IEC 61810-2-1:2017

(Main)Electromechanical elementary relays - Part 2-1: Reliability - Procedure for the verification of B10 values

Electromechanical elementary relays - Part 2-1: Reliability - Procedure for the verification of B<sub>10</sub> values

IEC 61810-2-1:2017 specifies reliability test procedures for electromechanical elementary relays when enhanced requirements for the verification of reliability apply.

Particular provisions are given for relays incorporated in safety-related control systems of machinery in accordance with IEC 62061 and ISO 13849-1. For such relays, B10 values for dangerous failures (B10D values) are derived from the tests specified in this document.

This edition includes the following significant technical changes with respect to the previous edition:

- limitation of tests to 10 M cycles in Clause 5;

- reduction of required number of test samples to 5 in specified cases;

- introduction of WeiBayes analysis for routine test under Clause 4.

Relais électromécaniques élémentaires - Partie 2-1: Fiabilité - Procédure de vérification des valeurs de B<sub>10</sub>

L'IEC 61810-2-1:2017 spécifie les procédures d'essai de fiabilité pour les relais électromécaniques élémentaires lorsque des exigences renforcées pour la vérification de la fiabilité s'appliquent.

Des dispositions particulières sont fournies pour les relais incorporés dans les systèmes de commande relatifs à la sécurité des machines selon l'IEC 62061 et l'ISO 13849-1. Pour ces relais, les valeurs de B10 pour des défaillances dangereuses (valeurs de B10D) sont obtenues à partir des essais spécifiés dans le présent document.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- limitation des essais à 10 M de manœuvres à l'Article 5;

- réduction du nombre exigé d'échantillons d'essai à 5 dans des cas spécifiés;

- introduction de l'analyse de WeiBayes pour l'essai individuel de série à l'Article 4.

General Information

- Status

- Published

- Publication Date

- 29-May-2017

- Technical Committee

- TC 94 - Electrical relays

- Drafting Committee

- WG 3 - TC 94/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 30-May-2017

- Completion Date

- 23-Jun-2017

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61810-2-1:2017 is an international standard published by the International Electrotechnical Commission (IEC) that specifies reliability test procedures for electromechanical elementary relays. This part 2-1 focuses on the verification of B10 values, which represent the number of operating cycles at which 10% of a batch of relays are expected to fail. It is essential for ensuring the enhanced reliability required of relays, especially those employed in safety-related control systems in machinery as per IEC 62061 and ISO 13849-1.

Updated in 2017, IEC 61810-2-1 introduces key technical revisions such as limiting tests to 10 million cycles, reducing test sample requirements from previous editions, and adopting the WeiBayes analysis method for routine testing. The standard is designed to support manufacturers and users in reliably assessing relay performance and preventing dangerous failures within safety-critical applications.

Key Topics

Scope and Application

The standard targets electromechanical elementary relays with stringent reliability verification needs. It provides methodologies for reliability testing, ensuring relays meet safety and operational criteria in industrial machinery environments.Verification of B10 Values

- B10 represents the mean number of cycles until 10% of tested relays fail.

- B10D values specifically refer to dangerous failures that may compromise machinery safety functions.

The document prescribes test specimens, circuit setups, environmental conditions, and failure criteria for accurate B10 and B10D determination.

Test Procedures

- Type Tests: Comprehensive testing to validate relay design reliability before production.

- Routine Tests: Periodic verification using WeiBayes analysis combined with sample testing for ongoing quality assurance.

Reliability in Safety-Related Systems

The standard aligns with machinery safety standards IEC 62061 and ISO 13849-1, where relay reliability directly impacts functional safety. The B10D values derived serve to estimate the Mean Time To Dangerous Failure (MTTFd), which is crucial for risk assessment and compliance.

Applications

IEC 61810-2-1:2017 applies primarily to manufacturers and engineers involved with:

Design and Production of Electromechanical Relays

Ensuring that relay components meet internationally recognized reliability benchmarks before market release.Safety-Related Control Systems in Machinery

Industrial machines using safety controls rely heavily on reliable relays. This standard helps validate relays for incorporation into safety layers, minimizing risks of dangerous failures.Quality Control and Certification Processes

Routine testing and statistical evaluation aid manufacturers in maintaining consistent relay reliability and support regulatory certification in global markets.Reliability Engineering and Risk Management

Professionals calculating safety reliability metrics such as MTTFd utilize B10D values as a critical parameter derived from these standardized test methods.

Related Standards

IEC 61810 Series

- Part 1: General and safety requirements for electromechanical elementary relays.

- Part 2: Overview of reliability requirements and criteria.

- Part 3: Relays with forcibly guided (mechanically linked) contacts, offering high diagnostic coverage.

IEC 62061

Safety of machinery - Functional safety of electrical, electronic, and programmable electronic control systems.ISO 13849-1

Safety-related parts of control systems - Part 1: General principles for design.

Understanding and applying IEC 61810-2-1:2017 ensures that electromechanical relays perform reliably under operational stresses, particularly in safety-critical applications where failure can result in hazardous conditions. This standard solidifies the foundation for robust relay reliability testing, aligning with international safety and quality expectations in industrial automation and machinery control systems.

Keywords: IEC 61810-2-1, electromechanical relays, B10 values, reliability testing, safety-related control systems, IEC 62061, ISO 13849-1, mean time to dangerous failure, MTTFd, WeiBayes analysis, relay reliability, electromechanical elementary relays standards.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 61810-2-1:2017 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electromechanical elementary relays - Part 2-1: Reliability - Procedure for the verification of B<sub>10</sub> values". This standard covers: IEC 61810-2-1:2017 specifies reliability test procedures for electromechanical elementary relays when enhanced requirements for the verification of reliability apply. Particular provisions are given for relays incorporated in safety-related control systems of machinery in accordance with IEC 62061 and ISO 13849-1. For such relays, B10 values for dangerous failures (B10D values) are derived from the tests specified in this document. This edition includes the following significant technical changes with respect to the previous edition: - limitation of tests to 10 M cycles in Clause 5; - reduction of required number of test samples to 5 in specified cases; - introduction of WeiBayes analysis for routine test under Clause 4.

IEC 61810-2-1:2017 specifies reliability test procedures for electromechanical elementary relays when enhanced requirements for the verification of reliability apply. Particular provisions are given for relays incorporated in safety-related control systems of machinery in accordance with IEC 62061 and ISO 13849-1. For such relays, B10 values for dangerous failures (B10D values) are derived from the tests specified in this document. This edition includes the following significant technical changes with respect to the previous edition: - limitation of tests to 10 M cycles in Clause 5; - reduction of required number of test samples to 5 in specified cases; - introduction of WeiBayes analysis for routine test under Clause 4.

IEC 61810-2-1:2017 is classified under the following ICS (International Classification for Standards) categories: 29.120.70 - Relays. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61810-2-1:2017 has the following relationships with other standards: It is inter standard links to IEC PAS 61810-2-1:2008, IEC 61810-2-1:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61810-2-1:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61810-2-1 ®

Edition 2.0 2017-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electromechanical elementary relays –

Part 2-1: Reliability – Procedure for the verification of B values

Relais électromécaniques élémentaires –

Partie 2-1: Fiabilité – Procédure de vérification des valeurs de B

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

65 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 61810-2-1 ®

Edition 2.0 2017-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electromechanical elementary relays –

Part 2-1: Reliability – Procedure for the verification of B values

Relais électromécaniques élémentaires –

Partie 2-1: Fiabilité – Procédure de vérification des valeurs de B

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.120.70 ISBN 978-2-8322-4389-3

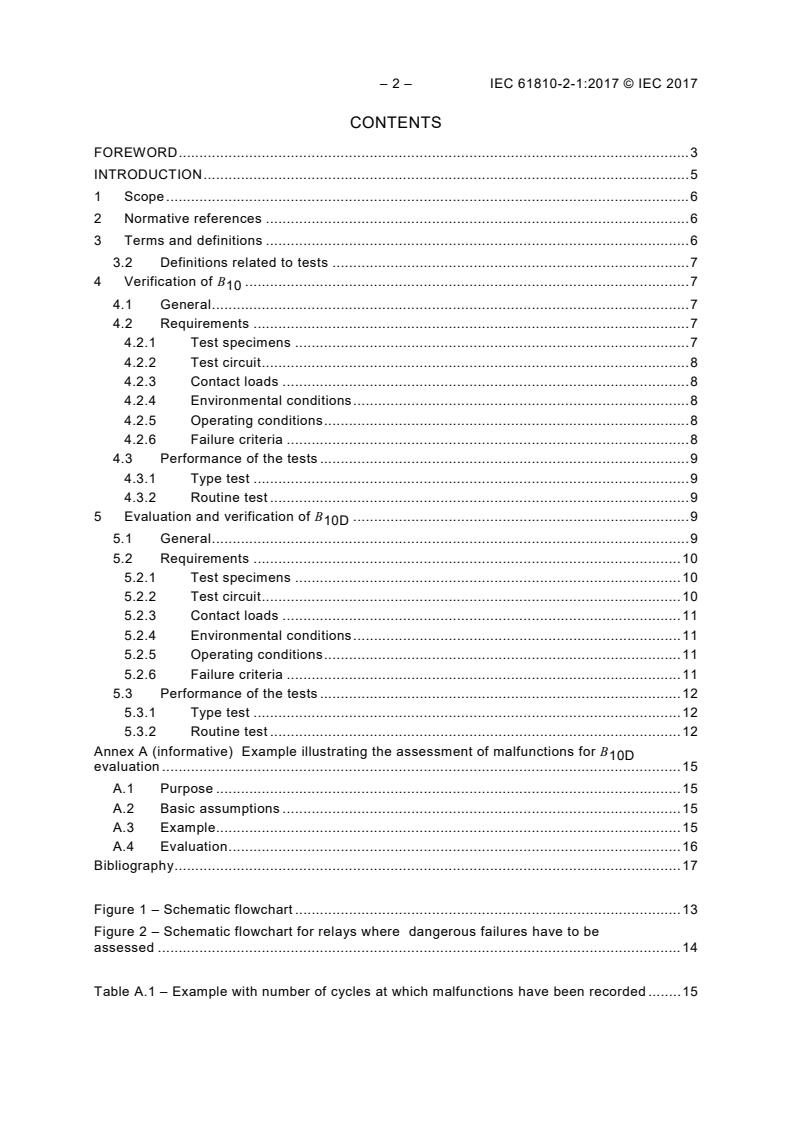

– 2 – IEC 61810-2-1:2017 © IEC 2017

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

3.2 Definitions related to tests . 7

4 Verification of B . 7

4.1 General . 7

4.2 Requirements . 7

4.2.1 Test specimens . 7

4.2.2 Test circuit . 8

4.2.3 Contact loads . 8

4.2.4 Environmental conditions . 8

4.2.5 Operating conditions . 8

4.2.6 Failure criteria . 8

4.3 Performance of the tests . 9

4.3.1 Type test . 9

4.3.2 Routine test . 9

5 Evaluation and verification of B . 9

10D

5.1 General . 9

5.2 Requirements . 10

5.2.1 Test specimens . 10

5.2.2 Test circuit . 10

5.2.3 Contact loads . 11

5.2.4 Environmental conditions . 11

5.2.5 Operating conditions . 11

5.2.6 Failure criteria . 11

5.3 Performance of the tests . 12

5.3.1 Type test . 12

5.3.2 Routine test . 12

Annex A (informative) Example illustrating the assessment of malfunctions for B

10D

evaluation . 15

A.1 Purpose . 15

A.2 Basic assumptions . 15

A.3 Example. 15

A.4 Evaluation . 16

Bibliography . 17

Figure 1 – Schematic flowchart . 13

Figure 2 – Schematic flowchart for relays where dangerous failures have to be

assessed . 14

Table A.1 – Example with number of cycles at which malfunctions have been recorded . 15

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTROMECHANICAL ELEMENTARY RELAYS –

Part 2-1: Reliability – Procedure for the verification of B values

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61810-2-1 has been prepared by IEC technical committee 94: All-

or-nothing electrical relays.

This second edition cancels and replaces the first edition published in 2011. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) limitation of tests to 10 M cycles in Clause 5;

b) reduction of required number of test samples to 5 in specified cases;

c) introduction of WeiBayes analysis for routine test under Clause 4.

– 4 – IEC 61810-2-1:2017 © IEC 2017

The text of this International Standard is based on the following documents:

FDIS Report on voting

94/416/FDIS 94/419/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

This International Standard is to be used in conjunction with IEC 61810-2:2017.

A list of all parts in the IEC 61810 series, published under the general title Electromechanical

elementary relays, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

INTRODUCTION

Based on the general provisions of IEC 61810-2, this part of IEC 61810 specifies reliability

test procedures for electromechanical elementary relays where enhanced requirements for

the verification of reliability apply. A type test is passed and then confirmed by routine tests

with specified periodicity. This document describes how figures for B (the mean number of

cycles until 10 % of the relays have failed) are derived from these life tests performed with

representative relay samples.

In particular when electromechanical elementary relays are intended to be incorporated in

safety-related control systems of machinery in accordance with IEC 62061 and ISO 13849-1,

the mean time to dangerous failure (MTTF ) is a measure that can be taken into account

d

when assessing the probability of dangerous failure of the safety function concerned.

Although a component failure cannot be defined as “dangerous” unless the detailed

application is known, it is common to consider a failure mode that is likely to result in danger

in a typical application of the component, and to refer to this failure mode as a “dangerous

failure”. The MTTF then becomes the expectation of the mean time to failure in this

d

"dangerous" mode. For the calculation of MTTF for electromechanical relays, the data

d

provided by the manufacturer for B can be used (see Clause C.4 of ISO 13849-1:2015).

10D

Electromechanical elementary relays with forcibly guided (mechanically linked) contacts offer

the possibility of a high diagnostic coverage according to 4.5.3 of ISO 13849-1:2015.

NOTE Requirements for such relays are given in IEC 61810-3.

– 6 – IEC 61810-2-1:2017 © IEC 2017

ELECTROMECHANICAL ELEMENTARY RELAYS –

Part 2-1: Reliability – Procedure for the verification of B values

1 Scope

This part of IEC 61810 specifies reliability test procedures for electromechanical elementary

relays when enhanced requirements for the verification of reliability apply.

Particular provisions are given for relays incorporated in safety-related control systems of

machinery in accordance with IEC 62061 and ISO 13849-1. For such relays, B values for

dangerous failures (B values) are derived from the tests specified in this document.

10D

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 61810-1:2015, Electromechanical elementary relays – Part 1: General and safety

requirements

IEC 61810-2:2017, Electromechanical elementary relays – Part 2: Reliability

IEC 61810-3, Electromechanical elementary relays – Part 3: Relays with forcibly guided

(mechanically linked) contacts

IEC 62061, Safety of machinery – Functional safety of safety-related electrical, electronic and

programmable electronic control systems

ISO 13849-1:2015 Safety of machinery – Safety-related parts of control systems – Part 1:

General principles for design

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 61810-2 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

dangerous failure

failure which has the potential to put the safety-related part of a control system in a hazardous

or fail-to-function state

[SOURCE: ISO 13849-1:2015, 3.1.5, modified – In the definition, the abbreviated term

"SRP/CS" has been replaced by "safety-related part of a control system".]

3.2 Definitions related to tests

3.2.1

type test

conformity test made on sample representative of the production to get basic performance

data or to verify that these relays comply with the specified requirements

[SOURCE: IEC 61810-2:2017, 3.21.1]

3.2.2

routine test

conformity test made on sample without any modifications and specification changes during or

after mass production with specified repetition

Note 1 to entry: The results from routine tests are used to verify that the level of technical performance is

maintained.

[SOURCE: IEC 61810-2:2017, 3.21.2, modified – The note has been added.]

4 Verification of B

4.1 General

Clause 4 specifies requirements where the reliability of the relay has to be assessed and

verified.

This procedure is applicable to relays where wearout mechanisms prevail.

NOTE 1 For relays where random failures prevail, provisions are under consideration.

NOTE 2 For relays intended to be used in safety-related control systems of machinery, the provisions of Clause 5

are applicable.

The following failure modes can occur:

• failure to open of a relay contact;

• failure to close of a relay contact;

• unintended bridging of a change-over contact;

• insulation failure of the relay.

From a type test, a value for B is obtained that indicates the probability of the occurrence of

a relay failure. The value for B is given in numbers of cycles.

NOTE 3 With the knowledge of the frequency of operation (cycling rate) of the relay within a specific application,

the number of cycles can be transformed into respective times.

Verification that this B value is applicable to relays from the series production shall be

carried out by routine tests.

An overview of this procedure is given in Figure 1.

4.2 Requirements

4.2.1 Test specimens

The test shall be carried out in accordance with IEC 61810-2.

– 8 – IEC 61810-2-1:2017 © IEC 2017

4.2.2 Test circuit

The test circuit described in Annex C of IEC 61810-1:2015 shall be used, unless otherwise

specified by the manufacturer and explicitly indicated in the test report. When feasible, one of

the circuits in accordance with Annex D of IEC 61810-1:2015 is to be used.

4.2.3 Contact loads

The contact loads shall be specified by the manufacturer and indicated in the test report. It is

recommended to select appropriate resistive loads according to 5.8 of IEC 61810-1:2015 or

inductive loads according to Annex B of IEC 61810-1:2015.

4.2.4 Environmental conditions

The conditions of Table 1 of IEC 61810-1:2015 apply. However, an extended ambient

temperature range of 18 °C to 40 °C is permitted.

4.2.5 Operating conditions

The provisions of 5.3 of IEC 61810-2:2017 apply.

Unless otherwise specified by the manufacturer, each cycle of the coil energization shall be

1 s ON and 9 s OFF.

The test is performed without coil suppression, unless explicitly specified.

4.2.6 Failure criteria

Generally, the test is to be continued until all test specimens have failed. When the test is

truncated at a specific number of cycles, all relays that have not yet failed are considered to

fail at that number of cycles (worst case assumption). However, at least 2/3 of the tested

relays shall fail, or each test specimen shall reach a lifetime of 10 M cycles.

For the assessment of recorded malfunctions severity B according to Clause 6 of

IEC 61810-2:2017 applies. The dielectric test is performed

• between coil and contacts,

• between adjacent contacts, and

• across open contacts.

A contact that fails to open cannot be tested for compliance with the requirements for open

contacts.

The insulation requirements shall be verified according to 11.4 of IEC 61810-1:2015. This may

be performed in either of the following ways.

a) During the test, the dielectric test is performed periodically at given numbers of cycles.

When the relay does not pass the dielectric test, the number of cycles for the previous

dielectric test that has been passed is considered as the cycles to failure value for this

individual relay.

b) In the case that no periodical monitoring according to item a) is performed, the dielectric

test shall be made when a relay under test fails due to a functional contact failure

(see 4.1). If the relay does not comply with the dielectric test, the whole test is not passed.

The same applies when the test is truncated at a certain number of cycles.

4.3 Performance of the tests

4.3.1 Type test

The type test is carried out with a sample of 10 relays. Each failure shall be recorded.

The B value is evaluated based on the procedure given in IEC 61810-2. For the purpose of

the following routine test according to 4.3.2.3, the shape parameter β and the characteristic

life shall be evaluated according to IEC 61810-2.

η

After completion of a type test, the first routine test shall be initiated for verification in

accordance with the periodicity specified under 4.3.2.

4.3.2 Routine test

4.3.2.1 General

The routine test shall be performed in regular intervals as specified by the manufacturer.

4.3.2.2 Routine test with Weibull

The test shall be performed with at least 5 relays, and B value shall be determined in

accordance with IEC 61810-2.

4.3.2.3 Routine test with WeiBayes

The test shall be performed with at least 5 relays, and B value shall be determined in

accordance with IEC 61810-2. In the event of deviation from 4.2.6, the test is stopped with no

failures recorded (WeiBayes without failure), and a WeiBayes confidence level of 90 % shall

be achieved.

4.3.2.4 Acceptance criteria of routine test

For each routine test, the evaluated B value shall be at least 80 % of the B value obtained

10 10

from the type test. For the routine test with WeiBayes, the B value obtained shall be at least

90 % of that of the type test.

NOTE 1 This requirement is intended to take into account possible variations for the routine tests.

NOTE 2 In IEC 61810-2 the WeiBayes result is determined using the characteristic life result from the initial

Weibull test. Accordingly, here the acceptance of the routine test can be evaluated by comparing the characteristic

life values of the initial Weibull and the WeiBayes from the routine test.

In the event that these requirements are not met, suitable corrective actions have to be taken

to remove the failure causes. The routine test shall be repeated with appropriately modified

test specimens. If it is not possible to achieve a positive routine test with non-constructive

corrective actions, constructional changes to the relay (e.g. new contact material, dimensional

changes of contact) are necessary, and the modified relay shall be regarded as a new

construction, and a new independent test procedure starting a with type test shall be

performed.

5 Evaluation and verification of B

10D

5.1 General

Clause 5 specifies requirements for relays intended to be used in safety-related control

systems of machinery in accordance with IEC 62061 and ISO 13849-1. For this purpose,

Clause 4 does not apply.

This procedure is applicable to relays where wearout mechanisms prevail.

– 10 – IEC 61810-2-1:2017 © IEC 2017

NOTE 1 For relays where random failures prevail, provisions are under consideration.

The following failure modes can occur:

• failure to open of a relay contact;

• failure to close of a relay contact;

• unintended bridging of a change-over contact;

• insulation failure of the relay.

NOTE 2 The term “unintended bridging of a changeover contact” is equivalent to “simultaneous short-circuit

between the three terminals of a changeover contact” (used in Table D.9 of ISO 13849-2:2012).

For a given application, it has to be assessed which of the above-listed failure mode(s) is

(are) to be considered as dangerous failure(s).

Simultaneous closing of make contacts and break contacts is excluded if forcibly guided

(mechanically linked) contacts are used which offer the possibility of a high diagnostic

coverage according to 4.5.3 of ISO 13849-1:2015. Electromechanical elementary relays with

forcibly guided (mechanically linked) contacts are specified in IEC 61810-3.

NOTE 3 In typical applications, the failure to open of a make contact and the insulation failure are dangerous

failure modes (see 7.2.2 and Table D.1 of ISO 13849-2:2012, where basic safety principles are compiled, in

particular the use of de-energisation with a normally open (make) contact for relays to achieve a system safe

state).

Where it is not clear which failure mode is to be considered as a dangerous failure, the

manufacturer shall record during the test any malfunction (in number of cycles and type of

malfunction). This allows them to evaluate B values for any failure mode after the test has

been completed.

From a type test, a value for B is obtained that indicates the probability of the occurrence

10D

of a dangerous failure. This value is given in number of cycles.

NOTE 4 With the knowledge of the frequency of operation (cycling rate) of the relay within a specific application,

the number of cycles can be transformed into respective times.

Verification that these B values are applicable to relays from the series production shall be

10D

carried out by routine tests.

An overview of this procedure is given in Figure 2.

5.2 Requirements

5.2.1 Test specimens

The test shall be carried out for each contact load rating in accordance with IEC 61810-2. In

the case of relays with several contacts, those two contacts – of the same type (e.g. two make

contacts) if available – shall be tested which are considered as most critical with respect to a

possible insulation failure.

NOTE In general, adjacent contacts are the most critical ones.

5.2.2 Test circuit

The test circuit described in Annex C of IEC 61810-1:2015 shall be used, unless otherwise

specified by the manufacturer and explicitly indicated in the test report. When feasible, one of

the circuits in accordance with Annex D of IEC 61810-1:2015 is to be used.

5.2.3 Contact loads

The contact loads shall be specified by the manufacturer and indicated in the test report. It is

recommended to select load types according to Annex B (endurance test) of

IEC 61810-1:2015. Unless otherwise specified, the type test shall be carried out for an AC

inductive load with 230 V and for a DC inductive load with 24 V with the following load

currents:

• I ;

e

• I /2;

e

• I /4;

e

where I = rated operating current.

e

The test with I /4 can be omitted. In this case, the B value for a smaller load than I /2 shall

e 10 e

be derived through linear interpolation of the B results at I and I /2 in a log-log graph.

10 e e

NOTE In general, the routine test is carried out with I only (see 5.3.2).

e

5.2.4 Environmental conditions

The conditions of Table 1 of IEC 61810-1:2015 apply. However, an ambient temperature

range of 18 °C to 40 °C is permitted.

5.2.5 Operating conditions

The provisions of 5.3 of IEC 61810-2:2017 apply.

Unless otherwise specified by the manufacturer, each cycle of the coil energisation shall be

1 s ON and 9 s OFF.

The test is performed without coil suppression, unless explicitly specified.

5.2.6 Failure criteria

The test shall be continued until all test specimens have failed or reached a lifetime of 10 M

cycles.

For the assessment of recorded malfunctions in accordance with Clause 6 of

IEC 61810-2:2017, the following applies:

• for malfunctions related to a dangerous failure mode: severity A;

• for other malfunctions: severity B.

The verification of insulation requirements according to Clause 11 of IEC 61810-1:2015 (with

100 % of the initial voltage for the dielectric test specified under 10.2 of IEC 61810-1:2015)

shall be performed when a relay under test fails due to a functional contact failure (see 5.1).

The dielectric test is performed

• between coil and contacts,

• between adjacent contacts, and

• across open contacts.

NOTE A contact that fails to open cannot be tested for compliance with the requirements for open contacts.

If the relay does not comply with the dielectric test, the whole test is not passed.

– 12 – IEC 61810-2-1:2017 © IEC 2017

5.3 Performance of the tests

5.3.1 Type test

The type test is carried out with a sample of 10 relays for each contact load rating. Each

failure shall be recorded. The dangerous failures are registered separately.

In the first step, the B value is evaluated based on the procedure given in IEC 61810-2

taking into account all registered failures (see also Annex A for a schematic example).

The B value is derived as follows:

10D

B = B × 10/N

10D 10 D

where

10 is the number of tested relays;

N is the number of registered dangerous failures.

D

When no dangerous failure has been registered, N = 1 is assumed.

D

EXAMPLE From data obtained with a life test of 10 relays, a B value has been derived:

B = 6 × 10 cycles

10D

During the test, 3 relays were registered with dangerous failures. Then the following estimation for B is

calculated:

10D 10 5 6

B = B × 10/3 = 6 × 10 × 10/3 = 2 × 10 cycles

The type test yields 3 different values of B for I , I /2 and I /4, each for AC inductive and

10D e e e

DC inductive loads.

After completion of a type test, the first routine test shall be initiated for verification in

accordance with the periodicity specified under 5.3.2.

5.3.2 Routine test

The routine test shall be performed with minimum 5 relays in regular intervals as specified by

the manufacturer, as a minimum with the rated operating current I only.

e

It is recommended to perform the routine test for each load every two years. This allows the

manufacturer to perform alternate tests with either an AC or a DC inductive load once a year.

The total number of dangerous failures during the routine test shall be evaluated based on the

value N registered during the type test. It shall be smaller than or equal to (N + 2) n’/10,

D D

where n’ is the number of relays tested in the routine test.

For each routine test, the evaluated B value shall be at least 80 % of the B value obtained

10 10

from the type test.

NOTE This requirement is intended to take into account possible variations for the routine tests.

In the case that these requirements are not met, suitable corrective actions have to be taken

to remove the failure causes. The routine test shall be repeated with appropriately modified

test specimens. If it is not possible to achieve a positive routine test, corrective actions (e.g.

constructional changes to the relay, new contact material, dimensional changes of contact)

are necessary, and the modified relay shall be regarded as a new construction, and a new,

independent test procedure shall be performed.

Take appropriate

Start routine test

Start type test corrective

measures

Life test

Life test

(same as for type test)

with specified contact load

Determine cause

B value for the relay

according to IEC 61810-2

No

B10’ ≥ B10 × 0,8

Yes

Following the type test, the first

routine test shall be performed

to verify the type test

Test passed

B = B value obtained from type test

10 10

B ’ = B value obtained from routine test

10 10

IEC

Figure 1 – Schematic flowchart

– 14 – IEC 61810-2-1:2017 © IEC 2017

Take appropriate

corrective

Start type test Start routine test

measures

Life test

Life test:

with I

e

each with I , I /2 and I /4

e e e

No

N ’ ≤ (N + 2) ×

D D

Determine cause

n’ / 10

Yes

B10 value for the relay

according to IEC 61810-2

No

B ’ ≥ B × 0,8

10 10

B = 10 / N × B

10D

D 10

Yes

(1 ≤ N )

D

Test passed

Following the type test, the

first routine test shall be

performed to verify the type

test

IEC

Key

Number of dangerous failures during the type test

N

D

N Number of dangerous failures during the routine test

D’

B B value obtained from the type test

B B value obtained from the routine test

B B value obtained from the type test

10D

10D

n’ Number of relays tested in the routine test

NOTE The type test yields 3 results:

B for I

10D e

B for I /2

10D e

B for I /4

10D e

Figure 2 – Schematic flowchart for relays where

dangerous failures have to be assessed

Annex A

(informative)

Example illustrating the assessment of malfunctions

for B evaluation

10D

A.1 Purpose

Annex A contains a schematic example that is intended to illustrate the application of the

provisions contained in Clause 5 for deriving relay failure data to be used for the estimation of

B .

10D

NOTE The given values for cycles until malfunction/failure are just arbitrary figures to describe the procedures,

not figures obtained from real tests.

A.2 Basic assumptions

In this example 10 relays are submitted to the life test. It is assumed that the failure to open

of a relay contact is a dangerous failure. The failure to close is a non-dangerous failure.

Insulation failures do not occur in this example.

For malfunctions related to failure to open (dangerous failure mode), the first malfunction

causes a relay failure (severity A).

For malfunctions related to failure to close (non-dangerous failure mode), two consecutive

malfunctions or a total of six malfunctions cause a relay failure (severity B).

A.3 Example

In Table A.1, the number of cycles at which malfunctions have occurred are listed for 4 out of

10 specimens.

Table A.1 – Example with number of cycles

at which malfunctions have been recorded

Specimen Number of cycles Case

Malfunction no.

1 2 3 4 5 6

1 73 679 ↓ a

2 50 001 50 003 b

53 505 ↓

3 74 902 75 047 77 834 77 835 ↓ c

… … … … … … … …

10 44 967 45 024 45 239 45 343 45 402 45 478 ↓ d

Data for B 73 679 53 505 77 835 45 478

NOTE Bold type indicates that this malfunction results in a dangerous failure.

– 16 – IEC 61810-2-1:2017 © IEC 2017

Case a: the first malfunction is due to a failure to open, and therefore causes a dangerous

failure (severity A).

Case b: the third malfunction is due to a failure to open, and therefore causes a dangerous

failure (severity A). The preceding malfunctions are due to failures to close (non-dangerous

failure mode) that did not result in a relay failure.

Case c: two consecutive malfunctions due to failures to close (non-dangerous failure mode)

cause a relay failure (severity B).

th

Case d: the 6 observed malfunction (all due to failures to close – non-dangerous failure

mode) results in a relay failure (severity B).

The resulting numbers of cycles for the failure of each of the four relay specimens are filled in

the bottom line of Table A.1.

A.4 Evaluation

The numbers of cycles at which the relay specimens failed are used to obtain the B value

following the procedures of IEC 61810-2.

Finally, the value for B is derived from this B value as given in 5.3.1.

10D 10

Bibliography

ISO 13849-2:2012, Safety of machinery – Safety-related parts of control systems – Part 2:

Validation

___________

– 18 – IEC 61810-2-1:2017 © IEC 2017

SOMMAIRE

AVANT-PROPOS . 19

INTRODUCTION . 21

1 Domaine d'application . 22

2 Références normatives . 22

3 Termes et définitions . 22

3.2 Définitions relatives aux essais . 23

4 Vérification de B . 23

4.1 Généralités . 23

4.2 Exigences . 24

4.2.1 Éprouvettes . 24

4.2.2 Circuit d'essai . 24

4.2.3 Charges de contact. 24

4.2.4 Conditions d'environnement . 24

4.2.5 Conditions de fonctionnement . 24

4.2.6 Critères de défaillance . 24

4.3 Réalisation des essais . 25

4.3.1 Essai de type . 25

4.3.2 Essai individuel de série . 25

5 Évaluation et vérification de B . 26

10D

5.1 Généralités . 26

5.2 Exigences . 27

5.2.1 Éprouvettes . 27

5.2.2 Circuit d'essai . 27

5.2.3 Charges de contact. 27

5.2.4 Conditions d'environnement . 27

5.2.5 Conditions de fonctionnement . 27

5.2.6 Critères de défaillance . 27

5.3 Réalisation des essais . 28

5.3.1 Essai de type . 28

5.3.2 Essai individuel de série . 28

Annexe A (informative) Exemple représentatif de l'évaluation des dysfonctionnements

pendant l'évaluation de B . 31

10D

A.1 Objet . 31

A.2 Hypothèses de base .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...