserved 1

Deleted:

viscosity

resistance to flow of fresh concrete once flow has started

4 Slump-flow test

4.1 General

This test specifies the procedure for determining the slump‐flow and t500 time for self‐compacting

concrete. The test is not suitable when the maximum size of the aggregate exceeds 40 mm.

4.2 Principle

The slump‐flow test is an indication of the flowability of self‐compacting concrete in the absence of

obstructions. It is based on the slump test described in ISO 1920‐2. The flowability is evaluated by

measuring the spreading maximum diameter, d , and the time it reaches the spreading diameter of

max

500 mm, t . The d of spreading is a measure of the self‐compacting concrete flow range when

500 max

subjected to load from its own weight. It is an indication of the yield stress of the self‐compacting

concrete. The t time is a measure of the speed of flow and an indication of the relative viscosity of the

self‐compacting concrete. The result is an indication of the filling ability of self‐compacting concrete.

The fresh concrete is poured into a cone as specified for the ISO 1920‐2 slump test. When the cone is

withdrawn upwards, the time from commencing upward movement of the cone to when the concrete

has flowed to a diameter of 500 mm is measured; this is the t500 time. The largest diameter of the flow

spread of the concrete and the diameter of the spread at right angles to it are then measured and the

mean is the slump‐flow.

4.3 Apparatus

4.3.1 Mould, in accordance with ISO 1920‐2:2016, 4.3.2.1 (see Figure 1).

4.3.2 Rule or measuring tape, of minimum length 1 000 mm and having sub‐divisions not greater

than 5 mm along its entire length.

4.3.3 Stop watch, capable of measuring to 0,1 s.

4.3.4 Spirit level, for checking horizontality of base plate prior to commencing the test.

4.3.5 Container, to hold the test sample and having a volume of at least 10 l.

4.3.6 Collar, (optional) having a mass of at least 9 kg (see Figure 2).

NOTE The collar allows the test to be carried out by one person.

4.4 Test sample

The sample shall be obtained in accordance with ISO 1920‐1.

4.5 Procedure

Place the baseplate on a flat and horizontal surface free from external vibration or shock. Check the top

surface for horizontality using the spirit level. Clean the table and the cone and dampen immediately

prior to testing, but keep free from excess moisture.

Fit the collar to the cone if being used.

Place the cone centrally within the 200 mm circle on the baseplate and hold in position by standing on

the foot pieces (or use the collar), ensuring that no concrete can leak from under the cone.

2 © ISO 2018 – All rights reserved

Fill the cone in one operation without any agitation or mechanical compaction, and strike off surplus

from the top of the cone. Allow the filled cone to stand for not more than 30 s; during this time remove

any spilled concrete from the baseplate.

Lift the cone vertically in 1 s to 3 s in one movement without interfering with the flow of concrete. If the

t time has been requested, start the stop watch immediately the cone ceases to be in contact with the

baseplate and record the time taken to the nearest 0,1 s for the concrete to first touch the 500 mm circle

After the flow of concrete has stabilized without disturbing the baseplate or concrete, measure the

largest diameter of the flow spread and record as d to the nearest 10 mm. Then measure the diameter

of the flow spread at right angles to d to the nearest 10 mm and record as d to the nearest 10 mm. If

1 2

the difference between d and d is greater than 50 mm another sample shall be taken and the

1 2

procedure repeated.

If two consecutive tests show the difference between d1 and d2 to be greater than 50 mm, the concrete

lacks the necessary flowability for the slump‐flow test to be suitable.

Check the concrete spread for signs of segregation and report under item 4.6, f) in a qualitative way, e.g.

no indication of segregation, strong indication of segregation.

NOTE Signs of segregation include a ring of cement paste/mortar and segregated coarse aggregate in the

central area.

Dimensions in millimetres

Figure 1 — Baseplate

Dimensions in millimetres

© ISO 2018 – All rights reserved 3

Deleted:

Figure 2 — Example of dimensions of a steelwighted collar

4.6 Test result

The slump‐flow, SF, is the mean of d and d, expressed to the nearest 10 mm, given by Formula (1).

1 2

dd

SF (1)

where

SF is the slump‐flow, in millimetres;

d is the largest diameter of flow spread, in millimetres;

d is the flow spread at 90° to d, in millimetres.

2 1

The t time is reported to the nearest 0,5 s.

4.7 Test report

The test report shall include:

a) the identification of the test sample;

b) the location where the test was performed;

c) the date and time of test;

d) the slump‐flow, SF, to the nearest 5 mm;

e) the t time, to the nearest 0,1 s (when requested);

f) any indication of segregation of the concrete;

g) any deviation from the standard test method;

h) a declaration by the person technically responsible for the test that it was carried out in accordance

with this document, except as noted in g).

The report may include:

— the temperature of the concrete at the time of test;

— the age of concrete at time of test (if known).

4 © ISO 2018 – All rights reserved

4.8 Repeatability and reproducibility

The repeatability, r, and reproducibility, R, have been determined by a programme including eight

laboratories, 16 operators and two replicates, and interpreted in accordance with ISO 5725‐2.

The resulting values for r and R are given in Tables 1 and 2.

Table 1 — Repeatability and reproducibility for typical values of Slump-flow

Slump-flow, SF

<600 600–750 >750

mm

Repeatability, r n/a 42 22

Reproducibility, R n/a 43 28

Table 2 — Repeatability and reproducibility for typical values of t times

t time

<3,5 3,5–6,0 >6,0

seconds

Repeatability, r 0,66 1,18 n/a

Reproducibility, R 0,88 1,18 n/a

5 V funnel test

5.1 General

This test specifies the procedure for determining the V‐funnel flow time for self‐compacting concrete.

The test is not suitable when the maximum size of the aggregate exceeds 25 mm.

5.2 Principle

The relative viscosity is indicated by the time the concrete to flow out of the funnel. And the filling

ability is assessed by the time the concrete takes, under the action of its own weight, to flow through

section variation of mold. A V‐shaped funnel is filled with fresh concrete and the time taken for the

concrete to flow out of the funnel is measured and recorded as the V‐funnel flow time.

5.3 Apparatus

5.3.1 V-funnel, made to the internal dimensions and tolerances (see Figure 3), fitted with a quick

release, watertight hinged or sliding gate at its base and supported by a frame so that the top of the

funnel is horizontal with sufficient clearance beneath the gate to place the container underneath.

The V‐funnel shall be made from metal not prone to be readily attacked by cement paste or be liable to

rusting; the surfaces shall be smooth, and not readily attacked by cement paste or be liable to rusting.

If the funnel is made from other materials, in‐use performance test data shall be available which

demonstrates long‐term equivalence with metal.

The funnels specified in national standards may be used where applicable.

5.3.2 Container, to hold the test sample and having a volume not less than 12 l.

5.3.3 Stop watch, capable of measuring to 0,1 s.

5.3.4 Straight edge, for striking off concrete level with the top of the funnel.

Dimensions in millimetres

© ISO 2018 – All rights reserved 5

Deleted:

Key

1 hinged or sliding gate

Figure 3 — V-funnel

5.4 Test sample

A sample of at least 12 l shall be obtained in accordance with ISO 1920‐1.

5.5 Procedure

Clean the funnel and bottom gate, then dampen all the inside surface including the gate. Close the gate

and pour the sample of concrete into the funnel in one operation, without any agitation or mechanical

compaction, then strike off the top with the straight edge so that the concrete is level with the top of the

funnel. Place the container under the funnel in order to collect the concrete. After a delay of (10 ± 2) s

from filling the funnel, open the gate quickly and measure the time, t, to 0,1 s, from opening the gate to

v

when it is possible to see vertically through the funnel into the container below for the first time. The

time tv is the V‐funnel flow time.

The flow of concrete from the funnel shall be continuous. If a blockage occurs, the test shall be repeated.

If a second blockage occurs, the concrete lacks the necessary viscosity and filling ability of self‐

compacting concrete. Report if a blockage has occurred.

5.6 Test report

The test report shall include:

a) the identification of the test sample;

b) the location where the test was performed;

c) the date and time of test;

d) the V‐funnel flow time, t, to the nearest 0,5 s;

v

e) any deviation from the standard test method;

f) a declaration by the person technically responsible for the test that it was carried out in accordance

with this document, except as noted in e).

Deleted: d

The report may include:

— the temperature of the concrete at the time of test;

6 © ISO 2018 – All rights reserved

— the age of concrete at time of test (if known).

5.7 Repeatability and reproducibility

The repeatability, r, and reproducibility, R, have been determined by a programme including

10 laboratories, 20 operators and two replicates, and interpreted in accordance with ISO 5725‐2.

The resulting values for r and R are given in Table 3.

Table 3 — Repeatability and reproducibility for typical values of V-funnel flow time

V-funnel flow time, t

v

3,0 5,0 8,0 12,0 >15,0

seconds

Repeatability, r 0,4 1,1 2,1 3,4 4,4

Reproducibility, R 0,6 1,6 3,1 5,1 6,6

6 L box test

6.1 General

This test specifies the procedure for determining the passing ability ratio for self‐compacting concrete

using the L box test according to the maximum size of th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...