IEC TR 61340-5-5:2018

(Main)Electrostatics - Part 5-5: Protection of electronic devices from electrostatic phenomena - Packaging systems used in electronic manufacturing

Electrostatics - Part 5-5: Protection of electronic devices from electrostatic phenomena - Packaging systems used in electronic manufacturing

IEC TR 61340-5-5:2018(E) discusses packaging material requirements for electrostatic discharge sensitive items (ESDS) as well as non–ESDS which can apply to packaging materials such as embossed carrier tape, trays, tubes (stick magazines), rails and others used in back end line processing and parts handling where test methods described in other standards are, for the most part, inadequate. Issues related to electrostatic charge generation, electrostatic attraction and repulsion are included. The recommendations and discussions within this document can also be applicable to other types of packaging that cannot be evaluated by other means.

This document discusses the issues related to

1) technical considerations for packaging material selection and packaging system design,

2) packaging material specifications for electrostatic control,

3) existing test methods and their limitations for packaging materials,

4) suggestions for the evaluation of small dimension packaging materials, and

5) industry common practices.

General Information

- Status

- Published

- Publication Date

- 27-Nov-2018

- Technical Committee

- TC 101 - Electrostatics

- Drafting Committee

- JWG 13 - TC 101/JWG 13

- Current Stage

- PPUB - Publication issued

- Start Date

- 28-Nov-2018

- Completion Date

- 17-Dec-2018

Overview

IEC TR 61340-5-5:2018 (Electrostatics - Part 5-5) is a Technical Report from the IEC that provides guidance on packaging systems used in electronic manufacturing to protect electrostatic discharge sensitive (ESDS) items and other parts that cannot be adequately evaluated by existing test methods. It addresses packaging material selection, system design, electrostatic charge generation, attraction/repulsion, dissipation, shielding and practical evaluation approaches for small-dimension packaging such as embossed carrier tape, trays, tubes, rails, cover tape and reels.

Key topics and technical focus

- Scope and purpose: Recommendations for packaging materials and systems where standard test methods are limited or inadequate.

- Packaging material principles: Low-charging materials, dissipative vs. conductive solutions, field shielding and discharge shielding, plus moisture barrier and outgassing considerations.

- Electrostatic phenomena: Analysis of charge generation (triboelectrification), induction, electrostatic attraction/repulsion and discharge mechanisms that impact ESDS components.

- Material types and processing: Filled polymers, intrinsically conductive/dissipative materials, surface coatings, antistats, anodized parts, vacuum forming, injection moulding, embossing and lamination.

- Evaluation and test methods: Review of existing standards and test limitations; proposals and concepts for new or adapted test methods (single-point probe, parallel plates, pin-point probe, shielding tests, triboelectric charging and discharge evaluation) tailored to small packaging geometries.

- Practical recommendations: Design guidelines, selection criteria and industry common practices for manufacturing and handling environments (inside and outside EPAs - electrostatic protected areas).

Practical applications

- Selection and specification of ESD-safe packaging materials for surface-mount devices (SMDs) and other ESDS components.

- Design of embossed tape, cover tape and trays to minimize tribocharging and enable safe automated handling.

- Evaluation of packing solutions used between EPAs and in back-end processing where standard tests may not apply.

- Guidance for QA, procurement and suppliers to define packaging attributes (dissipation, shielding, moisture barriers, outgassing) that meet handling and storage requirements.

Who should use this standard

- ESD control engineers and packaging engineers in electronics manufacturing

- Quality assurance and procurement teams specifying component packaging

- Test laboratories developing or adapting ESD test methods for packaging

- Packaging material suppliers and design houses for electronic components

Related standards

- IEC 61340 series (e.g., IEC 61340-5-3, IEC 61340-2-1, IEC TR 61340-2-2, IEC 61340-2-3, IEC 61340-4-8)

- ANSI/ESD S541 and relevant military specifications (e.g., MIL PRF 81705, MIL-STD-3010) - referenced for comparisons and supplemental requirements.

Keywords: IEC TR 61340-5-5:2018, electrostatic discharge, ESD, packaging systems, ESDS, packaging material, embossed carrier tape, trays, triboelectrification, charge dissipation, shielding, electronics manufacturing.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC TR 61340-5-5:2018 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Electrostatics - Part 5-5: Protection of electronic devices from electrostatic phenomena - Packaging systems used in electronic manufacturing". This standard covers: IEC TR 61340-5-5:2018(E) discusses packaging material requirements for electrostatic discharge sensitive items (ESDS) as well as non–ESDS which can apply to packaging materials such as embossed carrier tape, trays, tubes (stick magazines), rails and others used in back end line processing and parts handling where test methods described in other standards are, for the most part, inadequate. Issues related to electrostatic charge generation, electrostatic attraction and repulsion are included. The recommendations and discussions within this document can also be applicable to other types of packaging that cannot be evaluated by other means. This document discusses the issues related to 1) technical considerations for packaging material selection and packaging system design, 2) packaging material specifications for electrostatic control, 3) existing test methods and their limitations for packaging materials, 4) suggestions for the evaluation of small dimension packaging materials, and 5) industry common practices.

IEC TR 61340-5-5:2018(E) discusses packaging material requirements for electrostatic discharge sensitive items (ESDS) as well as non–ESDS which can apply to packaging materials such as embossed carrier tape, trays, tubes (stick magazines), rails and others used in back end line processing and parts handling where test methods described in other standards are, for the most part, inadequate. Issues related to electrostatic charge generation, electrostatic attraction and repulsion are included. The recommendations and discussions within this document can also be applicable to other types of packaging that cannot be evaluated by other means. This document discusses the issues related to 1) technical considerations for packaging material selection and packaging system design, 2) packaging material specifications for electrostatic control, 3) existing test methods and their limitations for packaging materials, 4) suggestions for the evaluation of small dimension packaging materials, and 5) industry common practices.

IEC TR 61340-5-5:2018 is classified under the following ICS (International Classification for Standards) categories: 17.220.99 - Other standards related to electricity and magnetism; 29.020 - Electrical engineering in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 61340-5-5:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TR 61340-5-5 ®

Edition 1.0 2018-11

TECHNICAL

REPORT

colour

inside

Electrostatics –

Part 5-5: Protection of electronic devices from electrostatic phenomena –

Packaging systems used in electronic manufacturing

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TR 61340-5-5 ®

Edition 1.0 2018-11

TECHNICAL

REPORT

colour

inside

Electrostatics –

Part 5-5: Protection of electronic devices from electrostatic phenomena –

Packaging systems used in electronic manufacturing

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 17.220.99; 29.020 ISBN 978-2-8322-6255-9

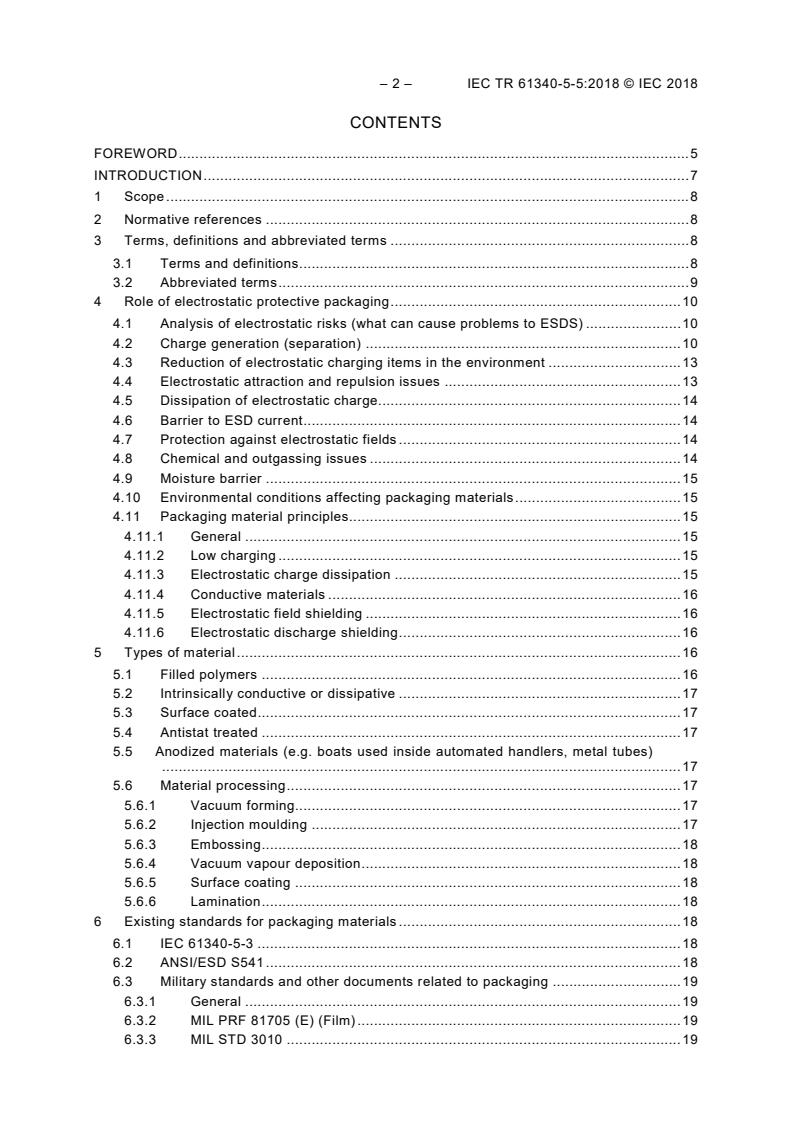

– 2 – IEC TR 61340-5-5:2018 © IEC 2018

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms, definitions and abbreviated terms . 8

3.1 Terms and definitions . 8

3.2 Abbreviated terms . 9

4 Role of electrostatic protective packaging . 10

4.1 Analysis of electrostatic risks (what can cause problems to ESDS) . 10

4.2 Charge generation (separation) . 10

4.3 Reduction of electrostatic charging items in the environment . 13

4.4 Electrostatic attraction and repulsion issues . 13

4.5 Dissipation of electrostatic charge. 14

4.6 Barrier to ESD current . 14

4.7 Protection against electrostatic fields . 14

4.8 Chemical and outgassing issues . 14

4.9 Moisture barrier . 15

4.10 Environmental conditions affecting packaging materials . 15

4.11 Packaging material principles. 15

4.11.1 General . 15

4.11.2 Low charging . 15

4.11.3 Electrostatic charge dissipation . 15

4.11.4 Conductive materials . 16

4.11.5 Electrostatic field shielding . 16

4.11.6 Electrostatic discharge shielding . 16

5 Types of material . 16

5.1 Filled polymers . 16

5.2 Intrinsically conductive or dissipative . 17

5.3 Surface coated . 17

5.4 Antistat treated . 17

5.5 Anodized materials (e.g. boats used inside automated handlers, metal tubes)

............................................................................................................................. 17

5.6 Material processing . 17

5.6.1 Vacuum forming. 17

5.6.2 Injection moulding . 17

5.6.3 Embossing . 18

5.6.4 Vacuum vapour deposition . 18

5.6.5 Surface coating . 18

5.6.6 Lamination . 18

6 Existing standards for packaging materials . 18

6.1 IEC 61340-5-3 . 18

6.2 ANSI/ESD S541 . 18

6.3 Military standards and other documents related to packaging . 19

6.3.1 General . 19

6.3.2 MIL PRF 81705 (E) (Film) . 19

6.3.3 MIL STD 3010 . 19

6.3.4 MIL PRF 131 . 19

7 Existing test methods for packaging materials . 19

7.1 IEC 61340-2-1 – Ability of materials and products to dissipate static electric

charge . 19

7.2 IEC TR 61340-2-2 – Measurement of chargeability . 20

7.3 IEC 61340-2-3 – Resistance and resistivity . 20

7.4 IEC 61340-4-8 – Discharge shielding – Bags . 20

8 Choosing a packaging technology . 21

8.1 Determining packaging material attributes . 21

8.2 Inside an EPA . 21

8.3 Outside an EPA or between EPAs . 21

8.4 Evaluation of packaging system attributes . 21

8.5 Charge dissipation test methods . 21

8.6 Resistance measurement methods . 21

8.7 Shielding test . 22

9 Does the packaging system meet the intended purpose? . 22

10 New test method concepts and development plans . 22

10.1 General . 22

10.2 Single point probe . 23

10.3 Parallel plates . 23

10.4 Pin-point probe . 24

10.5 Shielding related test methods . 24

10.6 Charge generation – Triboelectrification test methods . 24

10.7 Triboelectric charging of cover tape . 26

10.8 Discharge evaluation method . 27

10.9 Other resistance test methods . 27

Annex A (informative) Packaging forms and types . 28

A.1 Packaging materials for electronic devices . 28

A.2 Embossed tape . 28

A.3 Cover tape . 28

A.4 Reel types and materials . 29

A.5 Injection moulded trays . 30

A.6 Tubes and rails and other configurations of packaging materials . 31

A.7 Clam shell and test socket . 32

A.8 Bags . 32

A.9 Tote boxes and other rigid containers . 33

Bibliography . 34

Figure 1 – Induction charging process – Grounding a conductor in the presence of an

electrical field . 11

Figure 2 – Second part of induction charging process . 12

Figure 3 – First discharge pulse that occurs as shown in Figure 1b . 12

Figure 4 – Second discharge pulse that occurs as shown in Figure 2 . 12

Figure 5 – Single point probe test method set–up . 23

Figure 6 – Single point probe on embossed (pocket) tape . 23

Figure 7 – Parallel plate test method set–up . 24

Figure 8 – Set–up of isolated tape reels . 25

– 4 – IEC TR 61340-5-5:2018 © IEC 2018

Figure 9 – Resistance measurements – Reel to reel . 25

Figure 10 – Charge drain test – Reel to reel. 26

Figure 11 – Cover tape evaluation concepts . 26

Figure 12 – Discharge evaluation method . 27

Figure A.1 – Examples of embossed (pocket) tape. 28

Figure A.2 – Cover tape . 29

Figure A.3 – Cover tape . 29

Figure A.4 – Cover tape . 29

Figure A.5 – Cover tape . 29

Figure A.6 – Cover tape . 29

Figure A.7 – Cover tape . 29

Figure A.8 – Cover tape . 29

Figure A.9 – Reels . 30

Figure A.10 – Reels . 30

Figure A.11 – Reels . 30

Figure A.12 – Reels . 30

Figure A.13 – Trays . 30

Figure A.14 – Trays . 30

Figure A.15 –Trays . 30

Figure A.16 – Trays . 31

Figure A.17– Trays . 31

Figure A.18 –Trays . 31

Figure A.19 – Trays . 31

Figure A.20 – Trays . 31

Figure A.21 – Trays . 31

Figure A.22 –Trays . 31

Figure A.23 – Trays . 31

Figure A.24 – Tubes . 32

Figure A.25 – Tubes . 32

Figure A.26 Tubes . 32

Figure A.27 –Clam shells . 32

Figure A.28 – Static discharge shielding bag . 33

Figure A.29 Moisture barrier – Metal foil bags . 33

Figure A.30 – Moisture barrier – Metal vapour deposition . 33

Figure A.31 – Box . 33

Figure A.32 – Rigid container . 33

Table 1 – Test methods for electrostatic protective packaging . 22

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTROSTATICS –

Part 5-5: Protection of electronic devices from electrostatic phenomena –

Packaging systems used in electronic manufacturing

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a Technical Report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC TR 61340-5-5, which is a Technical Report, has been prepared by IEC technical

committee 101: Electrostatics and IEC technical committee 40: Capacitors and resistors for

electronic equipment.

The text of this Technical Report is based on the following documents:

Draft TR Report on voting

101/564/DTR 101/575/RVDTR

Full information on the voting for the approval of this Technical Report can be found in the

report on voting indicated in the above table.

– 6 – IEC TR 61340-5-5:2018 © IEC 2018

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 61340 series, published under the general title Electrostatics, can

be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

Packaging materials used within an electrostatic discharge (ESD) control programme often

are defined by an electrical resistance measurement. Packaging material manufacturers rely

on industry standardized test methods to ensure that the materials they supply meet industry

defined specifications. However, other attributes provided by a packaging material often are

difficult to quantify, leading to confusion between packaging material manufacturers and the

end users.

Increased use of automated handling equipment for the manufacture of electronic products

has resulted in changes in the design and form of packaging materials that contain electronic

parts and components. In particular, very small profile parts such as surface mount resistors

and capacitors are contained within pocket tape reels that are unloaded by automatic

equipment. Small dimension parts require small dimension packaging materials. Small

dimension packaging materials cannot be evaluated for electrical properties by the existing

industry accepted test methods.

Several types of packaging are used within the electronics industries that do not have the

basic properties generally associated with electrostatic control, such as paper tape. Industry

best practices involving these standard packaging material forms are discussed. Other forms

of packaging for non-ESDS (electrostatic discharge sensitive items) that are brought into the

ESD protected area (EPA) and considerations for handling such packaging forms are

described. This document has been prepared by a joint working group so that the

considerations of electrostatics and the application of protective measures are compatible

with the concerns of those who provide or use small dimension electronic components.

– 8 – IEC TR 61340-5-5:2018 © IEC 2018

ELECTROSTATICS –

Part 5-5: Protection of electronic devices from electrostatic phenomena –

Packaging systems used in electronic manufacturing

1 Scope

This part of IEC 61340 discusses packaging material requirements for electrostatic discharge

sensitive items (ESDS) as well as non–ESDS which can apply to packaging materials such as

embossed carrier tape, trays, tubes (stick magazines), rails and others used in back end line

processing and parts handling where test methods described in other standards are, for the

most part, inadequate. Issues related to electrostatic charge generation, electrostatic

attraction and repulsion are included. The recommendations and discussions within this

document can also be applicable to other types of packaging that cannot be evaluated by

other means.

This document discusses the issues related to

1) technical considerations for packaging material selection and packaging system design,

2) packaging material specifications for electrostatic control,

3) existing test methods and their limitations for packaging materials,

4) suggestions for the evaluation of small dimension packaging materials, and

5) industry common practices.

2 Normative references

There are no normative references in this document.

3 Terms, definitions and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1.1

electrostatic protective packaging

containers and other enclosures that have properties and functionality to limit electrostatic

charge generation, dissipate electrostatic charge, or limit interior electrostatic fields

3.1.2

intimate packaging

materials that come into direct contact with ESD sensitive items

3.1.3

proximity packaging

materials or items that cover or surround intimate packaging materials

3.1.4

conductive material

material with surface or volume conductive properties generally specified by electrical

resistance lower than dissipative materials

3.1.5

dissipative material

material with surface or volume conductive properties with an electrical resistance greater

than conductive materials but less than insulative materials

3.1.6

insulative material

material with electrical resistance high enough to impede charge flow to some degree

3.1.7

low charging

antistatic

property of a material that limits electrostatic charge transfer by contact and separation

(triboelectrification)

3.1.8

surface resistance

ratio of DC voltage to the current flowing between two electrodes of specified configuration

that contact the same side of a material

Note 1 to entry: Surface resistance is expressed in Ω.

3.1.9

surface resistivity

for electric current flowing across a surface, ratio of DC voltage drop per unit length to the

surface current per unit width

Note 1 to entry: In effect, the surface resistivity is the resistance between two electrodes on the opposite sides of

a square and is independent of the size of the square or its dimensional units.

Note 2 to entry: Surface resistivity is expressed in Ω. It is common practice to express surface resistivity in

ohms/square to distinguish from surface resistance.

3.1.10

volume resistance

ratio of the DC voltage per unit thickness to the amount of current per unit area passing

through a material

Note 1 to entry: Volume resistance is expressed in Ω.

3.1.11

electrostatic discharge shielding

materials that attenuate an electrostatic field and limit energy penetration induced by an

electrostatic discharge

3.1.12

electrostatic field shielding

materials that attenuate an electrostatic field

3.2 Abbreviated terms

CDM charged device model

CPM charged plate monitor

EPA ESD protected area

ESD electrostatic discharge

– 10 – IEC TR 61340-5-5:2018 © IEC 2018

ESDS electrostatic discharge sensitive item

HBM human body model

4 Role of electrostatic protective packaging

4.1 Analysis of electrostatic risks (what can cause problems to ESDS)

The risk to electronic parts, assemblies and equipment (collectively referred to as "ESDS")

from electrostatic phenomenon takes several forms and can be summarized as direct

electrostatic discharge from a charged conductor to the ESDS or electrostatic discharge from

the ESDS to another conductor (at a different potential) or ground if the ESDS becomes

excessively charged. Damage to an ESDS will always be the result of an excessive flow of

current through the ESDS.

It is necessary to note that the transfer of electrostatic charge (separation of charge) will

happen every time two materials come into contact and separate. The resulting separation of

charge will yield an equal positive and negative charge on the opposing surfaces. The

differences in interactions include how much charge is separated and where the charge goes

after it is separated, which is controlled by the electrical properties of the material. Charged

materials with the ability to conduct electricity can be neutralized (charge dissipation) by

contact with ground (earth). The rate of this charge neutralization/dissipation is controlled by

the electrical resistance of the material and the contact resistance between the material and

ground. The higher the resistance of the material and its contact resistance to ground, the

longer it will take to come to charge neutrality. A positively charged material will gain missing

electrons from ground while a negatively charged object will drain electrons to ground.

The amount of discharge an ESDS can tolerate is determined by a number of factors including

part sensitivity, assembly layout, rate of the charge transfer through the ESDS, total energy in

the discharge and environmental influences.

Discharge to an ESDS can occur by contact from a charged conductor, including a person,

machine component, tool or fixture or any other charged conductor involved in a process.

Reducing the probability of a damaging discharge to an ESDS is one of the principle methods

of electrostatic control. The risk of damage from charged conductors is reduced when all the

conductive materials and items are electrically bonded to ground. A grounded conductor

cannot hold an electrostatic charge.

Discharge from a charged ESDS to ground is controlled by reducing the charge accumulation

on the ESDS itself. Once an ESDS is charged, it is difficult to remove the charge without

some risk of excessive current flow through the ESDS. Therefore, one of the key factors in

packaging design is to reduce the charge generation propensity between an ESDS and the

container used for storage and shipment.

Charge generation cannot be reduced to "zero" but can be limited to below the threshold that

will cause excessive risk to the ESDS by the design of contacting surfaces, chemical changes

or additives placed in materials to alter surface charging characteristics and usually by

providing some level of electrical conductivity to allow charges to dissipate.

4.2 Charge generation (separation)

Triboelectric charging is the primary way that materials become charged. This process is

described by the actions of contact between dissimilar materials and then their separation.

The resulting charge level is influenced by the intimacy of contact, the speed of separation

and any rubbing motions that can be part of the contacting process before separation. The

physical properties of the surfaces of the contacting materials also influence the charging

process. Reducing the surface area of contact is one of the ways that triboelectric charging

can be reduced. Chemical additives to the material surfaces can also reduce charge

generation by decreasing the friction between the surfaces. Adding dissipative agents can

allow charges to spread out on surfaces or dissipate when in contact with ground thus

reducing the concentration of charge.

Charging by induction occurs when a conductive item is grounded while in the presence of an

electric field. While this is a complex phenomenon, it can occur where ESDS are handled in

both manual and automated processes if the electrical fields on materials in the environment

are not maintained below critical levels (determined by ESDS sensitivity). The first step in the

induction process occurs when an ESDS is brought into an electrical field. Charges realign

within the ESDS by polarization as shown in Figure 1 a). At this point, there is no charge

separation within the ESDS, only polarization.

a) Isolated conductor B polarized in the presence of electric field A

b) Conductor B grounded in the presence of electric field A – resulting in trapped charge on B.

Figure 1 – Induction charging process – Grounding a conductor

in the presence of an electrical field

If the ESDS is connected to ground while in the electric field, charge will flow to or from

ground depending on the polarity of the charge on the conductive portion of the ESDS. This is

the first discharge that occurs as shown in Figure 1 b).

If the ground connection is terminated before the electrical field removed from the area (this

happens when the part moves along in a process), a charge will be trapped on the ESDS as

shown in Figure 2 a). If another ground contact is made on the charged device, a second

discharge occurs that neutralizes the charge on the object, as shown in Figure 2 b).

– 12 – IEC TR 61340-5-5:2018 © IEC 2018

a) Charged device B after disconnecting from ground shown in Figure 1 b)

b) Discharge of charged device B by contact with ground

Figure 2 – Second part of induction charging process

Actual discharge pulses from an experimental induction process are shown in Figures 3 and 4.

As can be readily observed, there are nearly equal and opposite polarity discharge events in

each induction charging-discharging process.

Figure 3 – First discharge pulse that occurs as shown in Figure 1 b)

Figure 4 – Second discharge pulse that occurs as shown in Figure 2

If the structure of an ESDS is very small, the induction from an electric field may result in

internal voltage levels high enough to damage the ESDS. The critical voltage level depends

on the breakdown voltage of the insulating layers within the ESDS.

Charging by contact with a charged object can occur if the previously uncharged conductive

parts of an ESDS contact another conductor at a different potential. Charge sharing will occur

between conductors in this manner. The charge will discharge when the ESDS is connected to

ground, the same as the process shown in Figure 2 or by contact with an item with larger

capacitance and low resistance. There is a risk of damage if the current flow in the discharge

is over the ESDS sensitivity threshold.

4.3 Reduction of electrostatic charging items in the environment

The first step in reducing the risk of electrostatic damage in any process environment is to

make sure that all the electrically conductive or dissipative items and materials within that

environment are connected to ground or at least bonded together to share charge and

equalize electrical potential. ESDS can be handled with low risk from electrostatic discharge if

handled within the environment with equalized electrical potential.

The second step is to remove all unnecessary non-conductors (insulators) from the process

environment since the electrostatic charge on those materials cannot be dissipated by

grounding. If an insulative material is not needed in the process, it should be removed. The

electrical field strength where unprotected ESDS are handled shall not exceed 5 000 V/m.

Process essential insulators with surface electrostatic fields greater than 2 000 V at 2,5 cm

should be kept 30 cm away from the ESDS or the electrostatic field reduced to < 125 V at 2,5

cm for close proximity applications (< 2,5 cm). It has been shown experimentally that the size

of a charged insulator, the distance of separation from an ESDS, and the field strength all

should be considered in any risk assessment.

The third and most challenging step in reducing the process risk to ESDS is to reduce the

charge accumulation on the parts themselves. Since the contact and separation of the ESDS

from any surface can potentially cause charging, care should be taken in the evaluation and

selection of contacting materials, which includes packaging materials used for storage and

shipment.

The amount of charge that an ESDS can tolerate is the subject of much speculation and

discussion that is likely to continue for some time. The most logical assumption is that

charged device model (CDM) testing determines the sensitivity of a given ESDS to the

defined CDM discharge waveform and therefore an equivalent amount of charge measured on

the actual ESDS should be considered as a risk level for damage. Some relatively simple and

well understood charge measurements can be made on an ESDS, the capacitance of the

ESDS determined, and the voltage as well as stored energy calculated to compare to the

ESDS CDM failure threshold. While the direct relationship between the CDM and the actual

charge on an ESDS in a process might not be 1 to 1, the risks for damage can be better

understood in a process assessment so that the charging level threshold can be set.

Managing the charge generation on an ESDS can be monitored with a variety of instruments

including contact and non-contact electrostatic voltmeters and perhaps field meters if the

ESDS is large enough in area. It is likely that the most useful measurements will be made with

a Faraday cup or pail where the charge in coulombs is measured directly.

4.4 Electrostatic attraction and repulsion issues

One of the most important principles in electrostatics is that opposite sign charges attract and

same sign charges repel. The actual force that is present in attraction and repulsion is

determined by the charge on the involved items or materials and the resulting electric field.

The higher the charge, the stronger the electric field, and the stronger the attraction or

repulsion forces. This basic principle of attraction and repulsion is used throughout industry

and affects almost any activity that comes to mind. The copy machine in an office would not

work without this fundamental principle. Filters that clean the air in industrial processes would

lose efficiency without this principle. There are countless other activities that rely on this

simple law of physics that is learned in primary school around the world.

– 14 – IEC TR 61340-5-5:2018 © IEC 2018

This simple and well-known law of physics also is the cause of countless problems in industry

due to unwanted attraction or repulsion. Electrostatic charge and the resulting electric fields

cause dust attraction in a semiconductor wafer fabrication facility that can ruin electronic parts

while they are being imaged. Electrostatic attraction or repulsion can cause parts to not feed

correctly in automated handling equipment during circuit board assembly. Small profile parts

such as capacitors and resistors can be physically influenced by electric fields that would be

considered weak or inconsequential in many other applications.

The electric field requirements stated above in 4.3 might not be sufficient to reduce small part

clinging or attraction. Further reduction of electrostatic field strength can be necessary when

handling very small parts. Fortunately, the proper use of ionized air and the selection of low

charge generating packaging materials can help mitigate these small parts handling issues.

4.5 Dissipation of electrostatic charge

As mentioned in 4.1, electrostatic charge will dissipate or become neutralized by different

mechanisms, depending on the materials involved. Materials or items with some level of

conductivity will dissipate or lose their net charge by contact with ground. The rate of this

charge dissipation is controlled by the actual electrical resistance and capacitance involved in

the discharging circuit. For the purposes of packaging materials, the electrical resistance can

be relatively high on the surface of the material. Most of the standards call for a surface

resistance test method to measure packaging materials. The actual methods that are used

vary depending on the shape of the material and are discussed in Clause 6.

Electrostatic decay is one of the forms of charge dissipation that is used to determine the

upper limits of functionality for packaging materials. In concept, electrostatic decay is a

measurement of the time it takes for a sample under test to lose or equalize a defined portion

of charge when the sample is grounded. The electrostatic decay methods are discussed in

Clause 6.

4.6 Barrier to ESD current

Limiting or ideally preventing an electrostatic discharge from entering a packaging material

containing electrostatic discharge sensitive (ESDS) items is a function of an electrical

property known as insulation. Electrical insulation limits current or charge flow by definition

and the importance of insulation in electrical terms cannot be understated. Unfortunately,

insulating materials are also prone to gaining and holding electrostatic charge. One of the

primary packaging materials used in the protection of electronic items

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...