ISO 2596:2006

(Main)Iron ores — Determination of hygroscopic moisture in analytical samples — Gravimetric, Karl Fischer and mass-loss methods

Iron ores — Determination of hygroscopic moisture in analytical samples — Gravimetric, Karl Fischer and mass-loss methods

ISO 2496:2006 specifies the following four test methods for the determination of the hygroscopic moisture content of test samples: Method 1 -- Gravimetric method; Method 2 -- Karl Fischer volumetric method; Method 3 -- Karl Fischer coulometric method; Method 4 -- Mass-loss method. Any of these methods is applicable wherever the analytical value of a chemical constituent is to be calculated to a dried sample basis in the following ore types. Processed ores containing metallic iron (direct reduced iron). Natural or processed ores in which the sulfur content is greater than 0,2 % (mass fraction). Natural or processed ores in which the combined water is greater than 2,5 % (mass fraction). Any of these methods is applicable to a concentration range of 0,05 % (mass fraction) to 4,5 % (mass fraction) hygroscopic moisture.

Minerais de fer — Détermination de l'humidité hygroscopique dans les échantillons pour analyse — Méthodes gravimétrique, selon Karl Fischer et par perte de masse

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 2596

Fifth edition

2006-05-01

Iron ores — Determination of

hygroscopic moisture in analytical

samples — Gravimetric, Karl Fischer and

mass-loss methods

Minerais de fer — Détermination de l'humidité hygroscopique dans les

échantillons pour analyse — Méthodes gravimétrique, selon Karl

Fischer et par perte de masse

Reference number

©

ISO 2006

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2006

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2006 – All rights reserved

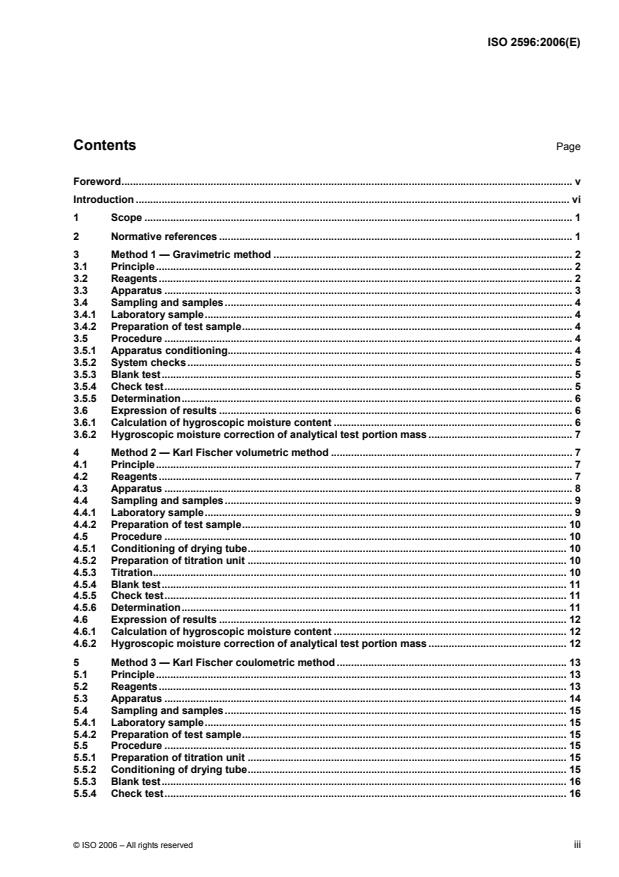

Contents Page

Foreword. v

Introduction . vi

1 Scope . 1

2 Normative references . 1

3 Method 1 — Gravimetric method . 2

3.1 Principle. 2

3.2 Reagents. 2

3.3 Apparatus . 3

3.4 Sampling and samples. 4

3.4.1 Laboratory sample. 4

3.4.2 Preparation of test sample. 4

3.5 Procedure . 4

3.5.1 Apparatus conditioning. 4

3.5.2 System checks . 5

3.5.3 Blank test. 5

3.5.4 Check test. 5

3.5.5 Determination. 6

3.6 Expression of results . 6

3.6.1 Calculation of hygroscopic moisture content . 6

3.6.2 Hygroscopic moisture correction of analytical test portion mass . 7

4 Method 2 — Karl Fischer volumetric method . 7

4.1 Principle. 7

4.2 Reagents. 7

4.3 Apparatus . 8

4.4 Sampling and samples. 9

4.4.1 Laboratory sample. 9

4.4.2 Preparation of test sample. 10

4.5 Procedure . 10

4.5.1 Conditioning of drying tube. 10

4.5.2 Preparation of titration unit . 10

4.5.3 Titration. 10

4.5.4 Blank test. 11

4.5.5 Check test. 11

4.5.6 Determination. 11

4.6 Expression of results . 12

4.6.1 Calculation of hygroscopic moisture content . 12

4.6.2 Hygroscopic moisture correction of analytical test portion mass . 12

5 Method 3 — Karl Fischer coulometric method . 13

5.1 Principle. 13

5.2 Reagents. 13

5.3 Apparatus . 14

5.4 Sampling and samples. 15

5.4.1 Laboratory sample. 15

5.4.2 Preparation of test sample. 15

5.5 Procedure . 15

5.5.1 Preparation of titration unit . 15

5.5.2 Conditioning of drying tube. 15

5.5.3 Blank test. 16

5.5.4 Check test. 16

5.5.5 Determination . 17

5.6 Expression of results. 17

5.6.1 Calculation of hygroscopic moisture content. 17

5.6.2 Hygroscopic moisture correction of analytical test-portion mass . 18

6 Method 4 — Mass-loss method . 18

6.1 Principle . 18

6.2 Reagents . 18

6.3 Apparatus. 19

6.4 Sampling and samples . 20

6.4.1 Laboratory sample . 20

6.4.2 Preparation of test sample. 20

6.5 Procedure. 20

6.5.1 Apparatus conditioning. 20

6.5.2 Check test . 21

6.5.3 Determination . 21

6.6 Expression of results. 22

6.6.1 Calculation of hygroscopic moisture content. 22

6.6.2 Hygroscopic moisture correction of analytical test portion mass . 22

Annex A (informative) Gravimetric and Karl Fischer apparatus. 23

Annex B (informative) Drying tube. 24

Annex C (informative) Titanium absorption tube . 26

Annex D (informative) Volumetric titration cell . 27

Annex E (informative) Coulometric titration cell . 28

Annex F (informative) Modified weighing chamber apparatus . 29

Annex G (informative) Modified weighing chamber. 30

Annex H (informative) Parcher equipment. 31

Bibliography . 32

iv © ISO 2006 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 2596 was prepared by Technical Committee ISO/TC 102, Iron ore and direct reduced iron, Subcommittee

SC 2, Chemical analysis.

This fifth edition cancels and replaces the fourth edition (ISO 2596:1994), which has been technically revised.

Introduction

In the analysis of iron ores, the reporting limit of the analytical value of each constituent on a dry sample basis

can be achieved by using predried samples. However, with certain ore types, where the constituent being

determined is above a certain concentration level as specified in the scope, this technique can produce

erroneous results. In these cases, for the calculation of analytical values of the other constituents in the ore to

a dry sample basis, a direct determination of the hygroscopic moisture content becomes necessary.

vi © ISO 2006 – All rights reserved

INTERNATIONAL STANDARD ISO 2596:2006(E)

Iron ores — Determination of hygroscopic moisture in

analytical samples — Gravimetric, Karl Fischer and mass-loss

methods

1 Scope

This International Standard specifies the following four test methods for the determination of the hygroscopic

moisture content of test samples:

Method 1 — Gravimetric method;

Method 2 — Karl Fischer volumetric method;

Method 3 — Karl Fischer coulometric method;

Method 4 — Mass-loss method.

Any of these methods is applicable wherever the analytical value of a chemical constituent is to be calculated

to a dried sample basis in the following ore types.

a) Processed ores containing metallic iron (direct reduced iron).

b) Natural or processed ores in which the sulfur content is greater than 0,2 % (mass fraction).

c) Natural or processed ores in which the combined water is greater than 2,5 % (mass fraction).

Any of these methods is applicable to a concentration range of 0,05 % (mass fraction) to 4,5 % (mass fraction)

hygroscopic moisture.

NOTE 1 Where the reportable moisture content of a commercial consignment of ore is required, the procedure in

ISO 3087 is used.

NOTE 2 With natural or processed ores outside the field of application specified in a), b) or c), a determination of a

constituent at any level of concentration may be conducted using any of these methods, or as specified in ISO 7764.

NOTE 3 Alternatively, the loss or ignition content may be measured as an estimate of the combined water content.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 760, Determination of water — Karl Fischer method (General method)

ISO 3082, Iron ores — Sampling and sample preparation procedures

3 Method 1 — Gravimetric method

3.1 Principle

The hygroscopic moisture content of an environmentally equilibrated test portion is determined at

105 °C ± 2 °C within a drying tube, into which dry nitrogen is passed (at a rate of 100 ml/min to 200 ml/min).

Evolved moisture (swept by gas) is collected in an absorption tube containing anhydrous magnesium

perchlorate, and the percentage moisture content is determined via the corrected mass increase of the tube.

3.2 Reagents

3.2.1 Desiccant

Anhydrous magnesium perchlorate Mg(ClO ) of size 0,80 mm to 1,25 mm, to ensure carrier-gas water-

4 2

vapour pressures below 5 µg H O/l.

As measurement accuracy and precision are highly dependent on blank determinations, the stability of

residual background moisture shall be controlled as a function of combining capacity.

The combining capacity (C ) is calculated as a percentage of desiccant and residual carrier-gas moisture

c

content using the following equation:

()mL⋅N

C = (1)

c

m

where

m is the mass of residual carrier-gas moisture content, in centigrams per litre, where

m = 0,000 1 cg/l for aluminium calcium silicate molecular sieves,

0,000 2 cg/l for silica gel desiccant;

L is the number of litres of gas per bottle;

N is the number of gas bottles consumed;

m is the mass, in grams, of desiccant added to drying tower.

For successful drying, the combining capacity should be restricted to 10 % (mass fraction).

WARNING Magnesium perchlorate is a powerful oxidant and cannot be allowed to be exposed to

organic materials. When exhausted, it should not be discarded into waste bins, but should be washed

down the sink.

3.2.2 Aluminium calcium silicate molecular sieves, made of 1/16 in pellets.

Before use, sieves shall be dried by heating to 400 °C for 4 h.

NOTE This limit is based on extending the service life of secondary desiccants (magnesium perchlorate), by limiting

input stream contaminants.

3.2.3 Silica gel desiccant, blue self-indicating.

Before use, gel shall be dried by heating to 105 °C for 4 h.

2 © ISO 2006 – All rights reserved

3.2.4 Copper(II) sulfate pentahydrate analytical reagent grade (AR) (CuSO ·5H O), free-flowing

4 2

crystalline material, press-crushed if necessary under a pestle by hand, without grinding, to a size of

approximately 1 mm.

3.2.5 Nitrogen, filtered, predried, oil-free, containing less than 10 µl of oxygen per litre at a pressure of

approximately 35 kPa to 50 kPa above atmospheric pressure.

3.3 Apparatus

NOTE A suitable apparatus for the determination is shown diagrammatically in Annex A.

3.3.1 Balance, capable of reading the mass of the absorption vessel to 0,1 mg.

3.3.2 Oven, preferably of the aluminium metal-block type, capable of accommodating one, but preferably

several, glass drying tubes (3.3.3) and of maintaining a temperature within the range 105 °C ± 2 °C over a

minimum tube length of 160 mm.

3.3.3 Borosilicate glass drying tubes and connections, fitted with Viton “O”-ring-seal pushrod cap

assemblies.

NOTE A suitable drying tube is shown diagrammatically in Annex B.

3.3.4 Drying towers, of capacity 250 ml, one filled with molecular sieves (3.2.2) or silica gel (3.2.3) and the

other packed with magnesium perchlorate desiccant (3.2.1), to dry the stream of nitrogen (3.2.5) entering the

drying tubes.

Molecular sieves (3.2.2) and silica gel (3.2.3) drying towers shall be repacked with freshly dried desiccants

fortnightly.

3 3

3.3.5 Flowmeters, capable of measuring a flow rate within the range 100 cm /min to 200 cm /min.

If a pressure drop over a constriction is used as a means of measuring flow rate, the manometer liquid shall

be a non-volatile oil.

3.3.6 Absorption tubes, manufactured of chemically inert conducting material to minimize static charging

effects (titanium is preferred), with pan-balance location pads to minimize corner-load weighing errors.

NOTE A suitable tube is shown in Annex C.

Tubes shall be of suitable design (8 mm ID × 300 mm) to contain sufficient desiccant (3.2.1) to remove the

moisture completely from the stream of nitrogen (3.2.5).

The tubes should have sealable inlet and outlet connections and the direction of gas flow should be

unambiguously identified. Desiccants shall be firmly packed to prevent “channelling” and be retained in

position with glass-wool plugs.

3.3.7 Guard tubes, of a suitable design, containing magnesium perchlorate desiccant (3.2.1) to prevent

back diffusion of moisture into absorption tubes.

3.3.8 Sample boats, of an inert and stable material, such as glass, stainless steel or glazed porcelain.

Approximate dimensions are 100 mm × 20 mm × 10 mm. Before use, boats should be dried at approximately

105 °C, and then cooled to ambient temperature in a desiccator. Boats shall be stored in a desiccator prior to

use.

3.3.9 Filter discs, of sintered metal, sintered glass or similar, inserted in the flexible connections

between the drying and absorption tubes.

3.3.10 Flexible connections

The selection of polymeric tubing shall be made by taking into consideration that some materials are

permeable to moisture. Annealed copper/stainless steel tubing is preferable. Swagelock-type connectors and

quick-release neoprene “O”-ring connector joints are recommended. On serviceable components that

necessitate removal, quick-release neoprene “O”-ring connector joints shall be used. Glass ends should be

sufficiently smoothed to minimize coupling-seal damage.

3.3.11 Flow-control needle valve, placed on the inlet of each flowmeter.

3.4 Sampling and samples

3.4.1 Laboratory sample

For analysis, use a laboratory sample of particle size less than 100 µm or less than 160 µm, which has been

taken and prepared in accordance with ISO 3082.

3.4.2 Preparation of test sample

Thoroughly mix the laboratory sample and, taking multiple increments, extract a test sample in such a manner

that it is representative of the whole contents of the container.

The test sample is brought into equilibrium with the laboratory atmosphere by exposure for at least 2 h on an

inert tray at a layer density not greater than 0,1 g/cm . The sample shall be thoroughly mixed immediately

before the determination.

3.5 Procedure

3.5.1 Apparatus conditioning

3.5.1.1 Conditioning of drying tube

Bring the temperature of the drying tubes (3.3.3) to 105 °C ± 2 °C and maintain this temperature throughout

steps 3.5.1 to 3.5.5.

3 3

Adjust the rate of flow of nitrogen (3.2.5) to provide a constant flow rate of 100 cm /min to 200 cm /min

through the drying tube, and maintain this flow rate throughout steps 3.5.1.2 to 3.5.5.

Connect the outlet from each drying tube to the inlet of a guard tube. Open the taps of the guard tube, and

pass nitrogen through the tube for a minimum of 15 min.

NOTE A preferred method for conditioning the drying tubes requires maintaining a constant gas flow rate of

3 3

50 cm /min to 100 cm /min (and a temperature of 105 °C ± 2 °C) during periods in which the instrument is idle.

3.5.1.2 Conditioning of absorption tube

3 3

Adjust the rate of flow of nitrogen (3.2.5) to provide a constant flow rate of 100 cm /min to 200 cm /min.

Connect a closed absorption tube (3.3.6) and guard tube (3.3.7) to an empty drying tube. Open the taps of the

guard tube first, followed by the outlet tap of the absorption tube, and lastly the inlet valve. Pass nitrogen

through the assembled apparatus for a minimum of 15 min.

NOTE Conditioning of the absorption tube is only necessary following the addition of a fresh charge of desiccant.

4 © ISO 2006 – All rights reserved

3.5.1.3 Weighing of absorption tube

Close the taps of the absorption tube, outlet first, and remove from the drying tube. Reconnect the opened

guard tube to the drying tube. Wipe the absorption tube with a clean, dry cloth, free from loose fibres, and

allow to stand for 20 min in the balance room.

To minimize the transfer of contaminants such as moisture and grease, conditioned absorption tubes and

sample boats shall be handled using cotton gloves.

Open the taps of the absorption tube momentarily to equalize the pressure, and then weigh to the nearest

0,1 mg.

3.5.2 System checks

Reconnect the weighed absorption tube and guard tube, opening the taps on the absorption tube outlet first,

and restore the nitrogen flow to the previous rate. After 2 h, follow the procedure exactly as described

in 3.5.1.2.

If the absorbent efficiency of drying-tower magnesium perchlorate (3.3.4) and absorption-tube (3.3.6)

desiccants are equal, no increase in absorption tube mass will occur during a system check. If an increase in

absorbent tube mass of greater than 0,1 mg is observed, drying-tower desiccant quality, system leaks, and

absorbent tube weighings should be checked as possible error sources.

3.5.3 Blank test

Reconnect the weighed absorption tube and guard tube, open the taps in accordance with 3.5.1.2, and restore

the nitrogen flow to the previous rate.

Quickly remove the drying-tube end cap (3.3.3), and place an empty sample boat (3.3.8) in the entrance of the

heat zone. Fit the end cap (and/or inlet connector), and using a pushrod (manual or magnetic), immediately

move the boat to the centre of the oven and note the introduction time.

During the placement of the boat in the drying tube, as specified in 3.5.2 to 3.5.4, precautions should be taken,

essentially involving a careful technique, to minimize entry of laboratory air (containing moisture) into the

drying tube.

To minimize the transfer of contaminants such as moisture and grease, conditioned absorption tubes and

sample boats should be handled using cotton gloves.

After 2 h, follow the procedure exactly as described in 3.5.1.3, recording the mass to the nearest 0,1 mg.

The increase in mass of the absorption tube for the blank test should be as low as possible and not more than

2 mg. Repeat the determination of the blank test after the analysis of the test sample, to ensure that the blank

test value is essentially constant.

3.5.4 Check test

NOTE 1 The check test is required when first commissioning the complete apparatus and at other appropriate times,

e.g. when changes in the equipment or operators have been made, and when a regular interval check on the condition of

the absorption tubes is required.

When a satisfactory value for the blank test has been obtained, weigh 0,05 g to 0,2 g of copper(II) sulfate

pentahydrate (3.2.4) to the nearest 0,2 mg, into the cooled sample boat used for the blank test. The mass

taken should be such that its moisture content approximates the anticipated moisture content of the ore type

being analysed.

Repeat the procedure in 3.5.2, using the boat containing the weighed copper(II) sulfate. The increase in mass

of the absorption tube, corrected with the blank test value, should indicate a value of the water content of

copper(II) sulfate within the range of 28,5 % (mass fraction) to 29,2 % (mass fraction). If not, the cause should

be determined.

NOTE 2 Alternatively, a calibrated micro-syringe (accuracy and reproducibility ± 1 %) may be used to introduce water

directly into the heated zone of the drying tube through a septum.

3.5.5 Determination

When a satisfactory value for the blank test has been obtained (and similarly for the check test, if appropriate),

weigh from the air-equilibrated sample (3.4.2), the required test portion for the determination of the constituent

to be reported on a dry basis. Immediately weigh to the nearest 0,1 mg, in accordance with Table 1, the test

portion for the determination of hygroscopic moisture.

Table 1 — Mass of test portion — Method 1 (Gravimetric method)

Hygroscopic moisture content Mass of test portion

% (mass fraction) g

0,05 to 2 2,0

2 to 4,5 1,0

Transfer the weighed sample portion into a conditioned sample boat (3.3.8), and distribute the material evenly.

Immediately, repeat the procedure in 3.5.3, using the boat containing the test portion instead of an empty boat.

2 2

Sample loading should not exceed 0,5 g/cm , for samples between 0,05 and 2,0 % moisture and 0,15 g/cm

for samples containing between 2,0 % and 4,5 % moisture.

NOTE Alternatively, the analytical sample can be weighed directly into a conditioned sample boat (3.3.8).

The weighing of analytical test samples shall be performed in parallel with hygroscopic moisture sampling and

preparation operations; otherwise erroneous moisture corrections will result. The determination of hygroscopic

moisture shall be performed whenever a constituent is reported to a dry basis.

The hygroscopic moisture values shall not be averaged, but shall be used individually to correct the

corresponding constituent values.

3.6 Expression of results

3.6.1 Calculation of hygroscopic moisture content

The content of hygroscopic moisture (HM), on an air-dry basis, is calculated as a percentage by mass using

the following equation:

mm−

HM=×100 (2)

m

where

m is the increase in mass, in grams, of the absorption tube during the test;

m is the increase in mass, in grams, of the absorption tube during the blank test;

m is the mass, in grams, of the test portion.

As the hygroscopic moisture content of a test sample is specific to ambient measurement conditions, the

result should be used for internal purposes only.

6 © ISO 2006 – All rights reserved

3.6.2 Hygroscopic moisture correction of analytical test portion mass

The sample mass for an analytical test sample shall be moisture corrected (as a percentage of the

hygroscopic mass) using the following equation:

⎛⎞HM

MCM=−mm× (3)

66⎜⎟

⎝⎠

where

m is the mass, in grams, of analytical test portion to be moisture corrected;

HM is the hygroscopic moisture content of the test portion, expressed as a percentage by mass;

MCM is the dried mass, in grams, of an analytical test portion.

4 Method 2 — Karl Fischer volumetric method

4.1 Principle

The hygroscopic moisture content of an environmentally equilibrated test portion is determined at

105 °C ± 2 °C in a drying tube, into which dry nitrogen is passed at a rate of 100 ml/min to 200 ml/min for 2 h.

Evolved moisture (swept by gas) is collected in an aqueous absorbent solution where, upon completion of

analysis, this solution is titrated (either automatically or under operator control) volumetrically.

4.2 Reagents

4.2.1 Desiccant, anhydrous magnesium perchlorate Mg(ClO ) of size 0,80 mm to 1,25 mm, to ensure

4 2

carrier-gas water-vapour pressures below 5 µg H O/l.

As measurement accuracy and precision are highly dependent on blank determinations, the stability of

residual background moisture shall be controlled as a function of combining capacity.

The combining capacity (C ) is calculated as a percentage of desiccant and carrier-gas impurity masses using

c

the following equation:

()mL⋅N

C = (4)

c

m

where

m is the mass of residual carrier-gas moisture content, in centigrams per litre, where

m = 0,000 1 cg/l for aluminium calcium silicate molecular sieves,

0,000 2 cg/l for silica gel desiccant;

L is the number of litres of gas per bottle;

N is the number of gas bottles consumed;

m is the mass, in grams, of desiccant added to the drying tower.

For successful drying, the combining capacity should be limited to maximum 10 % (mass fraction).

WARNING Magnesium perchlorate is a powerful oxidant and cannot be allowed to be exposed to

organic materials. When exhausted, it should not be discarded into waste bins, but should be washed

down the sink.

4.2.2 Aluminium calcium silicate molecular sieves, made of 1/16 in pellets.

Before use, sieves shall be dried by heating to 400 °C for 4 h.

NOTE This limit is based on extending the service life of secondary desiccants (magnesium perchlorate) by limiting

input stream contaminants.

4.2.3 Silica gel desiccant, blue self-indicating.

Before use, gel shall be dried at 105 °C for 4 h.

4.2.4 Copper(II) sulfate pentahydrate (CuSO⋅5H O), free-flowing crystalline material, press-crushed if

4 2

necessary under a pestle by hand, without grinding, to a size of approximately 1 mm.

4.2.5 Nitrogen, filtered, predried, oil-free, containing less than 10 µl of oxygen per litre at a pressure of

approximately 35 kPa to 50 kPa above atmospheric pressure.

4.2.6 Methanol (CH OH) anhydrous, Karl Fischer grade of water content less than 0,005 %.

4.2.7 Ethylene glycol (CH OH⋅CH OH), anhydrous Karl Fischer grade

2 2

4.2.8 Karl Fischer composite (one component) titrant, of 1,0 mg to 3,0 mg H O/ml titration capacity.

This reagent is commercially available or can be prepared as specified in ISO 760. Standardize this solution

using one of the following standard reagents:

a) a standard water/methanol solution;

b) water added by means of a microsyringe;

Transfer an appropriate quantity of one of the reagents a) or b) into the absorption cell (by means of a

microsyringe through the septum) containing absorbent solution that has been titrated to the end-point, then

follow the titration procedure described in 4.5.2.

The factor (F), in milligrams of water per millilitre of Karl Fischer solution, is calculated from this titration.

4.3 Apparatus

NOTE A suitable apparatus for the determination is shown diagrammatically in Annex A.

4.3.1 Oven, preferably of the aluminium metal-block type, capable of accommodating one, but preferably

several, drying tubes (4.3.2) and of maintaining a temperature within the range 105 °C ± 2 °C over a minimum

tube length of 160 mm.

4.3.2 Borosiliate glass drying tubes and connections, fitted with Viton “O”-ring seal pushrod cap

assemblies.

NOTE A suitable apparatus is shown diagrammatically in Annex B.

4.3.3 Drying towers, of 250 ml capacity, one filled with molecular sieves (4.2.2) or silica gel (4.2.3) and the

other packed with magnesium perchlorate desiccant (4.2.1), to dry the stream of nitrogen (4.2.5) entering the

drying tubes.

Molecular sieves (3.2.2) and silica gel (3.2.3) drying towers shall be repacked with freshly dried desiccants

fortnightly.

8 © ISO 2006 – All rights reserved

3 3

4.3.4 Flowmeters, capable of measuring a flow rate within the range 100 cm /min to 200 cm /min. If a

pressure drop over a constriction is used as a means of measuring flow rate, the manometer liquid shall be a

non-volatile oil.

4.3.5 Sample boats, of an inert and stable material, such as glass, stainless steel or glazed porcelain.

Approximate dimensions are 100 mm × 20 mm × 10 mm. Before use, boats should be dried at approximately

105 °C, and then cooled to ambient temperature in a desiccator. Boats shall be stored in a desiccator prior to

use.

4.3.6 Filter discs, of sintered metal, sintered glass or similar, inserted between the drying tubes and the

inlets to the absorption cells.

4.3.7 Flexible connections

The selection of polymeric tubing shall be made by taking into consideration that some materials are

permeable to moisture. Annealed copper/stainless steel tubing is preferable. Swagelock-type connectors and

quick-release neoprene “O”-ring connector joints are recommended. On serviceable components that

necessitate removal, quick-release neoprene “O”-ring connector joints shall be used. Glass ends should be

sufficiently smoothed to minimize coupling-seal damage.

4.3.8 Flow-control needle valve, placed on the inlet of each flowmeter.

4.3.9 Titration cells, preferably brown glass vessels of capacity 50 ml to 75 ml possessing drain valves.

The entries for the platinum electrodes should preferably be near the cell walls, whilst the burette tip should

preferably be centred above the stirrer to ensure rapid distribution of the added reagent.

NOTE 1 A suitable titration cell is shown diagrammatically in Annex D.

Burettes, detection electrode and gas inlets and outlets shall be impermeable to water vapour (ground-glass

joints are preferred).

NOTE 2 If a standard water/methanol solution is not to be used for the calibration, only one burette entry to the

absorption cell will be required.

4.3.10 Guard tubes, of a suitable design and able to contain sufficient desiccant (4.2.1) to prevent back

diffusion of moisture (into the titration cell) and emission of methanol and hydrocarbons (from the titration

vessel).

4.3.11 Platinum electrodes, either as a pair or as a dual platinum electrode.

4.3.12 Magnetic stirrers and rotators, of chemically inert material and variable speed.

4.3.13 Amperometric titrator, suitable for Karl Fischer volumetric analysis, equipped with an ammeter

(0,50 µA) or an equivalent means for the electrometric indication of the end-point.

4.3.14 Burettes, of suitable capacity (25 ml to 50 ml), conforming to class A specifications (or equivalent),

preferably possessing a smoke-glass reservoir bottle.

The burette should be vented solely by an anhydrous atmosphere of suitable capacity. Fillers should not be

pressurized through the lower inlet of the burette.

4.4 Sampling and samples

4.4.1 Laboratory sample

For analysis, use a laboratory sample of particle size less than 100 µm or less than 160 µm, which has been

taken and prepared in accordance with ISO 3082.

4.4.2 Preparation of test sample

Thoroughly mix the laboratory sample and, taking multiple increments, extract a test sample in such a manner

that it is representative of the whole contents of the container.

The test sample is brought into approximate equilibrium with the laboratory atmosphere by exposure for at

least 2 h on an inert tray at a layer density not greater than 1,0 mg/mm .

The sample shall be thoroughly mixed immediately before the determination.

4.5 Procedure

4.5.1 Conditioning of drying tube

Bring the temperature of the drying tubes (4.3.2) to 105 °C ± 2 °C and maintain this temperature throughout

steps 4.5.3 to 4.5.5.

3 3

Adjust the rate of flow of nitrogen (4.2.5) to provide a constant flow rate of 100 cm /min to 200 cm /min

through drying tubes and maintain this flow rate throughout steps 4.5.2 to 4.5.6.

Connect the outlet from each drying tube to the inlet of a guard tube (4.3.10). Open the taps of the guard tube,

and pass nitrogen through the tube for a minimum of 15 min.

NOTE A preferred method for conditioning the drying tubes requires maintaining a constant gas flow rate of

3 3

50 cm /min to 100 cm /min (and temperature of 105 °C ± 2 °C) during periods in which the instrument is idle.

4.5.2 Preparation of titration unit

Remove the rubber septum from the absorption cell and transfer 20 ml of ethylene glycol (4.2.7) and 20 ml of

methanol (4.2.6), or equivalent commercially available absorption solutions, into the titration cell.

Where automated titrators are used, instrument operators should ensure that the manufacturer's instructions

are followed with respect to reagent capacities.

NOTE Commercially available Karl Fischer two-component systems (absorption solvent and titrants) may be used as

an alternative to ethylene glycol/methanol absorption and composite Karl Fischer titrant solutions.

Switch on the electrometric titrator (4.3.13) and magnetic stirrer (4.3.12), adjusting the speed of the latter to

ensure adequate mixing. Maintain a constant stirring speed during the titration and between the successive

titrations of the blank test, standard, and test sample.

4.5.3 Titration

Add Karl Fischer solution (4.2.8) slowly to the absorption cell by burette (4.3.14). The approaching end-point

will be indicated by a rapid increase in current due to the presence of free iodine from the excess Karl Fischer

solution. At this point, a current is selected for the end-point (30 µA to 40 µA). The titration is continued until

this current can be maintained for a period of 20 s. The absorbent solution shall be titrated to this end-point

immediately prior to the commencement of all tests and calibrations.

The manufacturer's recommendations regarding titration procedures should be followed if commercially

purchased equipment and reagents are used.

To minimize the transfer of contaminants such as moisture and grease, conditioned absorption tubes and

sample boats should be handled using cotton gloves.

10 © ISO 2006 – All rights reserved

4.5.4 Blank test

Restore the gas flow to a conditioned titration cell (4.3.9) and adjust the nitrogen flow to a rate of 100 ml/min

to 200 ml/min.

Quickly remove the drying-tube end cap (4.3.2), and place an empty sample boat (4.3.5) in the entrance of the

heated zone. Fit the end cap (and/or inlet connector), and using a pushrod (manual or magnetic), immediately

move the boat to the centre of the oven and note the boat introduction.

During the placement of the boat in the drying tube, as specified in 4.5.2 to this subclause, precautions should

be taken, essentially involving a careful technique, to prevent entry of moisture from extraneous sources into

the drying tube.

After 2 h, disconnect the outlet of the drying tube from the absorption cell, and connect an opened guard tube

to the tube oven outlet. Follow the procedure exactly as described in 4.5.2.

Background-corrected blank tests should be as low as possible and not more than 2 mg. Repeat the

determination of the blank test after the analysis of the test sample, to ensure that the blank test value is

essentially constant.

4.5.5 Check test

NOTE 1 The check test is required when first commissioning the complete apparatus and at other appropriate times,

e.g. when changes in the equipment or operators have been made and when a regular interval check on the performance

of the equipment is required.

When a satisfactory value for the blank test has been obtained, weigh 0,05 g to 0,20 g of copper(II) sulfate

pentahydrate (4.2.4), to the nearest 0,2 mg, into the cooled sample boat used for the blank test. The mass

taken should relate to the approximate anticipated maximum moisture content of the ore type being analysed.

Repeat the procedure in 4.5.3 using the boat containing the weighed copper(II) sulfate. The indicated water

content, corrected with the bla

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...