IEC 61195:1999

(Main)Double-capped fluorescent lamps - Safety specifications

Double-capped fluorescent lamps - Safety specifications

Specifies the safety requirements for double-capped fluorescent lamps for general lighting purposes of all groups having Fa6, Fa8, G5, G13 and R17d caps. Also specifies the method a manufacturer should use to show compliance with the requirements of this standard. The contents of the corrigendum of August 2000 have been included in this copy.

Lampes à fluorescence à deux culots - Prescriptions de sécurité

Spécifie les prescriptions de sécurité auxquelles doivent répondre les lampes à fluorescence à deux culots, d'éclairage général de tous les groupes équipés des culots Fa6, Fa8, G5, G13 et R17d. Spécifie aussi la méthode que le fabricant utilisera pour démontrer la conformité de ses produits aux prescriptions de la présente norme. Le contenu du corrigendum d'août 2000 a été pris en considération dans cet exemplaire.

General Information

- Status

- Published

- Publication Date

- 28-Oct-1999

- Technical Committee

- SC 34A - Electric light sources

- Drafting Committee

- WG 6 - TC 34/SC 34A/WG 6

- Current Stage

- PPUB - Publication issued

- Start Date

- 29-Oct-1999

- Completion Date

- 15-Dec-1999

Relations

- Amended By

IEC 61195:1999/AMD2:2014 - Amendment 2 - Double-capped fluorescent lamps - Safety specifications - Effective Date

- 05-Sep-2023

- Amended By

IEC 61195:1999/AMD1:2012 - Amendment 1 - Double-capped fluorescent lamps - Safety specifications - Effective Date

- 05-Sep-2023

- Corrected By

IEC 61195:1999/COR1:2000 - Corrigendum 1 - Double-capped fluorescent lamps - Safety specifications - Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Revises

IEC 61195:1993/AMD1:1998 - Amendment 1 - Double-capped fluorescent lamps - Safety specifications - Effective Date

- 05-Sep-2023

Overview

IEC 61195:1999 is an international standard established by the International Electrotechnical Commission (IEC) that defines the safety specifications for double-capped fluorescent lamps used predominantly for general lighting purposes. This standard specifically covers lamps with caps including Fa6, Fa8, G5, G13, 2G13, R17d, and W4.3×8.5d types. It provides manufacturers with essential safety requirements and compliance methods to ensure product safety during use.

Key to this standard is its comprehensive approach to safety, which addresses mechanical, electrical, thermal, and photobiological hazards. Furthermore, IEC 61195 integrates updated requirements in line with IEC 62471 for photobiological safety, particularly focusing on limiting UV, blue light, and infrared radiation risks.

Key Topics

Scope and Application

- Applies to double-capped low-pressure mercury discharge lamps with specified cap types used for general lighting.

- Focuses exclusively on safety aspects and does not address performance parameters such as luminous flux or color characteristics.

- Includes methods for whole production appraisal and batch testing to verify compliance, which can aid in certification.

Safety Requirements

The standard outlines specific safety requirements covering:

- Mechanical requirements for caps to ensure secure fitting and prevent accidental contact.

- Electrical insulation resistance and electric strength tests to prevent electrical hazards.

- Measures to avoid accidental live parts becoming exposed.

- Requirements for heat and fire resistance, including glow-wire tests.

- Limits for lamp cap temperature rise to prevent overheating risks.

- Control of creepage distances around lamp caps for electrical safety.

- Restriction of UV radiation emissions to safe levels in accordance with IEC 62471 photobiological guidelines.

Compliance and Assessment

- Provides a systematic approach for manufacturers to assess whole production based on test records.

- Details sampling procedures and rejection criteria for batch testing.

- Offers normative annexes with test holder designs, test methods, and compliance condition specifications.

- Specifies the need for clear marking on lamps for identification and safety information.

Photobiological Safety Integration

- Aligns with IEC 62471 and IEC/TR 62471-2 standards, ensuring the lamps do not exceed risk group 1 for blue light hazard or produce dangerous IR radiation.

- Addresses UV radiation safety directly under the lamp safety section.

- Supports safe usage in general lighting service (GLS) applications where human exposure is typical.

Applications

IEC 61195 safety specifications are critical for:

- Fluorescent lamp manufacturers seeking to certify products for international markets, ensuring safety and regulatory compliance.

- Lighting designers and engineers who require assurance on lamp safety parameters when selecting lamps for commercial, industrial, or residential lighting.

- Certification bodies and regulatory agencies involved in testing and certifying double-capped fluorescent lamps.

- Luminaire and ballast designers, who need detailed information on lamp characteristics to ensure compatibility and safe operation.

- Safety and quality assurance professionals managing production control and product conformity in the lighting industry.

Related Standards

IEC 61195 references and aligns with several important IEC standards, including:

- IEC 60061 series - Lamp caps and holders standards, critical for cap interchangeability and safety.

- IEC 60081 - Performance specifications for double-capped fluorescent lamps, focusing on lamp operational characteristics.

- IEC 62471 and IEC/TR 62471-2 - Photobiological safety standards, integrated into IEC 61195 for UV and optical radiation risk management.

- IEC 60410 - Sampling plans and inspection for products, utilized for compliance assessment.

- IEC 60695-2-1/0 - Fire hazard testing including glow-wire methods for determining heat resistance.

- IEC 60921 - Ballast performance requirements, relevant for ensuring proper electrical supply.

IEC 61195:1999 represents the essential international guideline to ensure the safe use and manufacture of double-capped fluorescent lamps. Adherence to this standard helps mitigate operational hazards, promote consumer safety, and enable global market harmonization for general lighting products utilizing fluorescent technology.

IEC 61195:1999 - Double-capped fluorescent lamps - Safety specifications

IEC 61195:1999+AMD1:2012+AMD2:2014 CSV - Double-capped fluorescent lamps - Safety specifications Released:9/19/2014 Isbn:9782832218594

IEC 61195:1999+AMD1:2012 CSV - Double-capped fluorescent lamps - Safety specifications Released:10/14/2012 Isbn:9782832204153

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 61195:1999 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Double-capped fluorescent lamps - Safety specifications". This standard covers: Specifies the safety requirements for double-capped fluorescent lamps for general lighting purposes of all groups having Fa6, Fa8, G5, G13 and R17d caps. Also specifies the method a manufacturer should use to show compliance with the requirements of this standard. The contents of the corrigendum of August 2000 have been included in this copy.

Specifies the safety requirements for double-capped fluorescent lamps for general lighting purposes of all groups having Fa6, Fa8, G5, G13 and R17d caps. Also specifies the method a manufacturer should use to show compliance with the requirements of this standard. The contents of the corrigendum of August 2000 have been included in this copy.

IEC 61195:1999 is classified under the following ICS (International Classification for Standards) categories: 29.140.30 - Fluorescent lamps. Discharge lamps. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61195:1999 has the following relationships with other standards: It is inter standard links to IEC 61195:1999/AMD2:2014, IEC 61195:1999/AMD1:2012, IEC 61195:1999/COR1:2000, IEC 61195:1993, IEC 61195:1993/AMD1:1998. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61195:1999 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

NORME CEI

INTERNATIONALE IEC

INTERNATIONAL

Deuxième édition

STANDARD

Second edition

1999-10

Lampes à fluorescence à deux culots –

Prescriptions de sécurité

Double-capped fluorescent lamps –

Safety specifications

Numéro de référence

Reference number

CEI/IEC 61195:1999

Numéros des publications Numbering

Depuis le 1er janvier 1997, les publications de la CEI As from 1 January 1997 all IEC publications are

sont numérotées à partir de 60000. issued with a designation in the 60000 series.

Publications consolidées Consolidated publications

Les versions consolidées de certaines publications de Consolidated versions of some IEC publications

la CEI incorporant les amendements sont disponibles. including amendments are available. For example,

Par exemple, les numéros d’édition 1.0, 1.1 et 1.2 edition numbers 1.0, 1.1 and 1.2 refer, respectively, to

indiquent respectivement la publication de base, la the base publication, the base publication incor-

publication de base incorporant l’amendement 1, et la porating amendment 1 and the base publication

publication de base incorporant les amendements 1 incorporating amendments 1 and 2.

et 2.

Validité de la présente publication Validity of this publication

Le contenu technique des publications de la CEI est The technical content of IEC publications is kept

constamment revu par la CEI afin qu'il reflète l'état under constant review by the IEC, thus ensuring that

actuel de la technique. the content reflects current technology.

Des renseignements relatifs à la date de reconfir- Information relating to the date of the reconfirmation

mation de la publication sont disponibles dans le of the publication is available in the IEC catalogue.

Catalogue de la CEI.

Les renseignements relatifs à des questions à l’étude et Information on the subjects under consideration and

des travaux en cours entrepris par le comité technique work in progress undertaken by the technical

qui a établi cette publication, ainsi que la liste des committee which has prepared this publication, as well

publications établies, se trouvent dans les documents ci- as the list of publications issued, is to be found at the

dessous: following IEC sources:

• «Site web» de la CEI* • IEC web site*

• Catalogue des publications de la CEI • Catalogue of IEC publications

Publié annuellement et mis à jour Published yearly with regular updates

régulièrement (On-line catalogue)*

(Catalogue en ligne)*

• IEC Bulletin

• Bulletin de la CEI Available both at the IEC web site* and

Disponible à la fois au «site web» de la CEI* as a printed periodical

et comme périodique imprimé

Terminology, graphical and letter

Terminologie, symboles graphiques

symbols

et littéraux

For general terminology, readers are referred to

En ce qui concerne la terminologie générale, le lecteur IEC 60050: International Electrotechnical Vocabulary

se reportera à la CEI 60050: Vocabulaire Electro- (IEV).

technique International (VEI).

For graphical symbols, and letter symbols and signs

Pour les symboles graphiques, les symboles littéraux approved by the IEC for general use, readers are

et les signes d'usage général approuvés par la CEI, le referred to publications IEC 60027: Letter symbols to

lecteur consultera la CEI 60027: Symboles littéraux à be used in electrical technology, IEC 60417: Graphical

utiliser en électrotechnique, la CEI 60417: Symboles symbols for use on equipment. Index, survey and

graphiques utilisables sur le matériel. Index, relevé et compilation of the single sheets and IEC 60617:

compilation des feuilles individuelles, et la CEI 60617: Graphical symbols for diagrams.

Symboles graphiques pour schémas.

* See web site address on title page.

* Voir adresse «site web» sur la page de titre.

NORME CEI

INTERNATIONALE IEC

INTERNATIONAL

Deuxième édition

STANDARD

Second edition

1999-10

Lampes à fluorescence à deux culots –

Prescriptions de sécurité

Double-capped fluorescent lamps –

Safety specifications

IEC 1999 Droits de reproduction réservés Copyright - all rights reserved

Aucune partie de cette publication ne peut être reproduite ni No part of this publication may be reproduced or utilized in

utilisée sous quelque forme que ce soit et par aucun procédé, any form or by any means, electronic or mechanical,

électronique ou mécanique, y compris la photo-copie et les including photocopying and microfilm, without permission in

microfilms, sans l'accord écrit de l'éditeur. writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http://www.iec.ch

CODE PRIX

Commission Electrotechnique Internationale

T

PRICE CODE

International Electrotechnical Commission

Pour prix, voir catalogue en vigueur

For price, see current catalogue

– 2 – 61195 © CEI:1999

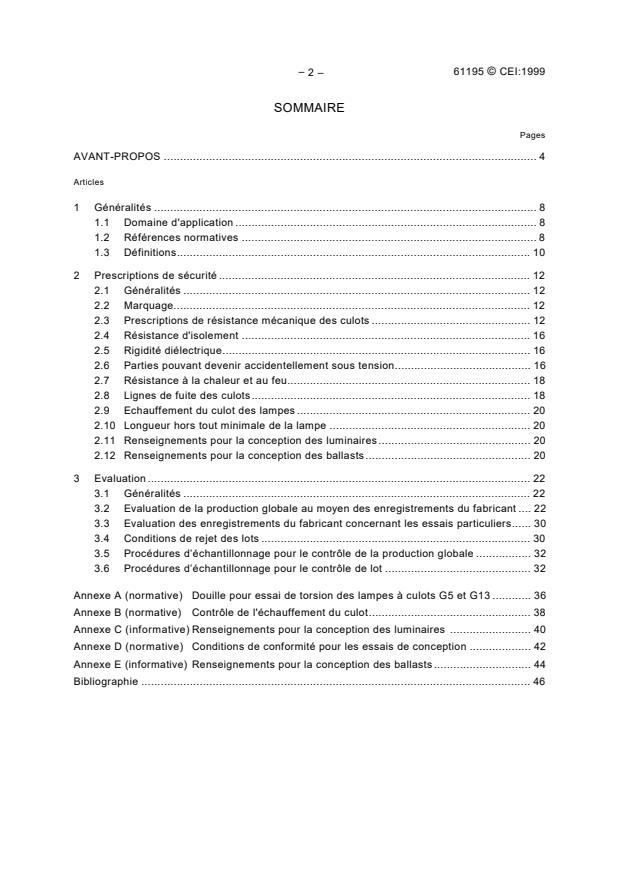

SOMMAIRE

Pages

AVANT-PROPOS . 4

Articles

1 Généralités . 8

1.1 Domaine d'application . 8

1.2 Références normatives . 8

1.3 Définitions. 10

2 Prescriptions de sécurité . 12

2.1 Généralités . 12

2.2 Marquage. 12

2.3 Prescriptions de résistance mécanique des culots . 12

2.4 Résistance d'isolement . 16

2.5 Rigidité diélectrique. 16

2.6 Parties pouvant devenir accidentellement sous tension. 16

2.7 Résistance à la chaleur et au feu. 18

2.8 Lignes de fuite des culots. 18

2.9 Echauffement du culot des lampes . 20

2.10 Longueur hors tout minimale de la lampe . 20

2.11 Renseignements pour la conception des luminaires. 20

2.12 Renseignements pour la conception des ballasts. 20

3 Evaluation . 22

3.1 Généralités . 22

3.2 Evaluation de la production globale au moyen des enregistrements du fabricant . 22

3.3 Evaluation des enregistrements du fabricant concernant les essais particuliers. 30

3.4 Conditions de rejet des lots . 30

3.5 Procédures d’échantillonnage pour le contrôle de la production globale . 32

3.6 Procédures d’échantillonnage pour le contrôle de lot . 32

Annexe A (normative) Douille pour essai de torsion des lampes à culots G5 et G13 . 36

Annexe B (normative) Contrôle de l'échauffement du culot. 38

Annexe C (informative) Renseignements pour la conception des luminaires . 40

Annexe D (normative) Conditions de conformité pour les essais de conception . 42

Annexe E (informative) Renseignements pour la conception des ballasts . 44

Bibliographie . 46

61195 © IEC:1999 – 3 –

CONTENTS

Page

FOREWORD . 5

Clause

1 General. 9

1.1 Scope . 9

1.2 Normative references. 9

1.3 Definitions. 11

2 Safety requirements . 13

2.1 General. 13

2.2 Marking. 13

2.3 Mechanical requirements for caps . 13

2.4 Insulation resistance . 17

2.5 Electric strength . 17

2.6 Parts which can become accidentally live . 17

2.7 Resistance to heat and fire. 19

2.8 Creepage distance for caps. 19

2.9 Lamp cap temperature rise. 21

2.10 Lamp minimum overall length. 21

2.11 Information for luminaire design . 21

2.12 Information for ballast design . 21

3 Assessment . 23

3.1 General. 23

3.2 Whole production assessment by means of the manufacturer’s records . 23

3.3 Assessment of the manufacturer’s records of particular tests. 31

3.4 Rejection conditions of batches . 31

3.5 Sampling procedures for whole production testing . 33

3.6 Sampling procedures for batch testing. 33

Annex A (normative) Test holder for torsion test for G5 and G13 capped lamps. 37

Annex B (normative) Test for lamp cap temperature rise . 39

Annex C (informative) Information for luminaire design. 41

Annex D (normative) Conditions of compliance for design tests . 43

Annex E (informative) Information for ballast design. 45

Bibliography . 47

– 4 – 61195 © CEI:1999

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

LAMPES À FLUORESCENCE À DEUX CULOTS –

PRESCRIPTIONS DE SÉCURITÉ

AVANT-PROPOS

1) La CEI (Commission Électrotechnique Internationale) est une organisation mondiale de normalisation composée

de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a pour objet de

favoriser la coopération internationale pour toutes les questions de normalisation dans les domaines de

l'électricité et de l'électronique. A cet effet, la CEI, entre autres activités, publie des Normes internationales.

Leur élaboration est confiée à des comités d'études, aux travaux desquels tout Comité national intéressé par le

sujet traité peut participer. Les organisations internationales, gouvernementales et non gouvernementales, en

liaison avec la CEI, participent également aux travaux. La CEI collabore étroitement avec l'Organisation

Internationale de Normalisation (ISO), selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux intéressés

sont représentés dans chaque comité d’études.

3) Les documents produits se présentent sous la forme de recommandations internationales. Ils sont publiés

comme normes, spécifications techniques, rapports techniques ou guides et agréés comme tels par les Comités

nationaux.

4) Dans le but d'encourager l'unification internationale, les Comités nationaux de la CEI s'engagent à appliquer de

façon transparente, dans toute la mesure possible, les Normes internationales de la CEI dans leurs normes

nationales et régionales. Toute divergence entre la norme de la CEI et la norme nationale ou régionale

correspondante doit être indiquée en termes clairs dans cette dernière.

5) La CEI n’a fixé aucune procédure concernant le marquage comme indication d’approbation et sa responsabilité

n’est pas engagée quand un matériel est déclaré conforme à l’une de ses normes.

6) L’attention est attirée sur le fait que certains des éléments de la présente Norme internationale peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 61195 a été établie par le sous-comité 34A: Lampes, du comité

d'études 34 de la CEI: Lampes et équipements associés.

Cette deuxième édition annule et remplace la première édition, parue en 1993, et son

amendement 1 (1998) dont elle constitue une révision technique.

Le texte de cette norme est issu des documents suivants:

FDIS Rapport de vote

34A/886/FDIS 34A/900/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à l'approbation de cette norme.

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 3.

Les annexes A, B et D font partie intégrante de cette norme.

Les annexes C et E sont données uniquement à titre d'information.

Le contenu du corrigendum d'août 2000 a été pris en considération dans cet exemplaire.

61195 © IEC:1999 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

DOUBLE-CAPPED FLUORESCENT LAMPS –

SAFETY SPECIFICATIONS

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International Organization

for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61195 has been prepared by sub-committee 34A: Lamps, of IEC

technical committee 34: Lamps and related equipment.

This second edition cancels and replaces the first edition published in 1993 and its

amendment 1 (1998). It constitutes a technical revision.

The text of this standard is based on the following documents:

FDIS Report on voting

34A/886/FDIS 34A/900/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

Annexes A, B and D form an integral part of this standard.

Annexes C and E are for information only.

The contents of the corrigendum of August 2000 have been included in this copy.

– 6 – 61195 © CEI:1999

Le comité à décidé que cette publication reste valable jusqu’en 2003-09.

A cette date, selon décision préalable du comité, la publication sera

• reconduite;

•

supprimée;

•

remplacée par une édition révisée, ou

• amendée.

61195 © IEC:1999 – 7 –

The committee has decided that this publication remains valid until 2003-09.

At this date, in accordance with the committee’s decision, the publication will be

• reconfirmed;

•

withdrawn;

•

replaced by a revised edition, or

• amended.

– 8 – 61195 © CEI:1999

LAMPES À FLUORESCENCE À DEUX CULOTS –

PRESCRIPTIONS DE SÉCURITÉ

1 Généralités

1.1 Domaine d'application

La présente Norme internationale spécifie les prescriptions de sécurité auxquelles doivent

répondre les lampes à fluorescence à deux culots destinées à l’éclairage général, de tous les

groupes à culots Fa6, Fa8, G5, G13, 2G13, R17d et W4.3×8.5d.

Elle spécifie aussi la méthode qu'il convient que le fabricant utilise pour démontrer la

conformité de ses produits aux prescriptions de la présente norme, méthode basée sur

l'évaluation de la qualité de la production globale, associée aux résultats d'essais enregistrés

sur les produits finis. Cette méthode peut aussi être appliquée à des fins de certification. Des

précisions sont également données dans la présente norme sur la procédure de contrôle par

lots qui peut être utilisée pour l'appréciation limitée de la qualité des lots.

NOTE – La conformité à la présente norme ne concerne que les critères de sécurité; la performance des lampes à

fluorescence à deux culots pour éclairage général n'est pas prise en compte pour tout ce qui concerne le flux

lumineux, la couleur et les caractéristiques d'amorçage et de fonctionnement. Pour toutes ces données, le lecteur

est renvoyé à la CEI 60081.

1.2 Références normatives

Les documents normatifs suivants contiennent des dispositions qui, par suite de la référence

qui y est faite, constituent des dispositions valables pour la présente Norme internationale.

Pour les références datées, les amendements ultérieurs ou les révisions de ces publications

ne s’appliquent pas. Toutefois, les parties prenantes aux accords fondés sur la présente

Norme internationale sont invitées à rechercher la possibilité d'appliquer les éditions les plus

récentes des documents normatifs indiqués ci-après. Pour les références non datées, la

dernière édition du document normatif en référence s’applique. Les membres de la CEI et de

l'ISO possèdent le registre des Normes internationales en vigueur.

CEI 60061-1, Culots de lampes et douilles ainsi que calibres pour le contrôle de

l'interchangeabilité et de la sécurité – Première partie: Culots de lampes

CEI 60061-2, Culots de lampes et douilles ainsi que calibres pour le contrôle de

l'interchangeabilité et de la sécurité – Deuxième partie: Douilles

CEI 60061-3, Culots de lampes et douilles ainsi que calibres pour le contrôle de

l'interchangeabilité et de la sécurité – Troisième partie: Calibres

CEI 60081, Lampes à fluorescence à deux culots – Prescriptions de performances

CEI 60410, Plans et règles d'échantillonnage pour les contrôles par attributs

CEI 60695-2-1/0, Essais relatifs aux risques du feu – Partie 2: Méthodes d'essai –

Section 1/feuille 0: Méthode d'essai au fil incandescent – Généralités

CEI 60921, Ballasts pour lampes tubulaires à fluorescence. Prescriptions de performances

61195 © IEC:1999 – 9 –

DOUBLE-CAPPED FLUORESCENT LAMPS –

SAFETY SPECIFICATIONS

1 General

1.1 Scope

This International Standard specifies the safety requirements for double-capped fluorescent

lamps for general lighting purposes of all groups having Fa6, Fa8, G5, G13, 2G13, R17d and

W4.3×8.5d caps.

It also specifies the method a manufacturer should use to show compliance with the

requirements of this standard on the basis of whole production appraisal in association with his

test records on finished products. This method can also be applied for certification purposes.

Details of a batch test procedure which can be used to make limited assessment of batches

are also given in this standard.

NOTE – Compliance with this standard concerns only safety criteria and does not take into account the

performance of double-capped fluorescent lamps for general lighting purposes with respect to luminous flux, colour,

starting and operational characteristics. Readers are referred to IEC 60081 for such characteristics.

1.2 Normative references

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this International Standard. For dated references, subsequent

amendments to, or revisions of, any of these publications do not apply. However, parties to

agreements based on this International Standard are encouraged to investigate the possibility

of applying the most recent editions of the normative documents indicated below. For undated

references, the latest edition of the normative document referred to applies. Members of IEC

and ISO maintain registers of currently valid International Standards.

IEC 60061-1, Lamp caps and holders together with gauges for the control of

interchangeability and safety – Part 1: Lamp caps

IEC 60061-2, Lamp caps and holders together with gauges for the control of interchangeability

and safety – Part 2: Lampholders

IEC 60061-3, Lamp caps and holders together with gauges for the control of

interchangeability and safety – Part 3: Gauges

IEC 60081, Double-capped fluorescent lamps – Performance specifications

Sampling plans and procedures for inspection by attributes

IEC 60410,

IEC 60695-2-1/0, Fire hazard testing – Part 2: Test methods – Section 1/sheet 0: Glow-wire

test methods – General

IEC 60921, Ballasts for tubular fluorescent lamps – Performance requirements

– 10 – 61195 © CEI:1999

1.3 Définitions

Pour les besoins de la présente Norme internationale, les définitions suivantes s'appliquent.

1.3.1

lampe à fluorescence à deux culots

lampe tubulaire à décharge à vapeur de mercure à basse pression, avec deux culots, et dans

laquelle la plus grande partie de la lumière est émise par une couche de substances

fluorescentes excitées par le rayonnement ultraviolet de la décharge

1.3.2

groupe

lampes ayant les mêmes caractéristiques électriques et de cathodes, les mêmes cotes

géométriques et la même méthode d'amorçage

1.3.3

type

lampes du même groupe ayant les mêmes caractéristiques de flux lumineux et de couleur

apparente

1.3.4

famille

groupe de lampes qui se distinguent par des traits communs touchant aux matériaux utilisés,

aux composants, au diamètre de lampe et/ou à la méthode de fabrication

1.3.5

puissance nominale

puissance utilisée pour désigner la lampe

1.3.6

essai de conception

essai effectué sur un échantillon dans le but de vérifier la conformité de la conception d'une

famille, d'un groupe ou d'un certain nombre de groupes aux prescriptions de l'article corres-

pondant

1.3.7

essai périodique

essai ou série d'essais exécutés à intervalles afin de vérifier que le produit ne dévie pas, à

certains égards, du modèle correspondant à la conception

1.3.8

essai courant

essai répété à intervalles courts en vue de réunir les données destinées à l'évaluation

1.3.9

lot

toutes les lampes d'une famille, ou d'un groupe, identifiées comme telles, et présentées en

même temps pour subir ensemble le contrôle de la conformité

1.3.10

production globale

ensemble de tous les types de lampes produits au cours d'une période de douze mois dans le

cadre de la présente norme et entrant dans une liste dressée par le fabricant en vue d'être

incluse dans le certificat de conformité

61195 © IEC:1999 – 11 –

1.3 Definitions

For the purposes of this International Standard, the following definitions apply.

1.3.1

double-capped fluorescent lamp

double-capped low-pressure mercury discharge lamp of tubular form in which most of the light

is emitted by a layer of fluorescent material excited by the ultra-violet radiation from the

discharge

1.3.2

group

lamps having the same electrical and cathode characteristics, the same physical dimensions

and the same starting method

1.3.3

type

lamps of the same group having the same photometric and colour characteristics

1.3.4

family

lamp groups which are distinguished by common features of materials, components, lamp

diameter and/or method of processing

1.3.5

nominal wattage

wattage used to designate the lamp

1.3.6

design test

test made on a sample for the purpose of checking compliance of the design of a family, group

or a number of groups with the requirements of the relevant clause

1.3.7

periodic test

test, or series of tests, repeated at intervals in order to check that the product does not deviate

in certain respects from the given design

1.3.8

running test

test repeated at frequent intervals to provide data for assessment

1.3.9

batch

all the lamps of one family and/or group identified as such and put forward at one time for

testing to check compliance

1.3.10

whole production

production during a period of twelve months of all types of lamps within the scope of this

standard and nominated in a list of the manufacturer for inclusion in the certificate

– 12 – 61195 © CEI:1999

2 Prescriptions de sécurité

2.1 Généralités

Les lampes doivent être conçues et construites de telle sorte qu'elles ne présentent en

utilisation normale aucun danger pour l'usager ou l'environnement.

D'une manière générale, la conformité est vérifiée en exécutant tous les contrôles spécifiés.

NOTE – Lorsque le contrôle peut sans nécessité devenir difficile en raison de la longueur des lampes, le fournisseur et

l'autorité de certification peuvent s'entendre pour appliquer des méthodes permettant d'atténuer la difficulté.

2.2 Marquage

2.2.1 Les renseignements suivants doivent être marqués sur les lampes de manière durable

et lisible:

a) marque d'origine (elle peut prendre la forme d'une marque commerciale, du nom du

fabricant ou de celui du vendeur responsable);

b) puissance nominale (marquée «W» ou «watts») ou toute autre indication identifiant la

lampe.

NOTE – Dans certains pays, la longueur de la lampe est marquée au lieu de la puissance.

2.2.2 La conformité est contrôlée comme suit:

a) présence et lisibilité de la marque par inspection visuelle;

b) durabilité du marquage en appliquant l'essai suivant à des lampes neuves.

La zone du marquage des lampes doit être frottée à la main au moyen d'un chiffon doux imbibé

d'eau pendant une période de 15 s.

Après l'exécution de cet essai, le marquage doit être encore lisible.

2.3 Prescriptions de résistance mécanique des culots

2.3.1 Construction et assemblage

Les culots doivent être construits et assemblés aux ampoules de manière qu'ils demeurent liés

à celles-ci durant et après le fonctionnement des lampes.

La conformité est vérifiée au moyen des essais suivants:

2.3.1.1 Pour les types de lampes utilisant les culots G5, G13 et R17d:

a) pour des lampes neuves, la conformité est vérifiée en appliquant l'essai de torsion des

broches comme suit:

– le culot de la lampe doit rester fermement fixé à l'ampoule et aucun déplacement

angulaire supérieur à 6° ne doit se produire entre les parties composant le culot,

lorsque sont appliqués les couples dont les niveaux figurent au tableau 1.

61195 © IEC:1999 – 13 –

2 Safety requirements

2.1 General

Lamps shall be so designed and constructed that in normal use they present no danger to the

user or surroundings.

In general, compliance is checked by carrying out all the tests specified.

NOTE – Where testing can become unnecessarily difficult due to the lamp length, methods to alleviate the problem

may be agreed between the supplier and the certification authority.

2.2 Marking

2.2.1 The following information shall be legibly and durably marked on the lamps:

a) mark of origin (this may take the form of a trade mark, the manufacturer's name or the

name of the responsible vendor);

b) the nominal wattage (marked "W" or "watts") or any other indication which identifies the

lamp.

NOTE – In some countries, the length of the lamp is marked in place of the wattage.

2.2.2

Compliance is checked by the following:

a) presence and legibility of the marking by visual inspection;

b) durability of marking by applying the following test on unused lamps.

The area of the marking on the lamp shall be rubbed by hand with a smooth cloth dampened

with water for a period of 15 s.

After this test, the marking shall still be legible.

2.3 Mechanical requirements for caps

2.3.1 Construction and assembly

Caps shall be so constructed and assembled to the bulbs that they remain attached during and

after operation.

Compliance is checked by the following tests:

2.3.1.1

For lamp types using caps G5, G13 and R17d:

a) for unused lamps compliance is checked by applying a torque test to the pins, as follows:

– the lamp cap shall remain firmly attached to the bulb and there shall be no rotational

movement between component parts of the cap exceeding an angular displacement

of 6° when subjected to the torque levels listed in table 1.

– 14 – 61195 © CEI:1999

Tableau 1 – Valeurs des couples pour les lampes neuves

Type de culot Valeur du couple

Nm

G5 0,5

G13 1,0

R17d 1,0

Le couple ne doit pas être appliqué brusquement mais doit être augmenté progressivement

de zéro à la valeur spécifiée dans le tableau 1.

Les douilles d'essai destinées à l'application du couple de torsion sont décrites à

l'annexe A. La douille d'essai correspondant au culot R17d est à l'étude;

b) après avoir subi un traitement de chauffage pendant une période de 2 000 h ± 50 h à la

température de 120 °C ± 5 °C, le culot doit rester fermement lié à l'ampoule et aucun

déplacement angulaire excédant 6° ne doit se produire entre les parties composant le culot

lorsque celui-ci est soumis aux couples des niveaux spécifiés au tableau 2.

Pour les lampes munies de culots G13 et de puissance nominale supérieure à 40 W, le

traitement thermique doit être effectué à la température de 140 °C ± 5 °C.

Tableau 2 – Valeurs des couples à appliquer après traitement de chauffage

Type de culot Valeur du couple

Nm

G5 0,3

G13 0,6

R17d 0,6

2.3.1.2

Pour les types de lampes utilisant des culots Fa6 et Fa8, la conformité est vérifiée par

l'inspection de lampes neuves.

2.3.1.3 Pour les types de lampes utilisant des culots 2G13:

a) pour des lampes neuves, le culot de la lampe doit rester fermement fixé à l’ampoule lorsque

sont appliqués une traction axiale de 40 N ou un moment de flexion de 3 Nm. Le moment de

flexion doit être appliqué en maintenant de façon uniforme la partie des tubes de verre la plus

proche du culot, le centre de rotation étant situé dans le plan de référence du culot (plan au

contact de la douille). La force de traction et le moment de flexion ne doivent pas être appliqués

brusquement mais doivent être augmentés progressivement de zéro à la valeur spécifiée;

±

b) après avoir subi un traitement de chauffage pendant une période de 2 000 h 50 h à la

±

température de 120 °C 5 °C, le culot doit rester fermement fixé à l’ampoule lorsque sont

appliqués des forces de traction et des moments de flexion qui sont à l’étude.

2.3.2 Prescriptions dimensionnelles pour les culots

2.3.2.1 Les lampes doivent être équipées de culots normalisés conformes aux prescriptions

de la CEI 60061-1.

61195 © IEC:1999 – 15 –

Table 1 – Torque values for unused lamps

Cap type Torque value

Nm

G5 0,5

G13 1,0

R17d 1,0

The torque shall not be applied suddenly but shall be increased progressively from zero to

the value specified in table 1.

The test holders for the application of the torque are shown in annex A. The test holder for

the R17d cap is under consideration;

b) following a heating treatment for a period of 2 000 h ± 50 h at a temperature of 120 °C ± 5 °C,

the cap shall remain firmly attached to the bulb and there shall be no rotational movement

between component parts of the cap exceeding an angular displacement of 6° when

subjected to the torque levels specified in table 2.

For G13 capped lamps with a nominal wattage greater than 40 W, the heating shall be

performed at a temperature of 140 °C ± 5 °C.

Table 2 – Torque values after heating treatment

Cap type Torque value

Nm

G5 0,3

G13 0,6

R17d 0,6

2.3.1.2

For lamp types using caps Fa6 and Fa8, compliance is checked by inspection on

unused lamps.

2.3.1.3 For lamp types using cap 2G13:

a) for unused lamps the cap shall remain firmly attached to the bulb when subjected to an axial pull

of 40 N or a bending moment of 3 Nm. The bending moment shall be applied by holding in a

uniform manner that part of the glass tubes closest to the cap, the pivot point lying at the cap

reference plane (mating plane with the lampholder). The pulling force and bending moment shall

not be applied suddenly but shall be increased gradually from zero to the specified value;

b) following a heating treatment for a period of 2 000 h ± 50 h at a temperature of 120 °C ± 5 °C, the

cap shall remain firmly attached to the bulb when subjected to the pulling forces and

bending moments which are under consideration.

2.3.2 Dimensional requirements for caps

2.3.2.1 Lamps shall use standardized caps in accordance with the requirements of

IEC 60061-1.

– 16 – 61195 © CEI:1999

2.3.2.2 La conformité est vérifiée en utilisant les calibres indiqués au tableau 3.

Tableau 3 – Feuilles de référence des feuilles de la CEI 60061

Numéros des feuilles

Type de culot

CEI 60061-1 CEI 60061-3

Culot de lampe Calibre

G13 7004-51 7006-45

G5 7004-52 7006-46A

Fa6 7004-55 7006-41

R17d 7004-56 7006-57

Fa8 7004-57 7006-40/7006-40A

2G13 7004-33 7006-33

2.4 Résistance d'isolement

2.4.1 La résistance d'isolement entre la chemise métallique du culot et la ou les broches ou

les contacts ne doit pas être inférieure à 2 MΩ.

2.4.2 La conformité est vérifiée par des mesures et au moyen d'un équipement d'essai

convenable utilisant une tension continue de 500 V.

2.5 Rigidité diélectrique

2.5.1 Ce contrôle ne doit pas être appliqué aux lampes munies de culots à résistance interne.

2.5.2 L'isolement entre la chemise du culot et la ou les broches ou les contacts doit résister à

la tension d'essai. Aucun contournement ou claquage ne doit se produire durant l'essai.

2.5.3

La conformité est vérifiée avec une tension alternative de 1 500 V de forme réellement

sinusoïdale, d'une fréquence de 50 Hz ou 60 Hz à appliquer pendant 1 min. La tension

initialement appliquée ne doit pas dépasser la moitié de la valeur prescrite; elle doit ensuite

être augmentée rapidement jusqu'à la valeur prescrite.

Les décharges en régime de lueur, sans chute de tension, sont négligées.

2.6 Parties pouvant devenir accidentellement sous tension

2.6.1 Les parties métalliques destinées à être isolées des parties sous tension ne doivent pas

être ni devenir sous tension.

2.6.2 Exception faite des broches du culot, aucune partie sous tension ne doit faire saillie

d'aucune partie du culot.

2.6.3

La conformité est vérifiée au moyen d’un système de mesure convenable qui peut

inclure, si applicable, un contrôle visuel. En outre, des contrôles réguliers journaliers des

équipements ou une vérification de l’efficacité du contrôle doivent être effectués. Voir 3.5.4.

61195 © IEC:1999 – 17 –

2.3.2.2 Compliance is checked by using the gauges shown in table 3.

Table 3 – Sheet references of IEC 60061

Sheet numbers

Cap type

IEC 60061-1 IEC 60061-3

Lamp caps Gauges

G13 7004-51 7006-45

G5 7004-52 7006-46A

Fa6 7004-55 7006-41

R17d 7004-56 7006-57

Fa8 7004-57 7006-40/7006-40A

2G13 7004-33 7006-33

2.4 Insulation resistance

2.4.1 The insulation resistance between the metal shell of the cap and the pin(s) or contacts

shall not be less than 2 MΩ.

2.4.2 Compliance is checked by measurement with suitable test equipment using a d.c.

voltage of 500 V.

2.5 Electric strength

2.5.1 This test shall not apply to lamps having caps with internal resistors.

2.5.2 The insulation between the shell of the cap and the pin(s) or contacts shall withstand

the test voltage. No flash-over or breakdown shall occur during the test.

2.5.3

Compliance is checked with a 1 500 V a.c. voltage of substantially sine-wave form,

with a frequency of 50 Hz or 60 Hz and applied for 1 min. Initially, not more than half the

prescribed voltage shall be applied; it shall then be raised rapidly to the full value.

Glow discharges without a drop in voltage are neglected.

2.6 Parts which can become accidentally live

2.6.1

Metal parts intended to be insulated from live parts shall not be or become live.

2.6.2

With the exception of cap pins no live part shall project from any part of the cap.

2.6.3 Compliance is checked by a suitable measuring system which may include visual

inspection where appropriate. In addition, there shall be regular daily checks of the equipment

or a verification of the effectiveness of the inspection. See 3.5.4.

– 18 – 61195 © CEI:1999

2.7 Résistance à la chaleur et au feu

2.7.1 Le matériau isolant des culots doit être résistant à la chaleur.

2.7.2 La conformité est vérifiée au moyen de l'essai suivant.

Les échantillons sont testés dans une étuve à la température de 125 °C ± 5 °C pendant une

période de 168 h.

Les échantillons de culots G13 de lampes ayant une puissance nominale supérieure à 40 W,

sont essayés à la température de 140 °C ± 5 °C.

A la fin de l'essai, les échantillons ne doivent avoir subi aucun changement mettant en cause la

fonction de sécurité qu'ils doivent assurer, surtout en ce qui concerne les points suivants:

– réduction de la protection contre les chocs électriques selon les exigences de 2.4 et 2.5;

– jeu dans les broches des culots, fêlures, gonflement et rétrécissement, à constater par

inspection visuelle.

A la fin de l'essai, les dimensions doivent être conformes aux prescriptions de 2.3.2.

2.7.3 Les parties externes du matériau isolant doivent résister à une chaleur anormale et au feu.

2.7.4 La conformité est vérifiée au moyen de l'essai suivant.

Les parties sont soumises à un essai au fil de nickel-chrome incandescent, chauffé à 650 °C.

L'appareil d'essai doit être celui décrit dans la CEI 60695-2-1/0.

L'échantillon à tester est monté verticalement sur le chariot et pressé contre l'extrémité du fil

incandescent avec une force de 1 N, de préférence à 15 mm ou plus du bord supérieur de

l'échantillon. La pénétration du fil incandescent dans l'échantillon est limitée mécaniquement à

7 mm. Le contact entre l'échantillon et l'extrémité du fil incandescent est interrompu après 30 s.

Toute flamme ou incandescence de l'échantillon doit s'éteindre dans les 30 s qui suivent le

retrait du fil incandescent, et les gouttes de matière fondue ou enflammée ne doivent pas

communiquer le feu à un ensemble de cinq couches de papier de soie dépliées horizontale-

ment à 200 mm ± 5 mm sous l'échantillon.

La température du fil incandescent et le courant de chauffage doivent demeurer constants

pendant la minute qui précède le début de l'essai. On doit prendre soin à ce que la chaleur

radiée n'influence pas le comportement de l'échantillon pendant cette période. La température

de l'extrémité du fil incandescent est mesurée au moyen d'un couple thermoélectrique à fil fin

gainé, construit et étalonné comme indiqué dans la CEI 60695-2-1/0.

NOTE – Il convient de prendre des précautions pour préserver la santé du personnel chargé de l'essai, contre les risques

– d'explosion ou de feu;

– d'inhalation de fumée et/ou de produits toxiques;

– de résidus toxiques.

2.8 Lignes de fuite des culots

2.8.1 La longueur minimale des lignes de fuite entre la ou les broches ou contacts et la

chemise du culot doit être conforme aux prescriptions de la CEI 60061-1. Les numéros des

feuilles de norme des culots correspondants sont donnés au tableau 3.

2.8.2

La conformité est vérifiée par une mesure, dans la position la plus défavorable.

61195 © IEC:1999 – 19 –

2.7 Resistance to heat and fire

2.7.1 Insulating material of caps shall be resistant to heat.

2.7.2 Compliance is checked by the following test.

Samples are tested in a heating cabinet at a temperature of 125 °C ± 5 °C for a period of 168 h.

For G13 caps to be used on lamps with a nominal wattage greater than 40 W, the samples

shall be tested at a temperature of 140 °C ± 5 °C.

At the end of the test, the samples shall not have undergone any change impairing their further

safety, especially in the following respects:

– reduction in the protection against electric shock as required in 2.4 and 2.5;

– loosening of cap pins, cracks, swelling and shrinking as determined by visual inspection.

At the end of the test, the dimensions shall comply with the requirements of 2.3.2.

2.7.3 External parts of insulating material shall be resistant to abnormal heat and to fire.

2.7.4 Compliance is checked by the following test.

Parts are subjected to a test using a nickel-chromium glow-wire heated to 650 °C. The test

apparatus shall be that described in IEC 60695-2-1/0.

The sample to be tested is mounted vertically on the carriage and pressed against the glow-

wire tip with a force of 1 N, preferably 15 mm or more from the upper edge of the sample. The

penetration of the glow-wire into the sample is mechanically limited to 7 mm. After 30 s the

sample is withdrawn from contact with the glow-wire tip.

Any flame or glowing of the sample shall extinguish within 30 s of withdrawing the glow-wire

and any burning or molten drop shall not ignite a piece of tissue paper consisting of five layers

spread out horizontally 200 mm ± 5 mm belo

...

IEC 61195 ®

Edition 2.2 2014-09

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Double-capped fluorescent lamps – Safety specifications

Lampes à fluorescence à deux culots – Prescriptions de sécurité

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC Plus de 55 000 entrées terminologiques électrotechniques, en

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 61195 ®

Edition 2.2 2014-09

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Double-capped fluorescent lamps – Safety specifications

Lampes à fluorescence à deux culots – Prescriptions de sécurité

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.140.30 ISBN 978-2-8322-1859-4

IEC 61195 ®

Edition 2.2 2014-09

CONSOLIDATED VERSION

REDLINE VERSION

VERSION REDLINE

colour

inside

Double-capped fluorescent lamps – Safety specifications

Lampes à fluorescence à deux culots – Prescriptions de sécurité

– 2 – IEC 61195:1999

+AMD1:2012+AMD2:2014 CSV © IEC 2014

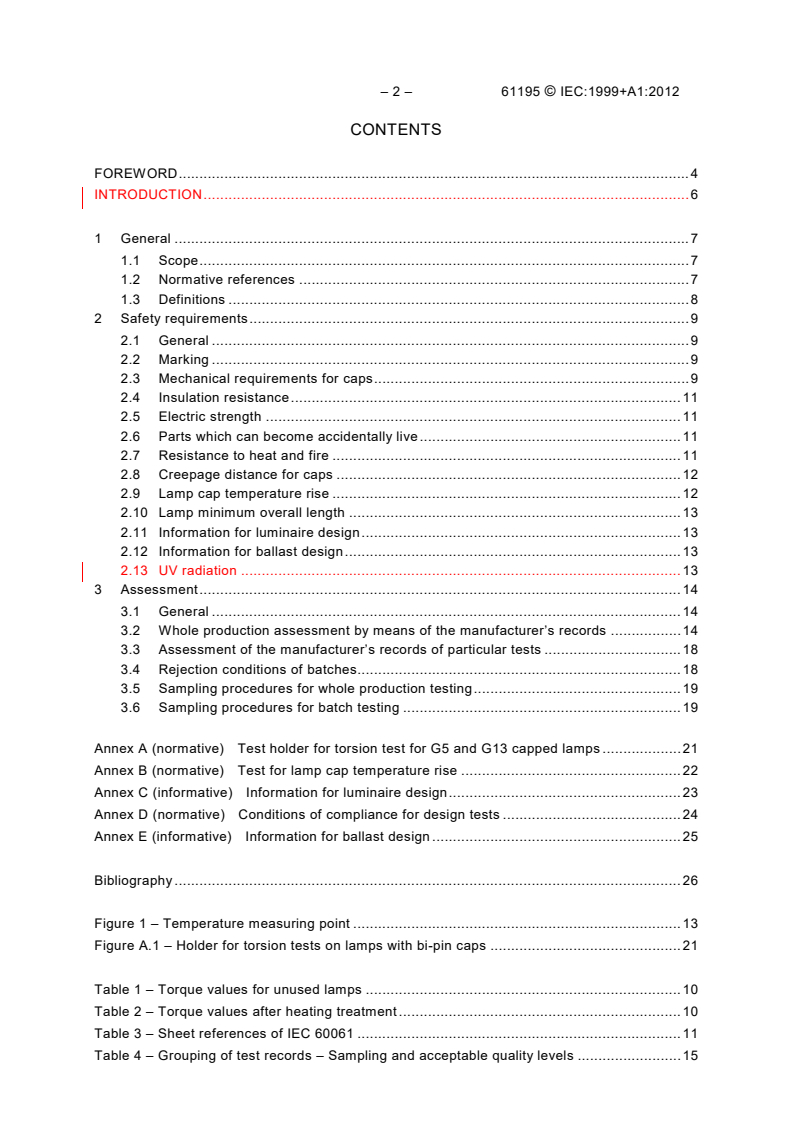

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 General . 6

1.1 Scope . 6

1.2 Normative references . 6

1.3 Definitions . 7

2 Safety requirements . 8

2.1 General . 8

2.2 Marking . 8

2.3 Mechanical requirements for caps . 8

2.4 Insulation resistance . 10

2.5 Electric strength . 10

2.6 Parts which can become accidentally live . 10

2.7 Resistance to heat and fire . 10

2.8 Creepage distance for caps . 11

2.9 Lamp cap temperature rise . 11

2.10 Lamp minimum overall length . 12

2.11 Information for luminaire design . 12

2.12 Information for ballast design . 12

2.13 UV radiation . 12

3 Assessment . 13

3.1 General . 13

3.2 Whole production assessment by means of the manufacturer’s records . 13

3.3 Assessment of the manufacturer’s records of particular tests . 17

3.4 Rejection conditions of batches . 17

3.5 Sampling procedures for whole production testing . 18

3.6 Sampling procedures for batch testing . 18

Annex A (normative) Test holder for torsion test for G5 and G13 capped lamps . 20

Annex B (normative) Test for lamp cap temperature rise . 21

Annex C (informative) Information for luminaire design . 22

Annex D (normative) Conditions of compliance for design tests . 23

Annex E (informative) Information for ballast design . 24

Bibliography . 25

+AMD1:2012+AMD2:2014 CSV © IEC 2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

DOUBLE-CAPPED FLUORESCENT LAMPS –

SAFETY SPECIFICATIONS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendments has been

prepared for user convenience.

IEC 61195 edition 2.2 contains the second edition (1999-10) [documents 34A/886/FDIS

and 34A/900/RVD], its amendment 1 (2012-10) [documents 34A/1536/CDV and 34A/1577/

RVC] and its amendment 2 (2014-09) [documents 34A/1739/CDV and 34A/1778/RVC].

In this Redline version, a vertical line in the margin shows where the technical content

is modified by amendments 1 and 2. Additions and deletions are displayed in red, with

deletions being struck through. A separate Final version with all changes accepted is

available in this publication.

– 4 – IEC 61195:1999

+AMD1:2012+AMD2:2014 CSV © IEC 2014

International Standard IEC 61195 has been prepared by sub-committee 34A: Lamps, of IEC

technical committee 34: Lamps and related equipment.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

Annexes A, B and D form an integral part of this standard.

Annexes C and E are for information only.

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of August 2000 have been included in this copy.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

+AMD1:2012+AMD2:2014 CSV © IEC 2014

INTRODUCTION

The standards IEC 62471 and IEC/TR 62471-2 contain horizontal requirements available that

need to be introduced into product standards, e.g. to IEC 61195.

The horizontal requirements are transformed into requirements for double-capped fluorescent

lamps.

The lamps within the scope of this standard are general lighting service (GLS) lamps according

to the definition 3.11 of IEC 62471:2006,".lamps intended for lighting spaces that are typically

occupied or viewed by people."

According to Clause 6 of IEC 62471:2006, radiation of GLS lamps is measured at a distance

equivalent to 500 lx.

Measured at the 500 lx distance, GLS lamps will not exceed risk group 1 for blue light hazard

and risk group 0 for IR radiation. This combination of risk group and hazard does not require

marking (Table 1 of IEC/TR 62471-2:2009).

Hazards from UV radiation of GLS lamps are now covered in 2.13 of IEC 61195.

Hence, IEC 62471 does not require any additional marking for GLS lamps.

– 6 – IEC 61195:1999

+AMD1:2012+AMD2:2014 CSV © IEC 2014

DOUBLE-CAPPED FLUORESCENT LAMPS –

SAFETY SPECIFICATIONS

1 General

1.1 Scope

This International Standard specifies the safety requirements for double-capped fluorescent

lamps for general lighting purposes of all groups having Fa6, Fa8, G5, G13, 2G13, R17d and

W4.3×8.5d caps.

It also specifies the method a manufacturer should use to show compliance with the

requirements of this standard on the basis of whole production appraisal in association with his

test records on finished products. This method can also be applied for certification purposes.

Details of a batch test procedure which can be used to make limited assessment of batches

are also given in this standard.

This part of the standard covers photobiological safety according to IEC 62471 and

IEC/TR 62471-2.

Blue light and infrared hazards are below the level which requires marking.

NOTE – Compliance with this standard concerns only safety criteria and does not take into account the

performance of double-capped fluorescent lamps for general lighting purposes with respect to luminous flux, colour,

starting and operational characteristics. Readers are referred to IEC 60081 for such characteristics.

1.2 Normative references

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this International Standard. For dated references, subsequent

amendments to, or revisions of, any of these publications do not apply. However, parties to

agreements based on this International Standard are encouraged to investigate the possibility

of applying the most recent editions of the normative documents indicated below. For undated

references, the latest edition of the normative document referred to applies. Members of IEC

and ISO maintain registers of currently valid International Standards.

IEC 60061-1, Lamp caps and holders together with gauges for the control of

interchangeability and safety – Part 1: Lamp caps

IEC 60061-2, Lamp caps and holders together with gauges for the control of interchangeability

and safety – Part 2: Lampholders

IEC 60061-3, Lamp caps and holders together with gauges for the control of

interchangeability and safety – Part 3: Gauges

IEC 60081, Double-capped fluorescent lamps – Performance specifications

IEC 60410, Sampling plans and procedures for inspection by attributes

IEC 60695-2-1/0, Fire hazard testing – Part 2: Test methods – Section 1/sheet 0: Glow-wire

test methods – General

IEC 60921, Ballasts for tubular fluorescent lamps – Performance requirements

+AMD1:2012+AMD2:2014 CSV © IEC 2014

1.3 Definitions

For the purposes of this International Standard, the following definitions apply.

1.3.1

double-capped fluorescent lamp

double-capped low-pressure mercury discharge lamp of tubular form in which most of the light

is emitted by a layer of fluorescent material excited by the ultra-violet radiation from the

discharge

1.3.2

group

lamps having the same electrical and cathode characteristics, the same physical dimensions

and the same starting method

1.3.3

type

lamps of the same group having the same photometric and colour characteristics

1.3.4

family

lamp groups which are distinguished by common features of materials, components, lamp

diameter and/or method of processing

1.3.5

nominal wattage

wattage used to designate the lamp

1.3.6

design test

test made on a sample for the purpose of checking compliance of the design of a family, group

or a number of groups with the requirements of the relevant clause

1.3.7

periodic test

test, or series of tests, repeated at intervals in order to check that the product does not deviate

in certain respects from the given design

1.3.8

running test

test repeated at frequent intervals to provide data for assessment

1.3.9

batch

all the lamps of one family and/or group identified as such and put forward at one time for

testing to check compliance

1.3.10

whole production

production during a period of twelve months of all types of lamps within the scope of this

standard and nominated in a list of the manufacturer for inclusion in the certificate

1.3.11

specific effective radiant UV power

effective power of the UV radiation of a lamp related to its luminous flux

– 8 – IEC 61195:1999

+AMD1:2012+AMD2:2014 CSV © IEC 2014

NOTE 1 Specific effective radiant UV power is expressed in mW/klm.

NOTE 2 The effective power of the UV radiation is obtained by weighting the spectral power distribution of the lamp

with the UV hazard function S (λ). Information about the relevant UV hazard function is given in IEC 62471. It only

UV

relates to possible hazards regarding UV exposure of human beings. It does not deal with the possible influence of

optical radiation on materials, like mechanical damage or discoloration.

2 Safety requirements

2.1 General

Lamps shall be so designed and constructed that in normal use they present no danger to the

user or surroundings.

In general, compliance is checked by carrying out all the tests specified.

NOTE – Where testing can become unnecessarily difficult due to the lamp length, methods to alleviate the problem

may be agreed between the supplier and the certification authority.

2.2 Marking

2.2.1 The following information shall be legibly and durably marked on the lamps:

a) mark of origin (this may take the form of a trade mark, the manufacturer's name or the

name of the responsible vendor);

b) the nominal wattage (marked "W" or "watts") or any other indication which identifies the

lamp.

NOTE – In some countries, the length of the lamp is marked in place of the wattage.

2.2.2 Compliance is checked by the following:

a) presence and legibility of the marking by visual inspection;

b) durability of marking by applying the following test on unused lamps.

The area of the marking on the lamp shall be rubbed by hand with a smooth cloth dampened

with water for a period of 15 s.

After this test, the marking shall still be legible.

2.3 Mechanical requirements for caps

2.3.1 Construction and assembly

Caps shall be so constructed and assembled to the bulbs that they remain attached during and

after operation.

Compliance is checked by the following tests:

2.3.1.1 For lamp types using caps G5, G13 and R17d:

a) for unused lamps compliance is checked by applying a torque test to the pins, as follows:

– the lamp cap shall remain firmly attached to the bulb and there shall be no rotational

movement between component parts of the cap exceeding an angular displacement

of 6° when subjected to the torque levels listed in table 1.

+AMD1:2012+AMD2:2014 CSV © IEC 2014

Table 1 – Torque values for unused lamps

Cap type Torque value

Nm

G5 0,5

G13 1,0

R17d 1,0

The torque shall not be applied suddenly but shall be increased progressively from zero to

the value specified in table 1.

The test holders for the application of the torque are shown in annex A. The test holder for

the R17d cap is under consideration;

b) following a heating treatment for a period of 2 000 h ± 50 h at a temperature of 120 °C ± 5 °C,

the cap shall remain firmly attached to the bulb and there shall be no rotational movement

between component parts of the cap exceeding an angular displacement of 6° when

subjected to the torque levels specified in table 2.

For G13 capped lamps with a nominal wattage greater than 40 W, the heating shall be

performed at a temperature of 140 °C ± 5 °C.

Table 2 – Torque values after heating treatment

Cap type Torque value

Nm

G5 0,3

G13 0,6

R17d 0,6

2.3.1.2 For lamp types using caps Fa6 and Fa8, compliance is checked by inspection on

unused lamps.

2.3.1.3 For lamp types using cap 2G13:

a) for unused lamps the cap shall remain firmly attached to the bulb when subjected to an axial pull

of 40 N or a bending moment of 3 Nm. The bending moment shall be applied by holding in a

uniform manner that part of the glass tubes closest to the cap, the pivot point lying at the cap

reference plane (mating plane with the lampholder). The pulling force and bending moment shall

not be applied suddenly but shall be increased gradually from zero to the specified value;

b) following a heating treatment for a period of 2 000 h ± 50 h at a temperature of 120 °C ± 5 °C, the

cap shall remain firmly attached to the bulb when subjected to the pulling forces and

bending moments which are under consideration.

2.3.2 Dimensional requirements for caps

2.3.2.1 Lamps shall use standardized caps in accordance with the requirements of

IEC 60061-1.

2.3.2.2 Compliance is checked by using the gauges shown in table 3.

2.3.3 System requirements

Where a cap sheet as specified in IEC 60061-1 includes information on system requirements,

lamps shall not exceed the limits specified.

Compliance is checked by measurement.

– 10 – IEC 61195:1999

+AMD1:2012+AMD2:2014 CSV © IEC 2014

Table 3 – Sheet references of IEC 60061

Sheet numbers

Cap type

IEC 60061-1 IEC 60061-3

Lamp caps Gauges

G13 7004-51 7006-45

G5 7004-52 7006-46A

Fa6 7004-55 7006-41

R17d 7004-56 7006-57

Fa8 7004-57 7006-40/7006-40A

2G13 7004-33 7006-33

2.4 Insulation resistance

2.4.1 The insulation resistance between the metal shell of the cap and the pin(s) or contacts

shall not be less than 2 MΩ.

2.4.2 Compliance is checked by measurement with suitable test equipment using a d.c.

voltage of 500 V.

2.5 Electric strength

2.5.1 This test shall not apply to lamps having caps with internal resistors.

2.5.2 The insulation between the shell of the cap and the pin(s) or contacts shall withstand

the test voltage. No flash-over or breakdown shall occur during the test.

2.5.3 Compliance is checked with a 1 500 V a.c. voltage of substantially sine-wave form,

with a frequency of 50 Hz or 60 Hz and applied for 1 min. Initially, not more than half the

prescribed voltage shall be applied; it shall then be raised rapidly to the full value.

Glow discharges without a drop in voltage are neglected.

2.6 Parts which can become accidentally live

2.6.1 Metal parts intended to be insulated from live parts shall not be or become live.

2.6.2 With the exception of cap pins no live part shall project from any part of the cap.

2.6.3 Compliance is checked by a suitable measuring system which may include visual

inspection where appropriate. In addition, there shall be regular daily checks of the equipment

or a verification of the effectiveness of the inspection. See 3.5.4.

2.7 Resistance to heat and fire

2.7.1 Insulating material of caps shall be resistant to heat.

2.7.2 Compliance is checked by the following test.

Samples are tested in a heating cabinet at a temperature of 125 °C ± 5 °C for a period of 168 h.

+AMD1:2012+AMD2:2014 CSV © IEC 2014

For G13 caps to be used on lamps with a nominal wattage greater than 40 W, the samples

shall be tested at a temperature of 140 °C ± 5 °C.

At the end of the test, the samples shall not have undergone any change impairing their further

safety, especially in the following respects:

– reduction in the protection against electric shock as required in 2.4 and 2.5;

– loosening of cap pins, cracks, swelling and shrinking as determined by visual inspection.

At the end of the test, the dimensions shall comply with the requirements of 2.3.2.

2.7.3 External parts of insulating material shall be resistant to abnormal heat and to fire.