ISO 1823:2015

(Main)Rubber hose and hose assemblies for oil suction and discharge service — Specification

Rubber hose and hose assemblies for oil suction and discharge service — Specification

ISO 1823:2015 specifies the characteristics of four types of oil suction and discharge hose assemblies used for the conveyance of petroleum, including crude oils and other liquid petroleum products. Each type being divided into three classes depend on the aromatic contents. It is not suitable for liquefied petroleum gas and natural gas. Hose assemblies to ISO 1823:2015 can be used in the temperature range −20 °C to 80 °C. The hoses specified are in the range of nominal size 50 to 500 and can be types of smooth bore, rough bore, armoured rough bore, and light weight.

Flexibles en caoutchouc pour chargement et déchargement des produits pétroliers — Spécification

General Information

- Status

- Published

- Publication Date

- 10-Feb-2015

- Technical Committee

- ISO/TC 45/SC 1 - Rubber and plastics hoses and hose assemblies

- Drafting Committee

- ISO/TC 45/SC 1/WG 1 - Industrial, chemical and oil hoses

- Current Stage

- 9060 - Close of review

- Completion Date

- 02-Sep-2030

Relations

- Revises

ISO 1823-2:1997 - Rubber hoses and hose assemblies — Part 2: Ship/dockside discharge — Specification - Effective Date

- 23-Jan-2010

- Effective Date

- 23-Jan-2010

Overview

ISO 1823:2015 - Rubber hose and hose assemblies for oil suction and discharge service specifies requirements for rubber hoses and hose assemblies used to convey petroleum (including crude oil and liquid petroleum products) for suction and discharge operations. The standard covers four hose types (rough bore, armoured rough bore, smooth bore, and light weight) across three classes based on aromatic content, and applies to nominal sizes 50 to 500 and a temperature range of −20 °C to 80 °C. It explicitly excludes liquefied petroleum gas (LPG) and natural gas.

Key topics and technical requirements

- Classification and designation

- Types: Type R (rough bore, stiff, electrically continuous), Type A (armoured, electrically continuous), Type S (smooth bore, flexible, electrically continuous or discontinuous), Type L (lightweight, discharge-only, electrically continuous or discontinuous).

- Classes: Class 25 (suitable for oils/gasoline below 25% aromatics), Class 50 (up to and including 50% aromatics), Class 100 (for higher aromatic-content products).

- Materials and construction

- Lining, reinforcing plies, wire helices (internal and armouring), and cover materials are specified to ensure compatibility and durability.

- Electrical continuity

- Requirements for electrically bonded vs electrically discontinuous hose assemblies - important for static-charge control. Warning: electrically discontinuous hoses require careful consideration and earth continuity measures during transfers.

- End connections and attachment methods

- Specifications for nipples, flanges and methods for securing couplings to hoses.

- Dimensions, tolerances and physical properties

- Nominal size range, length tolerances, rubber compound properties, abrasion and ozone resistance.

- Testing and conformity

- Type tests, hydrostatic tests, wet adhesion tests, test frequency and routine/production testing requirements; test reports and marking requirements.

- Informative annexes

- Purchaser information, packaging and transport recommendations, expected masses and normative test procedures.

Practical applications

- Transfer of crude oil and liquid petroleum products between tankers, barges and shore facilities

- Dock and bunkering hose services where robustness, flexibility, or lightweight handling is required

- Marine and shore-based petroleum transfer operations (excluding LPG and natural gas)

Who should use ISO 1823:2015

- Hose and coupling manufacturers and designers

- Ship operators, terminal and port operators, and bunkering services

- Procurement, quality, and maintenance engineers specifying oil transfer hose assemblies

- Safety and compliance officers ensuring transfer operations meet industry standards

Related standards

ISO 1823:2015 references several related standards for testing and components, including ISO 1402 (hydrostatic testing), ISO 8031 (electrical resistance), ISO 8033 (adhesion), ISO 8330 (vocabulary), and flange/metal coating standards for end fittings.

Keywords: ISO 1823:2015, rubber hose, oil suction and discharge hose, hose assemblies, petroleum transfer hose, dock hose, armoured hose, hydrostatic test, electrically bonded hose.

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

Smithers Quality Assessments

US management systems and product certification.

Sponsored listings

Frequently Asked Questions

ISO 1823:2015 is a standard published by the International Organization for Standardization (ISO). Its full title is "Rubber hose and hose assemblies for oil suction and discharge service — Specification". This standard covers: ISO 1823:2015 specifies the characteristics of four types of oil suction and discharge hose assemblies used for the conveyance of petroleum, including crude oils and other liquid petroleum products. Each type being divided into three classes depend on the aromatic contents. It is not suitable for liquefied petroleum gas and natural gas. Hose assemblies to ISO 1823:2015 can be used in the temperature range −20 °C to 80 °C. The hoses specified are in the range of nominal size 50 to 500 and can be types of smooth bore, rough bore, armoured rough bore, and light weight.

ISO 1823:2015 specifies the characteristics of four types of oil suction and discharge hose assemblies used for the conveyance of petroleum, including crude oils and other liquid petroleum products. Each type being divided into three classes depend on the aromatic contents. It is not suitable for liquefied petroleum gas and natural gas. Hose assemblies to ISO 1823:2015 can be used in the temperature range −20 °C to 80 °C. The hoses specified are in the range of nominal size 50 to 500 and can be types of smooth bore, rough bore, armoured rough bore, and light weight.

ISO 1823:2015 is classified under the following ICS (International Classification for Standards) categories: 75.200 - Petroleum products and natural gas handling equipment; 83.140.40 - Hoses. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 1823:2015 has the following relationships with other standards: It is inter standard links to ISO 1823-2:1997, ISO 1823-1:1997. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 1823:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 1823

Second edition

2015-02-15

Rubber hose and hose assemblies for

oil suction and discharge service —

Specification

Flexibles en caoutchouc pour chargement et déchargement des

produits pétroliers — Spécification

Reference number

©

ISO 2015

© ISO 2015

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2015 – All rights reserved

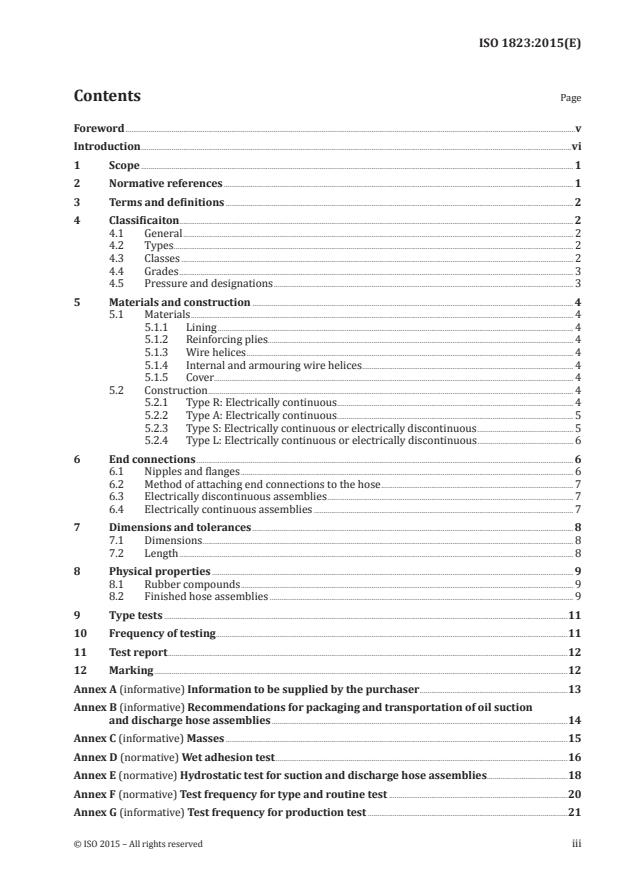

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Classificaiton . 2

4.1 General . 2

4.2 Types. 2

4.3 Classes . 2

4.4 Grades . 3

4.5 Pressure and designations . 3

5 Materials and construction . 4

5.1 Materials . 4

5.1.1 Lining . 4

5.1.2 Reinforcing plies. 4

5.1.3 Wire helices . 4

5.1.4 Internal and armouring wire helices . 4

5.1.5 Cover. 4

5.2 Construction . 4

5.2.1 Type R: Electrically continuous . 4

5.2.2 Type A: Electrically continuous . . 5

5.2.3 Type S: Electrically continuous or electrically discontinuous . 5

5.2.4 Type L: Electrically continuous or electrically discontinuous . 6

6 End connections . 6

6.1 Nipples and flanges . 6

6.2 Method of attaching end connections to the hose . 7

6.3 Electrically discontinuous assemblies . 7

6.4 Electrically continuous assemblies . 7

7 Dimensions and tolerances . 8

7.1 Dimensions . 8

7.2 Length . 8

8 Physical properties . 9

8.1 Rubber compounds . 9

8.2 Finished hose assemblies . 9

9 Type tests .11

10 Frequency of testing .11

11 Test report .12

12 Marking .12

Annex A (informative) Information to be supplied by the purchaser .13

Annex B (informative) Recommendations for packaging and transportation of oil suction

and discharge hose assemblies .14

Annex C (informative) Masses .15

Annex D (normative) Wet adhesion test .16

Annex E (normative) Hydrostatic test for suction and discharge hose assemblies .18

Annex F (normative) Test frequency for type and routine test .20

Annex G (informative) Test frequency for production test .21

Bibliography .22

iv © ISO 2015 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 45, Rubber and rubber products, Subcommittee

SC 1, Rubber and plastics hoses and hose assemblies.

This second edition of ISO 1823 cancels and replaces ISO 1823-1:1997 and ISO 1823-2:1997. Considering

the actual market situations, two classes (the lowest and highest aromatics content) and one grade for

maximum working pressure have been added in 4.3 and 4.4, respectively.

Introduction

This International Standard specifies minimum requirements for the satisfactory performance of

wire- or textile-reinforced rubber hose assemblies of both smooth and rough bore types for oil suction

and discharge services. The hoses are commonly used for transferring crude oil and liquid petroleum

products, other than liquefied petroleum gas and natural gas, to and from tanker and bunkering vessels

or for similar duties ashore.

Specific details of the construction of hoses are not rigidly defined in this International Standard since it

is felt that this could restrict the introduction of improved methods of construction. The hose assemblies

have been classified and designated in terms of service pressure, which includes an allowance for surge

pressure and which equates to the factory test pressure. To keep this specification in line with other

documents, this factory test pressure is also defined as the maximum working pressure (see Table 1). It

is the responsibility of the user to determine the appropriate working pressure, which will depend on the

severity of the user’s operating conditions and on the service life that is expected of the hose assembly.

It is necessary for the purchaser to provide certain information about the hose assembly and its

intended use at the time of enquiry and/or order; this information is listed in Annex A (informative).

Recommendations concerning packaging and transportation are given in Annex B (informative) and

expected masses of hoses, in kilograms per metre of free length, are given in Annex C (informative).

vi © ISO 2015 – All rights reserved

INTERNATIONAL STANDARD ISO 1823:2015(E)

Rubber hose and hose assemblies for oil suction and

discharge service — Specification

1 Scope

This International Standard specifies the characteristics of four types of oil suction and discharge

hose assemblies used for the conveyance of petroleum, including crude oils and other liquid petroleum

products. Each type being divided into three classes depend on the aromatic contents. It is not suitable

for liquefied petroleum gas and natural gas.

Hose assemblies to this International Standard can be used in the temperature range −20 °C to 80 °C.

The hoses specified are in the range of nominal size 50 to 500 and can be types of smooth bore, rough

bore, armoured rough bore, and light weight.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 228, Pipe threads where pressure-tight joints are not made on the threads

ISO 1402, Rubber and plastics hoses and hose assemblies — Hydrostatic testing

ISO 1431-1, Rubber, vulcanized or thermoplastic — Resistance to ozone cracking — Part 1: Static and

dynamic strain testing

ISO 1460, Metallic coatings — Hot dip galvanized coatings on ferrous materials — Gravimetric determination

of the mass per unit area

ISO 1461, Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods

ISO 1817, Rubber, vulcanized or thermoplastic ― Determination of the effect of liquids

ISO 2063, Metallic and other inorganic coatings — Thermal spraying — Zinc, aluminium and their alloys

ISO 4649, Rubber, vulcanized or thermoplastic — Determination of abrasion resistance using a rotating

cylindrical drum device

ISO 7005-1, Pipe flanges — Part 1: Steel flanges for industrial and general service piping systems

ISO 7233, Rubber and plastics hoses and hose assemblies — Determination of resistance to vacuum

ISO 8031, Rubber and plastics hoses and hose assemblies — Determination of electrical resistance and

conductivity

ISO 8033, Rubber and plastics hoses — Determination of adhesion between components

ISO 8330, Rubber and plastics hoses and hose assemblies — Vocabulary

ISO 10619-1, Rubber and plastics hoses and tubing — Measurement of flexibility and stiffness — Part 1:

Bending tests at ambient temperature

ISO 15614-1, Specification and qualification of welding procedures for metallic materials ― Welding

procedure test ― Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys

BS 3592-1, Steel wire for hose reinforcement — Part 1: Specification for coated round and flat steel wire for

rubber hose reinforcement

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 8330 and the following apply.

3.1

electrically bonded hose assembly

hose assembly that uses a metallic wire connection to create a low-resistance electrical connection

between the end connection

3.2

electrically discontinuous hose assembly

hose assembly that incorporates an electrical insulation between the end of the helical wire or/and wire

cord reinforcement and on or both couplings

4 Classificaiton

4.1 General

WARNING — Careful consideration needs to be given before the use of electrically discontinuous

hoses for transferring liquids known to generate static charges. In no circumstances should more

than one length of electrically discontinuous hose be used in an individual transfer pipeline and

effective electrical continuity to earth from both ends of the electrically discontinuous hose

should be maintained.

4.2 Types

Hose assemblies for this application are classified according to end-use as follows:

— Type R, rough bore hose assemblies for dock operation and intended for situations where a relatively

stiff, heavy, and robust assembly can be used. The lining of the rubberized fabric is supported

and reinforced by an internal (hot-dipped) zinc coated steel wire helix. Type R assemblies are

electrically continuous;

— Type A, armoured rough bore hose assemblies for dock operation. In addition to an internal zinc

coated steel wire helix, there shall be external helical armour of a similar material. Type A hoses are

electrically continuous and can be lighter and more flexible than type R;

— Type S, smooth bore hose assemblies for dock operation where flexibility and lightness are important.

Type S hose assemblies can be electrically continuous or electrically discontinuous (see Warning);

— Type L, hose assemblies for dock and general discharge service where greater flexibility, lower weight,

and ease of handling are of primary consideration. Type L hose assemblies can be electrically continuous

or electrically discontinuous. They are only suitable for discharge applications (see Warning).

4.3 Classes

Each type of hose assemblies shall be designated according to three classes, depending on the conveyance

of petroleum products containing the maximum aromatics content:

— Class 25: For oil and gasoline service (suitable for below 25 % aromatics content);

— Class 50: For oil and gasoline service (up to and including 50 % max. aromatics content);

— Class 100: For oil and gasoline service (suitable for up to 100 % aromatics content).

NOTE For the determination of aromatics content, see ISO 3837.

2 © ISO 2015 – All rights reserved

4.4 Grades

Each class is further divided into five grades depending on the maximum working pressure:

— Grade 5: For maximum working pressure 0,5 MPa (5 bar);

— Grade 7: For maximum working pressure 0,7 MPa (7 bar);

— Grade 10: For maximum working pressure 1,0 MPa (10 bar);

— Grade 15: For maximum working pressure 1,5 MPa (15 bar);

— Grade 20: For maximum woking pressure 2,0 MPa (20 bar).

4.5 Pressure and designations

Each type of hose assembly shall be designated according to the type letters R, A, S, or L, followed by the

class figures, and followed by the grade figures which indicate maximum working pressure given in Table 1.

Table 1 — Grade description, pressure and designation

a

Grade Maximum Proof pressure Designation

description working test (maximum

pressure 5 min)

MPa bar MPa bar

R25–5

A50–5

5 0,5 5 0,75 7,5

S25–5

L50–5

R50–7 R100–7

A50–7 A100–7

7 0,7 7 1,05 10,5

S50–7 S100–7

L50–7 L100–7

R25–10 R50–10 R100–10

A50–10 A100–10

10 1,0 10 1,50 15

S25–10 S50–10 S100–10

L50–10 L100–10

R25–15 R50–15 R100–15

A50–15 A100–15

15 1,5 15 2,25 22,5

S25–15 S50–15 S100–15

L50–15 L100–15

R50–20 R100–20

20 2,0 20 3,00 30,0

S50–20 S100–20

a

Other combinations are available if required. See the second paragraph of Introduction.

For the purposes of this International Standard, the maximum working pressure includes an allowance

for surge pressures above the normal operating pressure.

5 Materials and construction

5.1 Materials

5.1.1 Lining

The rubber lining shall be resistant to the materials the assembly is to convey.

The hose lining shall be suitable for continuous operation with the liquids to be conveyed.

NOTE The purchaser should state the products that the assembly is to carry (see Annex A).

5.1.2 Reinforcing plies

The reinforcing plies shall consist of textile or wire cord impregnated with rubber.

Reinforcing wire cord shall be brass, copper, or zinc coated carbon steel wire.

5.1.3 Wire helices

Wire helices shall be cold drawn carbon steel having sulfur and phosphorus contents each not greater

than 0,040 %, and coated with copper or phosphate and comply with the requirements given in BS 3592-1.

If joined, helical reinforcement wire shall be welded and shall conform to the following requirements:

a) welding shall be carried out using electric butt welding;

b) no weld shall be within 1,5 m of a nipple end or of another weld in the same wire neither along the

hose length nor, in the case of two or more wire plies, nearer than 600 mm in adjacent wires.

5.1.4 Internal and armouring wire helices

Internal and armouring, round and flat steel wire shall be cold drawn coated steel having sulfur and

phosphorus contents each not greater than 0,040 % and comply with the requirements given in BS 3592-1.

5.1.5 Cover

The cover of synthetic rubber shall be resistant to abrasion, outdoor exposure, and petroleum products,

including fuel.

5.2 Construction

5.2.1 Type R: Electrically continuous

5.2.1.1 Hoses

Hoses shall consist of the following:

a) an internal wire helix sunk into the inner wall of the hose;

NOTE An additional wire helix can be embedded into other layers.

b) at least one oil resistant rubber impregnated textile ply between the internal wire helix and the lining;

c) a lining of oil resistant rubber, conforming to the requirements given in 5.1.1;

d) plies of woven textile reinforcement or textile or wire cord;

e) an open weave breaker fabric;

4 © ISO 2015 – All rights reserved

f) an outer rubber cover conforming to the requirements given in 5.1.5.

5.2.1.2 Hose assemblies

The internal wire helix shall be connected to the nipple of the end connections by welding or brazing.

If an embedded wire helix is incorporated it shall be spiralled over the nipples to a point at least between

the first and second bands and shall be finished off with at least two closed turns anchored together by

welding or by clipping and soldering.

5.2.2 Type A: Electrically continuous

5.2.2.1 Hoses

Hoses shall consist of:

a) an internal round wire helix;

b) a textile ply impregnated with rubber conforming to the requirements given in 5.1.2;

c) a rubber lining filler resistant to the product to be carried by the hose (see Annex A) and conforming

to the requirements given in 5.1.1;

d) plies of textile reinforcement thoroughly impregnated with rubber;

e) an outer rubber cover conforming to the requirements given in 5.1.5;

f) an external round wire armouring helix lying in the corrugations of the outer cover with no

free movement in any direction when the hose is laid out straight and under no pressure. When

pressed against the cover, the wires shall stand proud of the cover by a minimum of one-third of

the diameter of the wire.

5.2.2.2 Hose assemblies

Where built-in nipples are used, the internal wire helix shall be spiralled over the nipples for at least

30 mm and shall be finished off with at least two close turns anchored together and attached to the

nipple by welding or brazing.

The external wire helix shall be close pitched when wiring on top of the nipple except on the top of the

nipple bands, where the wire can cross at open pitch and return to close pitch between bands.

Both ends of the wire helix shall be secured around the carcass of the hose by a number of close turns

having a minimum axial length equal to three-quarters of the nominal size of the hose. These turns shall

be fixed together by soldering, clipping, welding, or a combination of these. The ends of the wire helix

shall be bonded electrically to the nipple.

There shall be stepped stiffening layers of rubber-impregnated fabric overlapping the nipples.

NOTE Bolted clamps are used for metric dimensions up to 150 mm.

5.2.3 Type S: Electrically continuous or electrically discontinuous

5.2.3.1 Hoses

Hoses shall consist of the following:

a) a lining of rubber conforming to the requirements given in 5.1.1, which shall be smooth and reasonably

free from scores or indentations and shall be flush with the nipples when built-in nipples are used;

b) an open weave textile breaker fabric thoroughly impregnated with rubber laid between the hose

lining and the reinforcing plies and between the plies and the cover;

c) reinforcing plies of either woven textile or textile or wire cord thoroughly impregnated with rubber;

d) at least one helical wire embedded in a layer of rubber;

e) a smooth outer rubber cover conforming to the requirements given in 5.1.5.

5.2.3.2 Hose assemblies

The embedded wire helix (helices) shall be spiralled over the nipples to a point at least between the

first and second bands and shall be finished off with at least two turns anchored together by soldering,

clipping, welding, or a combination of these.

Where built-in nipples are used for electrically continuous hose assemblies, the end of the wire helix

shall be electrically bonded to the nipples by brazing, welding, or by soldering a short of flexible bonding

wire to the end of the helical wire and the nipple. For discontinuous hose assemblies, see 6.3.

5.2.4 Type L: Electrically continuous or electrically discontinuous

5.2.4.1 Hoses

Hoses shall consist of the following:

a) a lining conforming to the requirements given in 5.1.1, which shall be smooth and reasonably free

from scores or indentations and shall be substantially flush with the nipples when built-in nipples

are used for assemblies;

b) a breaker fabric incorporated between the lining and reinforcement when fine wire reinforcement

is used;

c) reinforcing plies of either textile or fine wire thoroughly impregnated with rubber; the ends of the

hose adjacent to the nipples shall have extra reinforcement to reduce the flexibility of the hose/nipple

junction; textile reinforcing plies shall incorporate at least two electrical bonding wires consisting

of at least nine strands of wire having a high resistance to fatigue and continuous throughout the

reinforcement;

d) a smooth outer rubber cover conforming to the requirements given in 5.1.5.

5.2.4.2 Hose assemblies

As this hose type is for discharge application only, the construction does not incorporate a wire helix

and therefore requires no special instructions for attachment of the hose to the nipple of the fitting.

For electrically continuous assemblies, the ends of the electrical bonding wire shall be in contact with

the fitting nipples by means of a low resistance, corrosion prot

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...