IEC 61810-7:2006

(Main)Electromechanical elementary relays - Part 7: Test and measurement procedures

Electromechanical elementary relays - Part 7: Test and measurement procedures

IEC 61810-7:2006 Lays down the test and measurement procedures for electromechanical elementary relays. Covers basic considerations which are common to all types of electromechanical elementary relays. Supplementary requirements may be necessitated by specific designs or application.

Relais électromécaniques élémentaires - Partie 7: Méthodes d'essai et de mesure

La CEI 61810-7:2006 énonce les procédures d'essai et de mesure pour les relais élémentaires électromécaniques. Elle couvre d'une manière générale tous les types de relais élémentaires électromécaniques. Des exigences complémentaires peuvent être nécessaires pour des conceptions ou des applications particulières. Les procédures d'essai et de mesure selon la présente norme sont décrites sous forme de dispositions individuelles couvrant une exigence spécifique. Pour les combiner avec un programme d'essai, on doit prendre soin (par un regroupement approprié des relais soumis à essai, par exemple) de s'assurer que des essais antérieurs ne dévaluent pas des essais postérieurs. Cette deuxième édition annule et remplace la première édition parue en 1997. Cette deuxième édition constitue une révision technique. Cette nouvelle édition a été révisée dans les buts suivants:

- mettre à jour toutes les références normatives,

- adapter son contenu aux éditions les plus récentes des autres parties de la série de normes de base relatives aux relais (CEI 61810-1 et CEI 61810-2),

- établir la cohérence avec d'autres normes CEI (de la série CEI 60068-2, par exemple),

- améliorer les procédures d'essai et de mesure, s'il y a lieu,

- supprimer les essais qui ne sont plus utilisés dans le cas des relais élémentaires pour application industrielle.

General Information

- Status

- Published

- Publication Date

- 13-Mar-2006

- Technical Committee

- TC 94 - Electrical relays

- Drafting Committee

- WG 3 - TC 94/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 14-Mar-2006

- Completion Date

- 31-May-2006

Relations

- Revises

IEC 61810-7:1997 - Electromechanical all-or-nothing relays - Part 7: Test and measurement procedures - Effective Date

- 05-Sep-2023

Overview

IEC 61810-7:2006 - Electromechanical elementary relays - Part 7: Test and measurement procedures - defines standardized test methods and measurement procedures for electromechanical elementary relays. This second-edition IEC standard (2006) establishes common test conditions, precision requirements, and test circuits that apply across relay types while allowing for supplementary tests specific to particular designs or applications. It is intended to support consistent type testing, quality control and conformity assessment of electromechanical relays.

Key Topics

The standard addresses a broad spectrum of test and measurement areas, including:

- General test principles: deviations, precision of measurement, power supplies and reference conditions for testing.

- Visual, mechanical and dimensional checks: inspection, weighing, mechanical endurance and robustness of terminals.

- Coil and contact testing: coil properties, thermal resistance, coil transient suppression, contact-circuit resistance (voltage drop), contact sticking and contact noise.

- Electrical safety and insulation: dielectric strength, impulse voltage, insulation resistance and continuity of protective earth.

- Functional and timing tests: relay operation modes (monostable, bistable, polarized), timing measurement methods, and functional verification.

- Environmental and durability tests: climatic sequences, damp heat, thermal and mechanical endurance, shock, bump, vibration, rapid change of temperature, internal moisture, mould growth and corrosive atmospheres.

- Electrical endurance and load tests: electrical/mechanical endurance, limiting continuous current, overload and load-transfer testing (including inductive/inrush loads).

- Electromagnetic compatibility and interference: EMC, magnetic interference, crosstalk, insertion loss, and magnetic remanence.

- Safety-related tests: fire hazard, resistance to cleaning solvents, temperature rise at rated load and thermal tests (normative annexes for heating and fire hazard).

Annexes provide normative test arrangements (heating, fire hazard) and test circuits for endurance and inductive loads.

Applications and Users

IEC 61810-7 is used by:

- Relay manufacturers for design verification, type testing and production quality control.

- Test laboratories and certification bodies performing compliance and safety testing.

- Design and reliability engineers integrating electromechanical relays into control systems and power equipment.

- Procurement and regulatory teams specifying test criteria in product specifications and tenders.

Practical applications include product development validation, acceptance testing, safety compliance, EMC assessment and lifetime/durability qualification for industrial, appliance and power-system relays.

Related Standards

- IEC 61810-1 (General and safety requirements)

- IEC 61810-2 (Reliability)

- IEC 60068-2 series (environmental testing procedures)

Keywords: IEC 61810-7, electromechanical relays, relay testing, test and measurement procedures, relay standards, relay endurance, dielectric test, EMC testing.

IEC 61810-7:2006 - Electromechanical elementary relays - Part 7: Test and measurement procedures Released:3/14/2006 Isbn:2831885264

IEC 61810-7:2006 - Electromechanical elementary relays - Part 7: Test and measurement procedures

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 61810-7:2006 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electromechanical elementary relays - Part 7: Test and measurement procedures". This standard covers: IEC 61810-7:2006 Lays down the test and measurement procedures for electromechanical elementary relays. Covers basic considerations which are common to all types of electromechanical elementary relays. Supplementary requirements may be necessitated by specific designs or application.

IEC 61810-7:2006 Lays down the test and measurement procedures for electromechanical elementary relays. Covers basic considerations which are common to all types of electromechanical elementary relays. Supplementary requirements may be necessitated by specific designs or application.

IEC 61810-7:2006 is classified under the following ICS (International Classification for Standards) categories: 29.120.70 - Relays. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61810-7:2006 has the following relationships with other standards: It is inter standard links to IEC 61810-7:1997. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61810-7:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 61810-7

Second edition

2006-03

Electromechanical elementary relays –

Part 7:

Test and measurement procedures

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 61810-7

Second edition

2006-03

Electromechanical elementary relays –

Part 7:

Test and measurement procedures

IEC 2006 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale XC

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

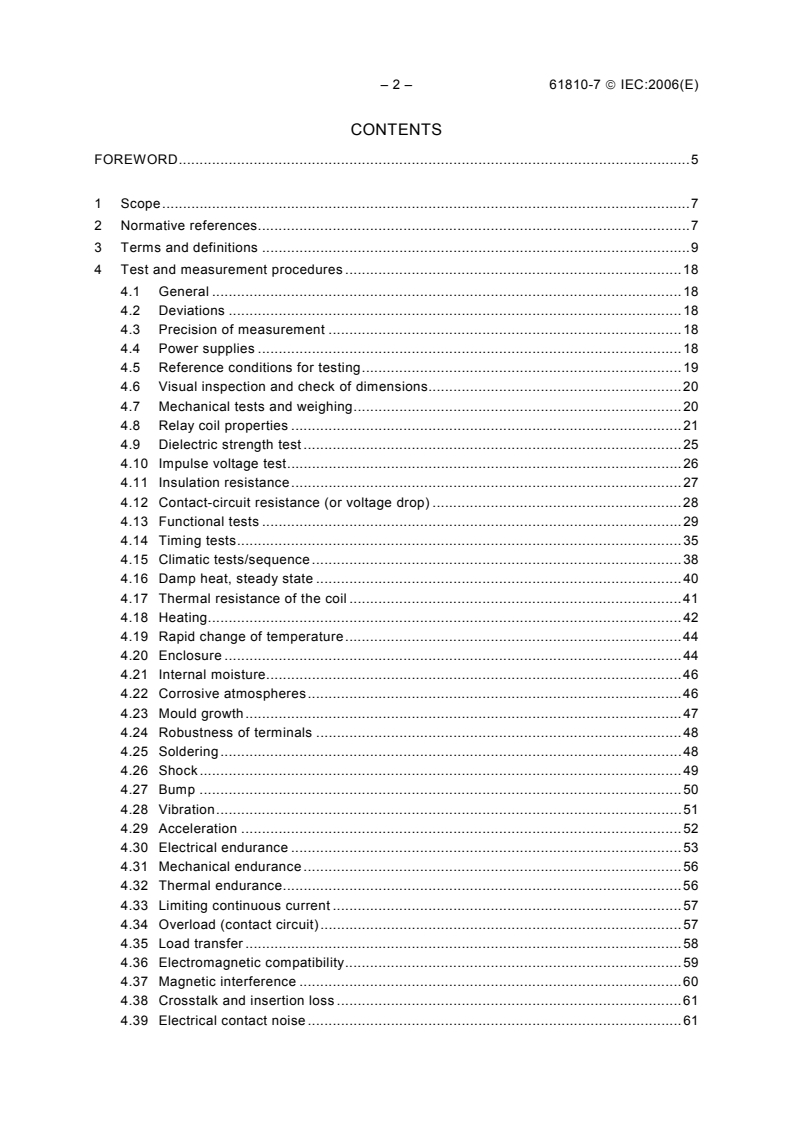

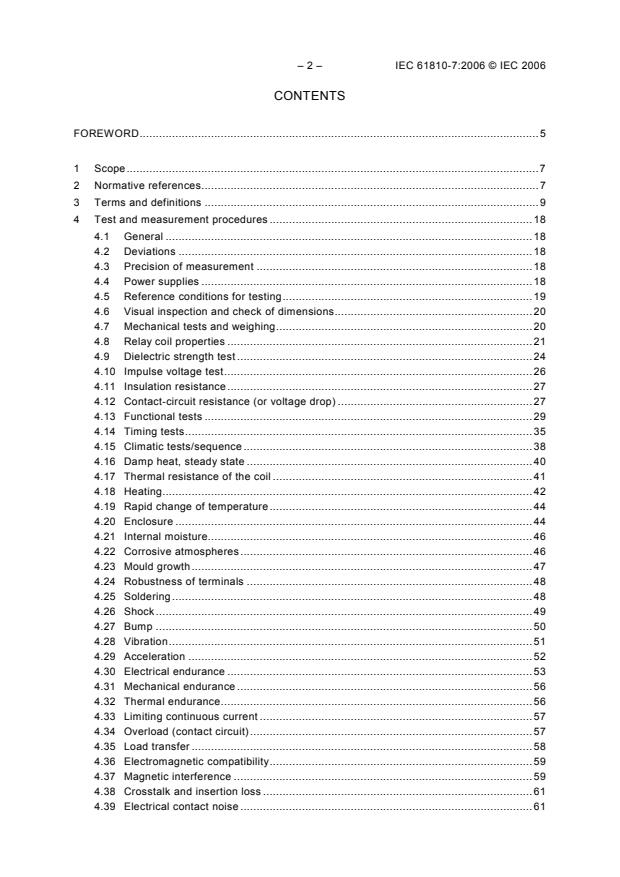

– 2 – 61810-7 IEC:2006(E)

CONTENTS

FOREWORD.5

1 Scope.7

2 Normative references.7

3 Terms and definitions .9

4 Test and measurement procedures .18

4.1 General .18

4.2 Deviations .18

4.3 Precision of measurement .18

4.4 Power supplies .18

4.5 Reference conditions for testing.19

4.6 Visual inspection and check of dimensions.20

4.7 Mechanical tests and weighing.20

4.8 Relay coil properties .21

4.9 Dielectric strength test .25

4.10 Impulse voltage test.26

4.11 Insulation resistance.27

4.12 Contact-circuit resistance (or voltage drop) .28

4.13 Functional tests .29

4.14 Timing tests.35

4.15 Climatic tests/sequence.38

4.16 Damp heat, steady state .40

4.17 Thermal resistance of the coil .41

4.18 Heating.42

4.19 Rapid change of temperature.44

4.20 Enclosure .44

4.21 Internal moisture.46

4.22 Corrosive atmospheres.46

4.23 Mould growth.47

4.24 Robustness of terminals .48

4.25 Soldering.48

4.26 Shock.49

4.27 Bump .50

4.28 Vibration.51

4.29 Acceleration .52

4.30 Electrical endurance .53

4.31 Mechanical endurance .56

4.32 Thermal endurance.56

4.33 Limiting continuous current .57

4.34 Overload (contact circuit).57

4.35 Load transfer .58

4.36 Electromagnetic compatibility.59

4.37 Magnetic interference .60

4.38 Crosstalk and insertion loss .61

4.39 Electrical contact noise .61

61810-7 IEC:2006(E) – 3 –

4.40 Thermoelectric e.m.f.62

4.41 Capacitance .62

4.42 Contact sticking (delayed release) .63

4.43 Magnetic remanence .63

4.44 Acoustic noise .65

4.45 Continuity of protective earth connection.66

4.46 Fluid contamination .66

4.47 Resistance to cleaning solvents .67

4.48 Fire hazard .68

4.49 Temperature rise at rated load.68

4.50 Mechanical interlock .69

4.51 Insertion and withdrawal force (mating relay and socket).69

Annex A (normative) Heating test arrangement.71

Annex B (normative) Fire hazard testing .72

Annex C (normative) Test circuit for endurance tests.77

Annex D (informative) Inductive contact loads .84

Bibliography .86

Figure 1 – Typical circuit for the measurement of coil transient suppression.23

Figure 2 – Typical traces on an oscilloscope screen during transient voltage

measurement.24

Figure 3 – Monostable non-polarized relay.30

Figure 4 – Monostable relay polarized by diode.31

Figure 5 – Monostable polarized relay with magnetic biasing.32

Figure 6 – Bistable non-polarized relay (not applicable to remanence relays) .33

Figure 7 – Bistable polarized relay (example) .34

Figure 8 – Typical circuit for the measurement of time parameters.36

Figure 9 – Typical traces on an oscilloscope screen during time measurements.37

Figure 10 – Test circuit for load transfer .59

Figure 11 – Mounting array for adjacent similar relays .60

Figure 12 – Directions of the test current for magnetic interference test, method 3.61

Figure 13 – Sequential diagram for magnetic remanence test .64

Figure 14 – Installation for the test for acoustic noise emission.65

Figure A.1 – Test arrangement.71

Figure B.1 – Glow-wire and position of the thermocouple.73

Figure B.2 – Glow-wire test apparatus (example).74

Figure B.3 – Needle flame test details .76

Figure C.1 – Standard test circuit .77

Figure C.2 – Functional block diagram.78

Figure C.3 – Circuit for cable load .80

Figure C.4 – Test circuit for inrush current loads (for example capacitive loads and

simulated tungsten filament lamp loads) – a.c. circuits.81

– 4 – 61810-7 IEC:2006(E)

Figure C.5 – Example for a tungsten filament lamp test for relays rated 10/100 A/250 V~/

2,5 ms .82

Figure C.6 – Test circuit for inrush current loads (for example capacitive loads and

simulated lamp loads) – d.c. circuits.82

Figure C.7 – Test circuit for inrush current loads (for example simulated fluorescent

lamp loads) with power-factor correction.83

Table 1 – Coil voltage values and corresponding functions .29

Table 2 – Cross-sectional areas and lengths of conductors dependent on the current

carried by the terminal.43

Table 3 – Schematics for contact loading .55

Table 4 – Test fluids and temperatures of tests .67

Table C.1 – Characteristics of power sources for contact loads.78

Table C.2 – Standard contact load characteristics .79

Table D.1 – Verification of the making and breaking capacity for AC-15/DC-13 (normal

conditions) .84

Table D.2 – Making and breaking capacity for electrical endurance test .85

61810-7 IEC:2006(E) – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTROMECHANICAL ELEMENTARY RELAYS –

Part 7: Test and measurement procedures

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61810-7 has been prepared by IEC technical committee 94: All-or-

nothing electrical relays.

This second edition cancels and replaces the first edition published in 1997. This second

edition constitutes a technical revision.

This new edition has been revised in order to

– update all normative references,

– adapt its contents to the newest issues of the other parts of this series of basic relay

standards (IEC 61810-1 and IEC 61810-2),

– establish coherence with other IEC standards (for example of the IEC 60068-2 series),

– improve test and measurement procedures where appropriate,

– delete those tests no longer used in case of elementary relays for industrial application.

– 6 – 61810-7 IEC:2006(E)

The text of this standard is based on the following documents:

FDIS Report on voting

94/226/FDIS 94/231/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC 61810 consists of the following parts, under the general title Electromechanical elementary

relays:

Part 1: General and safety requirements

Part 2: Reliability

Part 7: Test and measurement procedures

The committee has decided that the contents of this publication will remain unchanged until the

maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

61810-7 IEC:2006(E) – 7 –

ELECTROMECHANICAL ELEMENTARY RELAYS –

Part 7: Test and measurement procedures

1 Scope

This part of IEC 61810 states the test and measurement procedures for electromechanical

elementary relays. It covers basic considerations which are, in general, common to all types of

electromechanical elementary relays. Supplementary requirements may be necessitated by

specific designs or application.

The test and measurement procedures of this standard are described as individual provisions

covering a specific requirement. When combining them in a test programme, care must be

taken (for example by suitable grouping of tested relays) to ensure that preceding tests do not

devalue subsequent ones.

Where in this standard the term “specified” is used, this means a prescription in the

appropriate documentation for the relay, for example manufacturer’s data sheet, test

specification, customer detail specification. For application within the IECQ system such

prescriptions are contained in the detail specification as defined in Clause A.7 of QC 001001.

NOTE 1 To improve the readability of this standard, the term “relay” is generally used in place of

“electromechanical elementary relay”.

NOTE 2 Requirements and tests related to the type testing of electromechanical elementary relays are contained

in IEC 61810-1. For that purpose, the generally described test and measurement procedures of this standard have

been prescribed in a more restricted and stringent form in IEC 61810-1.

NOTE 3 Standards covering relays subjected to quality assessment in accordance with IECQ are compiled in the

IEC 61811 series of publications.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60068-2-1:1990, Environmental testing – Part 2: Tests – Tests A: Cold

Amendment 1 (1993)

Amendment 2 (1994)

IEC 60068-2-2:1974, Environmental testing – Part 2: Tests – Tests B: Dry heat

Amendment 1 (1993)

Amendment 2 (1994)

IEC 60068-2-6:1995, Environmental testing – Part 2: Tests – Test Fc: Vibration (sinusoidal)

IEC 60068-2-7:1983, Environmental testing – Part 2: Tests – Test Ga: Acceleration, steady state

Amendment 1 (1986)

IEC 60068-2-10:2005, Environmental testing – Part 2: Tests – Test J and guidance: Mould

growth

IEC 60068-2-11:1981, Environmental testing – Part 2: Tests – Test Ka: Salt mist

– 8 – 61810-7 IEC:2006(E)

IEC 60068-2-13:1983, Environmental testing – Part 2: Tests – Test M: Low air pressure

IEC 60068-2-14:1984, Environmental testing – Part 2: Tests – Test N: Change of temperature

Amendment 1 (1986)

IEC 60068-2-17:1994, Environmental testing – Part 2: Tests – Test Q: Sealing

IEC 60068-2-20:1979, Environmental testing – Part 2: Tests – Test T: Soldering

Amendment 2 (1987)

IEC 60068-2-21:1999, Environmental testing – Part 2-21: Tests – Test U: Robustness of

terminations and integral mounting devices

IEC 60068-2-27:1987, Environmental testing – Part 2: Tests – Test Ea and guidance: Shock

IEC 60068-2-29:1987, Environmental testing – Part 2: Tests – Test Eb and guidance: Bump

IEC 60068-2-30:2005, Environmental testing – Part 2: Tests – Test Db: Damp heat, cyclic (12 +

12-hour cycle)

IEC 60068-2-42:2003, Environmental testing – Part 2-42: Tests – Test Kc: Sulphur dioxide test

for contacts and connections

IEC 60068-2-43:2003, Environmental testing – Part 2-43: Tests – Test Kd: Hydrogen sulphide

test for contacts and connections

IEC 60068-2-45:1980, Environmental testing – Part 2: Tests – Test XA and guidance:

Immersion in cleaning solvents

Amendment 1 (1993)

IEC 60068-2-58:2004, Environmental testing – Part 2-58: Tests – Test Td – Test methods for

solderability, resistance to dissolution of metallization and to soldering heat of surface

mounting devices (SMD)

IEC 60068-2-64:1993, Environmental testing – Part 2: Test methods – Test Fh: Vibration,

broad-band random (digital control) and guidance

IEC 60068-2-68:1994, Environmental testing – Part 2: Tests – Test L: Dust and sand

IEC 60068-2-78:2001, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady

state

IEC 60512-7: 1993, Electromechanical components for electronic equipment; basic testing

procedures and measuring methods – Part 7: Mechanical operating tests and sealing tests

IEC 60695-2 (all parts), Fire hazard testing – Part 2: Test methods

IEC 60695-2-10:2000, Fire hazard testing – Part 2-10: Glowing/hot wire based test methods –

Glow-wire apparatus and common test procedure

IEC 60695-2-11:2000, Fire hazard testing – Part 2-11: Glowing/hot wire based test methods –

Glow-wire flammability test method for end-products

IEC 60695-2-12:2000, Fire hazard testing – Part 2-12: Glowing/hot wire based test methods –

Glow-wire flammability test method for materials

61810-7 IEC:2006(E) – 9 –

IEC 60695-2-13:2000, Fire hazard testing – Part 2-13: Glowing/hot wire based test methods –

Glow-wire ignitability test method for materials

IEC 60695-11-5:2004, Fire hazard testing – Part 11-5: Test flames – Needle-flame test method

– Apparatus, confirmatory test arrangement and guidance

IEC 60999-1:1999, Connecting devices – Electrical copper conductors – Safety requirements

for screw-type and screwless-type clamping units – Part 1: General requirements and particular

2 2

requirements for clamping units for conductors from 0,2 mm up to 35 mm (included)

IEC 61210:1993, Connecting devices – Flat quick-connect terminations for electric copper

conductors – Safety requirements

IEC 61180-1:1992, High-voltage test techniques for low-voltage equipment – Part 1:

Definitions, test and procedure requirements

IEC 61180-2:1994, High-voltage test techniques for low-voltage equipment – Part 2: Test

equipment

IEC 61672-1:2002, Electroacoustics – Sound level meters – Part 1: Specifications

IEC 61810-1:2004, Electromechanical elementary relays – Part 1: General and safety

requirements

IECQ QC 001001:2000, IEC Quality Assessment System for Electronic Components (IECQ) –

Basic Rules

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 Types of relays

3.1.1

electromechanical relay

electrical relay in which the intended response results mainly from the movement of

mechanical elements

[IEV 444-01-04]

3.1.2

all-or-nothing relay

electrical relay, which is intended to be energized by a quantity, the value of which is either

within its operative range or effectively zero

[IEV 444-01-02]

3.1.3

elementary relay

all-or-nothing relay which operates and releases without any intentional time delay

[IEV 444-01-03]

– 10 – 61810-7 IEC:2006(E)

3.1.4

monostable relay

electrical relay which, having responded to an energizing quantity and having changed its

condition, returns to its previous condition when that quantity is removed

[IEV 444-01-07]

3.1.5

bistable relay

electrical relay which, having responded to an energizing quantity and having changed its

condition, remains in that condition after the quantity has been removed; a further appropriate

energization is required to make it change its condition

[IEV 444-01-08]

3.1.6

polarized relay

electrical relay, the change of condition of which depends upon the polarity of its DC energizing

quantity

[IEV 444-01-09]

3.1.7

non-polarized relay

electrical relay, the change of condition of which does not depend upon the polarity of its

energizing quantity

[IEV 444-01-10]

3.2 Types of relays, based upon environmental protection (relay technology RT)

3.2.1

RT 0 unenclosed relay

relay not provided with a protective case

3.2.2

RT I dust protected relay

relay provided with a case which protects its mechanism from dust

3.2.3

RT II flux proof relay

relay capable of being automatically soldered without allowing the migration of solder fluxes

beyond the intended areas

NOTE Where an enclosed construction is used, venting to the outside atmosphere is permissible.

3.2.4

RT III wash tight relay

relay capable of being automatically soldered and subsequently undergoing a washing process

to remove flux residues without allowing the ingress of flux or washing solvents

NOTE In service, this type of relay is sometimes vented to the atmosphere after the soldering or washing process.

3.2.5

RT IV sealed relay

relay provided with a case which has no venting to the outside atmosphere, and having a time

constant better than 2 × 10 s (see IEC 60068-2-17)

61810-7 IEC:2006(E) – 11 –

3.2.6

RT V hermetically sealed relay

sealed relay having an enhanced level of sealing, assuring a time constant better than

2 × 10 s (see IEC 60068-2-17)

3.3 Functions of a relay

3.3.1

release condition

for a monostable relay, specified condition of the relay when it is not energized; for a bistable

relay, one of the conditions, as declared by the manufacturer

[IEV 444-02-01]

3.3.2

operate condition

for a monostable relay, specified condition of the relay when it is energized by the specified

energizing quantity and has responded to that quantity; for a bistable relay, the condition other

than the release condition as declared by the manufacturer

[IEV 444-02-02]

3.3.3

operate (verb)

change from the release condition to the operate condition

[IEV 444-02-04]

3.3.4

release (verb)

for a monostable relay, change from the operate condition to the release condition

[IEV 444-02-05]

3.3.5

reset (verb)

for a bistable relay, change from the operate condition to the release condition

[IEV 444-02-06]

3.3.6

change over (verb)

for a monostable relay, operate or release; for a bistable relay, operate or reset

[IEV 444-02-07]

3.3.7

cycle (verb)

for a monostable relay, operate and then release or vice versa; for a bistable relay, operate and

then reset or vice-versa

[IEV 444-02-08]

3.3.8

revert (verb)

for a specific type of polarized relay, release/reset again, or remain in the release condition,

when supplied with a coil voltage in excess of that required for operation and of the same

polarity as required for operation

[IEV 444-02-09, modified]

– 12 – 61810-7 IEC:2006(E)

3.3.9

revert reverse (verb)

for a specific type of polarized bistable relay, operate again, or remain in the operate condition,

when supplied with a coil voltage in excess of that required for resetting and of the same

polarity as required for resetting

[IEV 444-02-10, modified]

3.4 Types of contacts

3.4.1

make contact

contact which is closed when the relay is in its operate condition and which is open when the

relay is in its release condition

[IEV 444-04-17]

3.4.2

break contact

contact which is open when the relay is in its operate condition and which is closed when the

relay is in its release condition

[IEV 444-04-18]

3.4.3

change-over contact

combination of two contact circuits with three contact members, one of which is common to the

two contact circuits; such that when one of these contact circuits is open, the other is closed

[IEV 444-04-19]

3.4.4

change-over make-before-break contact

change-over contact in which the make contact circuit closes before the break contact circuit

opens

[IEV 444-04-20]

3.4.5

change-over break-before-make contact

change-over contact in which the break contact circuit opens before the make contact circuit

closes

[IEV 444-04-21]

3.5 Prefixes for the values applicable to relays

Values may be defined as rated, actual (“just”), test (“must”) or characteristic value and

identified as such by using one of these words as a prefix. The prefixes are also applicable to

timing values.

3.5.1

rated value

value of a quantity used for specification purposes, established for a specified set of operating

conditions of a relay

[IEV 444-02-18, modified]

61810-7 IEC:2006(E) – 13 –

3.5.2

actual (“just”) value

value of a quantity determined by measurement on a specific relay, during performance of a

specified function

[IEV 444-02-21]

3.5.3

test (“must”) value

value of a quantity for which the relay shall comply with a specified action during a test

[IEV 444-02-20]

3.5.4

characteristic value

value of a quantity with which, in the initial condition of a relay or for a specified number of

cycles as specified, the relay shall comply with a specified requirement

[IEV 444-02-19, modified]

3.6 Energization values

3.6.1

energizing quantity

electrical quantity which, when applied to the coil(s) of a relay under specified conditions,

enables it to fulfil its purpose

[IEV 444-03-01, modified]

NOTE 1 For elementary relays, the energizing quantity is usually a voltage. Therefore, the input voltage as

energizing quantity is used in the definitions given below. When a relay is energized by a given current instead, the

respective terms and definitions apply with “current” used instead of “voltage”.

NOTE 2 The general term “input voltage” used in IEV Chapter 444 applies to all types of elementary relays (e.g.

including solid-state relays). For electromechanical elementary relays the more specific term “coil voltage” has been

chosen for the terms of 3.6, as in IEC 61810-1.

3.6.2

coil voltage

voltage applied as an energizing quantity

[IEV 444-03-03]

3.6.3

operative range

range of values of coil voltage for which a relay is able to perform its specified function

[IEV 444-03-05, modified]

NOTE For the following terms, refer also to Figures 3 to 7 which show the sequential functions of relays covered

by the definitions.

3.6.4

magnetic preconditioning value

value of the coil voltage at which the relay attains a defined magnetic condition

[IEV 444-03-19]

NOTE 1 For polarized relays, distinction is made between preconditioning in forward (operate) direction, and

preconditioning in reverse direction.

NOTE 2 For bistable relays, preconditioning may also be used to set the relay to a defined position.

– 14 – 61810-7 IEC:2006(E)

3.6.5

non-operate voltage

value of the coil voltage at which a relay does not operate

[IEV 444-03-07, modified]

3.6.6

operate voltage, set voltage (for bistable relays only)

value of the coil voltage at which a relay operates

[IEV 444-03-06, modified]

3.6.7

non-release voltage

value of the coil voltage at which a monostable relay does not release

[IEV 444-03-09, modified]

3.6.8

release voltage

value of the coil voltage at which a monostable relay releases

[IEV 444-03-08, modified]

3.6.9

non-reset voltage

value of the coil voltage at which a bistable relay does not reset

[IEV 444-03-11, modified]

3.6.10

reset voltage

value of the coil voltage at which a bistable relay resets

[IEV 444-03-10, modified]

3.6.11

revert voltage

for a specific type of polarized relay, value of the coil voltage greater than and with the same

polarity as the operate voltage, at which the relay reverts

[IEV 444-03-12, modified]

3.6.12

non-revert voltage

for a specific type of polarized relay, value of the coil voltage greater than and with the same

polarity as the operate voltage, at which the relay does not revert

[IEV 444-03-13, modified]

3.6.13

revert reverse voltage

for a specific type of polarized bistable relay, value of the coil voltage greater than and with the

same polarity as the reset voltage, at which the relay reverts reverse

[IEV 444-03-14, modified]

61810-7 IEC:2006(E) – 15 –

3.6.14

non-revert reverse voltage

for a specific type of polarized bistable relay, value of the coil voltage greater than and with the

same polarity as the reset voltage, at which the relay does not revert reverse

[IEV 444-03-15, modified]

3.6.15

reverse polarity voltage

for a polarized monostable relay, value of the coil voltage of reverse polarity at which the relay

does not operate

[IEV 444-03-16, modified]

3.6.16

active power

under periodic conditions, mean value, taken over one period T, of the instantaneous power p:

T

P = 1 T p dt

∫

NOTE 1 Under sinusoidal conditions, the active power is the real part of the complex power.

NOTE 2 The SI unit for active power is the watt.

[IEV 131-11-42]

3.6.17

apparent power

product of the r.m.s. voltage U between the terminals of a two-terminal element or two-terminal

circuit and the r.m.s. electric current I in the element or circuit:

S = UI

NOTE 1 Under sinusoidal conditions, the apparent power is the modulus of the complex power.

NOTE 2 The SI unit for apparent power is the voltampere.

[IEV 131-11-41]

3.7 Electrical properties of contacts

3.7.1

contact current

electric current which a relay contact carries before opening or after closing

[IEV 444-04-26]

3.7.2

switching current

electric current which a relay contact makes and/or breaks

[IEV 444-04-27]

3.7.3

switching voltage

voltage between the contact members before closing or after opening of a relay contact

[IEV 444-04-25, modified]

– 16 – 61810-7 IEC:2006(E)

3.7.4

limiting continuous current

greatest value of electric current which a closed contact is capable of carrying continuously

under specified conditions

[IEV 444-04-28, modified]

3.7.5

contact noise

spurious voltage which appears across the terminals of a closed contact

[IEV 444-04-33]

3.8 Contact load categories

3.8.1

contact load category 0

CC 0

load characterized by a maximum switching voltage of 30 mV and a maximum switching

current of 10 mA

3.8.2

contact load category 1

CC 1

low load without contact arcing

NOTE Arcing with a duration of up to 1 ms is disregarded.

3.8.3

contact load category 2

CC 2

high load where contact arcing can occur

3.9 Mechanical properties of contacts

3.9.1

contact tip

contact point

part of a contact member at which the contact circuit opens or closes

[IEV 444-04-06]

3.9.2

contact gap

gap between the contact tips (points) when the contact circuit is open

[IEV 444-04-09, modified]

3.9.3

contact force

force which two contact members exert against each other at their contact tips (points) in the

closed position

[IEV 444-04-10, modified]

3.9.4

contact member

conductive part designed to co-act with another to close or open the contact

[IEV 444-04-05, modified]

61810-7 IEC:2006(E) – 17 –

3.10 Terms relating to times

3.10.1

operate time

time interval between the application of the specified coil voltage to a relay in the release

condition and the change of state of the last contact circuit, bounce time not included

[IEV 444-05-01, modified]

NOTE The operate time covers the closing time of a make contact, and the opening time of a break contact.

3.10.2

release time

time interval between the removal of the specified coil voltage from a monostable relay in the

operate condition and the change of state of the last contact circuit, bounce time not included

[IEV 444-05-02, modified]

NOTE The release time covers the opening time of a make contact and the closing time of a break contact.

3.10.3

reset time

time interval between the application of the specified coil voltage to a bistable relay in the

operate condition and the change of state of the last contact circuit, bounce time not included

[IEV 444-05-03, modified]

NOTE The reset time covers the opening time of a make contact and the closing time of a break contact.

3.10.4

bounce time

for a contact which is closing/opening its circuit, time interval between the instant when the

contact circuit first closes/opens and the instant when the circuit is finally closed/opened

[IEV 444-05-04]

3.10.5

transfer time; transit time

for a change-over break-before-make contact, time interval during which both contact circuits

are open

[IEV 444-05-06]

3.10.6

bridging time

for a change-over make-before-break contact, the time interval during which both contact

circuits are closed

[IEV 444-05-05]

3.10.7

stabilization time

time interval between the instant when a specified coil voltage is applied and the instant when

the last contact circuit is closed/opened and fulfils the specified requirements, bounce time

included

[IEV 444-05-07, modified]

3.10.8

minimum time of energization

minimum duration of application of the coil voltage to ensure that the relay operates or resets

– 18 – 61810-7 IEC:2006(E)

[IEV 444-05-08, modified]

3.10.9

contact time difference

for a relay having several contacts of the same type, difference between the maximum value of

the operate (release/reset) time and the minimum value of the operate (release/reset) time

3.11 Miscellaneous terms

3.11.1

coil transient suppression device

device connected to the relay coil to limit its back electromotive force (e.m.f.) to a prescribed

value

3.11.2

thermal equilibrium

variation of less than 1 K between any two out of three consecutive measurements made at an

interval of 5 min

4 Test and measurement procedures

4.1 General

The test and measurement procedures specified in this part of IEC 61810 are recommended to

be used for the testing of parameters given for a relay.

4.2 Deviations

Any test and measurement procedures deviating from those given in this standard may be

applied but shall be indicated in the documentation of the relay.

4.3 Precision of measurement

Measurement inaccuracies shall be taken into account when evaluating the results. If not

otherwise specified, all measurements shall be taken with an accuracy of ±2 % for electrical, of

±5 % for mechanical parameters and with ±2 K for temperatures.

4.4 Power supplies

Unless otherwise specified, the following shall apply to power supplies and their connections:

Voltage or current shall be maintained within a tolerance range of ±5 % of the specified value.

The alternating component (ripple content) of the output of a d.c. supply shall not exceed 6 %.

NOTE 1 The alternating component in d.c., expressed as a percentage, is defined as:

(maximum value – minimum value) × 10/(d.c. component)

The frequency of an a.c. supply shall be maintained within a tolerance range of ±2 % of the

specified value, and the distortion factor shall not exceed 5 %.

NOTE 2 The distortion factor is defined as the ratio of the harmonic content obtained by subtracting the

fundamental wave from a non-sinusoidal harmonic quantity and the r.m.s. value of the non-sinusoidal quantity. It is

usually expressed as a percentage.

The following shall be earthed as applicable: one side of the d.c. power supply, one side of the

single-phase a.c. power supply, or the neutral of the three-phase a.c. power supply. The

earthed side of the power supply shall be connected to: one terminal of each of one or more

61810-7 IEC:2006(E) – 19 –

coils of the relay under test and one terminal of each of the loads connected to the relay under

test.

4.5 Reference conditions for testing

4.5.1 General conditions

Unless otherwise specified, all tests shall be carried out under the standard atmospheric

conditions for testing as follows:

• temperature 23 °C ± 5 °C

• relative humidity 25 % to 75 %

• air pressure 86 kPa to 106 kPa (860 mbar to 1 060 mbar)

Before testing, the relays shall be subjected to the standard atmospheric conditions for a time

sufficient to allow them to reach thermal equilibrium.

Unless otherwise specified, the terms a.c. voltage and current indicate r.m.s. values throughout

this standard.

4.5.2 Use of sockets

4.5.2.1 General considerations

Relays with the option of connection via an appropriate socket may be tested using a specified

socket or via direct electrical connections. In either case, the wiri

...

IEC 61810-7 ®

Edition 2.0 2006-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electromechanical elementary relays –

Part 7: Test and measurement procedures

Relais électromécaniques élémentaires –

Partie 7: Méthodes d'essai et de mesure

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 61810-7 ®

Edition 2.0 2006-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electromechanical elementary relays –

Part 7: Test and measurement procedures

Relais électromécaniques élémentaires –

Partie 7: Méthodes d'essai et de mesure

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX XC

ICS 29.120.70 ISBN 978-2-8322-1627-9

– 2 – IEC 61810-7:2006 © IEC 2006

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references. 7

3 Terms and definitions . 9

4 Test and measurement procedures . 18

4.1 General . 18

4.2 Deviations . 18

4.3 Precision of measurement . 18

4.4 Power supplies . 18

4.5 Reference conditions for testing . 19

4.6 Visual inspection and check of dimensions . 20

4.7 Mechanical tests and weighing . 20

4.8 Relay coil properties . 21

4.9 Dielectric strength test . 24

4.10 Impulse voltage test . 26

4.11 Insulation resistance . 27

4.12 Contact-circuit resistance (or voltage drop) . 27

4.13 Functional tests . 29

4.14 Timing tests . 35

4.15 Climatic tests/sequence . 38

4.16 Damp heat, steady state . 40

4.17 Thermal resistance of the coil . 41

4.18 Heating . 42

4.19 Rapid change of temperature . 44

4.20 Enclosure . 44

4.21 Internal moisture . 46

4.22 Corrosive atmospheres . 46

4.23 Mould growth . 47

4.24 Robustness of terminals . 48

4.25 Soldering . 48

4.26 Shock . 49

4.27 Bump . 50

4.28 Vibration . 51

4.29 Acceleration . 52

4.30 Electrical endurance . 53

4.31 Mechanical endurance . 56

4.32 Thermal endurance . 56

4.33 Limiting continuous current . 57

4.34 Overload (contact circuit) . 57

4.35 Load transfer . 58

4.36 Electromagnetic compatibility . 59

4.37 Magnetic interference . 59

4.38 Crosstalk and insertion loss . 61

4.39 Electrical contact noise . 61

4.40 Thermoelectric e.m.f. . 62

4.41 Capacitance . 62

4.42 Contact sticking (delayed release) . 63

4.43 Magnetic remanence . 63

4.44 Acoustic noise . 65

4.45 Continuity of protective earth connection . 66

4.46 Fluid contamination . 66

4.47 Resistance to cleaning solvents . 67

4.48 Fire hazard . 68

4.49 Temperature rise at rated load . 68

4.50 Mechanical interlock . 69

4.51 Insertion and withdrawal force (mating relay and socket) . 69

Annex A (normative) Heating test arrangement . 71

Annex B (normative) Fire hazard testing . 72

Annex C (normative) Test circuit for endurance tests . 77

Annex D (informative) Inductive contact loads . 84

Bibliography . 86

Figure 1 – Typical circuit for the measurement of coil transient suppression . 23

Figure 2 – Typical traces on an oscilloscope screen during transient voltage

measurement . 24

Figure 3 – Monostable non-polarized relay . 30

Figure 4 – Monostable relay polarized by diode . 31

Figure 5 – Monostable polarized relay with magnetic biasing. 32

Figure 6 – Bistable non-polarized relay (not applicable to remanence relays) . 33

Figure 7 – Bistable polarized relay (example) . 34

Figure 8 – Typical circuit for the measurement of time parameters . 36

Figure 9 – Typical traces on an oscilloscope screen during time measurements . 37

Figure 10 – Test circuit for load transfer . 59

Figure 11 – Mounting array for adjacent similar relays . 60

Figure 12 – Directions of the test current for magnetic interference test, method 3 . 61

Figure 13 – Sequential diagram for magnetic remanence test . 64

Figure 14 – Installation for the test for acoustic noise emission . 65

Figure A.1 – Test arrangement . 71

Figure B.1 – Glow-wire and position of the thermocouple . 73

Figure B.2 – Glow-wire test apparatus (example) . 74

Figure B.3 – Needle flame test details . 76

Figure C.1 – Standard test circuit . 77

Figure C.2 – Functional block diagram . 78

Figure C.3 – Circuit for cable load . 80

Figure C.4 – Test circuit for inrush current loads (for example capacitive loads and

simulated tungsten filament lamp loads) – a.c. circuits . 81

– 4 – IEC 61810-7:2006 © IEC 2006

Figure C.5 – Example for a tungsten filament lamp test for relays rated 10/100 A/250 V~/

2,5 ms . 82

Figure C.6 – Test circuit for inrush current loads (for example capacitive loads and

simulated lamp loads) – d.c. circuits . 82

Figure C.7 – Test circuit for inrush current loads (for example simulated fluorescent

lamp loads) with power-factor correction . 83

Table 1 – Coil voltage values and corresponding functions . 29

Table 2 – Cross-sectional areas and lengths of conductors dependent on the current

carried by the terminal . 43

Table 3 – Schematics for contact loading . 55

Table 4 – Test fluids and temperatures of tests . 67

Table C.1 – Characteristics of power sources for contact loads. 78

Table C.2 – Standard contact load characteristics . 79

Table D.1 – Verification of the making and breaking capacity for AC-15/DC-13 (normal

conditions) . 84

Table D.2 – Making and breaking capacity for electrical endurance test . 85

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTROMECHANICAL ELEMENTARY RELAYS –

Part 7: Test and measurement procedures

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61810-7 has been prepared by IEC technical committee 94: All-or-

nothing electrical relays.

This bilingual version (2014-05) corresponds to the English version, published in 2006-03.

This second edition cancels and replaces the first edition published in 1997. This second

edition constitutes a technical revision.

This new edition has been revised in order to

– update all normative references,

– adapt its contents to the newest issues of the other parts of this series of basic relay

standards (IEC 61810-1 and IEC 61810-2),

– establish coherence with other IEC standards (for example of the IEC 60068-2 series),

– improve test and measurement procedures where appropriate,

– delete those tests no longer used in case of elementary relays for industrial application.

– 6 – IEC 61810-7:2006 © IEC 2006

The text of this standard is based on the following documents:

FDIS Report on voting

94/226/FDIS 94/231/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

The French version of this standard has not been voted upon.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC 61810 consists of the following parts, under the general title Electromechanical elementary

relays:

Part 1: General and safety requirements

Part 2: Reliability

Part 7: Test and measurement procedures

The committee has decided that the contents of this publication will remain unchanged until the

maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

ELECTROMECHANICAL ELEMENTARY RELAYS –

Part 7: Test and measurement procedures

1 Scope

This part of IEC 61810 states the test and measurement procedures for electromechanical

elementary relays. It covers basic considerations which are, in general, common to all types of

electromechanical elementary relays. Supplementary requirements may be necessitated by

specific designs or application.

The test and measurement procedures of this standard are described as individual provisions

covering a specific requirement. When combining them in a test programme, care must be

taken (for example by suitable grouping of tested relays) to ensure that preceding tests do not

devalue subsequent ones.

Where in this standard the term “specified” is used, this means a prescription in the

appropriate documentation for the relay, for example manufacturer’s data sheet, test

specification, customer detail specification. For application within the IECQ system such

prescriptions are contained in the detail specification as defined in Clause A.7 of QC 001001.

NOTE 1 To improve the readability of this standard, the term “relay” is generally used in place of

“electromechanical elementary relay”.

NOTE 2 Requirements and tests related to the type testing of electromechanical elementary relays are contained

in IEC 61810-1. For that purpose, the generally described test and measurement procedures of this standard have

been prescribed in a more restricted and stringent form in IEC 61810-1.

NOTE 3 Standards covering relays subjected to quality assessment in accordance with IECQ are compiled in the

IEC 61811 series of publications.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60068-2-1:1990, Environmental testing – Part 2: Tests – Tests A: Cold

Amendment 1 (1993)

Amendment 2 (1994)

IEC 60068-2-2:1974, Environmental testing – Part 2: Tests – Tests B: Dry heat

Amendment 1 (1993)

Amendment 2 (1994)

IEC 60068-2-6:1995, Environmental testing – Part 2: Tests – Test Fc: Vibration (sinusoidal)

IEC 60068-2-7:1983, Environmental testing – Part 2: Tests – Test Ga: Acceleration, steady state

Amendment 1 (1986)

IEC 60068-2-10:2005, Environmental testing – Part 2: Tests – Test J and guidance: Mould

growth

IEC 60068-2-11:1981, Environmental testing – Part 2: Tests – Test Ka: Salt mist

– 8 – IEC 61810-7:2006 © IEC 2006

IEC 60068-2-13:1983, Environmental testing – Part 2: Tests – Test M: Low air pressure

IEC 60068-2-14:1984, Environmental testing – Part 2: Tests – Test N: Change of temperature

Amendment 1 (1986)

IEC 60068-2-17:1994, Environmental testing – Part 2: Tests – Test Q: Sealing

IEC 60068-2-20:1979, Environmental testing – Part 2: Tests – Test T: Soldering

Amendment 2 (1987)

IEC 60068-2-21:1999, Environmental testing – Part 2-21: Tests – Test U: Robustness of

terminations and integral mounting devices

IEC 60068-2-27:1987, Environmental testing – Part 2: Tests – Test Ea and guidance: Shock

IEC 60068-2-29:1987, Environmental testing – Part 2: Tests – Test Eb and guidance: Bump

IEC 60068-2-30:2005, Environmental testing – Part 2: Tests – Test Db: Damp heat, cyclic (12 +

12-hour cycle)

IEC 60068-2-42:2003, Environmental testing – Part 2-42: Tests – Test Kc: Sulphur dioxide test

for contacts and connections

IEC 60068-2-43:2003, Environmental testing – Part 2-43: Tests – Test Kd: Hydrogen sulphide

test for contacts and connections

IEC 60068-2-45:1980, Environmental testing – Part 2: Tests – Test XA and guidance:

Immersion in cleaning solvents

Amendment 1 (1993)

IEC 60068-2-58:2004, Environmental testing – Part 2-58: Tests – Test Td – Test methods for

solderability, resistance to dissolution of metallization and to soldering heat of surface

mounting devices (SMD)

IEC 60068-2-64:1993, Environmental testing – Part 2: Test methods – Test Fh: Vibration,

broad-band random (digital control) and guidance

IEC 60068-2-68:1994, Environmental testing – Part 2: Tests – Test L: Dust and sand

IEC 60068-2-78:2001, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady

state

IEC 60512-7: 1993, Electromechanical components for electronic equipment; basic testing

procedures and measuring methods – Part 7: Mechanical operating tests and sealing tests

IEC 60695-2 (all parts), Fire hazard testing – Part 2: Test methods

IEC 60695-2-10:2000, Fire hazard testing – Part 2-10: Glowing/hot wire based test methods –

Glow-wire apparatus and common test procedure

IEC 60695-2-11:2000, Fire hazard testing – Part 2-11: Glowing/hot wire based test methods –

Glow-wire flammability test method for end-products

IEC 60695-2-12:2000, Fire hazard testing – Part 2-12: Glowing/hot wire based test methods –

Glow-wire flammability test method for materials

IEC 60695-2-13:2000, Fire hazard testing – Part 2-13: Glowing/hot wire based test methods –

Glow-wire ignitability test method for materials

IEC 60695-11-5:2004, Fire hazard testing – Part 11-5: Test flames – Needle-flame test method

– Apparatus, confirmatory test arrangement and guidance

IEC 60999-1:1999, Connecting devices – Electrical copper conductors – Safety requirements

for screw-type and screwless-type clamping units – Part 1: General requirements and particular

2 2

requirements for clamping units for conductors from 0,2 mm up to 35 mm (included)

IEC 61210:1993, Connecting devices – Flat quick-connect terminations for electric copper

conductors – Safety requirements

IEC 61180-1:1992, High-voltage test techniques for low-voltage equipment – Part 1:

Definitions, test and procedure requirements

IEC 61180-2:1994, High-voltage test techniques for low-voltage equipment – Part 2: Test

equipment

IEC 61672-1:2002, Electroacoustics – Sound level meters – Part 1: Specifications

IEC 61810-1:2004, Electromechanical elementary relays – Part 1: General and safety

requirements

IECQ QC 001001:2000, IEC Quality Assessment System for Electronic Components (IECQ) –

Basic Rules

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 Types of relays

3.1.1

electromechanical relay

electrical relay in which the intended response results mainly from the movement of

mechanical elements

[IEV 444-01-04]

3.1.2

all-or-nothing relay

electrical relay, which is intended to be energized by a quantity, the value of which is either

within its operative range or effectively zero

[IEV 444-01-02]

3.1.3

elementary relay

all-or-nothing relay which operates and releases without any intentional time delay

[IEV 444-01-03]

– 10 – IEC 61810-7:2006 © IEC 2006

3.1.4

monostable relay

electrical relay which, having responded to an energizing quantity and having changed its

condition, returns to its previous condition when that quantity is removed

[IEV 444-01-07]

3.1.5

bistable relay

electrical relay which, having responded to an energizing quantity and having changed its

condition, remains in that condition after the quantity has been removed; a further appropriate

energization is required to make it change its condition

[IEV 444-01-08]

3.1.6

polarized relay

electrical relay, the change of condition of which depends upon the polarity of its DC energizing

quantity

[IEV 444-01-09]

3.1.7

non-polarized relay

electrical relay, the change of condition of which does not depend upon the polarity of its

energizing quantity

[IEV 444-01-10]

3.2 Types of relays, based upon environmental protection (relay technology RT)

3.2.1

RT 0 unenclosed relay

relay not provided with a protective case

3.2.2

RT I dust protected relay

relay provided with a case which protects its mechanism from dust

3.2.3

RT II flux proof relay

relay capable of being automatically soldered without allowing the migration of solder fluxes

beyond the intended areas

NOTE Where an enclosed construction is used, venting to the outside atmosphere is permissible.

3.2.4

RT III wash tight relay

relay capable of being automatically soldered and subsequently undergoing a washing process

to remove flux residues without allowing the ingress of flux or washing solvents

NOTE In service, this type of relay is sometimes vented to the atmosphere after the soldering or washing process.

3.2.5

RT IV sealed relay

relay provided with a case which has no venting to the outside atmosphere, and having a time

constant better than 2 × 10 s (see IEC 60068-2-17)

3.2.6

RT V hermetically sealed relay

sealed relay having an enhanced level of sealing, assuring a time constant better than

2 × 10 s (see IEC 60068-2-17)

3.3 Functions of a relay

3.3.1

release condition

for a monostable relay, specified condition of the relay when it is not energized; for a bistable

relay, one of the conditions, as declared by the manufacturer

[IEV 444-02-01]

3.3.2

operate condition

for a monostable relay, specified condition of the relay when it is energized by the specified

energizing quantity and has responded to that quantity; for a bistable relay, the condition other

than the release condition as declared by the manufacturer

[IEV 444-02-02]

3.3.3

operate (verb)

change from the release condition to the operate condition

[IEV 444-02-04]

3.3.4

release (verb)

for a monostable relay, change from the operate condition to the release condition

[IEV 444-02-05]

3.3.5

reset (verb)

for a bistable relay, change from the operate condition to the release condition

[IEV 444-02-06]

3.3.6

change over (verb)

for a monostable relay, operate or release; for a bistable relay, operate or reset

[IEV 444-02-07]

3.3.7

cycle (verb)

for a monostable relay, operate and then release or vice versa; for a bistable relay, operate and

then reset or vice-versa

[IEV 444-02-08]

3.3.8

revert (verb)

for a specific type of polarized relay, release/reset again, or remain in the release condition,

when supplied with a coil voltage in excess of that required for operation and of the same

polarity as required for operation

[IEV 444-02-09, modified]

– 12 – IEC 61810-7:2006 © IEC 2006

3.3.9

revert reverse (verb)

for a specific type of polarized bistable relay, operate again, or remain in the operate condition,

when supplied with a coil voltage in excess of that required for resetting and of the same

polarity as required for resetting

[IEV 444-02-10, modified]

3.4 Types of contacts

3.4.1

make contact

contact which is closed when the relay is in its operate condition and which is open when the

relay is in its release condition

[IEV 444-04-17]

3.4.2

break contact

contact which is open when the relay is in its operate condition and which is closed when the

relay is in its release condition

[IEV 444-04-18]

3.4.3

change-over contact

combination of two contact circuits with three contact members, one of which is common to the

two contact circuits; such that when one of these contact circuits is open, the other is closed

[IEV 444-04-19]

3.4.4

change-over make-before-break contact

change-over contact in which the make contact circuit closes before the break contact circuit

opens

[IEV 444-04-20]

3.4.5

change-over break-before-make contact

change-over contact in which the break contact circuit opens before the make contact circuit

closes

[IEV 444-04-21]

3.5 Prefixes for the values applicable to relays

Values may be defined as rated, actual (“just”), test (“must”) or characteristic value and

identified as such by using one of these words as a prefix. The prefixes are also applicable to

timing values.

3.5.1

rated value

value of a quantity used for specification purposes, established for a specified set of operating

conditions of a relay

[IEV 444-02-18, modified]

3.5.2

actual (“just”) value

value of a quantity determined by measurement on a specific relay, during performance of a

specified function

[IEV 444-02-21]

3.5.3

test (“must”) value

value of a quantity for which the relay shall comply with a specified action during a test

[IEV 444-02-20]

3.5.4

characteristic value

value of a quantity with which, in the initial condition of a relay or for a specified number of

cycles as specified, the relay shall comply with a specified requirement

[IEV 444-02-19, modified]

3.6 Energization values

3.6.1

energizing quantity

electrical quantity which, when applied to the coil(s) of a relay under specified conditions,

enables it to fulfil its purpose

[IEV 444-03-01, modified]

NOTE 1 For elementary relays, the energizing quantity is usually a voltage. Therefore, the input voltage as

energizing quantity is used in the definitions given below. When a relay is energized by a given current instead, the

respective terms and definitions apply with “current” used instead of “voltage”.

NOTE 2 The general term “input voltage” used in IEV Chapter 444 applies to all types of elementary relays (e.g.

including solid-state relays). For electromechanical elementary relays the more specific term “coil voltage” has been

chosen for the terms of 3.6, as in IEC 61810-1.

3.6.2

coil voltage

voltage applied as an energizing quantity

[IEV 444-03-03]

3.6.3

operative range

range of values of coil voltage for which a relay is able to perform its specified function

[IEV 444-03-05, modified]

NOTE For the following terms, refer also to Figures 3 to 7 which show the sequential functions of relays covered

by the definitions.

3.6.4

magnetic preconditioning value

value of the coil voltage at which the relay attains a defined magnetic condition

[IEV 444-03-19]

NOTE 1 For polarized relays, distinction is made between preconditioning in forward (operate) direction, and

preconditioning in reverse direction.

NOTE 2 For bistable relays, preconditioning may also be used to set the relay to a defined position.

– 14 – IEC 61810-7:2006 © IEC 2006

3.6.5

non-operate voltage