ISO/FDIS 1130

(Main)Textiles - Sampling methods for fibres, yarns and fabrics for testing

Textiles - Sampling methods for fibres, yarns and fabrics for testing

Applicable for textile materials in all forms. No single technique of sampling can be devised that will serve in all circumstances. General terms and their definitions are given. A lot of different sampling methods are described (e.g. for bast fibres, cotton fibres, man-made staple fibres, and wool fibres). The determination of the number of individuals to be tested in dependence on the variability of the material and the accuracy required is given in the annex.

Textiles — Méthodes d'échantillonnage des fibres, des fils et des étoffes en vue des essais

General Information

- Status

- Not Published

- Technical Committee

- ISO/TC 38/SC 23 - Fibres and yarns

- Drafting Committee

- ISO/TC 38/SC 23 - Fibres and yarns

- Current Stage

- 5020 - FDIS ballot initiated: 2 months. Proof sent to secretariat

- Start Date

- 10-Nov-2025

- Completion Date

- 10-Nov-2025

Relations

- Effective Date

- 08-Jul-2024

Overview - ISO/FDIS 1130:2025 (Textiles - Sampling methods for fibres, yarns and fabrics for testing)

ISO/FDIS 1130 establishes standardized sampling methods for fibres, yarns and fabrics used when preparing laboratory samples for testing. Applicable to textile materials in all forms, the document recognizes that no single sampling technique fits every situation and therefore presents a selection of practical, widely accepted methods. This edition (FDIS stage 2025) replaces the earlier ISO 1130:1975 and updates terminology, clause structure and sampling procedures.

Key topics and technical requirements

- Scope and definitions: General terms (population, individual, zoning) and fibre-specific definitions to ensure consistent sampling language.

- Sampling fibres (Clause 4):

- Methods for bast fibres, cotton, man‑made staple fibres and wool.

- Specific techniques such as Method A / Method B, sampling from bales, small bulk sampling and zoning methods for loose fibres.

- Sampling from processed materials (Clause 5):

- Procedures for sliver/roving (cut‑square and random‑draw methods), sampling fibres from yarns and fabrics.

- Sampling of yarns (Clause 6):

- Guidance for lots, package lengths, beams and sampling during handling; number of specimens and procedures for yarn removed from fabrics.

- Sampling of fabrics (Clause 7):

- Lot‑based procedures and practical steps for selecting representative fabric samples.

- Test report (Clause 8):

- Required reporting elements to ensure traceability and reproducibility of sampling and testing.

- Annex A (informative):

- Determination of the number of tests based on material variability and the accuracy required - useful for designing test plans and acceptance criteria.

- Exclusions: selection of length‑biased samples, commercial weights, and moisture content procedures are outside the scope.

Practical applications and users

ISO/FDIS 1130 is intended for professionals who need representative test samples for quality assessment and acceptance testing:

- Textile quality managers and production engineers

- Spinning mills, carding operations and yarn manufacturers

- Cotton, wool and man‑made fibre merchants

- Textile testing laboratories and conformity assessment bodies

- Procurement and inspection teams responsible for lot acceptance/rejection

Typical uses:

- Designing sampling plans for incoming bales, cartons or rolls

- Preparing laboratory test samples that minimize sampling bias

- Determining appropriate sample counts for statistically sound test results

Related standards and context

- Prepared by ISO/TC 38/SC 23 (Fibres and yarns).

- Complements ISO test methods for textile properties; use alongside appropriate property‑specific ISO test standards and laboratory methods for complete testing workflows.

Keywords: ISO/FDIS 1130, sampling methods, textiles, fibres, yarns, fabrics, sampling for testing, cotton sampling, wool sampling, man‑made staple, sample size determination.

ISO/FDIS 1130 - Textiles — Sampling methods for fibres, yarns and fabrics for testing Released:10/27/2025

REDLINE ISO/FDIS 1130 - Textiles — Sampling methods for fibres, yarns and fabrics for testing Released:10/27/2025

Frequently Asked Questions

ISO/FDIS 1130 is a draft published by the International Organization for Standardization (ISO). Its full title is "Textiles - Sampling methods for fibres, yarns and fabrics for testing". This standard covers: Applicable for textile materials in all forms. No single technique of sampling can be devised that will serve in all circumstances. General terms and their definitions are given. A lot of different sampling methods are described (e.g. for bast fibres, cotton fibres, man-made staple fibres, and wool fibres). The determination of the number of individuals to be tested in dependence on the variability of the material and the accuracy required is given in the annex.

Applicable for textile materials in all forms. No single technique of sampling can be devised that will serve in all circumstances. General terms and their definitions are given. A lot of different sampling methods are described (e.g. for bast fibres, cotton fibres, man-made staple fibres, and wool fibres). The determination of the number of individuals to be tested in dependence on the variability of the material and the accuracy required is given in the annex.

ISO/FDIS 1130 is classified under the following ICS (International Classification for Standards) categories: 59.060.01 - Textile fibres in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/FDIS 1130 has the following relationships with other standards: It is inter standard links to ISO 1130:1975. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO/FDIS 1130 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

FINAL DRAFT

International

Standard

ISO/TC 38/SC 23

Textiles — Sampling methods for

Secretariat: SAC

fibres, yarns and fabrics for testing

Voting begins on:

2025-11-10

Voting terminates on:

2026-01-05

RECIPIENTS OF THIS DRAFT ARE INVITED TO SUBMIT,

WITH THEIR COMMENTS, NOTIFICATION OF ANY

RELEVANT PATENT RIGHTS OF WHICH THEY ARE AWARE

AND TO PROVIDE SUPPOR TING DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO

LOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE

TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL

TO BECOME STAN DARDS TO WHICH REFERENCE MAY BE

MADE IN NATIONAL REGULATIONS.

Reference number

FINAL DRAFT

International

Standard

ISO/TC 38/SC 23

Textiles — Sampling methods for

Secretariat: SAC

fibres, yarns and fabrics for testing

Voting begins on:

Voting terminates on:

RECIPIENTS OF THIS DRAFT ARE INVITED TO SUBMIT,

WITH THEIR COMMENTS, NOTIFICATION OF ANY

RELEVANT PATENT RIGHTS OF WHICH THEY ARE AWARE

AND TO PROVIDE SUPPOR TING DOCUMENTATION.

© ISO 2025

IN ADDITION TO THEIR EVALUATION AS

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO

LOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL

or ISO’s member body in the country of the requester.

TO BECOME STAN DARDS TO WHICH REFERENCE MAY BE

MADE IN NATIONAL REGULATIONS.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland Reference number

ii

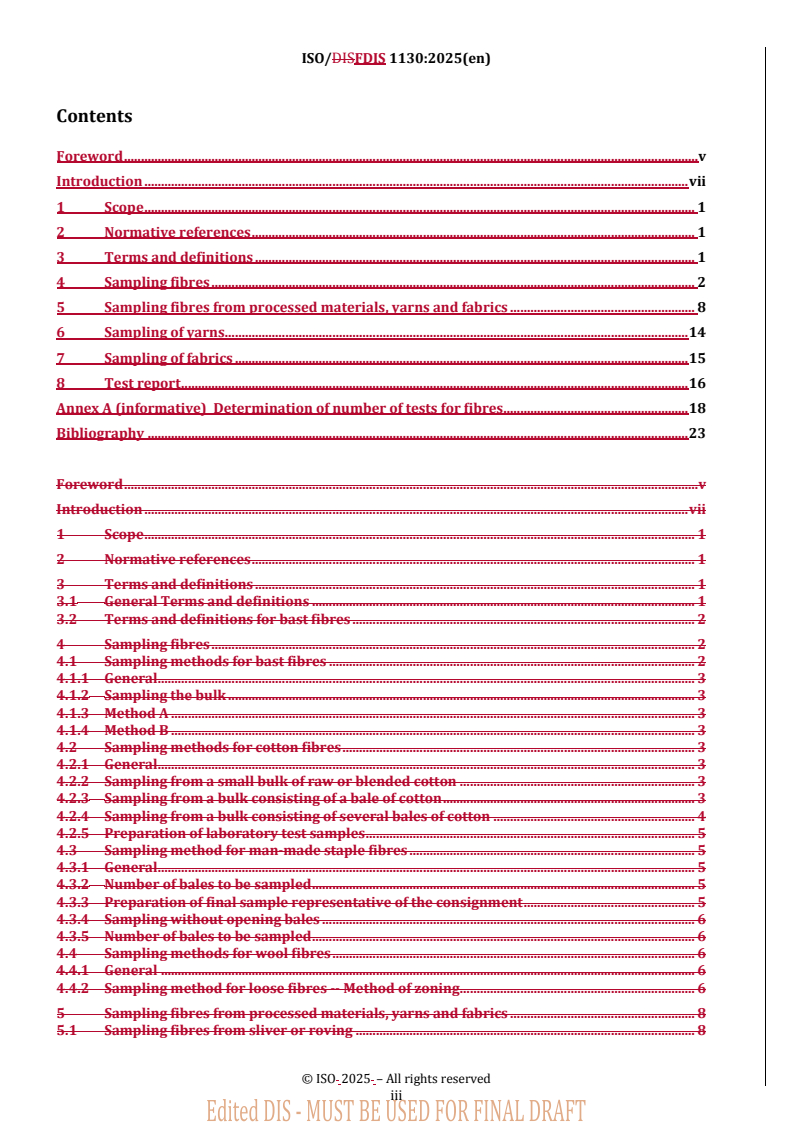

Contents Page

Foreword .v

Introduction .vii

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

3.1 General terms and definitions .1

3.2 Terms and definitions for bast fibres .2

4 Sampling fibres . 2

4.1 Sampling methods for bast fibres .2

4.1.1 General .2

4.1.2 Sampling the bulk .2

4.1.3 Method A . .3

4.1.4 Method B . .3

4.2 Sampling methods for cotton fibres .3

4.2.1 General .3

4.2.2 Sampling from a small bulk of raw or blended cotton .3

4.2.3 Sampling from a bulk consisting of a bale of cotton .3

4.2.4 Sampling from a bulk consisting of several bales of cotton .4

4.2.5 Preparation of laboratory test samples .4

4.3 Sampling method for man-made staple fibres .5

4.3.1 General .5

4.3.2 Number of bales to be sampled .5

4.3.3 Preparation of final sample representative of the consignment .5

4.3.4 Sampling without opening bales .5

4.3.5 Number of bales to be sampled .6

4.4 Sampling methods for wool fibres .6

4.4.1 General .6

4.4.2 Sampling method for loose fibres — Method of zoning .6

5 Sampling fibres from processed materials, yarns and fabrics . 8

5.1 Sampling fibres from slivers or rovings .8

5.1.1 General .8

5.1.2 Cut square method .8

5.1.3 Random draw method .9

5.2 Sampling fibres from yarns . .11

5.2.1 General .11

5.2.2 Sampling from a bulk consisting of yarns – Cut square method .11

5.2.3 Procedure .11

5.3 Sampling fibres from fabrics . 12

6 Sampling of yarns.12

6.1 General . 12

6.2 Procedure for shipments, consignments and lots . 13

6.3 Length of yarns on the package . 13

6.4 Sampling of yarns from beams . 13

6.5 Procedure during sampling and the number of specimens.14

6.6 Sampling of yarns from fabrics .14

7 Sampling of fabrics . 14

7.1 General .14

7.2 Procedure for shipments, consignments and lots .14

7.3 Procedure for sampling . 15

8 Test report .15

Annex A (informative) Determination of number of tests for fibres .16

iii

Bibliography . 19

iv

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee

has been established has the right to be represented on that committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely

with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types

of ISO documents should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent

rights in respect thereof. As of the date of publication of this document, ISO had not received notice of (a)

patent(s) which may be required to implement this document. However, implementers are cautioned that

this may not represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents. ISO shall not be held responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 38, Textiles, Subcommittee SC 23, Fibres and yarns.

This second edition cancels and replaces the first edition (ISO 1130:1975), which has been technically

revised.

The main changes are as follows:

— the title has been changed from “Textile fibres — Some methods of sampling for testing” to “Textiles —

Sampling methods for fibres, yarns and fabrics for testing”;

— This document has been updated in accordance with the editorial rules of the ISO/IEC Directives, Part 2

and subsequent clauses have been renumbered;

— The Introduction has been updated according to the changed title and description of methods from the

scope has be moved in to introduction;

— The Scope has been updated to align with the change in title;

— The mandatory normative references clause (Clause 2) has been added and subsequent clauses have

been renumbered;

— In Subclause 3.1, some definitions have been updated according to ISO/IEC Directives, Part 2, 2021, 16;

— “Sampling without opening bales” has been revised from Note to Subclause 4.2.4.2.3;

— Subclauses 4.2.4.2.2, related to the sampling from a bulk consisting of several bales of cotton, when the

number of bales is not more than 10, have been added.

— Subclauses 4.3.4 and 4.3.5 related to the sampling method for man-made staple fibres, have been added;

— Subclauses 5.1.2 related to the sampling fibres from slivers or rovings, have been added;

— Sampling fibres from processed materials, yarns and fabrics has been revised as an individual clause;

v

— Clauses about Sampling of yarns, sampling of fabrics and test report have been added;

— Figure 1 has been added;

— The Bibliography has been added.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

vi

Introduction

No single technique of sampling of fibres, yarns and fabrics can be devised that will serve in all circumstances.

Sampling from a bale of cotton, for example, presents problems quite different from those encountered in

sampling from a consignment of yarn packages, while sampling from a card web is again different from either.

If the fibres in the bulk have been well mixed, so that there is no variation in composition from one part to

another, i.e. the individual fibres are distributed at random, the sample can, without disadvantage, be taken

from one place anywhere in the bulk.

If the fibres in the bulk are not known to have been well mixed, so that the composition can vary from one

part to another, a sample taken from any one place would not be representative of the whole bulk.

The samples are generally taken as the shipping units making up a lot; such as bales of fibre, cases of yarn,

rolls of fabric, or cartons of garments or other finished products. Adequate sampling for acceptance testing

requires taking into account not only the variability between the laboratory samples but also the variability

between the laboratory test samples and between the test specimens.

The objective of sampling can vary with the purpose for which the test method is used. The objective of

sampling for acceptance testing is to obtain material which will estimate, without bias, a property of the lot

being evaluated- and which allows making a decision on whether to accept or reject a lot with reasonable

procedures and consumers risks when the acceptable quality level and the limiting quality level are at

realistic levels. There are normally many ways to estimate the property of interest to specified degree of

precision. The most economical way to do so will depend on the relative size of the sources of variability

associated with sampling the laboratory samples.

A selection of methods is therefore presented, illustrating techniques that have been found acceptable in

meeting the most common types of problem encountered in sampling for the assessment of fibre quality.

Methods peculiar to the requirements of research are not included, nor are such special techniques have to

be used, for example, in sampling of wool from the fleece, or cotton from the seed.

Although in this document, the principle of several methods for preparing laboratory samples of fibres, yarns

and fabrics is described, it is not possible for the coverage of each individual procedure for each method

to be fully comprehensive; in many instances, the selection of laboratory test samples or test specimens is

necessarily covered by the appropriate method of test.

vii

FINAL DRAFT International Standard ISO/FDIS 1130:2025(en)

Textiles — Sampling methods for fibres, yarns and fabrics

for testing

1 Scope

This document specifies several methods for preparing laboratory samples of fibres, yarns and fabrics and

presents a limited treatment of the problem of drawing specimens for testing.

The selection of length-biased samples is not within the scope of this document. It does not cover particular

procedures for the determination of commercial weights or moisture content.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1 General terms and definitions

3.1.1

individual

any single fibre, yarn or fabric that can be taken for the purpose of measurement

3.1.2

population

aggregate of individuals (3.1.1) that is desired to characterize in one or more particulars

EXAMPLE Fibres contained in a bale of cotton; all the constituent fibres in a set of yarn cops

3.1.3

zoning,verb

operation where individuals or groups of individuals (3.1.1) in the population (3.1.2) are taken at random

from within the different parts or zones

Note 1 to entry: This is performed when the population to be sampled is known to vary from part to part with respect

to the property to be investigated. The samples are chosen so that all variations of the property are represented in due

proportion.

3.1.4

laboratory sample

sample intended to be representative of a large bulk of material, in the state in which it is sent to the

laboratory

Note 1 to entry: A convenient size of laboratory sample for many types of test involving only small test specimens is

about 25 g to 50 g; a larger amount will be required for tests involving relatively large test specimens.

3.1.5

laboratory test sample

portion of fibres, yarns or fabrics taken from the laboratory sample (3.1.4), in such a way as to ensure

its representative character and, to provide a quantity small enough to be easily convertible into test

specimens (3.1.6)

3.1.6

test specimen

part of the laboratory test sample (3.1.5), (fibres, yarns, or fabrics) which is tested at one time

3.1.7

numerical sample

sample in which all fibres in the population (3.1.2) have an equal chance of being represented

3.1.8

length-biased sample

sample in which the chance of any fibre of the population (3.1.2) being represented is proportional to the

length of that fibre

3.2 Terms and definitions for bast fibres

3.2.1

reed

fibrous strands obtained from a jute stem after retting

3.2.2

head

bunch of jute reeds, given a twist and folded over before being made into a bale

3.2.3

bunch

aggregate of pieces of flax tied up with two or more ties preparatory to baling

3.2.4

strick

small bunch of flax straws, or scutched flax, or of hackled flax, of a size that can be held in the hand, or a

bunch of jute similar to a head, but smaller, usually 1 kg to 2 kg in mass

4 Sampling fibres

4.1 Sampling methods for bast fibres

NOTE Bast fibres which are required to be broken in the preliminary stages of processing, and consequently

sampling for fibre length measurement, are carried out on sliver or yarn, and not on the raw fibre.

4.1.1 General

Raw bast fibres are usually sampled only for determination of fibre fineness and fibre strength, and the

methods adopted depend on the type of bast fibre. Flax and hemp need different handling from jute and kenaf.

Method A applies to bales or other bulks of bast fibres such as flax and hemp in the raw state and to bulks of

dressed line in bunches.

Method B applies to bales or bulks of jute or kenaf in the raw state.

4.1.2 Sampling the bulk

Take a representative sample by abstracting small sub-samples from various parts of the bulk and reduce

each of these to a convenient number of fibres by repeated halving.

4.1.3 Method A

Select a number of bunches (preferably not less than twenty) at random from various parts of the bale or

bulk, and remove a strick of fibre from each one. Divide each strick lengthwise by gripping the centre and

pulling transversely to the length of the fibres to separate the two portions. Discard one portion and retain

the identity of the root and tip of the retained portion. Repeatedly halve the retained portion until the

amount of fibre retained is sufficiently small. Make a composite sample for test purposes by combining the

retained fibre from each strick, placing root ends together and tip ends together.

4.1.4 Method B

Take a number of heads of jute (preferably not less than fifty) at random from the bulk, and remove a reed

from each head. Cut each of these reeds into root end, middle, and tip end, keeping the sections separate and

the corresponding cut lengths from all reeds bundled together. Then tease out each of the three composite

bundles by hackling on pins, or by other means, to remove cross-linked and tangled fibres.

For determinations of fibre fineness and single fibre breaking load, cut small bundles of fibres, each weighing

a few milligrams and of fixed length (30 mm is suitable), from a composite bundle at a number of points and

put them together to form a test sample (25 mg is often a convenient mass).

4.2 Sampling methods for cotton fibres

4.2.1 General

Subclause 4.2 gives methods for the preparation of numerical laboratory samples.

The methods described in 4.2.2 to 4.2.5 are applicable to bulks of cotton fibres in various forms.

4.2.2 Sampling from a small bulk of raw or blended cotton

If the bulk consists of less than 5 kg of loose raw cotton, it shall be spread out in an even layer. Unless

otherwise stated, obtain the laboratory sample by selecting at random a minimum of 100 tufts, each of

0,25 g to 0,50 g.

If the bulk is greater than 5 kg, divide it into a number of equal portions, and take an equal number of tufts

(of 0,25 g to 0,50 g each) from each portion such that the total number from all portions exceeds 100.

4.2.3 Sampling from a bulk consisting of a bale of cotton

4.2.3.1 General

There is variation in most fibre properties between and within layers of the same bale of cotton. The values

of coefficients of within- and between-layer variation and of the ratio of these coefficients of variation vary

according to the fibre characteristics under consideration, and also with the type of cotton.

4.2.3.2 Procedure

If the bale is open, a suitable laboratory sample may be obtained by selecting 10 tufts at random throughout

each of 10 equally spaced layers.

If the bale has not been opened, the above procedure cannot be followed. In this case, the following procedure

may be feasible.

Extract the required number of tufts by removing cotton from one or more of the edges that are perpendicular

to the layers in the bale, so that the sample includes material from many layers. In taking the tufts, reject any

soiled cotton from the outside of the bale (the procedure may be facilitated by cutting one of the end bands

round the bale).

NOTE A less satisfactory sample is yielded by selecting tufts from various places over the upper and lower sides

of a bale.

Although this cotton is easily accessible, any laboratory sample obtained in this manner will represent at the

most two layers, one on each side of the bale.

4.2.4 Sampling from a bulk consisting of several bales of cotton

4.2.4.1 General

The detailed method of sampling depends on the type of test to be carried out, the number of bales, and the

likely variation between the bales.

4.2.4.2 Procedure

The following procedure shall be used unless the specification states otherwise.

4.2.4.2.1 When the number of bales is greater than 10 and the real variation in the bulk is not appreciably

greater than the precision required in the test result, make a random choice of 10 % of the bales (or 10 bales

if 10 % of the bulk is less than ten bales); then from the selected bales take a minimum of 100 tufts, taking an

equal number of tufts from each layer of each bale.

4.2.4.2.2 When the number of bales is not more than 10, select a minimum of 100 tufts; take an equal

number of tufts from each layer of each bale.

4.2.4.2.3 Sampling without opening bales

For most commercial purposes, when selecting a sample from a bale of cotton, it is impracticable to obtain a

representative sample by opening a bale and following the procedure described in 4.2.2. Samples prepared

by selecting cotton from one or two layers in a bale are acceptable for many purposes of quality classification,

and for some forms of testing (for example, determination of micronaire value) when past experience

indicates that the feature under consideration varies appreciably more from bale to bale in a commercial

lot than between layers in the same bale. Under such circumstances, it is recommended that a sample be

prepared in the form of two clumps of cotton, similar in surface area and mass, taken from opposite outer

layers of the bale and with the distance to the edges of the bale a minimum of 100 mm. The face of the

sample should be not less than 120 mm × 150 mm and the total mass not less than 150 g. A sample consisting

of a clump, of the same surface area and total mass, cut from one outer layer only, is less representative and

fulfil the requirements of this document only if mutually agreed by the parties concerned.

4.2.5 Preparation of laboratory test samples

4.2.5.1 General

In certain cases, it may be necessary to have a laboratory test sample, prepared from the laboratory sample.

These laboratory test samples shall be prepared by a method which takes into consideration the test to be

performed and the degree of accuracy desired.

In general, fibre blending by a mechanical blender is preferable, particularly when the test specimen is small

in size, as is the case in the flat-bundle strength test. However, in some cases, samples prepared by hand are

adequate.

When the laboratory sample consists of tufts taken by cutting into the bales, cut fibres shall not be included

in the laboratory test sample.

4.2.5.2 Mechanical blending (preferred method)

The mechanical blender is designed to use a certain mass of fibres, for example up to 10 g.

Spread out the laboratory sample so that pinches can be taken from it at any point. Take small pinches of

fibre from at least 32 different evenly spaced points in the

...

ISO/DISFDIS 1130:2025(en)

ISO/TC 38/SC 23

Secretariat: SAC

Date: 2025-08-3010-27

Textiles — Sampling methods for fibres, yarns and fabrics for testing

FDIS stage

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication

may be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying,

or posting on the internet or an intranet, without prior written permission. Permission can be requested from either ISO

at the address below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: + 41 22 749 01 11

EmailE-mail: copyright@iso.org

Website: www.iso.orgwww.iso.org

Published in Switzerland

ii © ISO #### 2025 – All rights reserved

ii

ISO/DISFDIS 1130:2025(en)

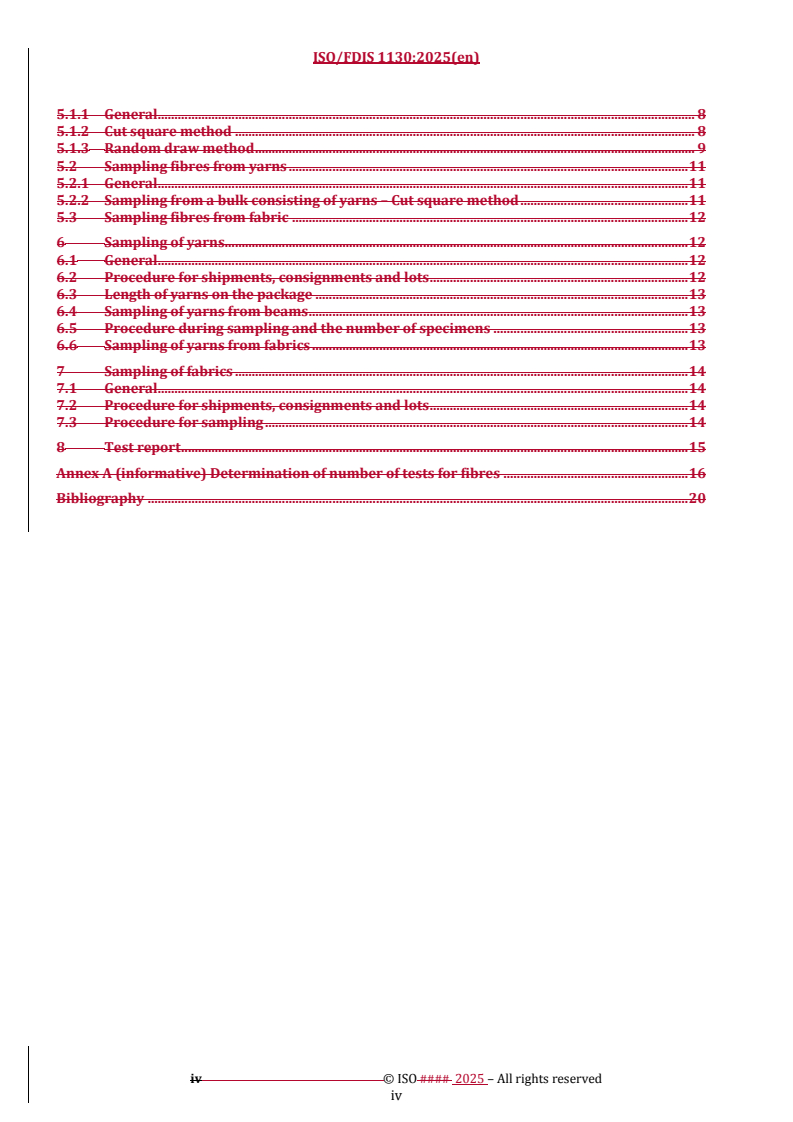

Contents

Foreword . v

Introduction . vii

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Sampling fibres . 2

5 Sampling fibres from processed materials, yarns and fabrics . 8

6 Sampling of yarns . 14

7 Sampling of fabrics . 15

8 Test report . 16

Annex A (informative) Determination of number of tests for fibres. 18

Bibliography . 23

Foreword . v

Introduction . vii

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

3.1 General Terms and definitions . 1

3.2 Terms and definitions for bast fibres . 2

4 Sampling fibres . 2

4.1 Sampling methods for bast fibres . 2

4.1.1 General . 3

4.1.2 Sampling the bulk . 3

4.1.3 Method A . 3

4.1.4 Method B . 3

4.2 Sampling methods for cotton fibres . 3

4.2.1 General . 3

4.2.2 Sampling from a small bulk of raw or blended cotton . 3

4.2.3 Sampling from a bulk consisting of a bale of cotton . 3

4.2.4 Sampling from a bulk consisting of several bales of cotton . 4

4.2.5 Preparation of laboratory test samples . 5

4.3 Sampling method for man-made staple fibres . 5

4.3.1 General . 5

4.3.2 Number of bales to be sampled . 5

4.3.3 Preparation of final sample representative of the consignment . 5

4.3.4 Sampling without opening bales . 6

4.3.5 Number of bales to be sampled . 6

4.4 Sampling methods for wool fibres . 6

4.4.1 General . 6

4.4.2 Sampling method for loose fibres -- Method of zoning . 6

5 Sampling fibres from processed materials, yarns and fabrics . 8

5.1 Sampling fibres from sliver or roving . 8

© ISO 2025 – All rights reserved

iii

5.1.1 General . 8

5.1.2 Cut square method . 8

5.1.3 Random draw method . 9

5.2 Sampling fibres from yarns . 11

5.2.1 General . 11

5.2.2 Sampling from a bulk consisting of yarns – Cut square method . 11

5.3 Sampling fibres from fabric . 12

6 Sampling of yarns . 12

6.1 General . 12

6.2 Procedure for shipments, consignments and lots . 12

6.3 Length of yarns on the package . 13

6.4 Sampling of yarns from beams . 13

6.5 Procedure during sampling and the number of specimens . 13

6.6 Sampling of yarns from fabrics . 13

7 Sampling of fabrics . 14

7.1 General . 14

7.2 Procedure for shipments, consignments and lots . 14

7.3 Procedure for sampling . 14

8 Test report . 15

Annex A (informative) Determination of number of tests for fibres . 16

Bibliography . 20

iv © ISO #### 2025 – All rights reserved

iv

ISO/DISFDIS 1130:2025(en)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types of

ISO documents should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent rights

in respect thereof. As of the date of publication of this document, ISO had not received notice of (a) patent(s)

which may be required to implement this document. However, implementers are cautioned that this may not

represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents.www.iso.org/patents. ISO shall not be held responsible for identifying any or all such

patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 38, Textiles, Subcommittee SC 23, Fibres and

yarns.

This second edition cancels and replaces the first edition (ISO 1130:1975), which has been technically revised.

The main changes are as follows:

— — the title has been changed from “Textile fibres — Some methods of sampling for testing “” to “Textiles

— Sampling methods for fibres, yarns and fabrics for testing”;

— — This document has been updated in accordance with the editorial rules of the ISO/IEC Directives, Part

2 and subsequent clauses have been renumbered;

— — The Introduction has been updated according to the changed title and description of methods from the

scope has be moved in to introduction;

— — The Scope has been updated according to align with the changedchange in title;

— — The mandatory normative references clause (Clause 2)(2) has been added and subsequent clauses

have been renumbered;

— — In Subclause 3.1,3.1, some definitions have been updated according to ISO/IEC Directives, Part 2, 2021,

16;

— — “Sampling without opening bales” has been revised from Note to Subclause 4.2.4.2.3;4.2.4.2.3;

© ISO 2025 – All rights reserved

v

— — Subclauses 4.2.4.2.2,4.2.4.2.2, related to the sampling from a bulk consisting of several bales of cotton,

when the number of bales is not more than 10, have been added.

— — Subclauses 4.3.44.3.4 and 4.3.54.3.5 related to the sampling method for man-made staple fibres, have

been added;

— — Subclauses 5.1.25.1.2 related to the sampling fibres from slivers or rovings, have been added;

— — Sampling fibres from processed materials, yarns and fabrics has been revised as an individual clause;

— — Clauses about Sampling of yarns, sampling of fabrics and test report have been added;

— — Figure 10 has been added;

— — The Bibliography has been added.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.htmlwww.iso.org/members.html.

vi © ISO #### 2025 – All rights reserved

vi

ISO/DISFDIS 1130:2025(en)

Introduction

No single technique of sampling of fibres, yarns and fabrics can be devised that will serve in all circumstances.

Sampling from a bale of cotton, for example, presents problems quite different from those encountered in

sampling from a consignment of yarn packages, while sampling from a card web is again different from either.

If the fibres in the bulk have been well mixed, so that there is no variation in composition from one part to

another, i.e. the individual fibres are distributed at random, the sample can, without disadvantage, be taken

from one place anywhere in the bulk.

If the fibres in the bulk are not known to have been well mixed, so that the composition maycan vary from one

part to another, a sample taken from any one place would not be representative of the whole bulk.

The samples are generally taken as the shipping units making up a lot; such as bales of fibre, cases of yarn,

rolls of fabric, or cartons of garments or other finished products. Adequate sampling for acceptance testing

requires taking into account not only the variability between the laboratory samples but also the variability

between the laboratory test samples and between the test specimens.

The objective of sampling maycan vary with the purpose for which the test method is used. The objective of

sampling for acceptance testing is to obtain material which will estimate, without bias, a property of the lot

being evaluated- and which allows making a decision on whether to accept or reject a lot with reasonable

procedures and consumers risks when the acceptable quality level and the limiting quality level are at realistic

levels. There are normally many ways to estimate the property of interest to specified degree of precision. The

most economical way to do so will depend on the relative size of the sources of variability associated with

sampling the laboratory samples.

A selection of methods is therefore presented, illustrating techniques that have been found acceptable in

meeting the commonermost common types of problem encountered in sampling for the assessment of fibre

quality. Methods peculiar to the requirements of research are not included, nor are such special techniques as

have to be used, for example, in sampling of wool from the fleece, or cotton from the seed.

Although in this document, the principle of several methods for preparing laboratory samples of fibres, yarns

and fabrics is described, it is not possible for the coverage of each individual procedure for each method to be

fully comprehensive; in many instances, the selection of laboratory test samples or test specimens is

necessarily covered by the appropriate method of test.

© ISO 2025 – All rights reserved

vii

DRAFT International Standard ISO/DIS 1130:2025(en)

Textiles - — Sampling methods for fibres, yarns and fabrics for testing

1 Scope

This document specifies several methods for preparing laboratory samples of fibres, yarns and fabrics and

presents a limited treatment of the problem of drawing specimens for testing.

The selection of length-biased samples is not within the scope of this document, nor are. It does not cover

particular procedures for the determination of commercial weights or moisture content.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— — ISO Online browsing platform: available at https://www.iso.org/obphttps://www.iso.org/obp

— — IEC Electropedia: available at https://www.electropedia.org/https://www.electropedia.org/

3.1 General terms and definitions

3.1.1

individual

any single fibre, yarn or fabric that can be taken for the purpose of measurement

3.1.2

population

aggregate of individuals (3.1.1)(Error! Reference source not found.) that it is desired to characterize in one

or more particulars

EXAMPLE Fibres contained in a bale of cotton; all the constituent fibres in a set of yarn cops

3.1.3

zoning, verb

operation where individuals or groups of individuals (3.1.1)(Error! Reference source not found.) in the

population (3.1.2)(Error! Reference source not found.) are taken at random from within the different parts

or zones

Note 1 to entry: This is performed when the population to be sampled is known to vary from part to part with respect

to the property to be investigated. The samples are chosen so that all variations of the property are represented in due

proportion.

3.1.4

laboratory sample

sample intended to be representative of a large bulk of material, in the state in which it is sent to the laboratory

Note 1 to entry: A convenient size of laboratory sample for many types of test involving only small test specimens is

about 25 g to 50 g; a larger amount will be required for tests involving relatively large test specimens.

3.1.5

laboratory test sample

portion of fibres, yarns or fabrics taken from the laboratory sample (3.1.4),(Error! Reference source not

found.), in such a way as to ensure its representative character and, to provide a quantity small enough to be

easily convertible into test specimens (3.1.6)(Error! Reference source not found.)

3.1.6

test specimen

part of the laboratory test sample (3.1.5),(Error! Reference source not found.), (fibres, yarns, or fabrics)

which is tested at one time

3.1.7

numerical sample

sample in which all fibres in the population (3.1.2)(Error! Reference source not found.) have an equal

chance of being represented

3.1.8

length-biased sample

sample in which the chance of any fibre of the population (3.1.2)(Error! Reference source not found.) being

represented is proportional to the length of that fibre

3.2 Terms and definitions for bast fibres

3.2.1

reed

fibrous strands obtained from a jute stem after retting

3.2.2

head

bunch of jute reeds, given a twist and folded over before being made into a bale

3.2.3

bunch

aggregate of pieces of flax tied up with two or more ties preparatory to baling

3.2.4

strick

small bunch of flax straws, or scutched flax, or of hackled flax, of a size that can be held in the hand, or a bunch

of jute similar to a head, but smaller, usually 1 kg to 2 kg in mass

4 Sampling fibres

4.1 Sampling methods for bast fibres

NOTE Bast fibres which are required to be broken in the preliminary stages of processing, and consequently

sampling for fibre length measurement, are carried out on sliver or yarn, and not on the raw fibre.

4.1.1 General

Raw bast fibres are usually sampled only for determination of fibre fineness and fibre strength, and the

methods adopted depend on the type of bast fibre. Flax and hemp need different handling from jute and kenaf.

Method A applies to bales or other bulks of bast fibres such as flax and hemp in the raw state and to bulks of

dressed line in bunches.

2 © ISO #### 2025 – All rights reserved

ISO/DISFDIS 1130:2025(en)

Method B applies to bales or bulks of jute or kenaf in the raw state.

4.1.2 Sampling the bulk

Take a representative sample by abstracting small sub-samples from various parts of the bulk and reduce each

of these to a convenient number of fibres by repeated halving.

4.1.3 Method A

Select a number of bunches (preferably not less than twenty) at random from various parts of the bale or bulk,

and remove a strick of fibre from each one. Divide each strick lengthwise by gripping the centre and pulling

transversely to the length of the fibres to separate the two portions. Discard one portion and retain the identity

of the root and tip of the retained portion. Repeatedly halve the retained portion until the amount of fibre

retained is sufficiently small. Make a composite sample for test purposes by combining the retained fibre from

each strick, placing root ends together and tip ends together.

4.1.4 Method B

Take a number of heads of jute (preferably not less than fifty) at random from the bulk, and remove a reed

from each head. Cut each of these reeds into root end, middle, and tip end, keeping the sections separate and

the corresponding cut lengths from all reeds bundled together. Then tease out each of the three composite

bundles by hackling on pins, or by other means, to remove cross-linked and tangled fibres.

For determinations of fibre fineness and single fibre breaking load, cut small bundles of fibres, each weighing

a few milligrams and of fixed length (30 mm is suitable), from a composite bundle at a number of points and

put them together to form a test sample (25 mg is often a convenient mass).

4.2 Sampling methods for cotton fibres

4.2.1 General

Subclause 4.24.2 gives methods for the preparation of numerical laboratory samples.

The methods described in 4.2.2 to 4.2.54.2.2 to 4.2.5 are applicable to bulks of cotton fibres in various forms.

4.2.2 Sampling from a small bulk of raw or blended cotton

If the bulk consists of less than 5 kg of loose raw cotton, it shall be spread out in an even layer. Unless otherwise

stated, obtain the laboratory sample by selecting at random a minimum of 100 tufts, each of 0,25 g to 0,50 g.

If the bulk is greater than 5 kg, divide it into a number of equal portions, and take an equal number of tufts (of

0,25 g to 0,50 g each) from each portion such that the total number from all portions exceeds 100.

4.2.3 Sampling from a bulk consisting of a bale of cotton

4.2.3.1 General

There is variation in most fibre properties between and within layers of the same bale of cotton. The values of

coefficients of within- and between-layer variation and of the ratio of these coefficients of variation vary

according to the fibre characteristics under consideration, and also with the type of cotton.

4.2.3.2 Procedure

If the bale is open, a suitable laboratory sample may be obtained by selecting 10 tufts at random throughout

each of 10 equally spaced layers.

© ISO 2025 – All rights reserved

If the bale has not been opened, the above procedure cannot be followed. In this case, the following procedure

may be feasible.

Extract the required number of tufts by removing cotton from one or more of the edges that are perpendicular

to the layers in the bale, so that the sample includes material from many layers. In taking the tufts, reject any

soiled cotton from the outside of the bale (the procedure may be facilitated by cutting one of the end bands

round the bale).

NOTE A less satisfactory sample is yielded by selecting tufts from various places over the upper and lower sides of

a bale.

Although this cotton is easily accessible, any laboratory sample obtained in this manner will represent at the

most two layers, one on each side of the bale.

4.2.4 Sampling from a bulk consisting of several bales of cotton

4.2.4.1 General

The detailed method of sampling depends on the type of test to be carried out, the number of bales, and the

likely variation between the bales.

4.2.4.2 Procedure

The following procedure shall be used unless the specification states otherwise.

4.2.4.2.1 4.2.4.2.1 When the number of bales is greater than 10 and the real variation in the bulk

is not appreciably greater than the precision required in the test result, Makemake a random choice of 10 %

of the bales (or 10 bales if 10 % of the bulk is less than ten bales); then from the selected bales take a minimum

of 100 tufts, taking an equal number of tufts from each layer of each bale.

4.2.4.2.2 4.2.4.2.2 When the number of bales is not more than 10, select a minimum of 100 tufts;

take an equal number of tufts from each layer of each bale.

4.2.4.2.3 4.2.4.2.3 Sampling without opening bales

For most commercial purposes, when selecting a sample from a bale of cotton, it is impracticable to obtain a

representative sample by opening a bale and following the procedure described in 4.2.2.4.2.2. Samples

prepared by selecting cotton from one or two layers in a bale are acceptable for many purposes of quality

classification, and for some forms of testing (for example, determination of micronaire value) when past

experience indicates that the feature under consideration varies appreciably more from bale to bale in a

commercial lot than between layers in the same bale. Under such circumstances, it is recommended that a

sample be prepared in the form of two clumps of cotton, similar in surface area and mass, taken from opposite

outer layers of the bale and with the distance to the edges of the bale a minimum of 100 mm. The face of the

sample should be not less than 120 mm × 150 mm and the total mass not less than 150 g. A sample consisting

of a clump, of the same surface area and total mass, cut from one outer layer only, is less representative and

fulfil the requirements of this document only if mutually agreed by the parties concerned.

4.2.5 Preparation of laboratory test samples

4.2.5.1 General

In certain cases, it may be necessary to have a laboratory test sample, prepared from the laboratory sample.

These laboratory test samples shall be prepared by a method which takes into consideration the test to be

performed and the degree of accuracy desired.

4 © ISO #### 2025 – All rights reserved

ISO/DISFDIS 1130:2025(en)

In general, fibre blending by a mechanical blender is preferable, particularly when the test specimen is small

in size, as is the case in the flat-bundle strength test. However, in some cases, samples prepared by hand are

adequate.

When the laboratory sample consists of tufts taken by cutting into the bales, cut fibres shall not be included in

the laboratory test sample.

4.2.5.2 Mechanical blending (preferred method)

The mechanical blender is designed to use a certain mass of fibres, for example up to 10 g.

Spread out the laboratory sample so that pinches can be taken from it at any point. Take small pinches of fibre

from at least 32 different evenly spaced points in the laboratory sample.

Perform a light drafting action on the pinches before feeding them into the mechanical blender, so as to form

as uniform a sheet of fibre as possible. Blend the fibres using the blender so as to produce a practically

homogeneous sample, taking care not to damage the fibres.

4.2.5.3 Manual methods

Different methods have been described in national standards. They are designed for different methods of test,

for example “cut-squaring”, making hand slivers and making small samples for successive halving and

combining. In some cases, it is preferable to prepare test specimens direct from the laboratory sample.

4.3 Sampling method for man-made staple fibres

4.3.1 General

This method gives a numerical sample. It is suitable for most types of man-made fibres in bale form. Unusual

consignments of staple fibre and supplies of staple produced from filament waste may require a modified

sampling procedure.

4.3.2 Number of bales to be sampled

If the consignment comprises not more than 5 bales, sample all the bales. If the consignment comprises more

than 5 but not more than 25 bales, take 5 bales at random. If there are more than 25 bales in the consignment,

take 10 bales at random.

4.3.3 Preparation of final sample representative of the consignment

From each bale to be sampled take four handfuls each of about

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...