IEC 60335-2-79:2012

(Main)Household and similar electrical appliances - Safety - Part 2-79: Particular requirements for high pressure cleaners and steam cleaners

Household and similar electrical appliances - Safety - Part 2-79: Particular requirements for high pressure cleaners and steam cleaners

IEC 60335-2-79:2012(E) deals with the safety of high-pressure cleaners without traction drive, intended for household and commercial indoor or outdoor use, having a rated pressure not less than 2,5 MPa and not exceeding 35 MPa. It also applies to steam cleaners and those parts of hot water high pressure cleaners incorporating a steam stage which have a capacity not exceeding 100 l, a rated pressure not exceeding 2,5 MPa and a product of capacity and rated pressure not exceeding 5 MPa x l. They are not equipped with a traction drive. The following power systems of the drive for the high pressure pump are covered:

- mains powered motors up to a rated voltage of 250 V for single-phase machines and 480 V for other machines,

- battery powered motors,

- internal combustion engines and

- hydraulic or pneumatic motors. This third edition cancels and replaces the second edition published in 2002 and its Amendments 1 (2004) and 2 (2007). It constitutes a technical revision. The principal changes in this edition as compared with the second edition of IEC 60335-2-79 are as follows (minor changes are not listed):

- the scope has been revised editorially to avoid misunderstandings;

- terms and definitions has been revised with regard to the requirements revised;

- the standard has been revised in general and updated regarding state-of-the-art, as far as necessary, in particular some changes have been made to Clauses 15, 22, and 25;

- a new Annex CC 'Emission of acoustical noise' was added;

- a new Annex DD 'Emission of vibration' was added and

- a new Annex EE with a model test report for vibration emission was added.

This publication is to be read in conjunction with IEC 60335-1:2010.

Appareils électrodomestiques et analogues - Sécurité - Partie 2-79: Exigences particulières pour les appareils de nettoyage à haute pression et les appareils de nettoyage à vapeur

General Information

- Status

- Published

- Publication Date

- 27-Feb-2012

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 07-Jun-2016

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60335-2-79:2012 is the IEC safety standard that sets particular requirements for high-pressure cleaners and steam cleaners intended for household and similar commercial indoor or outdoor use. Edition 3.0 (2012) is a technical revision of the earlier edition and is to be read in conjunction with IEC 60335-1:2010 (the general safety requirements for household appliances).

Key scope points:

- Applies to high-pressure cleaners without traction drive, with rated pressures from ≥ 2.5 MPa up to 35 MPa.

- Also covers steam cleaners and steam stages of hot-water high-pressure cleaners provided they meet capacity/pressure limits (capacity ≤ 100 L, rated pressure ≤ 2.5 MPa, and capacity × rated pressure ≤ 5 MPa·L).

- Drive power systems covered: mains motors (single-phase up to 250 V, others up to 480 V), battery, internal combustion engines, hydraulic and pneumatic motors.

Key technical topics and requirements

IEC 60335-2-79 supplements and modifies the general clauses of IEC 60335-1 and includes specific requirements and test methods for:

- Electrical safety: leakage current, electric strength, transient overvoltages and insulation (clearances and creepage).

- Moisture resistance and ingress protection for portable outdoor/indoor cleaning appliances.

- Mechanical strength and stability: handling, impact tests, and protection against mechanical hazards.

- Thermal safety: heating, overload protection, resistance to heat and fire.

- Construction and internal wiring: components, terminals, supply connection, external flexible cords and earthing provisions.

- Abnormal operation and endurance: tests that simulate fault and long-term running conditions.

- Backsiphonage prevention (Annex AA & BB): requirements and analysis methods to avoid contamination of potable water.

- Emission testing: new informative annexes for acoustical noise (Annex CC), vibration emission (Annex DD) and a model test report for vibration (Annex EE).

Notable technical updates in the 2012 edition:

- Editorial scope clarification and revised terms/definitions.

- Specific updates to Clauses 15 (moisture resistance), 22 (construction) and 25 (supply connection/flexible cords).

- Addition of noise and vibration emission annexes reflecting state-of-the-art testing.

Practical applications - who uses this standard

- Manufacturers and product designers of high-pressure cleaners and steam cleaners seeking to design safe, compliant products.

- Test laboratories and conformity assessment bodies performing safety and type testing.

- Certification and regulatory authorities evaluating product safety for market access.

- Procurement teams and facility managers specifying safe cleaning equipment for households, commercial facilities and outdoor use.

Related standards

- IEC 60335-1:2010 - General requirements for the safety of household and similar electrical appliances (normative companion).

- IEC 60335 series - other Part 2 standards that may apply where appliances incorporate additional functions.

- The standard takes into account wiring compatibility with IEC 60364 (national wiring rules may differ).

Keywords: IEC 60335-2-79, high pressure cleaners safety, steam cleaners standard, appliance safety, vibration emission, acoustical noise, backsiphonage, IEC 60335-1.

IEC 60335-2-79:2012 - Household and similar electrical appliances - Safety - Part 2-79: Particular requirements for high pressure cleaners and steam cleaners Released:2/28/2012

IEC 60335-2-79:2012 - Household and similar electrical appliances - Safety - Part 2-79: Particular requirements for high pressure cleaners and steam cleaners Released:2/28/2012

Frequently Asked Questions

IEC 60335-2-79:2012 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Household and similar electrical appliances - Safety - Part 2-79: Particular requirements for high pressure cleaners and steam cleaners". This standard covers: IEC 60335-2-79:2012(E) deals with the safety of high-pressure cleaners without traction drive, intended for household and commercial indoor or outdoor use, having a rated pressure not less than 2,5 MPa and not exceeding 35 MPa. It also applies to steam cleaners and those parts of hot water high pressure cleaners incorporating a steam stage which have a capacity not exceeding 100 l, a rated pressure not exceeding 2,5 MPa and a product of capacity and rated pressure not exceeding 5 MPa x l. They are not equipped with a traction drive. The following power systems of the drive for the high pressure pump are covered: - mains powered motors up to a rated voltage of 250 V for single-phase machines and 480 V for other machines, - battery powered motors, - internal combustion engines and - hydraulic or pneumatic motors. This third edition cancels and replaces the second edition published in 2002 and its Amendments 1 (2004) and 2 (2007). It constitutes a technical revision. The principal changes in this edition as compared with the second edition of IEC 60335-2-79 are as follows (minor changes are not listed): - the scope has been revised editorially to avoid misunderstandings; - terms and definitions has been revised with regard to the requirements revised; - the standard has been revised in general and updated regarding state-of-the-art, as far as necessary, in particular some changes have been made to Clauses 15, 22, and 25; - a new Annex CC 'Emission of acoustical noise' was added; - a new Annex DD 'Emission of vibration' was added and - a new Annex EE with a model test report for vibration emission was added. This publication is to be read in conjunction with IEC 60335-1:2010.

IEC 60335-2-79:2012(E) deals with the safety of high-pressure cleaners without traction drive, intended for household and commercial indoor or outdoor use, having a rated pressure not less than 2,5 MPa and not exceeding 35 MPa. It also applies to steam cleaners and those parts of hot water high pressure cleaners incorporating a steam stage which have a capacity not exceeding 100 l, a rated pressure not exceeding 2,5 MPa and a product of capacity and rated pressure not exceeding 5 MPa x l. They are not equipped with a traction drive. The following power systems of the drive for the high pressure pump are covered: - mains powered motors up to a rated voltage of 250 V for single-phase machines and 480 V for other machines, - battery powered motors, - internal combustion engines and - hydraulic or pneumatic motors. This third edition cancels and replaces the second edition published in 2002 and its Amendments 1 (2004) and 2 (2007). It constitutes a technical revision. The principal changes in this edition as compared with the second edition of IEC 60335-2-79 are as follows (minor changes are not listed): - the scope has been revised editorially to avoid misunderstandings; - terms and definitions has been revised with regard to the requirements revised; - the standard has been revised in general and updated regarding state-of-the-art, as far as necessary, in particular some changes have been made to Clauses 15, 22, and 25; - a new Annex CC 'Emission of acoustical noise' was added; - a new Annex DD 'Emission of vibration' was added and - a new Annex EE with a model test report for vibration emission was added. This publication is to be read in conjunction with IEC 60335-1:2010.

IEC 60335-2-79:2012 is classified under the following ICS (International Classification for Standards) categories: 97.080 - Cleaning appliances. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60335-2-79:2012 has the following relationships with other standards: It is inter standard links to IEC 60335-2-79:2002/AMD1:2004, IEC 60335-2-79:2002/AMD2:2007, IEC 60335-2-79:2002, IEC 60335-2-79:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60335-2-79:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60335-2-79 ®

Edition 3.0 2012-02

INTERNATIONAL

STANDARD

colour

inside

Household and similar electrical appliances – Safety –

Part 2-79: Particular requirements for high pressure cleaners and steam cleaners

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

IEC 60335-2-79 ®

Edition 3.0 2012-02

INTERNATIONAL

STANDARD

colour

inside

Household and similar electrical appliances – Safety –

Part 2-79: Particular requirements for high pressure cleaners and steam cleaners

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

XB

ICS 97.080 ISBN 978-2-88912-982-9

– 2 – 60335-2-79 © IEC:2012(E)

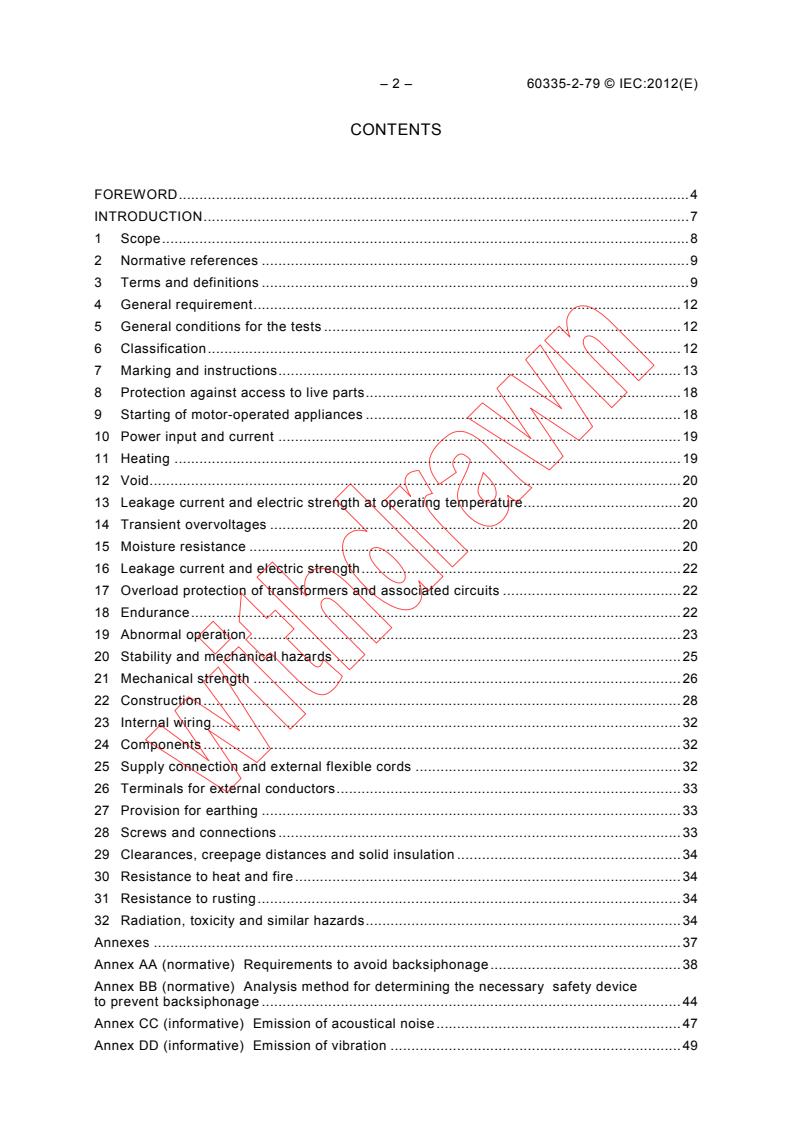

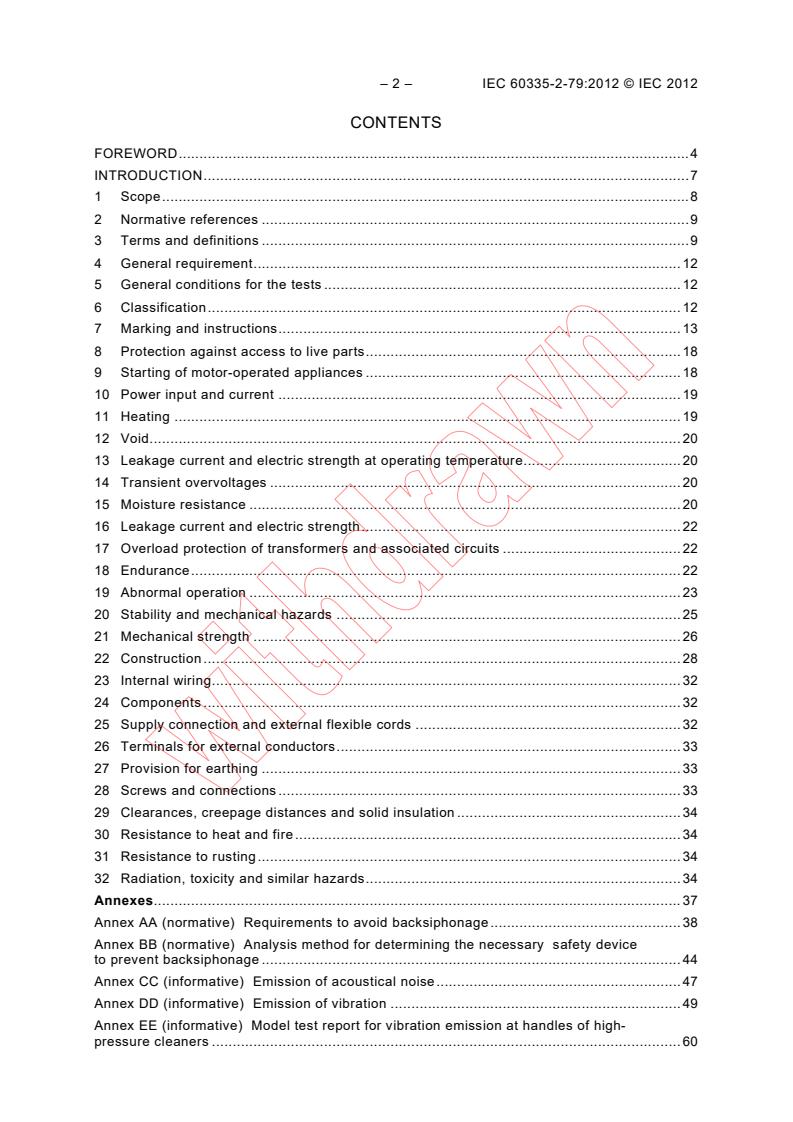

CONTENTS

FOREWORD . 4

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 9

3 Terms and definitions . 9

4 General requirement . 12

5 General conditions for the tests . 12

6 Classification . 12

7 Marking and instructions . 13

8 Protection against access to live parts . 18

9 Starting of motor-operated appliances . 18

10 Power input and current . 19

11 Heating . 19

12 Void. 20

13 Leakage current and electric strength at operating temperature . 20

14 Transient overvoltages . 20

15 Moisture resistance . 20

16 Leakage current and electric strength . 22

17 Overload protection of transformers and associated circuits . 22

18 Endurance . 22

19 Abnormal operation . 23

20 Stability and mechanical hazards . 25

21 Mechanical strength . 26

22 Construction . 28

23 Internal wiring . 32

24 Components . 32

25 Supply connection and external flexible cords . 32

26 Terminals for external conductors . 33

27 Provision for earthing . 33

28 Screws and connections . 33

29 Clearances, creepage distances and solid insulation . 34

30 Resistance to heat and fire . 34

31 Resistance to rusting . 34

32 Radiation, toxicity and similar hazards . 34

Annexes . 37

Annex AA (normative) Requirements to avoid backsiphonage . 38

Annex BB (normative) Analysis method for determining the necessary safety device

to prevent backsiphonage . 44

Annex CC (informative) Emission of acoustical noise . 47

Annex DD (informative) Emission of vibration . 49

60335-2-79 © IEC:2012(E) – 3 –

Annex EE (informative) Model test report for vibration emission at handles of high-

pressure cleaners . 60

Bibliography . 62

Figure 101 – Warning symbol . 34

Figure 102 – Impact test apparatus . 35

Figure 103 – Reactions on handle . 36

Figure 104 – Warning symbol: Machine not suitable for connection to the potable

water mains . 36

Figure 105 – Warning symbol: Do not inhale fumes . 36

Figure AA.1 – Arrangement for the durability test on backflow preventers with reduced

pressure zone . 43

Figure BB.1 – Example for an air break to drain . 46

Figure DD.1 – Trigger gun . 49

Figure DD.2 – Trigger gun with additional side handle . 50

Figure DD.3 – Measurement locations: Spraying device, main and secondary

measuring point . 52

Figure DD.4 – Measurement locations: Spraying device with additional side handle,

main and secondary measuring point . 53

Figure DD.5 – Operating conditions – Position of spraying device . 55

Table 101 – Degree of protection against harmful ingress of water . 13

Table 12 – Pull force and torque . 33

Table AA.1 – Nominal size versus durability test flow rate . 42

Table BB.1 – Matrix of the safety devices appropriate to fluid categories . 45

Table DD.1 – Description and units of the symbols used . 51

Table EE.1 – General information and reported results . 60

Table EE.2 – Measurement results for one machine . 61

– 4 – 60335-2-79 © IEC:2012(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HOUSEHOLD AND SIMILAR ELECTRICAL APPLIANCES –

SAFETY –

Part 2-79: Particular requirements

for high pressure cleaners and steam cleaners

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60335-2-79 has been prepared by subcommittee 61J: Electrical

motor-operated cleaning appliances for commercial use, of IEC technical committee 61:

Safety of household and similar electrical appliances.

This third edition cancels and replaces the second edition published in 2002 and its

Amendments 1 (2004) and 2 (2007). It constitutes a technical revision.

The principal changes in this edition as compared with the second edition of IEC 60335-2-79

are as follows (minor changes are not listed):

– the scope has been revised editorially to avoid misunderstandings;

– terms and definitions has been revised with regard to the requirements revised;

– the standard has been revised in general and updated regarding state-of-the-art, as far as

necessary, in particular some changes have been made to Clauses 15, 22, and 25;

60335-2-79 © IEC:2012(E) – 5 –

– a new Annex CC 'Emission of acoustical noise' was added;

– a new Annex DD 'Emission of vibration' was added;

– a new Annex EE with a model test report for vibration emission was added.

The text of this standard is based on the following documents:

FDIS Report on voting

61J/485/FDIS 61J/497/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This part 2 is to be used in conjunction with the latest edition of IEC 60335-1 and its

amendments. It was established on the basis of the fifth edition (2010) of that standard.

NOTE 1 When “Part 1” is mentioned in this standard, it refers to IEC 60335-1.

This part 2 supplements or modifies the corresponding clauses in IEC 60335-1, so as to

convert that publication into the IEC standard: Safety requirements for high pressure cleaners

and steam cleaners.

When a particular subclause of Part 1 is not mentioned in this part 2, that subclause applies

as far as is reasonable. When this standard states “addition”, “modification” or “replacement”,

the relevant text in Part 1 is to be adapted accordingly.

NOTE 2 The following numbering system is used:

– subclauses, tables and figures that are numbered starting from 101 are additional to those in Part 1;

– unless notes are in a new subclause or involve notes in Part 1, they are numbered starting from 101, including

those in a replaced clause or subclause;

– additional annexes are lettered AA, BB, etc.

NOTE 3 The following print types are used:

– requirements: in roman type;

– test specifications: in italic type;

– notes: in small roman type.

Words in bold in the text are defined in Clause 3. When a definition concerns an adjective, the adjective and the

associated noun are also in bold.

A list of all parts of the IEC 60335 series, under the general title: Household and similar

electrical appliances – Safety can be found on the IEC website.

– 6 – 60335-2-79 © IEC:2012(E)

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this standard may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

60335-2-79 © IEC:2012(E) – 7 –

INTRODUCTION

It has been assumed in the drafting of this International Standard that the execution of its

provisions is entrusted to appropriately qualified and experienced persons.

This standard recognizes the internationally accepted level of protection against hazards such

as electrical, mechanical, thermal, fire and radiation of appliances when operated as in

normal use taking into account the manufacturer's instructions. It also covers abnormal

situations that can be expected in practice and takes into account the way in which

electromagnetic phenomena can affect the safe operation of appliances.

This standard takes into account the requirements of IEC 60364 as far as possible so that

there is compatibility with the wiring rules when the appliance is connected to the supply

mains. However, national wiring rules may differ.

If an appliance within the scope of this standard also incorporates functions that are covered

by another part 2 of IEC 60335, the relevant part 2 is applied to each function separately, as

far as is reasonable. If applicable, the influence of one function on the other is taken into

account.

When a part 2 standard does not include additional requirements to cover hazards dealt with

in Part 1, Part 1 applies.

NOTE 1 This means that the technical committees responsible for the part 2 standards have determined that it is

not necessary to specify particular requirements for the appliance in question over and above the general

requirements.

This standard is a product family standard dealing with the safety of appliances and takes

precedence over horizontal and generic standards covering the same subject.

NOTE 2 Horizontal and generic standards covering a hazard are not applicable since they have been taken into

consideration when developing the general and particular requirements for the IEC 60335 series of standards. For

example, in the case of temperature requirements for surfaces on many appliances, generic standards, such as

ISO 13732-1 for hot surfaces, are not applicable in addition to Part 1 or part 2 standards.

An appliance that complies with the text of this standard will not necessarily be considered to

comply with the safety principles of the standard if, when examined and tested, it is found to

have other features that impair the level of safety covered by these requirements.

An appliance employing materials or having forms of construction differing from those detailed

in the requirements of this standard may be examined and tested according to the intent of

the requirements and, if found to be substantially equivalent, may be considered to comply

with the standard.

– 8 – 60335-2-79 © IEC:2012(E)

HOUSEHOLD AND SIMILAR ELECTRICAL APPLIANCES –

SAFETY –

Part 2-79: Particular requirements

for high pressure cleaners and steam cleaners

1 Scope

This clause of Part 1 is replaced by the following.

This International Standard deals with the safety of high-pressure cleaners without traction

drive, intended for household and commercial indoor or outdoor use, having a rated pressure

not less than 2,5 MPa and not exceeding 35 MPa.

It also applies to steam cleaners and those parts of hot water high pressure cleaners

incorporating a steam stage which have a capacity not exceeding 100 l, a rated pressure not

exceeding 2,5 MPa and a product of capacity and rated pressure not exceeding 5 MPa·l.

They are not equipped with a traction drive. The following power systems of the drive for the

high pressure pump are covered:

– mains powered motors up to a rated voltage of 250 V for single-phase machines and

480 V for other machines,

– battery powered motors,

– internal combustion engines,

– hydraulic or pneumatic motors.

This standard does not apply to

– high pressure water jet machines having a rated pressure exceeding 35 MPa;

NOTE 101 In Europe, those machines are covered by EN 1829-1.

– steam cleaners intended for domestic use (IEC 60335-2-54);

– hand-held and transportable motor-operated electric tools (IEC 60745 series, IEC 61029

series);

– appliances for medical purposes (IEC 60601);

– agricultural sprayers;

NOTE 102 In Europe, EN 907 gives requirements for sprayers and liquid fertilizer distributors for agricultural and

forestry purposes.

– non-liquid, solid abrasive cleaners;

– machines designed to be part of a production process;

– machines designed for use in corrosive or explosive environments (dust, vapour or gas);

– machines designed for use in vehicles or on board of ships or aircraft.

NOTE 103 Attention is drawn to the fact that in many countries additional requirements on the safe use of the

equipment covered can be specified by the national health authorities, the national authorities responsible for the

protection of labour, the national water supply authorities and similar authorities.

60335-2-79 © IEC:2012(E) – 9 –

2 Normative references

This clause of Part 1 is applicable except as follows.

Addition:

IEC 60364-1, Low-voltage electrical installations – Part 1: Fundamental principles,

assessment of general characteristics, definitions

IEC 61558-2-3, Safety of transformers, reactors, power supply units and combinations thereof

– Part 2-3: Particular requirements and tests for ignition transformers for gas and oil burners

Replacement:

IEC 61770:2008, Electric appliances connected to the water mains – Avoidance of

backsiphonage and failure of hose-sets

3 Terms and definitions

This clause of Part 1 is applicable except as follows.

3.1.9 Replacement:

normal operation

conditions under which the machine is operated in normal use

It denotes the operation at rated flow and rated pressure with the appropriate nozzle and

hose line fitted, all strainers and filters in a clean operating condition and the unloader valve

set to the rated pressure. The water heater, if fitted, is operated at maximum power. Electric

motor driven machines are supplied at rated voltage.

Socket outlets for accessories are loaded with a resistive load in accordance with the

marking.

The burner is operated at rated power. Machines designed for operation at more than one

rated power setting are additionally tested at the most disadvantageous power.

On machines designed for use with a flue pipe, a section of flue pipe is attached to the

machine. Flue gas determinations are taken in this flue pipe.

The draught is adjusted as recommended in the instructions.

3.101

unloader valve

pressure operated device which, when the pump pressure exceeds a preset value, releases

the pressure and leads the excess fluid into the inlet system

In addition, it bypasses the total pump flow at reduced pressure when its outlet flow is cut off.

3.102

safety valve

pressure operated device which, when the pump or steam cleaner pressure exceeds a preset

value, releases the pressure and which may return the excess fluid or steam either to the inlet

system or into the atmosphere

3.103

rated pressure

maximum working pressure at the pressure generator during normal operation

– 10 – 60335-2-79 © IEC:2012(E)

3.104

allowable pressure

maximum pressure up to which a machine and/or parts of the machine may be subjected

without impairing its safety

3.105

rated flow

maximum flow at rated pressure at the nozzle during normal operation

3.106

maximum flow rate

highest possible flow rate at the nozzle

Note 1 to entry: Typically, the maximum flow rate occurs at working pressures lower than rated pressure and

with a nozzle designed for spraying of cleaning agents.

3.107

rated temperature

maximum temperature of the cleaning agent during normal operation

3.108

pressure switch

device which, in response to varying fluid pressure, provides a controlling function at a pre-set

value

3.109

flow switch

device which, in response to a varying rate of fluid flow, provides a controlling function at a

pre-set value

3.110

trigger gun

hand-held spraying device where the flow of the cleaning agent is regulated by an integrated

manually operated control device

3.111

pencil jet nozzle

nozzle that gives a concentrated, parallel water jet

Note 1 to entry: Pencil jet nozzles are also known as needle jet nozzles, solid jet nozzles or 0 degree jet

nozzles.

3.112

water jetter

pipe-cleaning device, connected to and controlled by a trigger gun, consisting of a high

pressure hose and a cleaning head with nozzles

3.113

cleaning agent

water with or without the addition of gaseous, soluble or miscible detergent or solid abrasive

3.114

water heater

device for heating the cleaning agent by means of electricity, gas, liquid fuel or heat

exchange

60335-2-79 © IEC:2012(E) – 11 –

3.115

continuous ignition

ignition of an oil or gas fired burner that is continuously maintained throughout the time the

burner is operational, whether the burner is firing or not

3.116

primary safety control

control device that responds directly to flame properties sensing the presence of flame and, in

event of ignition failure or unintentional flame extinguishment, causes safety shut down

Note 1 to entry: Primary safety controls are also known as flame failure devices or flame safety controls.

3.117

motorized cleaning head

hand-held or hand-guided cleaning device connected to the machine, with an integrated

electrical motor

3.118

low pressure accessory

device, connected to and controlled by a trigger gun, with large nozzle openings generating

a pressure below rated pressure

Note 1 to entry: Typical examples of low pressure accessories are washing brushes, foam nozzles, washing

sponges.

3.119

hand-guided machine

machine that needs to be moved on the floor

3.120

hose line

assembly of high pressure hoses mounted with appropriate fittings

3.121

guard

part of the machine specifically designed to provide protection by means of a physical barrier,

such as, for example, a casing, a shield, a cover, a screen, a door, an enclosure or a fence;

other parts of the machine that fulfil a primarily operational function, such as, for example, the

frame of the machine, may also fulfil a protective function but are not referred to as guards

Note 1 to entry: Three main kinds of guards can be distinguished: fixed guards, interlocking moveable guards

and adjustable guards. Interlocking movable guards are required where frequent access is envisaged, while fixed

guards can be used where frequent access is not envisaged.

3.122

operator

person installing, operating, adjusting, cleaning, moving, or performing user maintenance on

the machine

3.123

test solution

a solution which consists of 20 g of NaCl and 1 ml of a solution of 28 % by mass of dodecyl

sodium sulphate in each 8 l of water

Note 1 to entry: The chemical designation of dodecyl sodium sulphate is C H NaSO .

12 25 4

– 12 – 60335-2-79 © IEC:2012(E)

3.124

reaction force

force which reacts on the spraying device (and thereby on the operator) as a result of the

action force by the water jet leaving the nozzle

Note 1 to entry: The reaction force can also be called recoil force. For other standards with regard to hand-arm-

vibration, the technical term is feed force (e.g. ISO 28927 series) or push force (e.g. ISO 15230) what describes

another force actually. For high-pressure cleaners, the reaction force is the relevant physical dimension.

4 General requirement

This clause of Part 1 is applicable except as follows.

Replacement of the first paragraph by the following:

Machines shall be constructed so that they function safely so as to cause no danger to

persons or surroundings during normal use, even in the event of carelessness, and during

installation, adjusting, maintenance, cleaning, repairing or transportation.

Addition:

For the purposes of this standard, the term ‘appliance’ as used in Part 1 is to be read as

‘machine’.

5 General conditions for the tests

This clause of Part 1 is applicable except as follows.

5.101 The test solution is stored in a cool atmosphere and used within seven days after its

preparation.

5.102 Protective devices and safety valves shall remain fully functional but shall not trip

under normal operation.

6 Classification

This clause of Part 1 is applicable except as follows.

6.1 Replacement:

Machines shall be one of the following classes with respect to the protection against electric

shock:

– class I,

– class II, or

– class III.

However, hand-held appliances and hand-held parts of steam cleaners and high pressure

cleaners shall be class II or class III.

Compliance is checked by inspection and by the relevant tests.

60335-2-79 © IEC:2012(E) – 13 –

6.2 Replacement:

The machines shall have a degree of protection against harmful ingress of water according to

Table 101:

Table 101 – Degree of protection against harmful ingress of water

Protection class Protection degree

(electric shock) (IEC 60529)

I – II IPX4

For indoor use only

III IPX3

Steam cleaners For outdoor use I-II-III IPX5

II IPX7

Hand-held parts

III IPX3

Hand-held appliances II-III IPX7

High pressure

Other types of machines I-II-III IPX5

cleaners

Hand-held parts II-III IPX7

However, fixed appliances that are specified for installation in a separate room, where they

will not be subject to spillage or splashing of water, shall be at least IPX0.

Compliance is checked by inspection and by the relevant tests.

7 Marking and instructions

This clause of Part 1 is applicable except as follows.

th

7.1 Replace the 4 dashed item as follows:

– the business name and address of the manufacturer and, if applicable, his authorized

representative; any address shall be sufficient to ensure postal contact;

Addition:

Machines shall be marked in addition with the following:

– serial number, if any;

– designation of the machine and series or type, allowing the technical identification of the

product. This may be achieved by a combination of letters and/or numbers;

NOTE 101 Designation of machine, series or type includes the model or type reference as required in Part 1.

– the year of construction, that is the year in which the manufacturing process is completed;

– rated pressure in Pascal;

– allowable pressure in Pascal;

– rated flow in litre per minute;

– maximum flow rate in litre per minute, if necessary. The number of flow rate markings is

limited to two;

– maximum rated temperature where this is above 50 °C;

– maximum power of the water heater in kW, if applicable (for electric heaters, the input

power, for gas-fired or oil-fired heaters the output power).

– 14 – 60335-2-79 © IEC:2012(E)

Machines equipped with wheels and other mobile machinery shall be marked with the mass of

the most usual configuration in kg.

A yellow label with black lines showing the substance of the warning symbols in accordance

with Figure 101 shall be permanently fixed to the machine.

Machines shall be marked in addition with the following, if applicable:

– When the surface of a flue or duct for exhaust gases from the heater exceeds a

temperature rise of 60 K, a warning notice shall be fitted near to the hot surface stating

WARNING Hot. Do not touch.

The height of the lettering shall be not less than 4 mm. This wording may be replaced by

symbol IEC 60417-5041 (2002-10).

– Steam cleaners shall be marked with symbol IEC 60417-5597 (2002-10).

– Machines not intended to be connected to the potable water mains shall be marked with

the symbol according to Figure 104, coloured as shown or in monochrome colour.

– Machines intended to be used indoors and powered by internal combustion engines,

except LPG-powered engines, shall be marked with the symbol according to Figure 105. It

is acceptable to show this symbol in monochrome colour.

7.1.101 All high pressure hoses shall be marked with the following:

– with a pressure of at least the allowable pressure in Pascal or bar;

– maximum temperature in degrees Celsius;

– business name of the manufacturer of the hose and the date of production. These data

may be coded.

Compliance is checked by inspection.

7.1.102 All high pressure accessories (e.g. trigger gun, spray lance) shall be marked with

the following:

– a pressure of at least the allowable pressure in Pascal or bar;

– maximum temperature in degrees Celsius.

Compliance is checked by inspection.

7.1.103 Motorized cleaning heads shall be marked with

– rated voltage or rated voltage range in volts;

– rated power input in watts;

– name, trade mark or identification mark of the manufacturer or responsible vendor;

– model or type reference;

– mass of the most usual configuration in kg.

Motorized cleaning heads for water-suction cleaning appliances, except those of class III

construction having a working voltage up to 24 V shall be marked with symbol

IEC 60417-5935 (2002-10).

NOTE This symbol is an information sign and, except for the colours, the rules of ISO 3864-1 apply.

Compliance is checked by inspection.

60335-2-79 © IEC:2012(E) – 15 –

7.1.104 Socket-outlets for accessories shall be marked with the maximum load in watts on

the socket-outlet or close to it.

Compliance is checked by inspection.

7.6 Addition:

[symbol IEC 60417-5597 (2002-10)] steam

[symbol IEC 60417-5041 (2002-10)] hot surface

7.12 Modification:

th

Replace the 4 paragraph by the following text.

This machine is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge.

Addition:

The front cover of the instructions shall include the substance of the following warning:

CAUTION Read the instructions before using the machine.

This wording may be replaced by symbols ISO 7000-0434 (2004-01) and either

ISO 7000-1641 (2004-01) or ISO 7000-0790 (2004-01).

The instructions shall contain at least the following:

– the business name and full address of the manufacturer and, if applicable, his authorized

representative;

– designation of series or type of the machine as marked on the machine itself, except for

the serial number;

NOTE 101 The designation of series or type can be abstracted, al long as the identification of the product is

ensured.

– the general description of the machine;

– the intended use of the machine and the auxiliary equipment as covered by the scope of

this standard;

NOTE 102 Examples of auxiliary equipment are lights and powered brushes.

– the meaning of the symbols used on the machine and in the instructions;

– drawings, diagrams, descriptions and explanations necessary for the safe use,

maintenance and repair of the machine and for checking its correct functioning;

– technical data including the markings on the machine and the maximum inlet water

pressure in Pascal;

– 16 – 60335-2-79 © IEC:2012(E)

– information regarding putting into service, safe operation, handling, transportation, and

storage of the machine taking into account its weight;

– instructions to enable adjustment and maintenance to be carried out safely, including the

protective measures that should be taken during these operations;

– the conditions in which the machine meets the requirement of stability during use,

transportation, assembly, dismantling when out of service, testing or foreseeable

breakdowns;

– the procedure to be followed to prevent unsafe situations in the event of accident (e.g.

contact with or spillage of detergents, battery acid, fuel or oil) or equipment breakdown

(such as flat tire or component failure).

The instructions shall indicate the type and frequency of inspections and maintenance

required for safe operation including the preventive maintenance measures. They shall, if

applicable, give the specifications of the spare parts if they affect the health and safety of the

operator.

In addition, the instructions shall give the following information, if applicable:

– information about appropriate personnel protection equipment (PPE) for high pressure

cleaners in operation, e.g. safety boots, safety gloves, safety helmets with visors, hearing

protection etc. which shall be worn while operating the equipment;

– instructions for water jetters shall be given, such as “Insert hose to red mark before

turning on the machine”;

– adequate information about the connection with the water mains, including the maximum

inlet pressure, if not given on the rating plate;

– adequate information about the nozzles to be used, the danger of the kickback force and

the sudden torque on the spray assembly when opening the trigger gun;

– the kickback forces if they exceed 20 N;

– the functioning of the safety devices, e.g. safety valves, flow switches, pressure

switches;

– for battery powered machines, the precautions to be taken for safe charging;

– information regarding safe disposal of batteries;

– if split rims are used for pneumatic tyres, instructions shall be given for the safe change of

tyres;

– for mains operated machines, the substance of the following:

The electric supply connection shall be made by a qualified electrician and comply with

IEC 60364-1. It is recommended that the electric supply to this machine should include

either a residual current device that will interrupt the supply if the leakage current to earth

exceeds 30 mA for 30 ms or a device that will prove the earth circuit.

– For oil fired machines without a primary safety control, the substance of the following:

This machine must be attended during operation.

– For fixed appliances intended to be used in a dry independent room, and for steam

cleaners intended for indoor use only, the substance of the following:

Do not splash or wash down.

For machines intended to be connected to the potable water mains, the instructions shall give

the following information, if applicable:

– adequate information for the correct connection to the potable water mains;

– necessary length and quality of the water supply hose;

– necessary measures for conversion of the connection from supply from the potable water

mains to supply from other water sources.

60335-2-79 © IEC:2012(E) – 17 –

For machines not intended to be connected to the potable water mains, the instructions shall

give the following information, if applicable:

– adequate information for the correct connection to the water supply;

– adequate information about suction operation;

– necessary length and quality of the water supply hose;

– necessary measures for conversion of the connection from supply from other water

sources to supply from the potable water mains.

7.12.101 The instructions shall include warnings concerning ways in which the machine shall

not be used, which in the experience of the manufacturer are likely to occur. At least, they

shall include the substance of the following warnings, if applicable.

– WARNING This machine has been designed for use with the cleaning agent supplied or

recommended by the manufacturer. The use of other cleaning agents or

chemicals may adversely affect the safety of the machine.

– WARNING High pressure jets can be dangerous if subject to misuse. The jet must not

be directed at persons, live electrical equipment or the machine itself.

– WARNING Do not use the machine within range of persons unless they wear protective

clothing.

– WARNING Do not direct the jet against yourself or others in order to clean clothes or

foot-wear.

– WARNING Risk of explosion – Do not spray flammable liquids.

– WARNING High pressure cleaners shall not be used by children or untrained personnel.

– WARNING High pressure hoses, fittings and couplings are important for the safety of

the machine. Use only hoses, fittings and couplings recommended by the

manufacturer.

– WARNING To ensure machine safety, use only original spare parts from the

manufacturer or approved by the manufacturer.

– WARNING Water that has flowed through backflow preventers is considered to be non-

potable.

– A warning that the machine shall be disconnected from its power source during cleaning or

maintenance and when replacing parts or converting the machine to another function:

• for mains operated machines, by removing the plug from the socket-outlet;

• for battery powered machines, by safely disconnecting at least the B+ or B‒ pole of

the battery or by an equivalent method (disconnecting device); for non-SELV both

poles must be disconnected;

• for internal combustion engine powered machines, by removing the ignition key and by

disconnecting the battery.

NOTE Where no ignition key and no battery exist, the disconnection can be achieved by equivalent means.

– WARNING Do not use the machine if a supply cord or important parts of the machine

are damaged, e.g. safety devices, high pressure hoses, trigger gun.

– WARNING Inadequate extension cords can be dangerous. If an extension cord is used,

it shall be suitable for outdoor use, and the connection has to be kept dry

and off the ground. It is recommended that this is accomplished by means of

a cord reel which keeps the socket at least 60 mm above the ground.

– WARNING Do not use combustion engine powered machines indoors unless adequate

ventilation is assessed by national labour authorities.

– WARNING Ensure that any exhaust emissions are not in the vicinity of air intakes.

– WARNING For gas or oil-heated machines it is important to provide adequate

ventilation and make sure that the flue gases are properly discharged.

– 18 – 60335-2-79 © IEC:2012(E)

– WARNING Always s

...

IEC 60335-2-79 ®

Edition 3.0 2012-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Household and similar electrical appliances – Safety –

Part 2-79: Particular requirements for high pressure cleaners and steam cleaners

Appareils électrodomestiques et analogues – Sécurité –

Partie 2-79: Exigences particulières pour les appareils de nettoyage à haute

pression et les appareils de nettoyage à vapeur

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Découvrez notre puissant moteur de recherche et consultez

webstore.iec.ch/advsearchform gratuitement tous les aperçus des publications. Avec un

La recherche avancée permet de trouver des publications IEC abonnement, vous aurez toujours accès à un contenu à jour

en utilisant différents critères (numéro de référence, texte, adapté à vos besoins.

comité d’études, …). Elle donne aussi des informations sur les

projets et les publications remplacées ou retirées. Electropedia - www.electropedia.org

Le premier dictionnaire d'électrotechnologie en ligne au monde,

IEC Just Published - webstore.iec.ch/justpublished

avec plus de 22 300 articles terminologiques en anglais et en

Restez informé sur les nouvelles publications IEC. Just

français, ainsi que les termes équivalents dans 19 langues

Published détaille les nouvelles publications parues.

additionnelles. Egalement appelé Vocabulaire

Disponible en ligne et une fois par mois par email.

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC Products & Services Portal - products.iec.ch

IEC 60335-2-79 ®

Edition 3.0 2012-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Household and similar electrical appliances – Safety –

Part 2-79: Particular requirements for high pressure cleaners and steam cleaners

Appareils électrodomestiques et analogues – Sécurité –

Partie 2-79: Exigences particulières pour les appareils de nettoyage à haute

pression et les appareils de nettoyage à vapeur

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 97.080 ISBN 978-2-8322-0452-8

– 2 – IEC 60335-2-79:2012 © IEC 2012

CONTENTS

FOREWORD . 4

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 9

3 Terms and definitions . 9

4 General requirement . 12

5 General conditions for the tests . 12

6 Classification . 12

7 Marking and instructions . 13

8 Protection against access to live parts . 18

9 Starting of motor-operated appliances . 18

10 Power input and current . 19

11 Heating . 19

12 Void. 20

13 Leakage current and electric strength at operating temperature . 20

14 Transient overvoltages . 20

15 Moisture resistance . 20

16 Leakage current and electric strength . 22

17 Overload protection of transformers and associated circuits . 22

18 Endurance . 22

19 Abnormal operation . 23

20 Stability and mechanical hazards . 25

21 Mechanical strength . 26

22 Construction . 28

23 Internal wiring . 32

24 Components . 32

25 Supply connection and external flexible cords . 32

26 Terminals for external conductors . 33

27 Provision for earthing . 33

28 Screws and connections . 33

29 Clearances, creepage distances and solid insulation . 34

30 Resistance to heat and fire . 34

31 Resistance to rusting . 34

32 Radiation, toxicity and similar hazards . 34

Annexes. 37

Annex AA (normative) Requirements to avoid backsiphonage . 38

Annex BB (normative) Analysis method for determining the necessary safety device

to prevent backsiphonage . 44

Annex CC (informative) Emission of acoustical noise . 47

Annex DD (informative) Emission of vibration . 49

Annex EE (informative) Model test report for vibration emission at handles of high-

pressure cleaners . 60

Bibliography . 62

Figure 101 – Warning symbol . 34

Figure 102 – Impact test apparatus . 35

Figure 103 – Reactions on handle . 36

Figure 104 – Warning symbol: Machine not suitable for connection to the potable

water mains . 36

Figure 105 – Warning symbol: Do not inhale fumes . 36

Figure AA.1 – Arrangement for the durability test on backflow preventers with reduced

pressure zone . 43

Figure BB.1 – Example for an air break to drain . 46

Figure DD.1 – Trigger gun . 49

Figure DD.2 – Trigger gun with additional side handle . 50

Figure DD.3 – Measurement locations: Spraying device, main and secondary

measuring point . 52

Figure DD.4 – Measurement locations: Spraying device with additional side handle,

main and secondary measuring point . 53

Figure DD.5 – Operating conditions – Position of spraying device . 55

Table 101 – Degree of protection against harmful ingress of water . 13

Table 12 – Pull force and torque . 33

Table AA.1 – Nominal size versus durability test flow rate . 42

Table BB.1 – Matrix of the safety devices appropriate to fluid categories . 45

Table DD.1 – Description and units of the symbols used . 51

Table EE.1 – General information and reported results . 60

Table EE.2 – Measurement results for one machine . 61

– 4 – IEC 60335-2-79:2012 © IEC 2012

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HOUSEHOLD AND SIMILAR ELECTRICAL APPLIANCES –

SAFETY –

Part 2-79: Particular requirements

for high pressure cleaners and steam cleaners

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60335-2-79 has been prepared by subcommittee 61J: Electrical

motor-operated cleaning appliances for commercial use, of IEC technical committee 61:

Safety of household and similar electrical appliances.

This third edition cancels and replaces the second edition published in 2002 and its

Amendments 1 (2004) and 2 (2007). It constitutes a technical revision.

The principal changes in this edition as compared with the second edition of IEC 60335-2-79

are as follows (minor changes are not listed):

– the scope has been revised editorially to avoid misunderstandings;

– terms and definitions has been revised with regard to the requirements revised;

– the standard has been revised in general and updated regarding state-of-the-art, as far as

necessary, in particular some changes have been made to Clauses 15, 22, and 25;

– a new Annex CC 'Emission of acoustical noise' was added;

– a new Annex DD 'Emission of vibration' was added;

– a new Annex EE with a model test report for vibration emission was added.

The text of this standard is based on the following documents:

FDIS Report on voting

61J/485/FDIS 61J/497/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This part 2 is to be used in conjunction with the latest edition of IEC 60335-1 and its

amendments. It was established on the basis of the fifth edition (2010) of that standard.

NOTE 1 When “Part 1” is mentioned in this standard, it refers to IEC 60335-1.

This part 2 supplements or modifies the corresponding clauses in IEC 60335-1, so as to

convert that publication into the IEC standard: Safety requirements for high pressure cleaners

and steam cleaners.

When a particular subclause of Part 1 is not mentioned in this part 2, that subclause applies

as far as is reasonable. When this standard states “addition”, “modification” or “replacement”,

the relevant text in Part 1 is to be adapted accordingly.

NOTE 2 The following numbering system is used:

– subclauses, tables and figures that are numbered starting from 101 are additional to those in Part 1;

– unless notes are in a new subclause or involve notes in Part 1, they are numbered starting from 101, including

those in a replaced clause or subclause;

– additional annexes are lettered AA, BB, etc.

NOTE 3 The following print types are used:

– requirements: in roman type;

– test specifications: in italic type;

– notes: in small roman type.

Words in bold in the text are defined in Clause 3. When a definition concerns an adjective, the adjective and the

associated noun are also in bold.

A list of all parts of the IEC 60335 series, under the general title: Household and similar

electrical appliances – Safety can be found on the IEC website.

– 6 – IEC 60335-2-79:2012 © IEC 2012

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

It has been assumed in the drafting of this International Standard that the execution of its

provisions is entrusted to appropriately qualified and experienced persons.

This standard recognizes the internationally accepted level of protection against hazards such

as electrical, mechanical, thermal, fire and radiation of appliances when operated as in

normal use taking into account the manufacturer's instructions. It also covers abnormal

situations that can be expected in practice and takes into account the way in which

electromagnetic phenomena can affect the safe operation of appliances.

This standard takes into account the requirements of IEC 60364 as far as possible so that

there is compatibility with the wiring rules when the appliance is connected to the supply

mains. However, national wiring rules may differ.

If an appliance within the scope of this standard also incorporates functions that are covered

by another part 2 of IEC 60335, the relevant part 2 is applied to each function separately, as

far as is reasonable. If applicable, the influence of one function on the other is taken into

account.

When a part 2 standard does not include additional requirements to cover hazards dealt with

in Part 1, Part 1 applies.

NOTE 1 This means that the technical committees responsible for the part 2 standards have determined that it is

not necessary to specify particular requirements for the appliance in question over and above the general

requirements.

This standard is a product family standard dealing with the safety of appliances and takes

precedence over horizontal and generic standards covering the same subject.

NOTE 2 Horizontal and generic standards covering a hazard are not applicable since they have been taken into

consideration when developing the general and particular requirements for the IEC 60335 series of standards. For

example, in the case of temperature requirements for surfaces on many appliances, generic standards, such as

ISO 13732-1 for hot surfaces, are not applicable in addition to Part 1 or part 2 standards.

An appliance that complies with the text of this standard will not necessarily be considered to

comply with the safety principles of the standard if, when examined and tested, it is found to

have other features that impair the level of safety covered by these requirements.

An appliance employing materials or having forms of construction differing from those detailed

in the requirements of this standard may be examined and tested according to the intent of

the requirements and, if found to be substantially equivalent, may be considered to comply

with the standard.

– 8 – IEC 60335-2-79:2012 © IEC 2012

HOUSEHOLD AND SIMILAR ELECTRICAL APPLIANCES –

SAFETY –

Part 2-79: Particular requirements

for high pressure cleaners and steam cleaners

1 Scope

This clause of Part 1 is replaced by the following.

This International Standard deals with the safety of high-pressure cleaners without traction

drive, intended for household and commercial indoor or outdoor use, having a rated pressure

not less than 2,5 MPa and not exceeding 35 MPa.

It also applies to steam cleaners and those parts of hot water high pressure cleaners

incorporating a steam stage which have a capacity not exceeding 100 l, a rated pressure not

exceeding 2,5 MPa and a product of capacity and rated pressure not exceeding 5 MPa·l.

They are not equipped with a traction drive. The following power systems of the drive for the

high pressure pump are covered:

– mains powered motors up to a rated voltage of 250 V for single-phase machines and

480 V for other machines,

– battery powered motors,

– internal combustion engines,

– hydraulic or pneumatic motors.

This standard does not apply to

– high pressure water jet machines having a rated pressure exceeding 35 MPa;

NOTE 101 In Europe, those machines are covered by EN 1829-1.

– steam cleaners intended for domestic use (IEC 60335-2-54);

– hand-held and transportable motor-operated electric tools (IEC 60745 series, IEC 61029

series);

– appliances for medical purposes (IEC 60601);

– agricultural sprayers;

NOTE 102 In Europe, EN 907 gives requirements for sprayers and liquid fertilizer distributors for agricultural and

forestry purposes.

– non-liquid, solid abrasive cleaners;

– machines designed to be part of a production process;

– machines designed for use in corrosive or explosive environments (dust, vapour or gas);

– machines designed for use in vehicles or on board of ships or aircraft.

NOTE 103 Attention is drawn to the fact that in many countries additional requirements on the safe use of the

equipment covered can be specified by the national health authorities, the national authorities responsible for the

protection of labour, the national water supply authorities and similar authorities.

2 Normative references

This clause of Part 1 is applicable except as follows.

Addition:

IEC 60364-1, Low-voltage electrical installations – Part 1: Fundamental principles,

assessment of general characteristics, definitions

IEC 61558-2-3, Safety of transformers, reactors, power supply units and combinations thereof

– Part 2-3: Particular requirements and tests for ignition transformers for gas and oil burners

Replacement:

IEC 61770:2008, Electric appliances connected to the water mains – Avoidance of

backsiphonage and failure of hose-sets

3 Terms and definitions

This clause of Part 1 is applicable except as follows.

3.1.9 Replacement:

normal operation

conditions under which the machine is operated in normal use

It denotes the operation at rated flow and rated pressure with the appropriate nozzle and

hose line fitted, all strainers and filters in a clean operating condition and the unloader valve

set to the rated pressure. The water heater, if fitted, is operated at maximum power. Electric

motor driven machines are supplied at rated voltage.

Socket outlets for accessories are loaded with a resistive load in accordance with the

marking.

The burner is operated at rated power. Machines designed for operation at more than one

rated power setting are additionally tested at the most disadvantageous power.

On machines designed for use with a flue pipe, a section of flue pipe is attached to the

machine. Flue gas determinations are taken in this flue pipe.

The draught is adjusted as recommended in the instructions.

3.101

unloader valve

pressure operated device which, when the pump pressure exceeds a preset value, releases

the pressure and leads the excess fluid into the inlet system

In addition, it bypasses the total pump flow at reduced pressure when its outlet flow is cut off.

3.102

safety valve

pressure operated device which, when the pump or steam cleaner pressure exceeds a preset

value, releases the pressure and which may return the excess fluid or steam either to the inlet

system or into the atmosphere

3.103

rated pressure

maximum working pressure at the pressure generator during normal operation

– 10 – IEC 60335-2-79:2012 © IEC 2012

3.104

allowable pressure

maximum pressure up to which a machine and/or parts of the machine may be subjected

without impairing its safety

3.105

rated flow

maximum flow at rated pressure at the nozzle during normal operation

3.106

maximum flow rate

highest possible flow rate at the nozzle

Note 1 to entry: Typically, the maximum flow rate occurs at working pressures lower than rated pressure and

with a nozzle designed for spraying of cleaning agents.

3.107

rated temperature

maximum temperature of the cleaning agent during normal operation

3.108

pressure switch

device which, in response to varying fluid pressure, provides a controlling function at a pre-set

value

3.109

flow switch

device which, in response to a varying rate of fluid flow, provides a controlling function at a

pre-set value

3.110

trigger gun

hand-held spraying device where the flow of the cleaning agent is regulated by an integrated

manually operated control device

3.111

pencil jet nozzle

nozzle that gives a concentrated, parallel water jet

Note 1 to entry: Pencil jet nozzles are also known as needle jet nozzles, solid jet nozzles or 0 degree jet

nozzles.

3.112

water jetter

pipe-cleaning device, connected to and controlled by a trigger gun, consisting of a high

pressure hose and a cleaning head with nozzles

3.113

cleaning agent

water with or without the addition of gaseous, soluble or miscible detergent or solid abrasive

3.114

water heater

device for heating the cleaning agent by means of electricity, gas, liquid fuel or heat

exchange

3.115

continuous ignition

ignition of an oil or gas fired burner that is continuously maintained throughout the time the

burner is operational, whether the burner is firing or not

3.116

primary safety control

control device that responds directly to flame properties sensing the presence of flame and, in

event of ignition failure or unintentional flame extinguishment, causes safety shut down

Note 1 to entry: Primary safety controls are also known as flame failure devices or flame safety controls.

3.117

motorized cleaning head

hand-held or hand-guided cleaning device connected to the machine, with an integrated

electrical motor

3.118

low pressure accessory

device, connected to and controlled by a trigger gun, with large nozzle openings generating

a pressure below rated pressure

Note 1 to entry: Typical examples of low pressure accessories are washing brushes, foam nozzles, washing

sponges.

3.119

hand-guided machine

machine that needs to be moved on the floor

3.120

hose line

assembly of high pressure hoses mounted with appropriate fittings