IEC 60193:2019

(Main)Hydraulic turbines, storage pumps and pump-turbines - Model acceptance tests

Hydraulic turbines, storage pumps and pump-turbines - Model acceptance tests

IEC 60193:2019 applies to laboratory models of any type of impulse or reaction hydraulic turbine, storage pump or pump-turbine.

This document applies to models of prototype machines either with unit power greater than 5 MW or with reference diameter greater than 3 m. Full application of the procedures herein prescribed is not generally justified for machines with smaller power and size. Nevertheless, this document may be used for such machines by agreement between the purchaser and the supplier.

This document excludes all matters of purely commercial interest, except those inextricably bound up with the conduct of the tests.

This document is concerned with neither the structural details of the machines nor the mechanical properties of their components, so long as these do not affect model performance or the relationship between model and prototype performances.

This document covers the arrangements for model acceptance tests to be performed on hydraulic turbines, storage pumps and pump-turbines to determine if the main hydraulic performance contract guarantees (see 4.2) have been satisfied.

It contains the rules governing test conduct and prescribes measures to be taken if any phase of the tests is disputed.

The main objectives of this document are:

– to define the terms and quantities used;

– to specify methods of testing and of measuring the quantities involved, in order to ascertain the hydraulic performance of the model;

– to specify the methods of computation of results and of comparison with guarantees;

– to determine if the contract guarantees that fall within the scope of this document have been fulfilled;

– to define the extent, content and structure of the final report.

The guarantees can be given in one of the following ways:

– guarantees for prototype hydraulic performance, computed from model test results considering scale effects;

– guarantees for model hydraulic performance.

This third edition cancels and replaces the second edition published in 1999. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a) update to methods/measuring tools currently used for checking dimensions on both model and prototype;

b) update to requirements of accuracy in the dimensional check procedure as a result of new technology;

c) merging of tables/sections with redundant information in dimension check in 5.2;

d) update to methods of measuring discharge;

e) update to pressure fluctuation methods and terminology;

f) specification of measuring times for accurate pressure fluctuation analyses in the model;

g) redefine definition for the transposition of pressure fluctuations to prototype;

h) update to surface waviness requirements in prototype;

i) redefining methods/references in clause on cavitation nuclei content (5.7.3.2.2);

j) update to 7.3 and review of methods on radial thrust measurements;

k) update to 7.4 (Hydraulic loads on control components);

l) update and develop methodology in 7.5 for testing in the extended operating range;

m) update to 7.6 concerning index testing;

n) update to methods for measuring roughness;

o) updates to references;

p) updates to figures;

q) revision of sigma definition;

r) reference to new method of transposition in accordance with IEC 62097.

Key Words: Hydraulic Turbines, Storage Pumps, Pump Turbines

Turbines hydrauliques, pompes d'accumulation et pompes-turbines - Essais de réception sur modèle

IEC 60193:2019 est applicable aux modèles de laboratoire de tout type de turbine hydraulique à action ou à réaction, de pompe d'accumulation ou de pompe-turbine.

Il s'applique aux modèles de machines prototypes ayant une puissance unitaire supérieure à 5 MW ou un diamètre de référence supérieur à 3 m. Bien que l'application intégrale des procédures prescrites ne soit généralement pas justifiée pour des machines de puissance et de dimension inférieures, le présent document peut néanmoins être utilisé pour de telles machines après accord entre l'acheteur et le fournisseur.

Dans ce document, le terme "turbine" inclut une pompe-turbine fonctionnant en turbine et le terme "pompe" inclut une pompe-turbine fonctionnant en pompe.

Ce document exclut tous les sujets à caractère purement commercial, excepté ceux intimement liés à la bonne conduite des essais.

Ce document ne concerne ni les détails de construction des machines, ni les propriétés mécaniques de leurs différentes parties pour autant que ces éléments n'affectent pas le fonctionnement du modèle ni la relation entre les performances du modèle et celles du prototype.

Le présent document régit les modalités des essais de réception sur modèle des turbines hydrauliques, pompes d'accumulation et pompes-turbines en vue de déterminer si les garanties contractuelles de performances hydrauliques principales (voir 4.2) sont respectées.

Il fixe les règles qui gouvernent la conduite de ces essais et prescrit les mesures à prendre en cas de contestation d'une phase quelconque des essais.

Les objectifs principaux du présent document sont:

- de définir les termes et les grandeurs utilisés;

- de prescrire les méthodes d'essai et les façons de mesurer les grandeurs permettant d'évaluer les performances hydrauliques du modèle;

- de prescrire les méthodes de calcul des résultats et de comparaison aux garanties;

- de déterminer si les garanties contractuelles qui sont du domaine de ce document sont respectées;

- de définir l'étendue, le contenu et la présentation du rapport final.

- Les garanties peuvent être données de l'une des façons suivantes:

- garanties reposant sur les performances hydrauliques du prototype, calculées à partir des résultats d'essai du modèle en tenant compte des effets d'échelle;

- garanties reposant sur les performances hydrauliques du modèle.

Cette troisième édition annule et remplace la seconde édition publiée en 1999. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) mise à jour des méthodes/appareils de mesures utilisés actuellement pour les contrôles dimensionnels sur modèle et sur prototype;

b) mise à jour des exigences de précision pour les procédures de contrôle dimensionnels tenant compte des nouvelles technologies;

c) fusion des tableaux/sections présentant des informations redondantes dans la section contrôles dimensionnels;

d) mise à jour des méthodes de mesurage du débit;

e) mise à jour des méthodes et de la terminologie relatives aux fluctuations de pression;

f) définition des temps de mesurages pour des analyses précises des fluctuations de pression sur modèle;

g) nouvelle définition de la transposition des fluctuations de pression au prototype;

h) mise à jour des exigences d'ondulations de surface sur prototype;

i) nouvelle définition des méthodes/références dans la section sur la teneur en germes de cavitation (5.7.3.2.2);

j) mise à jour du 7.3 et révision des méthodes de mesurage de poussée radiale;

k) mise à jour du 7.4 (Efforts hydrauliques sur les organes de réglage);

l) mise à jour et développement de méthodologie des essais dans le domaine de fonctionnement élargi, Paragraphe 7.5;

m) mise à jour du 7.6 concernant les essais indiciels;

n) mise à jour des mesurages de rugosité;

o) mise à jour des références;

p) mise à jour des figures;

q) révision de la définition de sigma;

r) reference à la nouvelle méthode de tr

General Information

- Status

- Replaced

- Publication Date

- 24-Apr-2019

- Technical Committee

- TC 4 - Hydraulic turbines

- Drafting Committee

- MT 32 - TC 4/MT 32

- Current Stage

- PPUB - Publication issued

- Start Date

- 25-Apr-2019

- Completion Date

- 12-Apr-2019

Relations

- Effective Date

- 05-Sep-2023

- Revises

IEC 60193:1999 - Hydraulic turbines, storage pumps and pump-turbines - Model acceptance tests - Effective Date

- 05-Sep-2023

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC 60193:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Hydraulic turbines, storage pumps and pump-turbines - Model acceptance tests". This standard covers: IEC 60193:2019 applies to laboratory models of any type of impulse or reaction hydraulic turbine, storage pump or pump-turbine. This document applies to models of prototype machines either with unit power greater than 5 MW or with reference diameter greater than 3 m. Full application of the procedures herein prescribed is not generally justified for machines with smaller power and size. Nevertheless, this document may be used for such machines by agreement between the purchaser and the supplier. This document excludes all matters of purely commercial interest, except those inextricably bound up with the conduct of the tests. This document is concerned with neither the structural details of the machines nor the mechanical properties of their components, so long as these do not affect model performance or the relationship between model and prototype performances. This document covers the arrangements for model acceptance tests to be performed on hydraulic turbines, storage pumps and pump-turbines to determine if the main hydraulic performance contract guarantees (see 4.2) have been satisfied. It contains the rules governing test conduct and prescribes measures to be taken if any phase of the tests is disputed. The main objectives of this document are: – to define the terms and quantities used; – to specify methods of testing and of measuring the quantities involved, in order to ascertain the hydraulic performance of the model; – to specify the methods of computation of results and of comparison with guarantees; – to determine if the contract guarantees that fall within the scope of this document have been fulfilled; – to define the extent, content and structure of the final report. The guarantees can be given in one of the following ways: – guarantees for prototype hydraulic performance, computed from model test results considering scale effects; – guarantees for model hydraulic performance. This third edition cancels and replaces the second edition published in 1999. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) update to methods/measuring tools currently used for checking dimensions on both model and prototype; b) update to requirements of accuracy in the dimensional check procedure as a result of new technology; c) merging of tables/sections with redundant information in dimension check in 5.2; d) update to methods of measuring discharge; e) update to pressure fluctuation methods and terminology; f) specification of measuring times for accurate pressure fluctuation analyses in the model; g) redefine definition for the transposition of pressure fluctuations to prototype; h) update to surface waviness requirements in prototype; i) redefining methods/references in clause on cavitation nuclei content (5.7.3.2.2); j) update to 7.3 and review of methods on radial thrust measurements; k) update to 7.4 (Hydraulic loads on control components); l) update and develop methodology in 7.5 for testing in the extended operating range; m) update to 7.6 concerning index testing; n) update to methods for measuring roughness; o) updates to references; p) updates to figures; q) revision of sigma definition; r) reference to new method of transposition in accordance with IEC 62097. Key Words: Hydraulic Turbines, Storage Pumps, Pump Turbines

IEC 60193:2019 applies to laboratory models of any type of impulse or reaction hydraulic turbine, storage pump or pump-turbine. This document applies to models of prototype machines either with unit power greater than 5 MW or with reference diameter greater than 3 m. Full application of the procedures herein prescribed is not generally justified for machines with smaller power and size. Nevertheless, this document may be used for such machines by agreement between the purchaser and the supplier. This document excludes all matters of purely commercial interest, except those inextricably bound up with the conduct of the tests. This document is concerned with neither the structural details of the machines nor the mechanical properties of their components, so long as these do not affect model performance or the relationship between model and prototype performances. This document covers the arrangements for model acceptance tests to be performed on hydraulic turbines, storage pumps and pump-turbines to determine if the main hydraulic performance contract guarantees (see 4.2) have been satisfied. It contains the rules governing test conduct and prescribes measures to be taken if any phase of the tests is disputed. The main objectives of this document are: – to define the terms and quantities used; – to specify methods of testing and of measuring the quantities involved, in order to ascertain the hydraulic performance of the model; – to specify the methods of computation of results and of comparison with guarantees; – to determine if the contract guarantees that fall within the scope of this document have been fulfilled; – to define the extent, content and structure of the final report. The guarantees can be given in one of the following ways: – guarantees for prototype hydraulic performance, computed from model test results considering scale effects; – guarantees for model hydraulic performance. This third edition cancels and replaces the second edition published in 1999. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) update to methods/measuring tools currently used for checking dimensions on both model and prototype; b) update to requirements of accuracy in the dimensional check procedure as a result of new technology; c) merging of tables/sections with redundant information in dimension check in 5.2; d) update to methods of measuring discharge; e) update to pressure fluctuation methods and terminology; f) specification of measuring times for accurate pressure fluctuation analyses in the model; g) redefine definition for the transposition of pressure fluctuations to prototype; h) update to surface waviness requirements in prototype; i) redefining methods/references in clause on cavitation nuclei content (5.7.3.2.2); j) update to 7.3 and review of methods on radial thrust measurements; k) update to 7.4 (Hydraulic loads on control components); l) update and develop methodology in 7.5 for testing in the extended operating range; m) update to 7.6 concerning index testing; n) update to methods for measuring roughness; o) updates to references; p) updates to figures; q) revision of sigma definition; r) reference to new method of transposition in accordance with IEC 62097. Key Words: Hydraulic Turbines, Storage Pumps, Pump Turbines

IEC 60193:2019 is classified under the following ICS (International Classification for Standards) categories: 27.140 - Hydraulic energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60193:2019 has the following relationships with other standards: It is inter standard links to IEC 63461:2024, IEC 60193:1999. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60193:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60193 ®

Edition 3.0 2019-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Hydraulic turbines, storage pumps and pump-turbines –

Model acceptance tests

Turbines hydrauliques, pompes d'accumulation et pompes-turbines –

Essais de réception sur modèle

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and once 67 000 electrotechnical terminology entries in English and

a month by email. French extracted from the Terms and Definitions clause of IEC

publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or need CISPR.

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Le premier dictionnaire d'électrotechnologie en ligne au monde,

webstore.iec.ch/advsearchform avec plus de 22 000 articles terminologiques en anglais et en

La recherche avancée permet de trouver des publications IEC français, ainsi que les termes équivalents dans 16 langues

en utilisant différents critères (numéro de référence, texte, additionnelles. Egalement appelé Vocabulaire

comité d’études,…). Elle donne aussi des informations sur les Electrotechnique International (IEV) en ligne.

projets et les publications remplacées ou retirées.

Glossaire IEC - std.iec.ch/glossary

IEC Just Published - webstore.iec.ch/justpublished 67 000 entrées terminologiques électrotechniques, en anglais

Restez informé sur les nouvelles publications IEC. Just et en français, extraites des articles Termes et Définitions des

Published détaille les nouvelles publications parues. publications IEC parues depuis 2002. Plus certaines entrées

Disponible en ligne et une fois par mois par email. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

Electropedia - www.electropedia.org

IEC 60193 ®

Edition 3.0 2019-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Hydraulic turbines, storage pumps and pump-turbines –

Model acceptance tests

Turbines hydrauliques, pompes d'accumulation et pompes-turbines –

Essais de réception sur modèle

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 27.140 ISBN 978-2-8322-6659-5

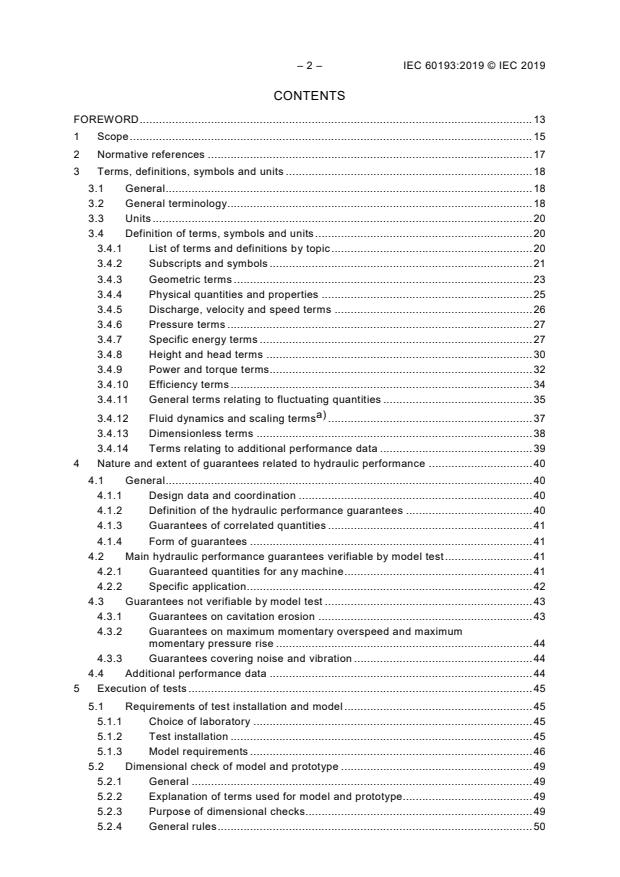

– 2 – IEC 60193:2019 © IEC 2019

CONTENTS

FOREWORD . 13

1 Scope . 15

2 Normative references . 17

3 Terms, definitions, symbols and units . 18

3.1 General . 18

3.2 General terminology . 18

3.3 Units . 20

3.4 Definition of terms, symbols and units . 20

3.4.1 List of terms and definitions by topic . 20

3.4.2 Subscripts and symbols . 21

3.4.3 Geometric terms . 23

3.4.4 Physical quantities and properties . 25

3.4.5 Discharge, velocity and speed terms . 26

3.4.6 Pressure terms . 27

3.4.7 Specific energy terms . 27

3.4.8 Height and head terms . 30

3.4.9 Power and torque terms . 32

3.4.10 Efficiency terms . 34

3.4.11 General terms relating to fluctuating quantities . 35

a)

3.4.12 Fluid dynamics and scaling terms . 37

3.4.13 Dimensionless terms . 38

3.4.14 Terms relating to additional performance data . 39

4 Nature and extent of guarantees related to hydraulic performance . 40

4.1 General . 40

4.1.1 Design data and coordination . 40

4.1.2 Definition of the hydraulic performance guarantees . 40

4.1.3 Guarantees of correlated quantities . 41

4.1.4 Form of guarantees . 41

4.2 Main hydraulic performance guarantees verifiable by model test . 41

4.2.1 Guaranteed quantities for any machine . 41

4.2.2 Specific application . 42

4.3 Guarantees not verifiable by model test . 43

4.3.1 Guarantees on cavitation erosion . 43

4.3.2 Guarantees on maximum momentary overspeed and maximum

momentary pressure rise . 44

4.3.3 Guarantees covering noise and vibration . 44

4.4 Additional performance data . 44

5 Execution of tests . 45

5.1 Requirements of test installation and model . 45

5.1.1 Choice of laboratory . 45

5.1.2 Test installation . 45

5.1.3 Model requirements . 46

5.2 Dimensional check of model and prototype . 49

5.2.1 General . 49

5.2.2 Explanation of terms used for model and prototype. 49

5.2.3 Purpose of dimensional checks. 49

5.2.4 General rules . 50

5.2.5 Procedure . 51

5.2.6 Application for different types of machines . 52

5.2.7 Methods . 52

5.2.8 Accuracy of measurements . 61

5.2.9 Dimensions of model and prototype to be checked . 62

5.2.10 Permissible maximum deviations in geometrical similarity between

prototype and model for turbines, pumps and pump-turbines . 66

5.2.11 Surface waviness and roughness . 71

5.3 Hydraulic similitude . 74

5.3.1 Theoretical basic requirements and similitude numbers . 74

5.3.2 Conditions for hydraulic similitude as used in this document . 74

5.3.3 Similitude requirements for various types of model tests . 75

5.3.4 Reynolds similitude . 76

5.3.5 Froude similitude . 77

5.3.6 Other similitude conditions . 80

5.4 Test conditions . 81

5.4.1 Determination of test conditions . 81

5.4.2 Minimum values for model size and test conditions to be fulfilled . 82

5.4.3 Stability and fluctuations during measurements . 83

5.4.4 Adjustment of the operating point . 83

5.5 Test procedures . 83

5.5.1 Organization of tests. 83

5.5.2 Inspections and calibrations . 86

5.5.3 Execution of tests . 88

5.5.4 Faults and repetition of tests . 93

5.5.5 Final test report . 94

5.6 Introduction to the methods of measurement . 95

5.6.1 General . 95

5.6.2 Measurements related to the main hydraulic performance guarantees . 95

5.6.3 Measurements related to additional data . 97

5.6.4 Acquisition and processing of data . 97

5.7 Physical properties . 97

5.7.1 General . 97

5.7.2 Acceleration due to gravity . 97

5.7.3 Physical properties of water . 98

5.7.4 Physical conditions of atmosphere . 104

5.7.5 Density of mercury . 104

6 Main hydraulic performances: methods of measurement and results . 105

6.1 Data acquisition and data processing . 105

6.1.1 Overview . 105

6.1.2 General requirements . 105

6.1.3 Data acquisition . 105

6.1.4 Component requirements . 107

6.1.5 Check of the data acquisition system . 110

6.2 Discharge measurement . 112

6.2.1 General . 112

6.2.2 Choice of the method of measurement . 112

6.2.3 Accuracy of measurement . 113

6.2.4 Primary methods . 114

– 4 – IEC 60193:2019 © IEC 2019

6.2.5 Secondary methods . 115

6.3 Pressure measurement . 118

6.3.1 General . 118

6.3.2 Choice of pressure-measuring section . 119

6.3.3 Pressure taps and connecting lines . 119

6.3.4 Apparatus for pressure measurement . 121

6.3.5 Calibration of pressure measurement apparatus . 128

6.3.6 Vacuum measurements . 129

6.3.7 Uncertainty in pressure measurements . 129

6.4 Free water level measurement (see also ISO 4373) . 129

6.4.1 General . 129

6.4.2 Choice of water level measuring sections . 130

6.4.3 Number of measuring points in a measuring section . 130

6.4.4 Measuring methods . 130

6.4.5 Uncertainty in free water level measurement . 131

6.5 Determination of E and NPSE . 132

6.5.1 General . 132

6.5.2 Determination of the specific hydraulic energy E . 133

6.5.3 Simplified formulae for E . 135

6.5.4 Determination of the net positive suction-specific energy NPSE . 142

6.6 Shaft torque measurement . 144

6.6.1 General . 144

6.6.2 Methods of torque measurement . 144

6.6.3 Methods of absorbing/generating power . 145

6.6.4 Layout of arrangement . 145

6.6.5 Checking of system . 150

6.6.6 Calibration . 150

6.6.7 Uncertainty in torque measurement (at a confidence level of 95 %) . 151

6.7 Rotational speed measurement . 152

6.7.1 General . 152

6.7.2 Methods of speed measurement . 152

6.7.3 Checking . 152

6.7.4 Uncertainty of measurement . 152

6.8 Computation and presentation of test results . 153

6.8.1 General . 153

6.8.2 Power, discharge and efficiency in the guarantee range . 158

6.8.3 Computation of steady-state runaway speed and discharge . 171

6.9 Error analysis . 176

6.9.1 Definitions . 176

6.9.2 Determination of uncertainties in model tests . 178

6.10 Comparison with guarantees . 182

6.10.1 General . 182

6.10.2 Interpolation curve and total uncertainty bandwidth . 183

6.10.3 Power, discharge and/or specific hydraulic energy and efficiency in the

guarantee range . 184

6.10.4 Runaway speed and discharge . 188

6.10.5 Cavitation guarantees . 189

7 Additional performance data – Methods of measurement and results . 191

7.1 Introduction to additional data measurement . 191

7.1.1 General . 191

7.1.2 Test conditions and test procedures . 192

7.1.3 Uncertainty in measurements . 192

7.1.4 Model to prototype conversion . 192

7.2 Fluctuating quantities . 193

7.2.1 Data acquisition and processing for measurement of fluctuating

quantities . 193

7.2.2 Pressure fluctuations . 197

7.2.3 Shaft torque fluctuations . 213

7.3 Axial and radial thrust . 214

7.3.1 General . 214

7.3.2 Hydraulic axial thrust . 215

7.3.3 Radial thrust . 223

7.4 Hydraulic loads on control components . 226

7.4.1 General . 226

7.4.2 Guide vane torque . 227

7.4.3 Runner blade torque . 233

7.4.4 Pelton needle force and deflector torque . 237

7.5 Testing in an extended operating range . 241

7.5.1 General . 241

7.5.2 Four quadrants . 241

7.5.3 Operating modes (see Figure 116) . 243

7.5.4 Scope of tests . 244

7.5.5 Methods of testing in the extended operating range . 246

7.6 Differential pressure measurement in view of prototype index test . 248

7.6.1 General . 248

7.6.2 Purpose of test . 249

7.6.3 Execution of test . 249

7.6.4 Analysis of test results . 249

7.6.5 Transposition to prototype conditions . 250

7.6.6 Uncertainty . 250

Annex A (informative) Dimensionless terms . 251

Annex B (normative) Physical properties, data . 253

Annex C (informative) Summarized test and calculation procedure . 261

C.1 General . 261

C.2 Agreements to be reached prior to testing . 261

C.3 Model, test facility and instrumentation . 262

C.3.1 Model manufacture and dimensional checks . 262

C.3.2 Test facility instrumentation and data acquisition system . 262

C.4 Tests and calculation of the model values . 262

C.4.1 Test types. 262

C.4.2 Measurement of the main quantities during the test . 263

C.4.3 Uncertainty of the measured quantities . 263

C.4.4 Calculation of the quantities related to the main hydraulic performance . 263

C.4.5 Calculation of the dimensionless factors or coefficients and of the

Thoma number . 263

C.4.6 Determination of δ for the transposition of efficiency . 264

ref

C.4.7 Calculation of efficiency and power coefficients referred to Re . 264

M*

– 6 – IEC 60193:2019 © IEC 2019

C.4.8 Correction of the model-measured values taking into account the

influence of cavitation . 264

C.5 Calculation of prototype quantities . 264

C.6 Plotting of model or prototype results . 264

C.7 Comparison with the guarantees . 265

C.8 Final protocol . 265

C.9 Final test report . 265

Annex D (normative) The scale effect on hydraulic efficiency for reaction machines . 266

D.1 Basic statements and assumptions . 266

D.2 Efficiency transposition formulae. 266

D.2.1 Derivation of the general formula for efficiency transposition . 266

D.2.2 Amount of relative scalable losses in the range of guaranteed

efficiencies . 267

D.2.3 Determination of the effect of scaling on the efficiency of the model . 269

D.2.4 Determination of the formula for the transposition of efficiency from

model to prototype . 271

Annex E (informative) Comparison of the hydraulic efficiency transposition methods of

IEC 60193 and IEC 62097 for reaction machines . 273

E.1 IEC 60193 transposition method . 273

E.1.1 Applications . 273

E.1.2 Limitations . 273

E.2 IEC 62097 transposition method . 274

E.2.1 Applications . 274

E.2.2 Limitations . 274

Annex F (normative) Computation of the prototype runaway characteristics taking into

account friction and windage losses of the unit . 275

Annex G (informative) Example of determination of the best smooth curve: method of

separate segments . 276

G.1 General . 276

G.2 Principle of the method . 276

G.3 Choice of the minimum width of the intervals . 278

G.4 Determination of the intervals . 278

Annex H (informative) Examples of analysis of sources of error and uncertainty

evaluation . 279

H.1 General . 279

H.2 Example of analysis of sources of error and of uncertainty evaluation in the

measurement of a physical quantity . 279

H.2.1 General . 279

H.2.2 Errors arising during calibration . 280

H.2.3 Errors arising during the tests . 281

H.3 Example of calculation of uncertainty due to systematic errors in the

determination of the specific hydraulic energy, mechanical runner/impeller

power and hydraulic efficiency . 281

H.3.1 General . 281

H.3.2 Discharge . 282

H.3.3 Pressure . 282

H.3.4 Specific hydraulic energy . 282

H.3.5 Power . 283

H.3.6 Hydraulic efficiency . 283

H.4 Example of calculation of uncertainty due to systematic errors in the

determination of the net positive suction specific energy . 284

H.4.1 General . 284

H.4.2 Discharge . 284

H.4.3 Pressure . 284

H.4.4 Net positive suction specific energy . 284

Annex I (normative) The scale effect on hydraulic efficiency for Pelton turbines . 286

I.1 General . 286

I.2 Similarity considerations . 286

I.3 Transposition formula . 288

Annex J (normative) Analysis of random errors for a test at constant operating

conditions . 289

J.1 General . 289

J.2 Standard deviation . 289

J.3 Confidence levels . 290

J.4 Student's t distribution . 290

J.5 Maximum permissible value of uncertainty due to random errors. 291

J.6 Example of calculation . 292

Annex K (normative) Calculation of plant Thoma number σ . 293

pl

K.1 Definition of σ , NPSE and NPSH . 293

pl

K.2 Data needed to calculate σ . 294

plc

Annex L (informative) Flux diagram of specific hydraulic energy, flow and power . 296

Annex M (informative) Synchronous and asynchronous components of pressure

signals . 299

Annex N (informative) Natural frequency of the hydraulic system . 301

Annex O (informative) Calculation of axial force components . 302

O.1 General . 302

O.2 Calculating the force acting on the runner crown (F ) . 302

O.2.1 General . 302

O.2.2 Pressure specific energy losses due to seal clearance . 302

O.2.3 Pressure specific energy losses through the centrifugal zones between

the stationary and rotating parts . 304

O.2.4 Pressure specific energy losses in a pressure relief/equilibrium pipe . 305

O.2.5 Additional specific energy losses . 306

O.3 Calculating the force acting on the runner band (F ) . 307

Bibliography . 308

Figure 1– Schematic representation of a hydraulic machine . 22

Figure 2 – Guide vane opening and angle . 22

Figure 3 – Reference diameter and bucket width . 24

Figure 4 – Determination of σ and σ for typical cavitation curves . 29

0 1

Figure 5 – Reference level of machine . 31

Figure 6 – Flux diagram for power and discharge . 33

Figure 7 – Illustration of some definitions related to oscillating quantities . 36

Figure 8 – Procedure for dimensional checks, comparison of results "steel to steel" and

application of tolerances for model and prototype . 51

Figure 9 – Example of spiral case and distributor dimensions to be checked . 54

Figure 10 – Example of draft tube dimensions to be checked . 54

– 8 – IEC 60193:2019 © IEC 2019

Figure 11 – Example of the dimensions to be checked on a bulb unit . 55

Figure 12 – Example of the dimensions to be checked on the runner/impeller of a

radial flow machine . 56

Figure 13 – Runner/impeller of radial flow machine: examples of locations for blade

profile measuring sections for templates or measuring points for CMM . 57

Figure 14 – Runner/impeller of radial flow machine: check of outlet width and blade

profiles by means of templates as illustrated on a Francis runner . 57

Figure 15 – Runner/impeller of radial flow machine: check of inlet and outlet widths

between blades (example of a pump-turbine runner) . 58

Figure 16 – Runner/impeller of axial flow machine: example of locations for blade

profile measuring sections for templates or measuring points for CMM . 58

Figure 17 – Runner/impeller of axial flow machine: definition of blade adjustment and

of blade profile tolerances . 58

Figure 18 – Pelton turbine: example of dimensions to be checked on the distributor and

the housing of vertical and horizontal shaft machines . 59

Figure 19 – Pelton turbine: example of dimensions to be checked on the buckets and

nozzles . 60

Figure 20 – Definition of waviness and surface roughness . 72

Figure 21 – Low specific hydraulic energy turbine example of recommended maximum

surface roughness values on the runner blades (pressure side and suction side) . 73

Figure 22 – Relation between the setting level z of a Francis turbine and the cavitation

r

reference level z . 78

c

Figure 23 – Dependence of σ values on level z for model and prototype . 78

-2

Figure 24 – Acceleration due to gravity g (m ⋅ s ) . 98

−3

Figure 25 – Density of distilled water ρ (kg ⋅ m ) . 101

wd

Figure 26 – Time multiplexing data acquisition system . 106

Figure 27 – Bus operated data acquisition system . 107

Figure 28 – Time delay . 108

Figure 29 – Typical low-pass filter attenuation characteristics . 109

Figure 30 – Different measurement chains and their recommended checkpoints . 111

Figure 31 – Examples of pressure taps . 120

Figure 32 – Types of pressure manifolds: a) with separate connecting lines to manifold

and b) with ring manifold . 121

Figure 33 – Examples of experimental setup of liquid column manometers . 123

Figure 34 – Dead weight manometer with compensation by pressure or force

transducer (example of experimental set-up) . 126

Figure 35 – Pressure weighbeam (example of experimental set-up) . 127

Figure 36 – Stilling well . 130

Figure 37 – Point and hook gauges . 131

Figure 38 – Example showing main elevations, heights and reference levels of the test

rig and model machine . 134

Figure 39 – Determination of specific hydraulic energy through differential pressure

measuring instrument . 137

Figure 40 – Determination of specific hydraulic energy of the machine through

separate measurement of gauge pressures . 138

Figure 41 – Determination of specific hydraulic energy of the machine through

separate measurement of pressures by water column manometers . 139

Figure 42 – Pelton turbines with vertical axis: determination of specific hydraulic

energy of the machine . 140

Figure 43 – Pelton turbines with horizontal axis: determination of specific hydraulic

energy of the machine . 141

Figure 44 – Low-head machines: determination of specific hydraulic energy of the

machine using free water levels . 142

Figure 45 – Determination of net positive suction energy NPSE and net positive

suction head NPSH .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...