ISO 14291:2012

(Main)Vacuum gauges - Definitions and specifications for quadrupole mass spectrometers

Vacuum gauges - Definitions and specifications for quadrupole mass spectrometers

ISO 14291:2012 defines terms relevant to quadrupole mass spectrometers (QMSs) and specifies the parameters required for specification by QMS manufacturers necessary for proper calibration and for maintaining the quality of partial pressure measurement. ISO 14291:2012 applies to QMSs with an ion source of the electron impact ionization type. Such QMSs are designed for the measurement of atomic mass-to-charge ratios m/z typically /z above 300, which are mainly used to specify organic materials, lie outside the scope of ISO 14291:2012.

Manomètres à vide — Définitions et spécifications des spectromètres de masse quadripolaires

General Information

- Status

- Published

- Publication Date

- 05-Jul-2012

- Technical Committee

- ISO/TC 112 - Vacuum technology

- Drafting Committee

- ISO/TC 112/WG 2 - Vacuum instrumentation

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 06-Mar-2023

- Completion Date

- 13-Dec-2025

Overview

ISO 14291:2012 - Vacuum gauges: Definitions and specifications for quadrupole mass spectrometers (QMSs) defines terminology and the manufacturer-specified parameters needed to calibrate and maintain quality in partial‑pressure measurements using quadrupole mass spectrometers. The standard applies to QMSs that use electron‑impact ionization and are designed for typical mass‑to‑charge (m/z) ranges below 300. QMS types and ionization methods used primarily for high‑m/z organic analysis (m/z > 300) are outside its scope.

Key topics and technical requirements

ISO 14291:2012 establishes clear definitions and a baseline of manufacturer information required for reliable QMS operation and comparison:

- Terms & definitions for components (sensor head, ion source, quadrupole mass filter, electronic unit) and detectors (Faraday cup, SEM, CEM, MCP).

- Symbols and principles describing QMS operation and analyzers.

- Manufacturer‑supplied specifications required for calibration and use, including:

- Mass range and mass resolution

- Type of ion source (open, closed, molecular beam) and detector (Faraday cup, SEM variants)

- Sensitivity, linear response range, minimum detectable partial pressure/concentration

- Mass stability, scanning parameters, signal output and potentials

- Operational limits (maximum operating pressure, bake‑out temperature), warm‑up time, filament and detector details

- Mechanical and electrical data: dimensions, mounting, internal volume, power, cabling, interfaces, software

- Optional specifications such as fragmentation (cracking) patterns, temperature coefficients, degassing/outgassing data, and inspection records.

Practical applications and who uses this standard

ISO 14291:2012 is practical for:

- QMS manufacturers - to document and declare instrument performance and calibration‑relevant parameters.

- Calibration laboratories and QA teams - to establish baseline conditions and traceable partial‑pressure measurements.

- Vacuum technologists and process engineers - in vacuum processing (PVD/CVD, etch), leak detection, and residual gas analysis where quantitative partial‑pressure data are required.

- Research laboratories - to ensure comparability of QMS data across instruments and vendors.

Using ISO 14291 helps ensure consistent QMS specification, improves comparability between devices, and supports standardized calibration practices for reliable partial‑pressure measurement.

Related standards

- ISO 3529-3:1981 (cited as a source for QMS definitions)

- Developed under ISO Technical Committee ISO/TC 112 (Vacuum technology)

Keywords: ISO 14291:2012, quadrupole mass spectrometer, QMS, vacuum gauges, electron impact ionization, partial pressure measurement, residual gas analysis, calibration, Faraday cup, secondary electron multiplier.

Frequently Asked Questions

ISO 14291:2012 is a standard published by the International Organization for Standardization (ISO). Its full title is "Vacuum gauges - Definitions and specifications for quadrupole mass spectrometers". This standard covers: ISO 14291:2012 defines terms relevant to quadrupole mass spectrometers (QMSs) and specifies the parameters required for specification by QMS manufacturers necessary for proper calibration and for maintaining the quality of partial pressure measurement. ISO 14291:2012 applies to QMSs with an ion source of the electron impact ionization type. Such QMSs are designed for the measurement of atomic mass-to-charge ratios m/z typically /z above 300, which are mainly used to specify organic materials, lie outside the scope of ISO 14291:2012.

ISO 14291:2012 defines terms relevant to quadrupole mass spectrometers (QMSs) and specifies the parameters required for specification by QMS manufacturers necessary for proper calibration and for maintaining the quality of partial pressure measurement. ISO 14291:2012 applies to QMSs with an ion source of the electron impact ionization type. Such QMSs are designed for the measurement of atomic mass-to-charge ratios m/z typically /z above 300, which are mainly used to specify organic materials, lie outside the scope of ISO 14291:2012.

ISO 14291:2012 is classified under the following ICS (International Classification for Standards) categories: 23.160 - Vacuum technology. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 14291:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 14291

First edition

2012-07-15

Vacuum gauges — Definitions and

specifications for quadrupole mass

spectrometers

Manomètres à vide — Définitions et spécifications des spectromètres

de masse quadripolaires

Reference number

©

ISO 2012

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO’s

member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2012 – All rights reserved

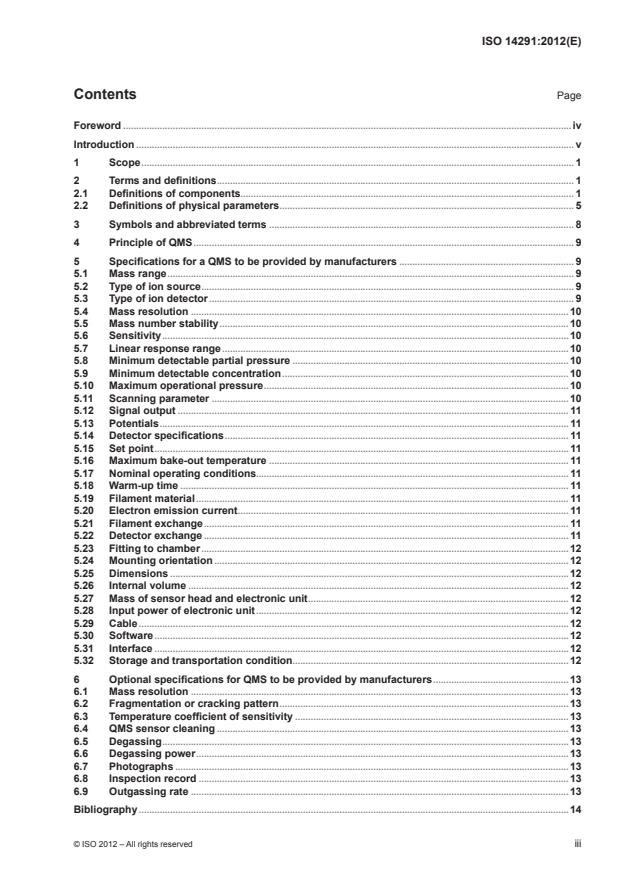

Contents Page

Foreword .iv

Introduction . v

1 Scope . 1

2 Terms and definitions . 1

2.1 Definitions of components. 1

2.2 Definitions of physical parameters . 5

3 Symbols and abbreviated terms . 8

4 Principle of QMS . 9

5 Specifications for a QMS to be provided by manufacturers . 9

5.1 Mass range . 9

5.2 Type of ion source . 9

5.3 Type of ion detector . 9

5.4 Mass resolution .10

5.5 Mass number stability .10

5.6 Sensitivity .10

5.7 Linear response range .10

5.8 Minimum detectable partial pressure .10

5.9 Minimum detectable concentration .10

5.10 Maximum operational pressure .10

5.11 Scanning parameter .10

5.12 Signal output . 11

5.13 Potentials . 11

5.14 Detector specifications . 11

5.15 Set point . 11

5.16 Maximum bake-out temperature . 11

5.17 Nominal operating conditions. 11

5.18 Warm-up time . 11

5.19 Filament material . 11

5.20 Electron emission current . 11

5.21 Filament exchange . 11

5.22 Detector exchange . 11

5.23 Fitting to chamber .12

5.24 Mounting orientation .12

5.25 Dimensions .12

5.26 Internal volume .12

5.27 Mass of sensor head and electronic unit .12

5.28 Input power of electronic unit .12

5.29 Cable .12

5.30 Software .12

5.31 Interface .12

5.32 Storage and transportation condition.12

6 Optional specifications for QMS to be provided by manufacturers .13

6.1 Mass resolution .13

6.2 Fragmentation or cracking pattern .13

6.3 Temperature coefficient of sensitivity .13

6.4 QMS sensor cleaning .13

6.5 Degassing .13

6.6 Degassing power .13

6.7 Photographs .13

6.8 Inspection record .13

6.9 Outgassing rate .13

Bibliography .14

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the International

Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 14291 was prepared by Technical Committee ISO/TC 112, Vacuum technology.

iv © ISO 2012 – All rights reserved

Introduction

Quadrupole mass spectrometers (QMSs) are nowadays used not only for leak detection and residual gas

analysis in vacuum but also as instruments to provide quantitative analysis in processes and control processes

such as physical and chemical vapor deposition, and etch processes.

Total pressure, composition of the gas mixture, QMS settings, environment conditions, etc., have a significant

influence on the measured signal, its uncertainty and interpretation. For this reason, it is not possible to calibrate

QMS for all its possible applications. Instead, it has either to be calibrated for the particular conditions of use

or for a standardized condition.

There is also some need for standardization in order to enable QMS users to compare devices of different

manufacturers and to use the QMS properly.

In continuation of efforts of TC 112 during the 1990s, this International Standard takes a first step towards

establishment of a standardized calibration procedure for QMS by defining the terms and parameters.

INTERNATIONAL STANDARD ISO 14291:2012(E)

Vacuum gauges — Definitions and specifications for

quadrupole mass spectrometers

1 Scope

This International Standard defines terms relevant to quadrupole mass spectrometers (QMSs) and specifies

the parameters required for specification by QMS manufacturers necessary for proper calibration and for

maintaining the quality of partial pressure measurement.

This International Standard applies to QMSs with an ion source of the electron impact ionization type. Such

QMSs are designed for the measurement of atomic mass-to-charge ratios m/z typically <300. QMSs with other

ion sources, such as those of the chemical ionization, photoionization, and field ionization types, as well as the

measurements of m/z above 300, which are mainly used to specify organic materials, lie outside the scope of

this International Standard.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1 Definitions of components

2.1.1

quadrupole mass spectrometer

QMS

mass spectrometer in which ions are injected axially into a quadrupole lens consisting of a system of four

electrodes, usually rods, to which radio frequency and d.c. electric fields in a critical ratio are applied, so that

only ions with a certain mass/charge ratio emerge

[2]

[SOURCE: ISO 3529-3:1981, 3.5.2.2]

Note 1 to entry Such a QMS consists of a sensor head and electronic unit.

2.1.2

sensor head

analyser tube

sensor

sensor unit

sensing head

gauge head

equipment consisting of an ion source, quadrupole mass filter, and ion detector in one enclosure

2.1.3

ion source

part of the QMS in which ions of gas molecules and atoms are produced

Note 1 to entry For the production of positive ions, the ion source generally uses an electron impact ionization process.

2.1.3.1

open ion source

ion source with a high conductance to the surrounding vacuum environment, often designed as an open grid structure

Note 1 to entry All of the operational components of this ionization hardware are exposed to the same vacuum region.

2.1.3.2

closed ion source

enclosed ion source

differential pressure ion source

ion source that uses a nearly sealed container to ionize the gas to be analysed with openings only for passing;

sample gas; energetic electrons (for impact ionization); and exciting ions

Note 1 to entry This type of ion source permits ionization at pressures that are higher than the mass filter and detector.

It should be used in a sample pressure reduction system with a high vacuum pump on the mass filter.

2.1.3.3

molecular beam ion source

crossed beam ion source

ion source that accepts a focused beam of neutral gas molecules directed at the ion formation region without

interference from any ion source components

Note 1 to entry The molecular beam traverses the ion formation region and is usually at right angles to the electron

beam and mass filter axes.

Note 2 to entry For molecular beam epitaxy, the crossed beam ion source is also designed to accept molecular beams

at various acceptance angles. Some molecular beam ion source designs include a protective shroud around the ion

source with an aperture to the ion formation region. As the molecular beam exits the ion source, it may be trapped or

pumped to minimize contribution to background from scattered molecules.

2.1.4

quadrupole mass filter

device consisting of four parallel conductive rods arranged in a square array with opposite rods connected

electrically in parallel

Note 1 to entry A quadrupole mass filter separates the ions coming from the ion source on the basis of their mass-to-

charge ratios by a critical ratio of radio frequency (r.f.) and direct current (d.c.) electrical fields applied to the rods. The rod

pairs are driven with opposite r.f. phase and d.c. polarity.

2.1.5

ion detector

ion collector

device collecting the positive ions that have passed through the mass filter to measure the ion current

Note 1 to entry Two types of ion detectors are common: Faraday cup and secondary electron multiplier (SEM).

2.1.5.1

Faraday cup

metal plate or open cylinder or similar on which the ions from the mass filter are collected

Note 1 to entry An actual Faraday cup ion detector is illustrated in Figure 1 a). However, a metal plate, Figure 1 b), open

cylinder, Figure 1 c), or similar on which the ions from the mass filter are collected is usually called a Faraday cup-type

ion detector. A Faraday cup generally has a gain of unity, i.e. for each ion collected, one electron flows from the detecting

electrometer.

2.1.5.2

secondary electron multiplier

SEM

detector in which the ions from the mass filter strike the entrance surface and release electrons

Note 1 to entry The released electrons are accelerated and strike another surface of the SEM resulting in multistage

amplification of the electron current. SEMs can use discrete dynodes or a continuous dynode surface with a potential

gradient to increase the electron current and microchannel plate electron multiplier.

2 © ISO 2012 – All rights reserved

a) Faraday cup type b) Metal plate type c) Open cylinder type

Figure 1 — Faraday cup type ion detector

2.1.5.2.1

discrete dynode electron multiplier

secondary electron multiplier that uses discrete dynodes between which secondary electrons are accelerated

Note 1 to entry The voltages applied to each dynode establish the potential gradients that accelerate the secondary

electrons and lead to increased numbers of electrons at each stage. Figure 2 is a schematic diagram of a discrete dynode

electron multiplier.

Key

1 ammeter

2 electron

3 negative high voltage

Figure 2 — Discrete dynode electron multiplier

2.1.5.2.2

1)

continuous dynode electron multiplier

CEM

type of secondary electron multiplier with a continuous dynode, often with a horn-like channel

Note 1 to entry See Figure 3.

Note 2 to entry The applied voltage from entrance to exit of the channel establishes the potential gradient along the

channel which accelerates secondary electrons and leads to increased numbers of electrons from entrance to exit.

® ®

1) One of the original CEMs is known as Channeltron . Channeltron is the trademark of a product supplied by Burle.

This information is given for the convenience of users of this document and does not constitute an endorsement by ISO of

the product named.

Key

1 ammeter

2 electron

3 negative high voltage

Figure 3 — Continuous dynode electron multiplier (CEM)

2.1.5.2.3

microchannel plate electron multiplier

MCP electron multiplier

type of secondary electron multiplier which consists of a large number of small, parallel continuous-dynode

channels (typically 5 µm to 25 µm in diameter), in a planar array, or “plate”

2.1.6

electronic unit

unit consisting of a radio frequency source and several regulated power supplies and amplifiers which operate

the ion source and mass filter as well as measure detected ion current

Note 1 to entry The electronic unit usually incorporates a microprocessor and firmware to control the electronics and

usually pass data to an external computer. Electronic units may be integrated or separate.

2.1.6.1

integrated type

electronic unit mounted directly on sensor head

Note 1 to entry See Figure 4.

2.1.6.2

separated type

electronic unit separated from the sensor head but connected to it via one or more cables

Note 1 to entry See Figure 5.

Key

1 electronic unit

2 computer

Figure 4 — Integrated electronic unit

4 © ISO 2012 – All rights reserved

Key

1 electronic unit

2 computer

Figure 5 — Separated electronic unit

2.2 Definitions of physical parameters

2.2.1

sensitivity

S

ratio of the change in spectrum peak height (ion current), I - I , to the corresponding change in partial

pressure, p - p

II−

Sp =

()

pp−

()

(1)

where

I is the ion current measured at partial pressure p;

I is the ion current measured at residual pressure p

0 0

Note 1 to entry Sensitivity is expressed in amperes per pascal.

[4]

Note 2 to entry Sensitivity is defined differently in ISO 27894:2009 for an ionization gauge with an emissive cathode.

The sensitivity of a hot-cathode ionization gauge is defined as

II−

c 0

S = (2)

Ip − p

()

e 0

where

I is the ion current measured at pressure p;

c

I is the ion current measured at residual pressure p ;

0 0

I is the emission current.

e

2.2.2

relative sensitivity factor

r

x

sensitivity S for a specified gas species, x, divided by sensitivity S for nitrog

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...