IEC 60519-6:2011

(Main)Safety in electroheat installations - Part 6: Specifications for safety in industrial microwave heating equipment

Safety in electroheat installations - Part 6: Specifications for safety in industrial microwave heating equipment

IEC 60519-6:2011 is applicable to equipment using microwave energy alone or in combination with other kinds of energy for industrial heating of materials. This part is applicable to industrial microwave heating equipment operating in the frequency range 300 MHz to 300 GHz. This third edition cancels and replaces the second edition published in 2002 and constitutes a technical revision. The significant changes with respect to the previous edition are as follows:

- the third edition of IEC 60519-1:2003 has been taken into account (the structure of clauses was adapted to it as far as practicable);

- some definitions are modified or brought into line with IEC 60050-841:2004;

- clauses on abnormal operation, access openings, microwave enclosure and barriers are added;

- the microwave leakage measurements are in a normative Annex A;

- an informative Annex B on the rationales for microwave exposure and leakage limits is added;

- Bibliography is added.

This publication is to be read in conjunction with IEC 60519-1:2003.

Sécurité dans les installations électrothermiques - Partie 6: Spécifications pour les installations de chauffage industriel à hyperfréquences

La CEI 60519-6:2011 est applicable aux installations qui utilisent l'énergie à hyperfréquences, seule ou en combinaison avec d'autres formes d'énergie pour le chauffage industriel des matériaux. La présente partie est applicable aux installations électrothermiques industrielles fonctionnant dans la plage de fréquences comprises entre 300 MHz et 300 GHz. Cette troisième édition annule et remplace la deuxième édition parue en 2002, dont elle constitue une révision technique. Les modifications techniques significatives par rapport à l'édition précédente sont les suivantes:

- la troisième édition de la CEI 60519-1:2003 a été prise en compte (la structure des articles a été adaptée à celle-ci dans la mesure du possible);

- certaines définitions ont été modifiées ou alignées avec la CEI 60050-841:2004;

- des articles concernant un fonctionnement anormal, les ouvertures d'accès, l'enceinte hyperfréquences et les barrages ont été ajoutés;

- les mesures de la fuite d'hyperfréquences se trouvent dans une Annexe normative A;

- une Annexe informative B concernant les justifications des limites d'exposition aux hyperfréquences et des fuites d'hyperfréquences a été ajoutée;

- une bibliographie a été ajoutée.

Cette publication doit être lue conjointement avec la CEI 60519-1:2003.

General Information

- Status

- Published

- Publication Date

- 26-Jan-2011

- Technical Committee

- TC 27 - Industrial electroheating and electromagnetic processing

- Drafting Committee

- MT 23 - TC 27/MT 23

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 20-Jan-2022

- Completion Date

- 01-Dec-2017

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60519-6:2011 is an international standard published by the International Electrotechnical Commission (IEC) that specifies safety requirements for industrial microwave heating equipment. This standard applies to electroheat installations using microwave energy alone or in combination with other energy sources for industrial heating in the frequency range of 300 MHz to 300 GHz.

The third edition of IEC 60519-6:2011 is a technical revision that updates and replaces the previous edition from 2002. It aligns its structure with IEC 60519-1:2003 and introduces new or revised clauses related to abnormal operation, access safety, microwave enclosures, and leakage measurements.

IEC 60519-6:2011 is focused on industrial applications and should be used in conjunction with IEC 60519-1:2003 to ensure comprehensive safety in electroheat installations. It excludes household, commercial, and laboratory microwave appliances, which are covered under different standards.

Key Topics

Scope and Applicability

This standard is applicable to industrial microwave heating equipment designed for processing materials in industrial settings. It covers equipment that operates primarily at ISM frequency bands (800 MHz to 6 GHz), including 2.45 GHz and 5.8 GHz, which are common in industrial microwave applications.Safety Requirements

The standard provides detailed specifications for protecting operators and equipment from hazards associated with microwave energy, including electrical shock, thermal effects, fire, and explosion risks. It addresses:- Equipment isolation and electrical switching

- Connection to supply networks and internal wiring integrity

- Protection against overcurrent and electric shock

- Equipotential bonding to mitigate electrical hazards

- Control circuit design for safe operation and emergency shutdown

- Thermal influence precautions and fire/explosion risk management

Microwave Leakage Control

Annex A of the standard mandates normative measurement methods to assess microwave leakage levels from industrial equipment. Annex B provides informative guidance on the rationale behind microwave exposure limits, establishing appropriate safety barriers to prevent harmful microwave radiation escape.Markings and Documentation

IEC 60519-6:2011 specifies requirements for warning labels, technical documentation, and user instructions to support safe inspection, commissioning, and maintenance of industrial microwave heating systems.Terminology and Classifications

The standard defines key terms such as microwave generator, applicator, cavity, load, and leakage to ensure consistent understanding. It also includes classifications based on operating voltage and frequency bands for electroheat equipment.

Applications

Industrial microwave heating equipment standardized by IEC 60519-6:2011 is widely used across various sectors, providing efficient heating, drying, curing, and processing of materials including:

- Food processing industries for pasteurization and drying

- Chemical manufacturing for heating reactants and catalysts

- Textile and paper industries for drying and bonding processes

- Rubber and plastics industries for vulcanization and curing

- Ceramic and composite materials production requiring precise heating control

Adherence to IEC 60519-6:2011 ensures these applications operate safely, minimizing risks associated with microwave exposure and electrical hazards. The standard supports equipment manufacturers, safety engineers, facility managers, and regulatory bodies in implementing best practices for industrial microwave heating safety.

Related Standards

IEC 60519-1:2003 - General requirements for safety in electroheat installations; IEC 60519-6:2011 is to be used alongside this Part 1 standard for complete safety compliance.

IEC 60050-841:2004 - Provides industrial electroheat vocabulary and definitions referenced extensively in IEC 60519-6.

IEC 62311 - Addresses assessment of electronic and electrical equipment related to human exposure limits for electromagnetic fields, relevant for certain microwave frequencies outside IEC 60519-6’s leakage measurement scope.

IEC 60335-2-25 - Safety standards for household microwave ovens, differentiating industrial and consumer equipment classification.

IEC 60335-2-90 - Covers safety requirements for commercial microwave ovens used in professional kitchens.

IEC 61010-2-010 - Safety standards for laboratory microwave equipment, distinct from industrial applications.

Utilizing IEC 60519-6:2011 with these complementary standards ensures robust safety frameworks tailored for diverse microwave heating equipment categories and operating environments.

By implementing IEC 60519-6:2011, organizations benefit from internationally recognized safety specifications that protect personnel, equipment, and products while optimizing industrial microwave heating processes. The standard’s detailed requirements and measurement protocols establish critical controls for mitigating microwave leakage and electrical risks, supporting safe and efficient industrial operations worldwide.

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

IEC 60519-6:2011 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Safety in electroheat installations - Part 6: Specifications for safety in industrial microwave heating equipment". This standard covers: IEC 60519-6:2011 is applicable to equipment using microwave energy alone or in combination with other kinds of energy for industrial heating of materials. This part is applicable to industrial microwave heating equipment operating in the frequency range 300 MHz to 300 GHz. This third edition cancels and replaces the second edition published in 2002 and constitutes a technical revision. The significant changes with respect to the previous edition are as follows: - the third edition of IEC 60519-1:2003 has been taken into account (the structure of clauses was adapted to it as far as practicable); - some definitions are modified or brought into line with IEC 60050-841:2004; - clauses on abnormal operation, access openings, microwave enclosure and barriers are added; - the microwave leakage measurements are in a normative Annex A; - an informative Annex B on the rationales for microwave exposure and leakage limits is added; - Bibliography is added. This publication is to be read in conjunction with IEC 60519-1:2003.

IEC 60519-6:2011 is applicable to equipment using microwave energy alone or in combination with other kinds of energy for industrial heating of materials. This part is applicable to industrial microwave heating equipment operating in the frequency range 300 MHz to 300 GHz. This third edition cancels and replaces the second edition published in 2002 and constitutes a technical revision. The significant changes with respect to the previous edition are as follows: - the third edition of IEC 60519-1:2003 has been taken into account (the structure of clauses was adapted to it as far as practicable); - some definitions are modified or brought into line with IEC 60050-841:2004; - clauses on abnormal operation, access openings, microwave enclosure and barriers are added; - the microwave leakage measurements are in a normative Annex A; - an informative Annex B on the rationales for microwave exposure and leakage limits is added; - Bibliography is added. This publication is to be read in conjunction with IEC 60519-1:2003.

IEC 60519-6:2011 is classified under the following ICS (International Classification for Standards) categories: 25.180.10 - Electric furnaces. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60519-6:2011 has the following relationships with other standards: It is inter standard links to IEC 60519-6:2002, IEC 60519-6:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60519-6:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60519-6 ®

Edition 3.0 2011-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Safety in electroheat installations –

Part 6: Specifications for safety in industrial microwave heating equipment

Sécurité dans les installations électrothermiques –

Partie 6: Spécifications pour les installations de chauffage industriel à

hyperfréquences

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60519-6 ®

Edition 3.0 2011-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Safety in electroheat installations –

Part 6: Specifications for safety in industrial microwave heating equipment

Sécurité dans les installations électrothermiques –

Partie 6: Spécifications pour les installations de chauffage industriel à

hyperfréquences

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX U

ICS 25.180.10 ISBN 978-2-88912-322-3

– 2 – 60519-6 © IEC:2011

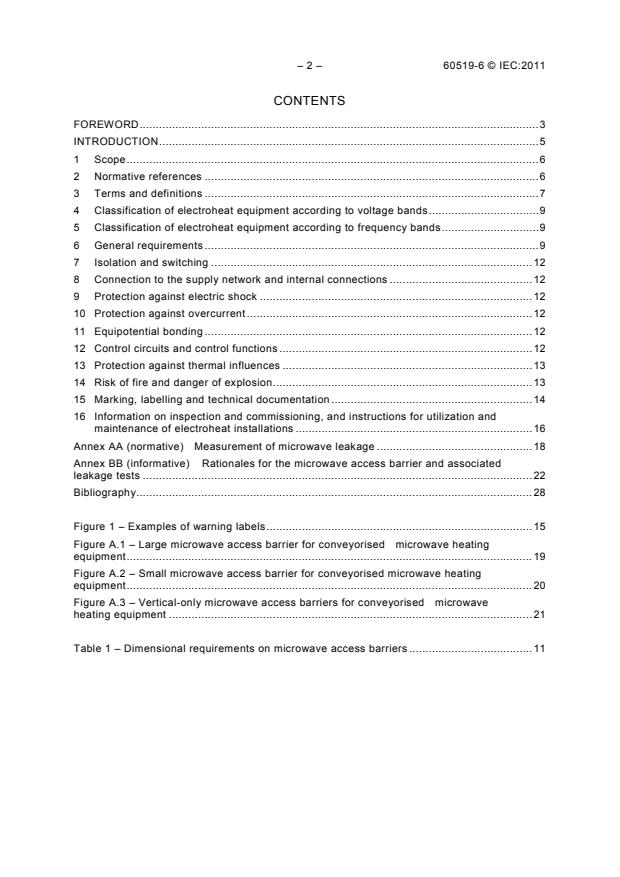

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Classification of electroheat equipment according to voltage bands . 9

5 Classification of electroheat equipment according to frequency bands . 9

6 General requirements . 9

7 Isolation and switching . 12

8 Connection to the supply network and internal connections . 12

9 Protection against electric shock . 12

10 Protection against overcurrent . 12

11 Equipotential bonding . 12

12 Control circuits and control functions . 12

13 Protection against thermal influences . 13

14 Risk of fire and danger of explosion . 13

15 Marking, labelling and technical documentation . 14

16 Information on inspection and commissioning, and instructions for utilization and

maintenance of electroheat installations . 16

Annex AA (normative) Measurement of microwave leakage . 18

Annex BB (informative) Rationales for the microwave access barrier and associated

leakage tests . 22

Bibliography . 28

Figure 1 – Examples of warning labels . 15

Figure A.1 – Large microwave access barrier for conveyorised microwave heating

equipment . 19

Figure A.2 – Small microwave access barrier for conveyorised microwave heating

equipment . 20

Figure A.3 – Vertical-only microwave access barriers for conveyorised microwave

heating equipment . 21

Table 1 – Dimensional requirements on microwave access barriers . 11

60519-6 © IEC:2011 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SAFETY IN ELECTROHEAT INSTALLATIONS –

Part 6: Specifications for safety in industrial

microwave heating equipment

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and

non-governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates

closely with the International Organization for Standardization (ISO) in accordance with conditions determined

by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60519-6 has been prepared by IEC technical committee 27:

Industrial electroheating.

This third edition cancels and replaces the second edition published in 2002 and constitutes

a technical revision. The significant changes with respect to the previous edition are as

follows:

– the third edition of IEC 60519-1:2003 has been taken into account (the structure of

clauses was adapted to it as far as practicable);

– some definitions are modified or brought into line with IEC 60050-841:2004;

– clauses on abnormal operation, access openings, microwave enclosure and barriers are

added;

– the microwave leakage measurements are in a normative Annex A;

– an informative Annex B on the rationales for microwave exposure and leakage limits is

added;

– Bibliography is added.

– 4 – 60519-6 © IEC:2011

This part of IEC 60519 is to be used in conjunction with IEC 60519-1:2003. It is intended to

specify particular requirements for industrial microwave heating equipment. This Part 6

supplements or modifies the corresponding clauses of IEC 60519-1, so as to convert it into an

IEC standard. Where a particular subclause of Part 1 is not mentioned in this Part 6, that

subclause applies as far as is reasonable. Where this standard states "addition", modification"

or "replacement", the relevant text of Part 1 is to be adapted accordingly.

NOTE Subclauses and notes which are additional to those in Part 2 are numbered starting from 101, additional

items and annexes are lettered aa, bb or AA, BB, etc.

The text of this standard is based on the following documents:

CDV Report on voting

27/704/CDV 27/752/RVC

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The list of all parts of the IEC 60519 series, under the general title Safety in electroheat

installations, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

60519-6 © IEC:2011 – 5 –

INTRODUCTION

This edition of IEC 60519-6 contains updates and revisions of IEC 60519-6:2002, which was

used over several years. It specifies safety requirements for industrial microwave heating

equipment and installations specially designed for specific applications, unlike household,

commercial and laboratory microwave appliances. Criteria for discrimination between these

categories are dealt with in the scope.

– 6 – 60519-6 © IEC:2011

SAFETY IN ELECTROHEAT INSTALLATIONS –

Part 6: Specifications for safety in industrial

microwave heating equipment

1 Scope

This part of IEC 60519 is applicable to equipment using microwave energy alone or in

combination with other kinds of energy for industrial heating of materials.

This part is applicable to industrial microwave heating equipment operating in the frequency

range 300 MHz to 300 GHz.

NOTE 1 Since the wavelength of the high end of the microwave band at 300 GHz is very short and particular

leakage measurement instrumentation is needed in the low end of the band, the microwave leakage specification in

Annex A applies only for the ISM frequencies between 800 MHz and 6 GHz. The centre frequencies of these are

2,45 GHz and 5,8 GHz universally, and between 896 MHz and 918 MHz in some regions. For such microwave

equipment IEC 62311 applies. For other microwave frequencies, the basic restriction as addressed in informative

Annex B or the ICNIRP Guidelines (see Bibliography) may be used.

This part does not apply to appliances for household and similar use (covered by

IEC 60335-2-25), commercial use (covered by IEC 60335-2-90) or laboratory use (covered by

IEC 61010-2-010).

NOTE 2 Since microwave tunnel ovens and also some other types of microwave equipment may be either for

commercial, laboratory or industrial use, the following criteria are suitable for determination of the classification as

industrial equipment:

– commercial equipment is typically designed and planned for series production of many identical units, whereas

industrial equipment is typically produced in small series or even as single units. The processed goods are

consumed or ready for final use at the end of the heating process.

– laboratory heating equipment is for preparing material in a laboratory environment, and the processed material

is immediately available for investigations or further processing. Regular production of large quantities of

material is not foreseen.

– with industrial equipment, the processed goods are not immediately accessible to the end user, and the goods

may additionally not be in a final state from the perspective of the end user.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050-841:2004, International Electrotechnical Vocabulary – Part 841: Industrial

electroheat

IEC 60417, Graphical symbols for use on equipment

IEC 60519-1:2003, Safety in electroheat installations – Part 1: General requirements

IEC 61307, Industrial microwave heating installations – Test methods for the determination of

power output

60519-6 © IEC:2011 – 7 –

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60519-1:2003 and

IEC 60050-841, as well as the following apply.

3.1

microwave generator

source used to produce electromagnetic energy in the frequency range from 300 MHz to

300 GHz

[IEC 60050-841:2004, 841-29-16]

3.2

microwave applicator

structure which applies the microwave energy to the load

[IEC 60050-841:2004, 841-29-11]

3.3

microwave cavity

space enclosed by inner metal walls and a door or an access opening and in which the load is

placed

[IEC 60050-841:2004, 841-29-19]

3.4

microwave load

objects introduced into the microwave applicator or microwave cavity

[IEC 60050-841:2004, 841-29-12, modified]

3.5

microwave heating equipment

assembly of electric and mechanical devices intended for the transfer of microwave energy to

the microwave load and comprising in general power supplies, microwave applicators or

cavities, interconnecting cables and waveguides, control circuitry, means for transporting the

microwave load, and ventilation equipment

[IEC 60050-841:2004, 841-29-06, modified]

3.6

microwave leakage

superficial power density of microwave radiation escaping from the microwave heating

equipment

3.7

microwave access barrier

physical barrier, which has the property of microwave transparency, limiting access to the

microwave enclosure, mounted outside the microwave enclosure and can only be removed

with the aid of tools

NOTE 1 The function of the microwave access barrier is to act solely as a mechanical barrier.

NOTE 2 Microwave access barriers may be fixed to the microwave heating equipment or not, and are in the latter

case a part of the installation.

NOTE 3 Devices such as an array of metal chains or hinged metal plates at entrance and exit ports intended to

reduce microwave leakage are not considered microwave access barriers.

– 8 – 60519-6 © IEC:2011

3.8

microwave enclosure

structure which is intended to confine the microwave energy to a defined region

NOTE 1 Examples are a cavity, door seals and waveguides.

NOTE 2 Microwave access barriers mounted outside the microwave enclosure are not considered as a part of the

microwave enclosure.

[IEC 60050-841:2004, 841-29-20, modified]

3.9

means of access

all structural features of the microwave heating equipment which can be opened or removed

without the use of a tool to provide access to the interior of the microwave applicator or

microwave cavity

3.10

maintenance door

all structural features of any part of the microwave heating equipment which can be opened or

removed without the use of a tool to provide access to other locations than the microwave

applicator or microwave cavity

3.11

cover

structural feature of any part of the microwave heating equipment which can be opened or

removed by the use of a tool to provide access for routine maintenance, service, replacement

of expendable parts, etc.

3.12

entrance or exit port

openings in the microwave enclosure through which the microwave load moves

3.13

microwave transparency

property of a material having negligible absorption and reflection of microwaves

NOTE The relative permittivity of a microwave transparent material is usually less than 7 and the loss factor is

usually less than 0,015.

[IEC 60050-841:2004, 841-29-14]

3.14

interlock

mechanical or electrical safety device or system, the function of which is to prohibit one class

of events if another class of condition does not exist

NOTE For example, a microwave interlock prohibits the operation of a microwave generator, if the means of

access are not closed.

3.15

microwave output power

microwave power as defined and measured according to IEC 61307

3.16

normal load

nominal microwave load at full microwave output power as specified by the manufacturer’s

documentation

60519-6 © IEC:2011 – 9 –

3.17

normal operation

range of microwave output power and normal loads in allowable working conditions of the

microwave heating equipment, as agreed between the manufacturer and user

3.18

reference surface

fictitious surface in the vicinity of mainly entrance and exit ports, located as a consequence of

microwave leakage measurements

NOTE 1 If the microwave leakage reading without microwave access barrier is less or equal to the limits of

Annex A, the reference surface is the surface of the geometric opening of the microwave enclosure.

NOTE 2 See 6.3 and Figures A.1, A.2 and A.3 for further explanations.

4 Classification of electroheat equipment according to voltage bands

Clause 4 of IEC 60519-1:2003 applies.

5 Classification of electroheat equipment according to frequency bands

Clause 5 of IEC 60519-1:2003 applies.

6 General requirements

Clause 6 of IEC 60519-1:2003 applies except as follows.

6.1 Electroheating equipment

Additional subclause:

6.1.101 Abnormal operation

Any single electrical or mechanical fault in the microwave heating equipment shall not result

in energising of a microwave generator under normal operation.

NOTE 1 A mechanical fault in an array of metal chains or hinged metal plates at entrance and exit ports intended

to reduce microwave leakage, is a single fault condition.

NOTE 2 Compliance with this requirement may be checked by inspection of the circuit diagrams and/or with the

microwave leakage measurement as specified in Annex A.

For the purpose of testing, all maintenance doors, means of access and microwave access

barriers are removed or opened, except those which incorporate microwave interlocks which

prohibit generation of microwave power when removed or open. Attempts of normal operation

are then made and shall not result in microwave leakage exceeding the limit in Annex A.

Operation of microwave heating equipment for continuous processing under conditions of

interruption of the flow of microwave load(s) shall not result in a temporary microwave

leakage exceeding the limit specified in Annex A, but with a limit of 100 W/m .

Attempts to operate the microwave heating equipment without microwave load shall not result

in microwave leakage exceeding the limit specified in Annex A, but with a limit of 100 W/m .

NOTE 3 Compliance with this requirement can be checked by detecting microwave emission by an active

microwave leakage monitor which switches off the microwave generator in order for the requirements of Annex A to

be fulfilled. Defeating the sensor circuit is considered a single fault condition, as is interruption of the flow of

microwave load(s).

– 10 – 60519-6 © IEC:2011

6.3 Static charges – stray fields – electric and/or magnetic fields

Additional subclauses:

6.3.101 Microwave leakage

Compliance for microwave leakage with the safety requirements is checked by measurements

according to Annex A.

6.3.102 Protection against microwave leakage

Microwave heating equipment shall be designed, constructed and operated as to provide

adequate protection against radiation hazards due to microwave leakage.

The microwave heating equipment shall be provided with a device giving adequate indication

when the microwave power is switched on and which is clearly visible to anyone entering the

general area of the installation.

Where the microwave power can be or is varied by a user control, an indicator shall show the

operator the level of microwave power applied.

There shall be a key switch, code panel, card reader or similar device on the control panel

requiring the insertion of a key, input of a code or card or similar before microwave power can

be generated.

6.3.103 Protection against access to microwave containing regions

Microwave heating equipment including microwave access barriers installed in order to limit

access of personnel to a distance from the microwave enclosure are either enclosing the

entrance or exit port and mounted on the microwave heating equipment, or not a part of it but

of the installation and may then be essentially only vertical. Both types shall comply with the

following:

• the microwave access barrier shall not be constructed of metal or microwave-absorbing

material in such a way that it can guide or absorb microwaves;

• dimensions of the accessible opening of the microwave access barrier as such shall not

be larger than the openings of the microwave enclosure which they protect, with a

maximum of 65 mm × 65 mm; the requirement of maximum dimensions 65 mm × 65 mm is

not applicable for any openings in microwave access barriers through which the

microwave loads move;

• the microwave access barrier shall either be removable only with the aid of a tool, or its

removal shall operate at least one interlock;

• microwave access barriers that are only vertical and located along the microwave load

transport direction shall start at maximum 75 mm and end at least 1 800 mm above the

floor.

NOTE 1 Microwave access barriers that are only vertical may be supported by some few metal poles or similar.

NOTE 2 For microwave access barriers which are not fixed to the microwave heating equipment and are instead a

part of the installation, 15.2.7 also applies.

NOTE 3 The ≤65 mm × 65 mm requirement on accessible opening dimensions are for prohibiting insertion of the

human hand, as is the <Ø 75 mm requirement in Table 1. The ≥1 800 mm barrier height requirement, with the

warning sign in 15.2.7, is for making it obvious that access is not allowed; the ≤75 mm limit is for prohibiting access

by arm’s length while simplifying cleaning of the floor.

The dimensional and location requirements on microwave access barriers in relation to the

type of barrier and the dimension and type of opening are given in Table 1. The barrier

geometry is calculated from the reference surface. In order for this to be determined,

microwave access barriers are removed and their associated interlocks are defeated.

60519-6 © IEC:2011 – 11 –

The location of the reference surface is determined as follows. Microwave leakage is

measured according to Annex A. The spacer tip of the microwave leakage instrument is

moved over and away from the external surface of the microwave heating equipment to locate

the highest microwave leakage, particular attention being given the openings. The region

inside a geometric opening into the microwave enclosure is not regarded as accessible during

these measurements.

If the microwave leakage reading is less than the limit of Annex A, the reference surface is at

the surface of the geometric opening of the microwave enclosure.

If the microwave leakage reading exceeds the limit of Annex A, the locations of the sensor

(not the tip) further away from the microwave enclosure where this value is measured are

recorded. The position of the reference surface away from the surface of the microwave

heating equipment is then determined as 50 mm straight inwards from these sensor positions

and towards the surface of the microwave heating equipment.

Table 1 – Dimensional requirements on microwave access barriers

Opening

Allowed use Required barrier length Notes on microwave frequencies

dimension

Allows the Entrance or exit 5 × the minor axis length of an ellipse At about 915 MHz, there is

insertion of a ports, and unattenuated propagation in a 160 mm

inscribing the opening, but maximum

Ø 75 mm or microwave access long but narrow slot, and an energy

850 mm from the reference surface;

barriers that are decay distance of about 50 mm in a

65 mm × 65 mm only sideways/ behind for microwave

object only vertical access barriers that are only vertical Ø 130 mm opening. However, loads

may convey surface waves.

Allows the Entrance or exit 180 mm from the reference surface; At Ø 75 mm, the energy decay distance

insertion of an ports, and only sideways/ behind for microwave is about 2 mm at about 915 MHz, and

object with microwave access access barriers that are only vertical very long at 2,45 GHz. There is

dimensions barriers that are unattenuated propagation at 5,8 GHz.

between only vertical However, high permittivity loads may

Ø 75 mm and convey surface waves.

20 mm × 50 mm

Allows the Any purpose 80 mm from the reference surface At 20 mm × 50 mm, cut-off is very

insertion of an efficient for about 915 MHz; the energy

object with

decay distance is 30 mm at 2,45 GHz

dimensions

and there is unattenuated propagation

between

at 5,8 GHz. However, continuous high

20 mm × 50 mm permittivity loads may convey surface

and Ø 12 mm waves.

Allows the Any purpose — There is a very efficient cut-off for all

insertion of an ISM frequencies. Surface wave

object with propagation at continuous loads in the

dimensions less opening may exist.

than Ø 12 mm

The minimum distance between the plane of a meshed microwave access barrier and the

reference surface shall be according to Table 1, using the mesh opening dimensions. The

same principle applies to the barrier start height above the floor.

In the determination of the location of microwave access barriers that are only vertical and located

along the microwave load transport direction, the horizontal projection of the maximum extension

of the reference surface shall be used.

NOTE 4 In order to simplify the design of microwave access barriers, the projections of the maximum horizontal

and vertical extensions of the reference surface is normally used. This, and the use of Table 1 are exemplified in

Figures A.1, A.2 and A.3.

6.5 Ionizing radiation

Addition:

– 12 – 60519-6 © IEC:2011

The X-ray leakage from the generator, measured in the same locations as specified in 6.3.5,

shall not exceed the value specified by national authorities responsible for public health.

7 Isolation and switching

Clause 7 of IEC 60519-1:2003 applies.

8 Connection to the supply network and internal connections

Clause 8 of IEC 60519-1:2003 applies.

9 Protection against electric shock

Clause 9 of IEC 60519-1:2003 applies except as follows.

9.1 General

Addition:

NOTE Microwave frequencies do not cause electric shock.

Additional subclause:

9.101 Accessibility to high voltage parts

Maintenance doors allowing access to high voltage parts and/or the microwave generator for

maintenance shall be provided with key locks.

NOTE If microwave exposure may also occur, Subclause 12.3.2 applies.

10 Protection against overcurrent

Clause 10 of IEC 60519-1:2003 applies.

11 Equipotential bonding

Clause 11 of IEC 60519-1:2003 applies except as follows.

11.4.2

Replacement:

Earthing of one of the high voltage poles of the microwave generator is allowed.

If the high voltage power supply and the microwave generator are not in the same metal

housing and have a common chassis, an additional high voltage cable, in addition to normal

means for earthing, having the same class of insulation as for the high voltage cables, shall

be mounted between the chassis of the high voltage power supply and the microwave

generator chassis. The mounting point shall not be used for any other purpose.

12 Control circuits and control functions

Clause 12 of IEC 60519-1:2003 applies except as follows.

60519-6 © IEC:2011 – 13 –

Additional subclauses:

12.101 Requirements for microwave interlocking devices

12.101.1 Means of access

The opening of a means of access of microwave heating equipment shall operate two

microwave interlocks, designed for high security and long-term operation. These interlocks

shall prohibit the operation of any microwave generator.

NOTE If not obvious by the main electrical circuit design, the operation of the microwave generator is verified by

the leakage measurement according to Annex A.

The failure of any single electrical or mechanical component shall not cause all microwave

interlocks on any means of access to be inoperative.

The failure of one of the two electromechanical microwave interlocks on the means of access

to perform its intended function shall trigger an alarm and at the same time render the

microwave heating equipment inoperative.

12.101.2 Maintenance doors and covers

The opening or removal of each maintenance door or cover shall operate at least one

interlock, or be provided with a key lock, if the microwave exposure may exceed the value

specified in Annex A with the maintenance door or cover removed.

12.101.3 Microwave absorbing means

In microwave heating equipment with means for absorbing microwave energy which require

flow of a liquid, reduction of liquid flow at the output of any absorbing means shall operate at

least one interlock, if the said reduction results in microwave leakage in excess of the limit

specified in Annex A.

In microwave heating equipment with means for absorbing microwave energy without any

dedicated cooling, the absorbing function shall not be impaired by excessive temperature

rises in the absorber. This is tested under normal operation, and also under conditions of

abnormal operation as specified in 6.1.2. The absorbing means shall remain securely in place

and not be degraded.

13 Protection against thermal influences

Clause 13 of IEC 60519-1:2003 applies.

14 Risk of fire and danger of explosion

Clause 14 of IEC 60519-1:2003 applies except as follows.

Addition:

Microwave heating equipment shall be so designed, constructed and operated that risks of

burns, fire, and explosions are minimised as far as practicable. In addition to the provisions of

IEC 60519-1:2003, the following requirements shall be met when applicable:

Additional subclauses:

– 14 – 60519-6 © IEC:2011

14.101 Risk of fire

If a fire which would present a safety hazard can result from overheating of the microwave

load, it is recommended, as far as possible and practicable, to provide the microwave heating

equipment with automatic means to:

• indicate the existence of a fire;

• eliminate microwave and other energy input to the material in the event of a fire;

• stop material flow through the applicator or, if decided according to the risk analysis, to

quickly remove material in the event of a fire in order to extinguish the fire;

• extinguish a fire quickly.

The operating instructions given by the manufacturer shall indicate that, if such a fire can be

initiated by an arc in the applicator, the provisions of 16.3.4 shall also apply.

When the microwave heating equipment is operated in premises liable to the risk of

hazardous fires, the provisions of 14.2 shall apply.

NOTE Materials may be overheated to high temperatures without initially catching fire, due to lack of oxygen.

Once materials are exposed to ambient atmosphere, a violent fire may suddenly start.

14.102 Risk of explosion

The operating instructions given by the manufacturer shall indicate that microwave heating

shall not be employed in premises liable to risk of explosion, nor shall it normally be applied

to microwave loads which if heated would result in an explosion risk. Where it is necessary to

apply microwave heating to such microwave loads, the following precautions shall be

observed.

If gases liberated from the microwave load during the heating process are potentially

explosive, special precautions shall be taken to avoid the formation of an explosive

atmosphere in the microwave applicator or microwave cavity. It is recommended that:

• sufficient air be supplied to the microwave applicator or microwave cavity to ensure that

the vapour-to-air ratio does not exceed one-quarter of the lower flammable limit. If this is

not possible, the process is to be performed in an inert atmosphere;

• means be provided for automatically cutting off the microwave power input to the

microwave applicator or microwave cavity if the exhaust system fails;

• particular standards dealing with explosive protection shall be taken into consideration.

The risk of superheating of liquid microwave loads shall be taken care of. It is recommended

that

• pre-testing is carried out and particular restrictions are applied;

• shields prohibiting eruption towards personnel are installed.

15 Marking, labelling and technical documentation

Clause 15 of IEC 60519-1:2003 applies except as follows.

15.1 Marking

Modification:

e) Rated voltage is rated input voltage.

f) Rated current is rated input current.

Addition:

60519-6 © IEC:2011 – 15 –

aa) identification of the principal connections (for example, reference number of a drawing

showing the principal circuit of the microwave heating equipment).

bb) maximum voltage within the generator, microwave frequency and maximum power output

of the microwave generator, in compliance with IEC 61307.

15.2 Labelling

Additional subclauses:

15.2.101 Microwave heating equipment, which includes entrance and exit ports or

accessible openings into the microwave enclosure, with or without microwave access barriers,

shall be clearly marked in visible areas near each port or opening with a warning label (see

Figure 1 a), using a graphical symbol of IEC 60417 (IEC 60417-5140:2003-04) and warning

text in the necessary language(s).

15.2.102 Maintenance doors of microwave heating equipment, behind which there may be

access to high voltage live parts and a microwave generator, shall be clearly marked at each

such maintenance door with a warning label (see Figure 1 b) or an equivalent warning, using

graphical symbols of IEC 60417 (IEC 60417-5036:2002-10 and IEC 60417-5140:2003-04) and

warning text in the necessary language(s). The marking shall be located near lockpoints, if

applicable.

15.2.103 Microwave access barriers, which are not a part of the microwave heating

equipment, shall be clearly marked with a warning label (see Figure 1c) or an equivalent

warning, using a graphical symbol of IEC 60417 (IEC 60417-5140:2003-04) and warning text

in the necessary language(s). Additionally, the microwave heating equipment shall be clearly

marked with the similar warning sign in an area close to the barrier.

IEC 044/11 IEC 045/11 IEC 046/11

Figure 1a) – Label near ports and Figure 1b) – Label on Figure 1c) – Label at and near

openings maintenance doors microwave access barriers

NOTE Warning labels and signs are designed according to ISO 3864-1 (black symbols and text on yellow

background).

Figure 1 – Examples of warning labels

15.2.104 Microwave heating equipment shall have the essence of the applicable following

text marked in a visible area near the operation controls, in the necessary language(s):

CAUTION

Personnel must not be exposed to microwave energy

Never operate the installation without its intended loading

Do not remove barriers

To maintain the microwave leakage at an acceptable value, the microwave heating

equipment shall be periodically inspected and kept in good operating condition

– 16 – 60519-6 © IEC:2011

In cases when the installation contains accessible waveguides, the following text shall be

added:

All connections, waveguides, flanges, gaskets, etc., must be secure in order to ensure

that microwave leakage remains below specified limits

15.3 Technical documentation

Replacement:

Operating and maintenance instructions for the electroheating installations, according to

Subclause 15.3 of IEC 60519-1:2003, including circuit diagrams and list of components in the

necessary language(s), and which include precautions on how to avoid possible exposure to

high voltage, microwave leakage, risk of fire and burns and explosions shall be provided in

good time.

The documentation shall contain the following:

• the statement that the system is for industrial use only;

• definition of the normal operation and its limits, for which the microwave heating

equipment is specified and manufactured.

NOTE Additional information necessary for shipping, installation and handling such as weight and dimensions

should be given in additional documentation provided by the manufacturer.

Additional subclauses:

15.101 Operating and service instructions

Manufacturers of microwave heating equipment shall provide, for each equipment model,

operating and service instructions in the necessary language(s), which include clear warnings

and the precautions to be taken to avoid possible exposure to microwave leakage, as well as

the risk of burns, fires, explosions and ionising radiation (see Clause 6 and Clause 14).

The instructions for use shall include the substance of the following, if applicable:

• the installation shall not be operated if there are any visible damages in the entrance and

exit port regions,

• any barriers at the entrance and exit ports are intended to protect against microwave

leakage, as well as personnel damages such as squeezing of hands,

• only specially instructed maintenance staff are allowed to carry out any service or repair

involving possible exposure to microwave energy and high voltages.

15.102 Instructions for maintenance

The instructions for maintenance shall contain information on the following, in the necessary

language(s):

• the minimum intervals between complete cleaning operations and removal of any residual

material in the microwave enclosure;

• details on how to replace microwave components;

• the minimum intervals for testing, and test instructions, for any microwave sensing devices

used in the interlock system.

16 Information on inspection and commissioning, and instructions for

utilization and maintenance of electroheat installations

Clause 16 of IEC 60519-1:2003 applies except as follows.

60519-6 © IEC:2011 – 17 –

Addition subclause:

16.3.101 Special precautions shall be taken to avoid the formation of arcs in the microwave

applica

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...