ISO 22484:2024

(Main)Displacement and dynamic compressors — Performance test code for electric driven low-pressure air compressor packages

Displacement and dynamic compressors — Performance test code for electric driven low-pressure air compressor packages

This document specifies the performance test method of electrically driven low-pressure air compressor packages, where the compression is performed by positive displacement or dynamic compression; utilising atmospheric air as the compression gas. Low-pressure air compressor packages are often referred to as “blowers”. NOTE Throughout this document, the term ‘low-pressure compressor’ is used to describe a low-pressure air compressor (“blower”) package Low-pressure compressors with and without means of controlling flow (control may be electrical (e.g. with a variable frequency drive) or mechanical or both) are covered. This document applies to low-pressure compressors meeting all the following limits: — Atmospheric inlet air pressure between 0,5 bar and 1,1 bar. — Discharge vs inlet pressure differential between 0,1 bar and 2,5 bar. — Discharge vs inlet pressure ratio between 1,1 and 3,5. This document is not applicable to: — positive displacement low-pressure compressors with a liquid in the compression element (such as liquid ring pumps and liquid injected low-pressure compressor of screw type) — multi-stage low-pressure compressors other than multistage centrifugal compressors comprised of multiple, identical or very similar uncooled sections along a single shaft (repeating stages). — single shaft, multistage centrifugal compressors are treated from the point of measurement and calculation as a single stage

Compresseurs volumétriques et turbocompresseurs — Code d'essai de performance des ensembles de compresseurs à air basse pression à entraînement électrique

General Information

- Status

- Published

- Publication Date

- 31-Oct-2024

- Technical Committee

- ISO/TC 118/SC 6 - Air compressors and compressed air systems

- Drafting Committee

- ISO/TC 118/SC 6 - Air compressors and compressed air systems

- Current Stage

- 6060 - International Standard published

- Start Date

- 01-Nov-2024

- Due Date

- 21-Jul-2024

- Completion Date

- 01-Nov-2024

Overview

ISO 22484:2024 - "Displacement and dynamic compressors - Performance test code for electric driven low-pressure air compressor packages" - defines a standardized, wire-to-air performance test method for electrically driven low-pressure air compressor packages (commonly called blowers). It covers both positive displacement and dynamic (centrifugal) compression types using atmospheric air, and applies to packaged units with or without flow control (electrical or mechanical).

Key scope limits:

- Atmospheric inlet pressure: 0.5 to 1.1 bar

- Discharge vs inlet pressure differential: 0.1 to 2.5 bar

- Discharge vs inlet pressure ratio: 1.1 to 3.5

Exclusions include liquid-filled compression elements (e.g., liquid ring pumps or liquid-injected screw types) and most multi-stage compressors except repeating-stage centrifugal designs; single-shaft multistage centrifugal compressors are treated as a single stage for measurement purposes.

Key topics and requirements

ISO 22484:2024 establishes test procedures, measurement methods and result corrections to ensure repeatable, comparable performance data. Major technical topics include:

- Test scope and preconditions: packaged compressor definition, guarantee conditions, and required pre-test information.

- Instrumentation and accuracy: measurement of pressure, temperature, humidity, rotational frequency, flow rate, external coolant flow and electrical power; and calibration requirements.

- Test procedures: allowed deviations for speed, ambient conditions, flow selection, pressure selection, steady-state criteria, two-speed tests and test validity checks.

- Result corrections and calculations: corrections for flow, pressure and specific energy demand; corrected package power; isentropic efficiency calculations; and comparison with guaranteed values.

- Reporting: mandatory test-report content, summaries and example acceptance reports.

- Ancillary material: equipment checklist, test result templates, calculation examples and thermodynamic background.

Applications and who should use it

This standard is aimed at stakeholders involved in design, testing, procurement and commissioning of low-pressure air compressor packages, including:

- Compressor and blower manufacturers and OEMs

- Independent test laboratories and quality assurance teams

- System integrators and end-users in industries using blowers (ventilation, wastewater aeration, pneumatic conveying, process air)

- Procurement, commissioning and maintenance engineers who require verified, comparable performance guarantees

Using ISO 22484 helps ensure consistent, traceable performance verification, fair acceptance testing, and reliable specification of package guarantees.

Related standards

- ISO 1217 (compressor performance testing) - legacy reference for positive displacement compressors

- ISO 5389, ISO 18740 - existing compressor standards noted in the introduction for context

Keywords: ISO 22484:2024, low-pressure air compressor, blower, performance test, electric driven, positive displacement, dynamic compressor, test code, packaged compressor, VFD, isentropic efficiency.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

ISO 22484:2024 is a standard published by the International Organization for Standardization (ISO). Its full title is "Displacement and dynamic compressors — Performance test code for electric driven low-pressure air compressor packages". This standard covers: This document specifies the performance test method of electrically driven low-pressure air compressor packages, where the compression is performed by positive displacement or dynamic compression; utilising atmospheric air as the compression gas. Low-pressure air compressor packages are often referred to as “blowers”. NOTE Throughout this document, the term ‘low-pressure compressor’ is used to describe a low-pressure air compressor (“blower”) package Low-pressure compressors with and without means of controlling flow (control may be electrical (e.g. with a variable frequency drive) or mechanical or both) are covered. This document applies to low-pressure compressors meeting all the following limits: — Atmospheric inlet air pressure between 0,5 bar and 1,1 bar. — Discharge vs inlet pressure differential between 0,1 bar and 2,5 bar. — Discharge vs inlet pressure ratio between 1,1 and 3,5. This document is not applicable to: — positive displacement low-pressure compressors with a liquid in the compression element (such as liquid ring pumps and liquid injected low-pressure compressor of screw type) — multi-stage low-pressure compressors other than multistage centrifugal compressors comprised of multiple, identical or very similar uncooled sections along a single shaft (repeating stages). — single shaft, multistage centrifugal compressors are treated from the point of measurement and calculation as a single stage

This document specifies the performance test method of electrically driven low-pressure air compressor packages, where the compression is performed by positive displacement or dynamic compression; utilising atmospheric air as the compression gas. Low-pressure air compressor packages are often referred to as “blowers”. NOTE Throughout this document, the term ‘low-pressure compressor’ is used to describe a low-pressure air compressor (“blower”) package Low-pressure compressors with and without means of controlling flow (control may be electrical (e.g. with a variable frequency drive) or mechanical or both) are covered. This document applies to low-pressure compressors meeting all the following limits: — Atmospheric inlet air pressure between 0,5 bar and 1,1 bar. — Discharge vs inlet pressure differential between 0,1 bar and 2,5 bar. — Discharge vs inlet pressure ratio between 1,1 and 3,5. This document is not applicable to: — positive displacement low-pressure compressors with a liquid in the compression element (such as liquid ring pumps and liquid injected low-pressure compressor of screw type) — multi-stage low-pressure compressors other than multistage centrifugal compressors comprised of multiple, identical or very similar uncooled sections along a single shaft (repeating stages). — single shaft, multistage centrifugal compressors are treated from the point of measurement and calculation as a single stage

ISO 22484:2024 is classified under the following ICS (International Classification for Standards) categories: 23.140 - Compressors and pneumatic machines. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 22484:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

International

Standard

ISO 22484

First edition

Displacement and dynamic

2024-11

compressors — Performance

test code for electric driven low-

pressure air compressor packages

Compresseurs volumétriques et turbocompresseurs — Code

d'essai de performance des ensembles de compresseurs à air

basse pression à entraînement électrique

Reference number

© ISO 2024

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Units. 6

5 Guarantee and measurement . 8

5.1 Packaged compressor .8

5.2 Preconditions of the guarantee .8

5.3 Object of the guarantee .9

5.4 Low-pressure compressor to be tested .9

5.5 Low-pressure compressor specifications to be provided prior to testing .10

6 Measuring equipment, methods and accuracy . 10

6.1 General .10

6.2 Measurement of pressure .10

6.2.1 General .10

6.2.2 Atmospheric pressure .11

6.2.3 Pressure measurement for ambient inlet .11

6.2.4 Pressure measurement for piped inlet .11

6.2.5 Pressure measurement for piped discharge.11

6.3 Measurement of temperature .11

6.3.1 General .11

6.3.2 Temperature measurement for ambient inlet . 12

6.3.3 Temperature measurement for piped inlet . 12

6.3.4 Temperature measurement for piped discharge . 12

6.4 Measurement of humidity . 12

6.5 Measurement of rotational frequency . 12

6.6 Measurement of flow rate . 12

6.7 Measurement of external coolant flow rate . 12

6.8 Measurement of power and energy . 12

6.8.1 General . 12

6.9 Calibration of instruments. 13

7 Test .13

7.1 General test process . . 13

7.2 Allowed deviation of rotational speed between test and guarantee .14

7.3 Allowed deviation of ambient conditions . 15

7.3.1 Testing against general performance data . 15

7.3.2 Testing against customer specified data sheets . 15

7.4 Allowed deviation of preconditions . . 15

7.5 Allowed deviation of machine Mach number . 15

7.6 Selection of test flow .16

7.6.1 Selection of flow setting .16

7.7 Selection of test pressure .16

7.7.1 Note: The following terms are required for R and K with formulae and source. .16

te te

7.7.2 For positive displacement low-pressure compressors with or without internal

compression . . .16

7.7.3 For dynamic low-pressure compressors .17

7.8 Allowed deviation of flow and work coefficient .17

7.8.1 Allowed deviations to be checked for test validity .17

7.9 Fluctuations on the specific test readings/results during test at steady state .17

7.10 Two-speed test.18

7.10.1 General .18

iii

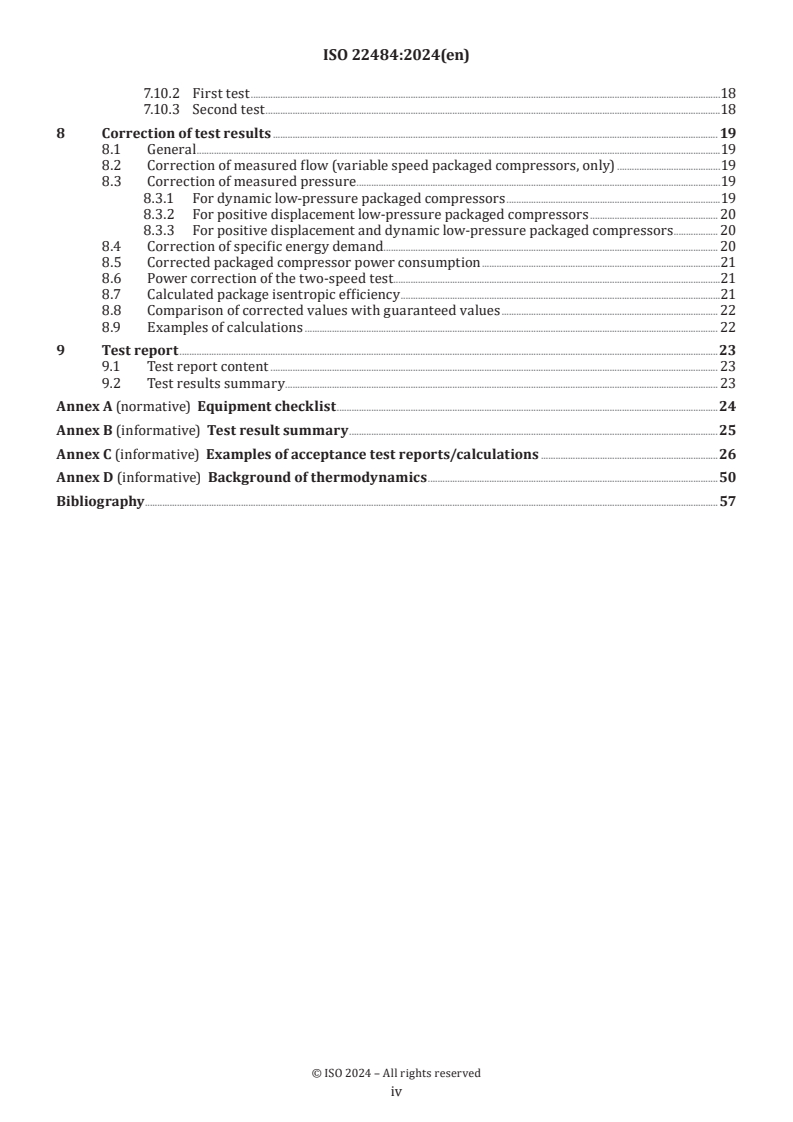

7.10.2 First test .18

7.10.3 Second test .18

8 Correction of test results . 19

8.1 General .19

8.2 Correction of measured flow (variable speed packaged compressors, only) .19

8.3 Correction of measured pressure . .19

8.3.1 For dynamic low-pressure packaged compressors .19

8.3.2 For positive displacement low-pressure packaged compressors . 20

8.3.3 For positive displacement and dynamic low-pressure packaged compressors . 20

8.4 Correction of specific energy demand . 20

8.5 Corrected packaged compressor power consumption .21

8.6 Power correction of the two-speed test.21

8.7 Calculated package isentropic efficiency .21

8.8 Comparison of corrected values with guaranteed values . 22

8.9 Examples of calculations . 22

9 Test report .23

9.1 Test report content . 23

9.2 Test results summary . . 23

Annex A (normative) Equipment checklist .24

Annex B (informative) Test result summary .25

Annex C (informative) Examples of acceptance test reports/calculations .26

Annex D (informative) Background of thermodynamics .50

Bibliography .57

iv

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee

has been established has the right to be represented on that committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely

with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types

of ISO document should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent

rights in respect thereof. As of the date of publication of this document, ISO had not received notice of (a)

patent(s) which may be required to implement this document. However, implementers are cautioned that

this may not represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents. ISO shall not be held responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 118, Compressors and pneumatic tools,

machines and equipment, Subcommittee SC 6 Air compressors and compressed air systems.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

Introduction

This document was developed in response to a recognized need to provide a methodology to correct

performance of a low-pressure air compressor to guarantee conditions for positive displacement and

dynamic compression types.

1)

In dynamic compression, air is drawn between the blades on a rapid rotating compression impeller and

accelerates to high velocity. The gas is then discharged through a diffuser, where the kinetic energy is

transformed into static pressure. Dynamic low-pressure compressors are of a radial flow design, with the

following typical examples:

— single-stage centrifugal (aka high speed “turbo”) compressors;

— multi-stage centrifugal compressors without intercooling.

Positive displacement low-pressure compressors work on the principle of trapping a volume of air and

reducing its volume, internally or externally. Two basic types are typical, as follows:

— Rotary screw positive displacement compressor where air is drawn into a compression chamber formed

by intermeshing rotors . As the rotors turn, the cavity between the rotors becomes smaller, reducing the

volume of the trapped air and increasing its pressure;

— Rotary lobe positive displacement compressor where air is drawn into the case and is trapped between

the rotor and the case wall. These air pockets are progressively moved to the discharge port. At the

discharge port, a back flow of air into the pocket from the higher-pressure discharge line produces a

constant volume pressure rise.

Existing standards (e.g. ISO 1217, ISO 5389, ISO 18740) for positive displacement compressors and dynamic

compressors, do not provide clear and concise means of comparing different technologies.

This document provides simplified wire to air performance test methods that measure true performance of

low-pressure air compressor packages.

1) In this document the terms “rotor” and “impeller” are used to describe the rotating element(s) which cause(s)

compression, and can be considered to be interchangeable.

vi

International Standard ISO 22484:2024(en)

Displacement and dynamic compressors — Performance

test code for electric driven low-pressure air compressor

packages

1 Scope

This document specifies the performance test method of electrically driven low-pressure air compressor

packages, where the compression is performed by positive displacement or dynamic compression; utilising

atmospheric air as the compression gas. Low-pressure air compressor packages are often referred to as

“blowers”.

NOTE Throughout this document, the term ‘low-pressure compressor’ is used to describe a low-pressure air

compressor (“blower”) package

Low-pressure compressors with and without means of controlling flow (control may be electrical (e.g. with

a variable frequency drive) or mechanical or both) are covered.

This document applies to low-pressure compressors meeting all the following limits:

— Atmospheric inlet air pressure between 0,5 bar and 1,1 bar.

— Discharge vs inlet pressure differential between 0,1 bar and 2,5 bar.

— Discharge vs inlet pressure ratio between 1,1 and 3,5.

This document is not applicable to:

— positive displacement low-pressure compressors with a liquid in the compression element (such as liquid

ring pumps and liquid injected low-pressure compressor of screw type)

— multi-stage low-pressure compressors other than multistage centrifugal compressors comprised of

multiple, identical or very similar uncooled sections along a single shaft (repeating stages).

— single shaft, multistage centrifugal compressors are treated from the point of measurement and

calculation as a single stage

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

ISO 5167-1, Measurement of fluid flow by means of pressure differential devices inserted in circular cross-section

conduits running full — Part 1: General principles and requirements

ISO 9300, Measurement of gas flow by means of critical flow nozzles

ISO 17089-1, Measurement of fluid flow in closed conduits — Ultrasonic meters for gas — Part 1: Meters for

custody transfer and allocation measurement

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

acceptance test

performance test carried out in accordance with this document

Note 1 to entry: See Annex C for an example of acceptance test report.

3.2

displacement compressor

packaged compressor where a static pressure rise is obtained by allowing successive volumes of gas to be

aspired into and exhausted out of a closed space by means of the displacement of a moving member

[SOURCE: ISO 5390:1977, 3.1]

3.3

dynamic compressor

packaged compressor in which the fluid pressure increase is obtained by transformation of kinetic energy

into potential energy with continuous flow from intake point to discharge point

[SOURCE: ISO 5390:1977, 3.2]

3.4

external coolant

medium externally supplied to the compressor to which the generated heat is finally rejected

Note 1 to entry: This is usually ambient air or cooling water

[SOURCE: ISO 1217:2009, 3.1.7]

3.5

packaged compressor

compressor with prime mover, transmission, fully piped and wired internally, including ancillary and

auxiliary items of equipment where these are within the scope of supply

[SOURCE: ISO 1217:2009, 3.1.13]

3.6

isentropic compression

idealized (i.e. reversible) adiabatic thermodynamic compression process that occurs without transfer of

heat into or out of a system

3.7

rotational speed

number of revolutions of the compressor drive shaft per unit of time

[SOURCE: ISO 1217:2009, 3.1.18]

3.8

process air inlet point

point upstream of any technically required component

Note 1 to entry: In the case in which a technically required component is not physically present during the test the

impact of the component on performance shall be accounted for

3.9

process air discharge point

point downstream of any technically required component

Note 1 to entry: In the case in which a technically required component is not physically present during the test the

impact of the component on performance shall be accounted for

3.10

guarantee conditions

site conditions for which the equipment is expected to perform. Typically, this will include atmospheric

pressure and ambient temperature

3.11

absolute pressure

pressure with reference to absolute zero, i.e. with reference to an absolute vacuum

Note 1 to entry: It equals the algebraic sum of atmospheric pressure and gauge pressure (static pressure or total

pressure).

[SOURCE: ISO 3857-1:1977, 1.3, modified — The second sentence was moved as a note.]

3.12

ambient pressure

absolute pressure (3.11) of the atmospheric air measured in the vicinity of the compressor

[SOURCE: ISO 1217:2009, 3.2.2]

3.13

atmospheric pressure

absolute pressure (3.11) of the atmospheric air measured at the test place

[SOURCE: ISO 1217:2009, 3.2.3]

3.14

discharge pressure

total mean absolute pressure (3.11) at the process air discharge point (3.9)

3.15

inlet pressure

total mean absolute pressure (3.11) at the standard process air inlet point (3.8)

3.16

total pressure

pressure measured at the stagnation point when a gas stream is brought to rest and its kinetic energy is

converted by an isentropic compression (3.6) from the flow condition to the stagnation condition

[SOURCE: ISO 1217:2009, 3.2.9]

3.17

ambient temperature

total temperature (3.20) of the atmospheric air in the vicinity of the compressor, but unaffected by it

[SOURCE: ISO 1217:2009, 3.3.1]

3.18

discharge temperature

total temperature (3.20) at the process air discharge point (3.9)

3.19

inlet temperature

total temperature (3.21) at the standard process air inlet point (3.8)

3.20

total temperature

temperature that would be measured at the stagnation point if a gas stream were brought to rest and

its kinetic energy converted by an isentropic compression (3.6) from the flow condition to the stagnation

condition

[SOURCE: ISO 1217:2009, 3.3.4]

3.21

relative humidity

ratio, in humid air, expressed as a percentage, of the water vapour actual pressure to the saturated vapour

pressure at the same dry bulb temperature

p

ϕ=

p

sat

where p is partial pressure (ISO 80000-4:2019, item 4-14.1) of vapour and p is its partial pressure at

sat

saturation (at the same temperature)

[SOURCE: ISO 80000-5:2019, 5-33]

3.22

isentropic exponent

ratio of the specific heat at constant pressure to the specific heat at constant volume

3.23

actual volume flow rate

volume flow rate of air, compressed and delivered at the standard discharge point, referred to conditions of

total temperature (3.20), total pressure and composition prevailing at the standard inlet point

3.24

isentropic power

power that is theoretically required to compress an ideal gas under constant entropy, from given inlet

conditions to a given discharge pressure (3.14)

Note 1 to entry: The term “ideal gas” is used to indicate any gas in a condition or state so that it follows closely the

ideal gas law

[SOURCE: ISO 1217:2009/Amd.1:2016, 3.5.1]

3.25

isentropic efficiency

ratio of the required isentropic power (3.24) to measured power for the same specified boundaries with the

same gas and the same inlet conditions and discharge pressure (3.14)

P

isen

η =

isen

P

real

[SOURCE: ISO 1217:2009/Amd.1:2016, 3.6.1]

3.26

power input

sum of the electrical power inputs to the prime mover and any ancillaries and auxiliaries driven from

the compressor shaft or by a separate prime mover at rated supply conditions, including the effect of all

equipment included in the packaged compressor (3.5)

Note 1 to entry: Auxiliaries include oil pump, cooling fan and integral compressed air dryer

Note 2 to entry: Rated supply conditions refer to phase, voltage, frequency and ampere capability

[SOURCE: ISO 1217:2009, 3.5.3]

3.27

specific energy requirement

power input (3.26) per unit of compressor actual volume flow rate

[SOURCE: ISO 1217:2009, 3.7.2]

3.28

specific isentropic compression work

work expressed as energy per unit mass of air during isentropic compression (3.6)

3.29

specific isochoric compression work

work expressed as energy per unit mass of air during isochoric compression

3.30

specific combined compression work

sum of the specific isentropic compression work (3.28) and specific isochoric compression work (3.29), weighted

by the internal volume ratio

3.31

internal volume ratio

ratio of the enclosed volume at moment of closure of the inlet port to the enclosed volume at the moment of

opening of the discharge port for a positive displacement compressor (3.2)

3.32

rotor tip speed

peripheral speed at the largest rotor/impeller tip diameter

3.33

machine Mach number

ratio of the rotor tip speed to the speed of sound of the fluid inlet state at inlet conditions

3.34

accounted for value

means (measured/estimated/calculated/corrected) – a simulated or calculated substitute characteristic of

components not available for the test, for example; the pressure drop of a remote air filter

3.35

idle power consumption

total consumed power when the packaged compressor (3.5) is not producing flow to the discharge but is

rotating at significant speed. i.e. for packaged compressor (3.5) equipped with idling functionality

3.36

standby power consumption

power required to keep the packaged compressor (3.5) ready for immediate start from non-rotating state

3.37

flow coefficient

flow velocity formed from the inlet volume flow and an impeller cross-section area and rendered

dimensionless by the tip speed of the impeller

3.38

work coefficient

specific compression work of the reference process rendered dimensionless by the kinetic energy of tip speed

3.39

reduced speed

alternate test speed used to achieve ratio of Mach number for contract to test equal to one

3.40

two speed test

combination of one test to determine the thermodynamic performance and one test to determine the

electromechanical performance

3.41

package motor

item(s) that is a part of the packaged compressor (3.5) including any additional drive train components

3.42

test motor

item(s) that replaces the package motor (3.41) for testing

3.43

shaft power

mechanical input power at the rotor/impeller

3.44

electromechanical

part of the total losses, total power consumption or total efficiency, that is not the result of the compression

work on the gas

Note 1 to entry: This shall include the impact on said values from motor(s), control(s), gear(s), bearing(s), seal(s) and

all auxiliaries (e.g. fans and pumps), whether said components are mounted on or related to the driver(s), compression

element(s) or part of the package.

4 Units

General use of SI units (see ISO 80000-1) as given throughout this document is recommended, see Table 1

and Table 2. However, in agreement with accepted practice in the pneumatic industry sector, some non-

preferred SI units, accepted by ISO, are also used, see

Table 1 — List of symbols

Symbol Term SI unit

c sonic velocity m/s

c specific heat capacity J/(kg·K)

p

D the largest rotor/impeller tip diameter m

e specific energy J/m

h specific enthalpy J/kg

Ma machine Mach number —

M molar mass kg/mol

m mass kg

q mass flow kg/s

m

n rotational speed 1/s

P power W

p pressure Pa

R specific gas constant J/(kg·K)

Re Reynolds number —

s specific entropy J/(kg·K)

T thermodynamic temperature K

t Celsius temperature °C

U supply voltage V

u tip speed m/s

TTabablele 1 1 ((ccoonnttiinnueuedd))

Symbol Term SI unit

v specific volume m /kg

v internal volume ratio —

i

V volume m

q volume flow m /s

V

X ratio of reduced speeds of rotation —

n

x mass ratio of water vapour to dry gas kg/kg

y specific compression work J/kg

Δ difference —

η efficiency —

ϑ ratio of (RZ1 T1) values —

κ ratio of specific heat capacities (isentropic exponent) —

π pressure ratio —

ρ density kg/m

ϕ ratio of volume flow rate ratios —

φ flow coefficient —

φ relative humidity —

rel

ψ work coefficient —

σ standard deviation —

Table 2 — List of subscripts used in this document

Subscript Term

0 ambient

1 inlet (suction side)

2 discharge (discharge side)

air dry air

abs absolute (pressure)

amb ambient (air, temperature)

co corrected to guarantee conditions

cog corrected to the pressure ratio and inlet volume flow of the guarantee point

comb combined

cool coolant

d dynamic

em electromechanical

dry dry

g guarantee conditions or performance data at guarantee conditions

i internal or intermediate

isoc isochoric

ideal according to an ideal thermodynamic process

out output

pack Packaged compressor boundary

Pr reference or standard process

red reduced speed

ref reference value

rel relative

TTabablele 2 2 ((ccoonnttiinnueuedd))

Subscript Term

s isentropic

sat saturated

st static

target target

te test result

te1 first test in 2-speed testing

te2 second test in 2-speed testing

tol permissible deviation

tot total

u tip or peripheral

vap vapour, vapor, steam

wet moist

idle idle

standby standby

5 Guarantee and measurement

5.1 Packaged compressor

The packaged compressor shall comprise all components that are necessary for the long-term functioning of

the low-pressure compressor under guarantee conditions and are needed to fulfil the object of the guarantee

and the preconditions of the guarantee:

— low-pressure compressor with drive system;

— variable frequency drive (as applicable);

— cooling/lubrication system;

— inlet filter;

— inlet valve/guide vanes (as applicable);

— bearing power supply (as applicable);

— fully piped and wired internally;

— including ancillary and auxiliary items of equipment and all power devices that affect power consumption.

5.2 Preconditions of the guarantee

If no preconditions are defined in the contract, the preconditions of the guarantee shall be applied in

accordance with Table 3 below.

For testing to be possible, at least the following shall be specified as the preconditions of the guarantee:

— air inlet pressure;

— air inlet temperature;

— air inlet humidity;

— coolant inlet temperature;

— coolant flow;

— supply voltage;

— supply frequency.

NOTE Air inlet pressure, air inlet temperature, air inlet humidity and coolant inlet temperature can be taken from

the default conditions in Table 3.

Table 3 — Reference conditions

Default inlet condition Value

a

Inlet air pressure 100 kPa

Inlet air temperature 20 °C

Inlet relative humidity 0 %

Temperature of the coolants at package inlet 20 °C

a

1 bar.

Additional limits can be specified, such as:

— electromagnetic compatibility standard to be fulfilled;

— specified maximum noise level outside the packaged compressor;

— total harmonics distortion on the electrical supply;

— input current supply;

— minimum permissible starts/hour;

— minimum permissible unload cycles/hour;

— allowable pulsation level at the discharge of the packaged compressor;

— filtration grade of the air inlet filter.

5.3 Object of the guarantee

The object of the guarantee is the set of values to be guaranteed within the defined preconditions:

— inlet volume flow rate;

— discharge pressure at the discharge of the packaged compressor;

— specific energy of the packaged compressor for the delivered flow at the guaranteed discharge pressure;

— isentropic efficiency of the packaged compressor for the delivered flow at the guaranteed discharge

pressure;

— idle power consumption;

— standby power consumption.

5.4 Low-pressure compressor to be tested

The low-pressure compressor configuration to be tested shall include all components required to fulfil all

the preconditions.

As a general rule, the configuration of the unit under test shall be identical to the configuration of the unit to

be delivered.

A packaged compressor checklist, such as given in Annex A, shall be completed by the manufacturer and

shall be part of each low-pressure compressor test report. The checklist shall be used to ensure that the

tested packaged compressor matches that specified.

The checklist shall indicate which components and their performance related characteristics are included,

excluded, accounted for value, or not applicable for normal functioning at guarantee conditions.

If any required components are not installed in the test configuration, the correction calculations for these

components shall be shown in conjunction with the checklist.

Ancillaries required for the sustainable operation of the low-pressure packaged compressor, excluding

stand-by ancillaries, are to be in operation.

5.5 Low-pressure compressor specifications to be provided prior to testing

The low-pressure compressor is tested against a specified discharge pressure (at the discharge of the

packaged compressor).

In addition to the preconditions, the reference inlet conditions (or the guarantee inlet conditions) and the

checklist, certain data needs to be provided by the manufacturer before the test event, typically with a

tender to provide the equipment:

— rotational speed at guarantee conditions when the machine is fulfilling the object of the guarantee (for

variable speed machines or if the motor in testing a fixed speed machine can differ from the one to be

used at the site of assembly);

— internal volume ratio for positive displacement low-pressure compressor;

— variable geometry settings (if applicable) for the low-pressure compressor.

6 Measuring equipment, methods and accuracy

6.1 General

The equipment and methods given in this document are not intended to restrict the use of other equipment

and methods with the same or better accuracy. Where an international standard relating to a particular

measurement or type of instrument exists, any measurements carried out or instruments used shall be in

accordance with such an international standard.

All inspection, measuring, test equipment and devices that can affect the test shall be calibrated and adjusted

at prescribed intervals, or prior to use, against certified equipment having a known valid relationship to

nationally recognized standards. The use of data acquisition systems shall be allowed and the test logs may

be print outs resulting from the system.

No measurement uncertainty tolerances are to be taken into account in corrections or acceptance. For

guarantee acceptance, as tested results are treated as measured in comparison to Table 5 without additional

uncertainty tolerances applied.

6.2 Measurement of pressure

6.2.1 General

Pressure taps in the pipe or receiver shall be normal to, and flush with, the inside wall. A minimum of two

static or total pressure-measuring instruments shall be utilized for each measurement location spaced at

180° intervals around the pipe circumference, and 90° to temperature instrumentation

NOTE For low pressures or high flow velocities, minor irregularities such as burrs can lead to serious error.

Connecting piping shall be leak-free, as short as possible, of sufficient diameter and arranged to avoid

blockage by dirt or condensed liquid. For measurement of liquid pressure or pressure of liquid-gas mixtures,

the instrument shall be mounted at the same height as the measuring point and the connecting piping shall

be arranged so that the height of liquid columns in the piping exerts no influence. Otherwise, account shall

be taken of the difference in height.

Instruments shall be mounted so that they are not susceptible to disturbing vibrations.

The measuring instrument (analogue or digital) shall have an accuracy of ±1 % at the measured value.

The pressure measurement shall be a total measurement, or static measurement corrected to total

conditions.

For definitions of static, dynamic and total measurements refer to ISO 5389:2005, 5.2 and 5.3.

6.2.2 Atmospheric pressure

The absolute atmospheric pressure shall be measured with a barometer having an accuracy better than

±0,15 %.

6.2.3 Pressure measurement for ambient inlet

The compressor package inlet pressure, p , is the atmospheric pressure measured by a barometer near the

compressor package where the velocity is zero.

6.2.4 Pressure measurement for piped inlet

The pressure is the total pressure, p , measured at the process air inlet point. The pressure shall be measured

at a location at least one pipe diameter upstream of the inlet.

6.2.5 Pressure measurement for piped discharge

The pressure is the total pressure, p , measured at the process air discharge point. The pressure shall be

measured at a location at least two pipe diameters downstream of the discharge.

6.3 Measurement of temperature

6.3.1 General

Temperature shall be measured by certified or calibrated instruments such as thermometers, thermo-

electrical instruments, resistance thermometers or thermistors having an accuracy of ±0,5 K inserted into

the pipe or into pockets.

A minimum of two temperature-measuring instruments shall be used for each measurement location. For

measurements made on piping these shall be spaced at 180° intervals around the pipe circumference.

Thermometer pockets shall be as thin, and their diameters as small, as is practical, with their outside surface

substantially free from corrosion or oxide. The pocket shall be partially filled with a suitable liquid.

The thermometers or the pockets shall extend into the pipe to a distance of 100 mm, or one third the

diameter of the pipe, whichever is less.

When taking readings, the thermometer shall not be lifted out of the medium being measured nor out of the

pocket when one is used.

Precautions shall be taken to ensure that the:

— immediate vicinity of the insertion point and the projecting parts of the connection are well insulated so

that the pocket is virtually at the same temperature as the medium being observed;

— sensor of any temperature measuring device or thermometer pocket is well swept by the medium

(the sensor or thermometer pocket shall point against the gas stream; in extreme cases a position

perpendicular to the gas stream may be used);

— thermometer pocket does not disturb the normal flow.

6.3.2 Temperature measurement for ambient inlet

The packaged compressor ambient temperature is the atmospheric temperature measured at the packaged

compressor in the plane of the intake system.

6.3.3 Temperature measurement for piped inlet

The inlet temperature is the total temperature, T , measured at the process air inlet point. The temperature

instrumentation shall be located at half of one pipe diameter upstream of the inlet.

6.3.4 Temperature measurement for piped discharge

The discharge temperature is the total temperature, T , measured at the process air discharge point. The

temperature instrumentation shall be located one pipe diameter downstream of the discharge and 90°

relatively rotated to the pressure measurement.

6.4 Measurement of humidity

If the gas contains moisture, the humidity shall be checked during the test. The humidity shall be measured

at the process air inlet point with an instrument having an accuracy of ±3 % or better.

6.5 Measurement of rotational frequency

Rotational speed shall be determined by using methods that have an accuracy of ±0,2 % or better.

6.6 Measurement of flow rate

The actual volume flow rate is the net mass flow rate through the process connection of the packaged

compressor discharge. All seal losses and side streams not delivered to the process piping connection of the

packaged compressor shall be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...