ISO/TR 14345:2012

(Main)Fatigue — Fatigue testing of welded components — Guidance

Fatigue — Fatigue testing of welded components — Guidance

ISO/TR 14345:2012 gives guidance on best practice for fatigue testing under constant- or variable-amplitude loading of welded components in the medium- and high-cycle regimes, corresponding to applied loading that results in nominal stresses that do not exceed yield. Low-cycle fatigue testing under strain control is not specifically covered, although the same test specimens can be suitable for either low- or high-cycle fatigue testing. The different steps involved in the manufacture and preparation of the welded specimens and the final presentation and evaluation of the test results are also covered. ISO/TR 14345:2012 does not cover corrosion or high-temperature fatigue testing.

Fatigue — Essais de fatigue sur composants soudés — Lignes directrices

General Information

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 14345

First edition

2012-06-01

Fatigue — Fatigue testing of welded

components — Guidance

Fatigue — Essais de fatigue sur composants soudés — Lignes

directrices

Reference number

ISO/TR 14345:2012(E)

©

ISO 2012

---------------------- Page: 1 ----------------------

ISO/TR 14345:2012(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2012

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2012 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TR 14345:2012(E)

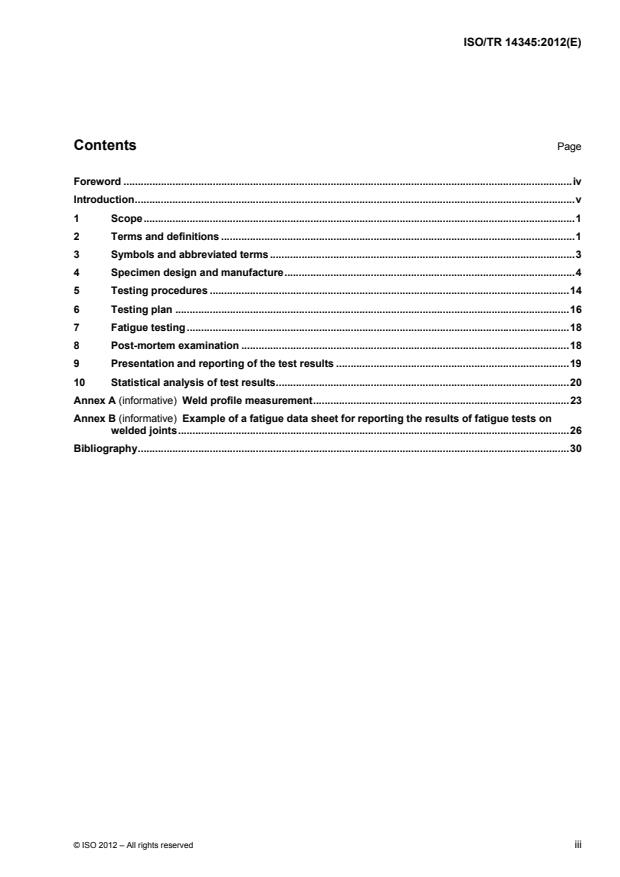

Contents Page

Foreword . iv

Introduction . v

1 Scope . 1

2 Terms and definitions . 1

3 Symbols and abbreviated terms . 3

4 Specimen design and manufacture . 4

5 Testing procedures . 14

6 Testing plan . 16

7 Fatigue testing . 18

8 Post-mortem examination . 18

9 Presentation and reporting of the test results . 19

10 Statistical analysis of test results . 20

Annex A (informative) Weld profile measurement . 23

Annex B (informative) Example of a fatigue data sheet for reporting the results of fatigue tests on

welded joints . 26

Bibliography . 30

© ISO 2012 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/TR 14345:2012(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In exceptional circumstances, when a technical committee has collected data of a different kind from that

which is normally published as an International Standard (“state of the art”, for example), it may decide by a

simple majority vote of its participating members to publish a Technical Report. A Technical Report is entirely

informative in nature and does not have to be reviewed until the data it provides are considered to be no

longer valid or useful.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TR 14345 was prepared by the International Institute of Welding, which has been approved as an

international standardizing body in the field of welding by the ISO Council.

Requests for official interpretations of any aspect of this part of ISO/TR 14345 should be directed to the ISO

Central Secretariat, who will forward them to the IIW Secretariat for an official response.

iv © ISO 2012 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/TR 14345:2012(E)

Introduction

Fatigue tests of welded specimens are the basis of all the main fatigue design codes and standards for

welded components and structures. However, inevitably these are not fully comprehensive and there is a

constant need for new data to extend them. Recognizing this, there is a growing tendency to allow the user to

deviate from the rules by performing special fatigue tests to validate a design. This Technical Report

addresses both these situations by providing guidance on the production of welded test specimens and their

fatigue testing for producing data either for general application or to validate a specific design.

Welded metallic structures can be large and complex, incorporating many weld details and structural

configurations. Furthermore, the loading that they are required to withstand in service can also be complex.

Therefore, the scope for performing fatigue tests on full-scale welded structures under truly representative

loading conditions is very limited, and usually expensive. Consequently, for both technical and economic

reasons, it is rarely attempted. Instead, in many circumstances, it is sufficient to isolate individual weld details

and incorporate them in small-scale specimens to test them. An important condition is that the resulting

specimens should be realistic in terms of features in real structures that affect fatigue strength, such as

material type, section thickness, plate preparation, weld type and welding conditions, residual stresses and

the nature of the fatigue loading. This Technical Report provides guidance on the production and fatigue

testing of specimens representing weld details. Reference is made to other IIW guidance on the fatigue testing

of large-scale specimens representing sub-assemblies or structural components (Reference [1]); more

detailed guidance on the loading required for variable-amplitude testing is given in Reference [2] and the

statistical evaluation of fatigue data in Reference [3].

By its nature, this Technical Report covers two distinct disciplines, welding and mechanical testing. If reliable

fatigue data are to be obtained, both need to be truly representative of practical conditions. Thus, the

laboratory test specimens need to duplicate actual welded structures and the test conditions need to duplicate

real-life loading and operating conditions. Apart from the provision of design data, use of the

recommendations in this Technical Report is intended to facilitate comparison of fatigue test data and avoid

biased statistics if results obtained from different sources are combined.

Use of this Technical Report is intended to allow, on the one hand, more adequate comparison of the results

from different origins (e.g. same welded joint but from another workshop or testing laboratory) and, on the

other hand, the plotting of more reliable fatigue curves for design purposes.

© ISO 2012 – All rights reserved v

---------------------- Page: 5 ----------------------

TECHNICAL REPORT ISO/TR 14345:2012(E)

Fatigue — Fatigue testing of welded components — Guidance

1 Scope

This Technical Report gives guidance on best practice for fatigue testing under constant- or variable-

amplitude loading of welded components in the medium- and high-cycle regimes, corresponding to applied

loading that results in nominal stresses that do not exceed yield. Low-cycle fatigue testing under strain control

is not specifically covered, although the same test specimens can be suitable for either low- or high-cycle

fatigue testing. The different steps involved in the manufacture and preparation of the welded specimens and

the final presentation and evaluation of the test results are also covered.

This Technical Report does not cover corrosion or high-temperature fatigue testing.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

failure criterion

specimen damage chosen for ending the test

2.2

flank angle

contact angle between the weld face and the plate at the weld toe

2.3

irregularity factor

I

ratio of the number of mean crossings, N , with positive slope to number of peaks or valleys in the given load

0

history, N

p

N

0

I

N

p

NOTE See Figure 1.

2.4 Maxima

2.4.1

maximum load range

F

max

maximum load range encountered in a variable-amplitude applied load spectrum

2.4.2

maximum stress range

max

maximum stress range encountered in a variable-amplitude applied stress spectrum

© ISO 2012 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/TR 14345:2012(E)

2.5

number of cycles to failure

N

f

number of cycles when the failure criterion is reached

2.6

peak factor

ratio of the maximum value attained in the applied load (or stress) history to the mean load (or stress)

2.7

range

algebraic difference between the maximum and minimum values of a quantity under cyclic loading

2.8

standard deviation

positive square root of the mean of the squared deviations of a variable from its arithmetic mean

2.9

weld toe radius

contact radius between the weld toe and the plate

2

2

x

5 x

4

x

3

x o

2

x o

1

1

x

o

0

o x

-1

o

-2

o

-3

o

-4

N

0

-5

t /s

a

N

p

1

a) Random signal: load levels versus time b) Counting for irregularity factor

definition: load level versus

number of peaks

Key Key

1 negative peaks 1 mean level

2 positive peaks

2 number of level crossings up

t time

N number of mean crossings

a

0

N number of peaks or valleys in the given load

p

history

cumulative distribution of peaks

○ cumulative distribution of valleys

Figure 1 — Random signal and counting for irregularity factor definition

2 © ISO 2012 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/TR 14345:2012(E)

3 Symbols and abbreviated terms

See Table 1.

Table 1 — Symbols and abbreviated terms

Symbol Quantity Designation

a, b, d Length Dimensions used to calculate misalignment parameters

F Force Load range

F Force Maximum load range in the spectrum

max

Stress Nominal stress range

nom

(or S) Stress Stress range

Stress Membrane stress range

m

Stress Secondary bending stress range

S

Stress Maximum stress range in the spectrum

max

Stress Fatigue limit for parent material

D

Stress Corrected stress range including secondary bending stress due to misalignment

cor

Stress Structural hot-spot stress range

shs

Length/length or % Strain range

e Length Axial misalignment

Radians Angular distortion

h Length Weld leg length

I — Irregularity factor, N /N

0 p

L Length Distance over which misalignment extends

l Length Distance from weld toe to radius measuring circle

Dimensionless Correction factor dependent on restraint on misaligned cruciform joints

N Cycles Number of cycles to failure

f

N — Number of mean crossings with positive slope in spectrum loading sequence

0

N — Number of peaks or valleys in spectrum loading sequence

p

R — Stress ratio, S /S

min max

Length weld toe radius

S , S Stress Minimum and maximum (algebraic) applied stress (tension positive, compression

min max

negative)

S Stress Fatigue strength at life N cycles

N

s (or Stdv) — Standard deviation

s — Standard deviation of log N

log N

s — Standard deviation of log S

log S

s Stress Standard deviation of S

S N

Stress Membrane stress

m

Stress Secondary bending stress

S

t Length Plate thickness

Degrees Weld toe flank angle

© ISO 2012 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO/TR 14345:2012(E)

4 Specimen design and manufacture

4.1 Specimen design

4.1.1 General

The specimen design depends on the objectives of the tests, together with any practical limitations such as

the available type of fatigue-testing equipment, material and time. If the specimen is intended to model a

welded joint in an actual structure, it shall be as representative as possible of that joint in terms of material,

weld detail, geometry, dimensions, and manufacturing quality. In addition, the specimen design should take

account of how loads are applied to the test section to ensure consistency with the original structural element.

A relevant example to illustrate this point is given in Reference [4].

If it is required to produce several nominally identical specimens, e.g. to produce an S–N curve, a suitable

technique is to extract them from larger panels, as shown in Figure 2. Normally, extension pieces are welded

at each end to allow the test weld to traverse the entire width of the panel. These are then removed and the

resulting edges ground smooth. Similarly, several strip specimens can be extracted from a single butt or fillet

welded girth joint between two tubes. However, these approaches can only be used if the weld detail is a

continuous weld oriented transverse to the direction of fatigue loading. In other cases, such as those shown in

Figure 3, each specimen shall be fabricated individually.

An important feature of welded structures is the nature of the residual stresses due to welding and subsequent

manufacturing operations. In most cases, these can be very high, up to yield, and tensile. Their effect under

fatigue loading is the same as that of an applied high tensile mean stress. Most fatigue design rules provide

design data that include the effect of such tensile residual stress. However, small-scale welded specimens are

unlikely to embody high residual stresses from welding. One option with steel specimens is to induce them by

spot heating (Reference [5]), or their effect can usually be simulated by the choice of loading (see 6.3).

Dimensions in millimetres

Key

1 unused

n specimen identification number

Figure 2 — Example of a welded panel and the extraction of narrower fatigue test specimens

4 © ISO 2012 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/TR 14345:2012(E)

Figure 3 — Examples of fatigue test specimens that would need to be made individually

4.1.2 Influence of method of loading

Care is needed to ensure that fatigue failure of the test specimen occurs at the weld detail of interest, rather

than prematurely at some location associated with the method of testing. In this respect, there is always the

risk that axially loaded plate specimens gripped in wedge jaws fail in that region as a result of the notching

effect of the jaws if they indent the specimen. This problem is particularly acute if the weld detail is one with

relatively high fatigue strength. It can usually be avoided by the use of waisted specimens that are narrower in

the test section than where they are gripped. Similarly, specimens loaded in bending can fail at the load points

if they indent the specimen or the local shear stress in the specimen is too high. General recommendations on

the dimensions of fatigue test specimens are given in Figure 4.

© ISO 2012 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO/TR 14345:2012(E)

a) Axial

b) 3-Point bending

c) 4-Point bending

Figure 4 — Geometrical characteristics of welded specimens loaded in tension or bending

4.2 Manufacture of test specimens

4.2.1 Material

The test specimens should be manufactured from material of the same specification, form, and thickness as

that used for the component or structure that the specimen is intended to represent. Since the fatigue

performance of some welded joints is effectively independent of material tensile strength, some flexibility is

possible on the choice of material grade. Similarly, some tolerance on material form and thickness may be

possible. Any such deviations should be justified and recorded.

4.2.2 Welding procedure

The welding operation should conform to those performed on components or structures of the type and

material that the specimen is intended to represent, in compliance with recognized codes. Panels used to

produce several small-scale specimens (Figure 2) should be assembled so as to maintain the thermal

6 © ISO 2012 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/TR 14345:2012(E)

conditions and disposition of the welds in the real structure. When relevant, the rolling direction of a plate

should be the same as that in the original structure.

To simulate practical conditions, it is prudent to include weld runs containing start-stops.

If the tests are being performed to validate a particular component or structure, each type of welded joint

should be accurately characterized in terms of relevant dimensions and parameters. For example, in the case

of arc welding, the following characteristics may be relevant:

plate thickness;

base metal type;

rolling direction;

welding process;

shielding gas type, if any;

welding position (flat, overhead, etc.);

travel speed;

preheat temperature;

post-weld heat treatment, if any;

electrical parameters of the welding process;

size and shape of the welds;

type and diameter of the electrodes;

sequence of the different passes;

locations of any start-stop positions.

Additionally, it is helpful to mark locations where the characteristics of the weld may have changed, e.g. due to

a change in welding position or direction, or at a repair.

Unless it is a feature of the test, care should be taken to ensure that the finished weld is not cleaned by wire

brushing or shot blasting or coated with oil or grease, since such treatments are likely to influence the fatigue

performance of the welded specimen.

4.2.3 Joint alignment

Welded joints, particularly butt and cruciform joints, are highly susceptible to misalignment, arising mainly from

distortion during welding, variations in section shape or thickness and practical difficulties of achieving perfect

alignment during assembly. The two general types of misalignment are axial, due to a mismatch of the

centrelines of abutting parts, and angular, usually due to distortion, as illustrated in Figure 5. Misalignment can

affect the fatigue performance of the welded specimen in that it may influence the weld profile (Reference [6])

or, as shown in Figure 5, because it leads to the introduction of secondary bending stress when the joint is

loaded (Reference [7]). Thus, care is needed to ensure that any misalignment in the specimen is

representative of that in the actual structure and, ideally, that its effect as a source of secondary stress is

quantified (see 5.3.3).

© ISO 2012 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO/TR 14345:2012(E)

a) Axial misalignment

b) Angular misalignment

Key

C under compression

T under tension

Figure 5 — Secondary bending stresses arising under tensile axial loading in misaligned welded joints

4.2.4 Specimen preparation

If specimens are extracted from a welded panel (Figure 2) or tube, it is preferable to produce them by saw

cutting or machining. If there is no alternative to flame cutting, care is needed to avoid distorting the

specimens, and the flame-cut edges should be machined or ground smooth. It may be necessary to allow for

this loss of width when deciding on the size to be removed by flame cutting.

To avoid fatigue crack initiation at the edges of the specimen, these should be filed, ground, or machined

smooth in the longitudinal direction. For an even smoother finish, they can then be polished longitudinally with

grade 600 grit emery paper until all filing and finishing marks have been removed.

Similarly, any weld spatter should be removed and the surface ground smooth, taking care not to scratch or

grind the weld or the plate near the toe of the weld.

Welded specimens are not usually perfectly straight and it may be necessary to straighten them, e.g. to

facilitate testing under axial loading. This can be done by local bending, but in so doing it is vitally important to

avoiding bending in the vicinity of the test weld, especially the weld toes, since this can induce favourable

residual stresses that have a marked effect on the fatigue performance of the welded specimen. One

consequence of this is that any misalignment of the welded joint (see Figure 5) is unaffected by the

straightening operation and therefore its effect as a source of secondary bending stress still needs to be taken

into account (see 5.3.3).

Each specimen should be identified with a unique number and marked permanently before it is tested. Ink,

paint or stamping can be used for marking. Any stamping should be applied to the ends of the specimen so as

to avoid introducing potential points of stress concentration. If the specimen is to be tested to complete failure,

it is prudent to apply the specimen identification number to both ends of the specimen.

4.3 Specimen characteristics

4.3.1 Material

Details of the type of material used to make the test specimen, its specification, chemical composition, and

tensile properties should be recorded. In some circumstances it may also be relevant to note its fracture

toughness and hardness, particularly in the regions where fatigue cracking takes place.

8 © ISO 2012 – All rights reserved

---------------------- Page: 13 ----------------------

ISO/TR 14345:2012(E)

4.3.2 Geometry and dimensions

A full description of the test specimen type and geometry should be recorded, preferably including a sketch.

The relevant dimensions should also be measured and recorded. Normally, these include the width and

thickness in the test section, the wider width of a waisted specimen, the specimen length, and the size of any

welded attachment or secondary member.

4.3.3 Specimen distortion and alignment

Special care is needed when conducting fatigue tests on welded specimens under axial loading since the

presence of misalignment leads to the introduction of secondary bending, with the result that the stress

adjacent to the weld experiences either additional tension or compression, as indicated for tensile loading in

Figure 5. The same situation arises in tests in bending on welded sections if the misaligned welded joint is in a

region of low stress gradient that approximates to axial loading conditions (e.g. the flange of an I-beam, the

wall of a pipe or tube). However, secondary bending does not arise if the loading produces only shell bending,

or indeed from the bending stress component for combined axial and bending stresses.

The secondary bending stresses due to misalignment should be taken into consideration when determining

the stress range experienced by the welded specimen in the fatigue test.

If the misalignment can be measured, the formulae in Table 2 can be used to calculate the secondary bending

stress in terms of the nominal applied membrane stress component (Reference [7]). Figure 6 shows an

S m

arrangement that can be used to determine the axial misalignment due to centreline mismatch e and the

angular distortion in a joint between two plates. Each side shall be linear and the deviation from perfect

alignment shall be small. Sometimes local deformation occurs in a limited region, which can be only measured

using modelling compound or by scanning measurement using dial gauges, mechanical length measuring

instruments, laser comparators, etc.

In the case of assessment of angular misalignment, note that unless use is made of the non-linear tanh

corrections in the formulae in Table 2,

SS

mm

otherwise needs to be established at the minimum and maximum applied stresses in the test in order to

S

calculate . The resulting total corrected stress range is then = + .

S cor m S

However, it is generally easier and more accurate to determine the actual stresses arising in the vicinity of a

misaligned welded joint by measurement during the test, typically using electrical resistance strain gauges

attached to the surfaces of the specimen in the region of interest. In such cases, the corrected stress range,

, is given by Equation (1):

cor

BF

1

(1)

cor m

BF

where

is the nominal applied axial, or membrane, stress;

m

is the measured strain on the back surface of the specimen;

B

is the measured strain on the front surface of the specimen.

F

© ISO 2012 – All rights reserved 9

---------------------- Page: 14 ----------------------

ISO/TR 14345:2012(E)

10 © ISO 2012 – All rights reserved

Table 2 — Formulae for the calculation of the secondary bending stresses due to misalignment in cruciform or butt joints

Secondary bending stress,

Type Detail S Remarks

n a) Refers to the plate surfaces adjacent to

elt

S 11

the weld in the loaded plates, and

nn

tl l

tt

m11 2

12

hence to potential fatigue failure from a

weld toe.

where is a factor dependent on restraint. Examples in the case of cruciform joints are:

b) For remotely loaded joints, assume

= 6 for unrestrained butt or cruciform joints.

l = l .

Axial misalignment

1 2

c) Some experimental support for n =

1,5

a) Refers to the plate surfaces adjacent to

Assuming boundary conditions equivalent to:

the weld in the loaded plates, and

fixed ends:

hence to potential fatigue failure from a

weld toe.

tanh/ 2 tanh / 2

33yl

S

b) For remotely loaded joints, assume

tt/2 2 /2

m

l = l .

1 2

Angular

c) The tanh correction (in brackets)

distortion

y

allows for reduction in angular

pinned ends:

misalignment due to straightening of

2l 3 joint under tensile loading. It is

m

63yl tanh tanh

β =

S

where negligible for (l + l )/t < 10 and it is

tE 1 2

tt

m

independent of the assumed end

fixing condition for (l + l )/t > 100

1 2

l l , in radians

1 2

e

S Refers to weld root in loaded plate and

th

hence to potential fatigue failure in weld

m

throat from root

Axial

misalignment in fillet

welded cruciform

joints

---------------------- Page: 15 ----------------------

ISO/TR 14345:2012(E)

Angular distortion, , is given by Equation (2)

dddd

21 3 4

(2)

12

a

Axial misalignment, e, is given by Equation (3)

tt

b

12

edddddd (3)

23 2 3 4 1

a 2

Figure 6 — Procedure for measuring misalignment parameters using dial gauges

4.3.4 Local weld geometry

It is sometimes useful or necessary to measure the local weld geometry. This is usually described in terms of

two parameters, the contact angle, , and the radius, , between the weld face and plate surface at the weld

toe, as shown in Figure 7. The depth of any undercut would also be relevant. The weld toe radius and depth of

any undercut can be measured directly using a standard welding gauge or a radius gauge. However, the most

accurate measurements are made from cross-sections of welds, particularly if these can be enlarged by

typically 5 to 10 times. These could be obtained from the end of the actual weld, after first machining or

grinding it square with the plate edge, or from an off-cut of the original welded panel (see Figure 2), if the

specimen was produced in this way. Alternatively, they can be reproduced in casting material (e.g. plaster,

resin), if necessary, after first producing a mould (e.g. silicon rubber). Enlarged views of the resulting cross-

sections can be produced from photographic images or using a profile projector (Reference [8]). Procedures

for making the measurements are described in Annex A.

© ISO 2012 – All rights reserved 11

---------------------- Page: 16 ----------------------

ISO/TR 14345:2012(E)

Key

radius between the weld face and plate surface at the weld toe

contact angle

Figure 7 — Definition of the radius and the flank at the weld toe

4.3.5 Residual stress measurement

4.3.5.1 General

The nature and distribution of residual stresses due to welding can have a marked influence on fatigue

performance. Therefore, it is sometimes useful to measure the residual stresses in a test specimen, especially

in the region of fatigue crack initiation. Such measurements should be performed on unteste

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.