IEC 60335-2-72:2002/AMD1:2005

(Amendment)Amendment 1 - Household and similar electrical appliances - Safety - Part 2-72: Particular requirements for automatic machines for floor treatment for commercial and industrial use

Amendment 1 - Household and similar electrical appliances - Safety - Part 2-72: Particular requirements for automatic machines for floor treatment for commercial and industrial use

General Information

- Status

- Published

- Publication Date

- 22-Nov-2005

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 29-Mar-2012

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview - IEC 60335-2-72:2002/AMD1:2005 (Amendment 1)

IEC 60335-2-72 Amendment 1 updates the safety requirements for automatic machines for floor treatment used in commercial and industrial environments. This amendment supplements the base Part 2-72 of the IEC 60335 family (safety of household and similar electrical appliances) by adding new annexes, tests, marking and instruction requirements, and specific mechanical and electrical test procedures for components such as motorized cleaning heads and current-carrying hoses.

Key topics and technical requirements

- New Annexes

- Annex BB: Measurement of acoustical noise (noise emission declaration and test methods).

- Annex CC: Falling-object protective structures (FOPS) - dynamic test and performance requirements.

- Marking & Instructions

- Mandatory front-cover cautions, warnings for hazardous dust, wet conditions, brush use, gradient symbol (minimum gradient value of 2) and symbol IEC 60417-5935 for motorized cleaning heads.

- Instruction manual must declare operator vibration exposure values per ISO 5349-1 (hand/arm) and ISO 2631-1 (whole-body).

- Motorized cleaning head requirements

- Separate power-input measurement.

- Moisture/ingress resistance: impact test (IEC 60068-2-75, 2 J), free-fall test (IEC 60068-2-32: 4 000 drops from 100 mm), and IP-style immersion test with ~1% NaCl solution (per IEC 60529 clause).

- Locked-rotor test: brush locked for 30 s under abnormal operation.

- Current-carrying hose tests

- Electrical strength and immersion: 1 h in ~1% NaCl then dielectric tests (2 000 V and 3 000 V sequences).

- Mechanical durability: crushing, abrasion (ISO 6344-2 abrasive), flexing (multi-axis cyclic flex test), torsion (2 000 cycles), and cold treatment (–15 °C test configuration).

- Safety features for ride-on machines

- Acoustic warning device, and for hazardous brushes a yellow pulsating/rotating light that cannot be inadvertently disconnected.

- Normative references added

- Multiple ISO standards for acoustics, vibration, mechanical safety and abrasives (e.g., ISO 11201, ISO 3744, ISO 5349-1, ISO 2631-1, ISO 12100-2, ISO 3471).

Practical applications and who uses this standard

- Manufacturers of commercial/industrial floor cleaning machines (sweepers, scrubbers, ride-on units) for design validation and CE/region-specific compliance.

- Test laboratories and conformity assessment bodies performing safety, ingress, electrical strength, vibration and noise testing.

- Product safety engineers, compliance officers, procurement teams and end-users who require assurance of electrical and mechanical safety for floor treatment equipment.

- Component suppliers (motorized heads, hoses, ROPS/FOPS systems) to ensure parts meet durability and marking requirements.

Related standards

- ISO 5349-1 (hand-arm vibration), ISO 2631-1 (whole-body vibration), ISO 11201 / ISO 3744 (noise measurements), ISO 6344-2 (abrasives), IEC 60068 series (environmental tests), IEC 60529 (IP tests), ISO 12100-2 (machine safety principles).

Keywords: IEC 60335-2-72, Amendment 1, automatic machines for floor treatment, safety standard, motorized cleaning head, current-carrying hose, noise emission, FOPS, ROPS, vibration exposure.

IEC 60335-2-72:2002/AMD1:2005 - Amendment 1 - Household and similar electrical appliances - Safety - Part 2-72: Particular requirements for automatic machines for floor treatment for commercial and industrial use Released:11/23/2005 Isbn:2831883024

Frequently Asked Questions

IEC 60335-2-72:2002/AMD1:2005 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Amendment 1 - Household and similar electrical appliances - Safety - Part 2-72: Particular requirements for automatic machines for floor treatment for commercial and industrial use". This standard covers: Amendment 1 - Household and similar electrical appliances - Safety - Part 2-72: Particular requirements for automatic machines for floor treatment for commercial and industrial use

Amendment 1 - Household and similar electrical appliances - Safety - Part 2-72: Particular requirements for automatic machines for floor treatment for commercial and industrial use

IEC 60335-2-72:2002/AMD1:2005 is classified under the following ICS (International Classification for Standards) categories: 97.080 - Cleaning appliances. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60335-2-72:2002/AMD1:2005 has the following relationships with other standards: It is inter standard links to IEC 60335-2-72:2002, IEC 60335-2-72:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60335-2-72:2002/AMD1:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 60335-2-72

AMENDMENT 1

2005-11

Amendment 1

Household and similar electrical appliances –

Safety –

Part 2-72:

Particular requirements for automatic

machines for floor treatment for commercial

and industrial use

IEC 2005 Droits de reproduction réservés Copyright - all rights reserved

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale R

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

– 2 – 60335-2-72 Amend. 1 IEC:2005(E)

FOREWORD

This amendment has been prepared by subcommittee 61J: Electrical motor-operated cleaning

appliances for industrial use, of IEC technical committee 61: Safety of household and similar

electrical appliances.

The text of this amendment is based on the following documents:

FDIS Report on voting

61J/203/FDIS 61J/211/RVD

Full information on the voting for the approval of this amendment can be found in the report

on voting indicated in the above table.

The committee has decided that the contents of this amendment and the base publication will

remain unchanged until the maintenance result date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

_____________

CONTENTS

Add the titles of the new Annexes BB and CC as follows:

Annex BB Measurement of acoustical noise.

Annex CC Falling-object protective structures (FOPS) – Dynamic test and performance

requirements.

Add, in the list of figures, the titles of the new Figures 102 to 105 as follows:

Figure 102 – Apparatus for testing the abrasion resistance of current-carrying hoses

Figure 103 – Apparatus for testing the resistance to flexing of current-carrying hoses

Figure 104 – Configuration of the hose for the freezing treatment

Figure 105 – Flexing positions for the hose after removal from the freezing cabinet

FOREWORD

Add, at the end of the Foreword, the following new text:

The following differences exist in the countries indicated below:

– 7.12 No requirements for sound and vibration markings exist (USA).

60335-2-72 Amend. 1 IEC:2005(E) – 3 –

INTRODUCTION

Replace the second sentence of the second paragraph by the following:

It also covers abnormal situations that can be expected in practice and takes into account the

way in which electromagnetic phenomena can affect the safe operation of appliances.

1 Scope

Delete Note 101and renumber the subsequent notes accordingly.

2 Normative references

Add the following new references:

ISO 2631-1, Mechanical vibration and shock – Evaluation of human exposure to whole-body

vibration – Part 1: General requirements

ISO 3471, Earth-moving machinery – Roll-over protective structures – Laboratory tests and

performance requirements

ISO 3743-1, Acoustics – Determination of sound power levels of noise sources – Engineering

methods for small, movable sources in reverberant fields – Part 1: Comparison method for

hard-walled test rooms

ISO 3744, Acoustics – Determination of sound power levels of noise sources using sound

pressure – Engineering method in an essentially free field over a reflecting plane

ISO 4743-1, Acoustics – Determination of sound power levels of noise sources – Engineering

methods for small, movable sources in reverberant fields – Part 1: Comparison method for

hard-walled test rooms

ISO 4871, Acoustics – Declaration and verification of noise emission values of machinery and

equipment

ISO 5349-1, Mechanical vibration – Measurement and evaluation of human exposure to hand-

transmitted vibration – Part 1: General requirements

ISO 5353, Earth-moving machinery, and tractors and machinery for agriculture and forestry –

Seat index point

ISO 6344-2, Coated abrasives – Grain size analysis – Part 2: Determination of grain size

distribution of macrogrits P12 to P220

ISO 11201, Acoustics – Noise emitted by machinery and equipment – Measurement of

emission sound pressure levels at a work station and at other specified positions –

Engineering method in an essentially free field over a reflecting plane

ISO/TR 11688-1, Acoustics – Recommended practice for the design of low-noise machinery

and equipment – Part 1: Planning

ISO 12100-2, Safety of machinery – Basic concepts, general principles for design – Part 2:

Technical principles

– 4 – 60335-2-72 Amend. 1 IEC:2005(E)

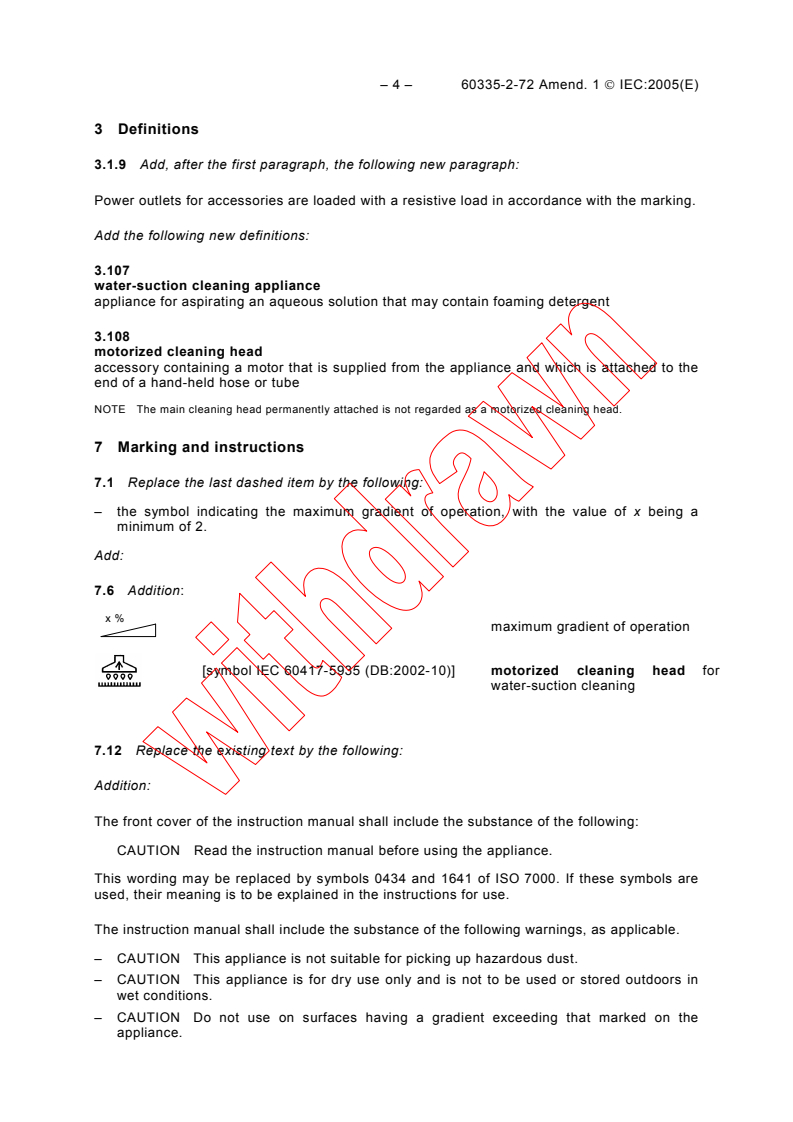

3 Definitions

3.1.9 Add, after the first paragraph, the following new paragraph:

Power outlets for accessories are loaded with a resistive load in accordance with the marking.

Add the following new definitions:

3.107

water-suction cleaning appliance

appliance for aspirating an aqueous solution that may contain foaming detergent

3.108

motorized cleaning head

accessory containing a motor that is supplied from the appliance and which is attached to the

end of a hand-held hose or tube

NOTE The main cleaning head permanently attached is not regarded as a motorized cleaning head.

7 Marking and instructions

7.1 Replace the last dashed item by the following:

– the symbol indicating the maximum gradient of operation, with the value of x being a

minimum of 2.

Add:

7.6 Addition:

x %

maximum gradient of operation

[symbol IEC 60417-5935 (DB:2002-10)] motorized cleaning head for

water-suction cleaning

7.12 Replace the existing text by the following:

Addition:

The front cover of the instruction manual shall include the substance of the following:

CAUTION Read the instruction manual before using the appliance.

This wording may be replaced by symbols 0434 and 1641 of ISO 7000. If these symbols are

used, their meaning is to be explained in the instructions for use.

The instruction manual shall include the substance of the following warnings, as applicable.

– CAUTION This appliance is not suitable for picking up hazardous dust.

– CAUTION This appliance is for dry use only and is not to be used or stored outdoors in

wet conditions.

– CAUTION Do not use on surfaces having a gradient exceeding that marked on the

appliance.

60335-2-72 Amend. 1 IEC:2005(E) – 5 –

– WARNING Only use the brushes provided with the appliance or those specified in the

instruction manual. The use of other brushes may impair safety.

The instruction manual shall give details regarding the following, as applicable:

– a statement that the appliance is only to be used by persons who have been adequately

instructed;

– the precautions to be taken when using the appliance under specific conditions such as

handling flammable liquids or dust, and dust hazardous to health;

– a statement that the appliance is to be disconnected from its power source during cleaning

or maintenance and when replacing parts or converting the appliance to another function:

• for mains operated appliances, the plug is to be removed from the socket-outlet;

• for battery operated appliances, the key of the supply switch is to be removed or an

equivalent disconnection is to be made;

– a statement that doors and covers are to be positioned as indicated in the instruction

manual before using the appliance;

– the precautions to be taken when changing brushes or other attachments which require

the appliance to be energized;

– the intended use of brushes which are specified for the appliance;

– a warning that large diameter brushes provided specifically for dry buffing are not intended

for general polishing.

The instruction manual shall state

– the weighted r.m.s. acceleration value to which the operators’ arms are subjected in m/s²,

separately for each arm (if applicable), measured in accordance with ISO 5349-1 for arm

vibrations, the appliance being supplied at rated voltage or at the maximum rated

voltage for machines with a range of voltages

2,

– the weighted r.m.s. acceleration value to which the operator is subjected in m/s measured

in accordance with ISO 2631-1, the appliance being supplied at rated voltage and

operated under normal operation.

The instruction manual for mains operated appliances shall include the substance of the

following:

– do not allow the rotating brushes to come into contact with the supply cord;

– regularly examine the supply cord for damage, such as cracking or ageing. If damage is

found, replace the cord before further use;

– only replace the supply cord with the type specified in the instruction manual;

– only use the socket outlet on the appliance for purposes specified in the instruction

manual.

The instruction manual for appliances having a traction drive and a mass exceeding 100 kg

shall include the substance of the following:

– in order to prevent unauthorised use of the appliance, the power source is to be switched

off or locked, for example by removing the key of the power switch;

– appliances left unattended are to be secured against unintentional movement.

The instruction manual for appliances having anchorage points for installing roll-over

protection systems (ROPS) or falling object protection systems (FOPS) shall include

instructions for fitting the system. The intended purpose of any protection system shall be

stated.

– 6 – 60335-2-72 Amend. 1 IEC:2005(E)

The instructions for appliances having a current-carrying hose operating at other than safety

extra-low voltage shall include the substance of the following:

CAUTION: This hose contains electrical connections:

– do not use to collect water;

– do not immerse in water for cleaning;

– the hose should be checked regularly and must not be used if damaged.

If the symbol IEC 60417-5935 is used, its meaning shall be explained.

Add the following new subclauses:

7.12.101 The instructions shall include a noise emission declaration according to BB 2.7.

7.14 Addition:

The height of symbol IEC 60417-5935 shall be at least 15 mm.

Compliance is checked by measurement.

7.101 Motorized cleaning heads shall be marked with

– rated voltage or rated voltage range in volts;

– rated power input in watts;

– name, trade mark or identification mark of the manufacturer or responsible vendor;

– model or type reference.

Motorized cleaning heads for water-suction cleaning appliances, except those of class III

construction having a working voltage up to 24 V shall be marked with symbol IEC 60417-

5935.

NOTE This symbol is an information sign and, except for the colours, the rules of ISO 3864-1 apply.

Compliance is checked by inspection.

7.102 Power outlets for accessories shall be marked with the maximum load in watts.

NOTE This marking may be on the appliance close to the appliance outlet.

Compliance is checked by inspection.

10 Power input and current

Replace the existing text by the following:

This clause of Part 1 is applicable except as follows.

10.1 Addition:

The power input of motorized cleaning heads is measured separately.

60335-2-72 Amend. 1 IEC:2005(E) – 7 –

15 Moisture resistance

15.2 Replace the last sentence by the following:

Motorized cleaning heads of water-suction cleaning appliances are placed in a container,

the base of which is level with the surface supporting the appliance. The container is filled

with a detergent solution to a level of 5 mm above its base, this level being maintained

throughout the test. The solution consists of 20 g of NaCl and 1 ml of a solution of 28 % by

mass of dodecyl sodium sulphate in each 8 l of water.

The appliance is operated until its liquid container is completely full and for a further 5 min.

NOTE 102 The solution is to be stored in a cool atmosphere and used within seven days of its preparation.

NOTE 103 The chemical designation of dodecyl sodium sulphate is C12H25NaSO4.

After each of these tests, the appliance shall withstand the electric strength test of 16.3.

Inspection shall show that there is no trace of liquid on insulation that could result in a

reduction of clearances or creepage distances below the values specified in Clause 29.

NOTE 104 The appliance is allowed to stand in normal test room atmosphere for 24h before being subjected to

the test of 15.3

Add the following new subclause:

15.101 Motorized cleaning heads of water suction cleaning appliances shall be resistant

to liquids that may come into contact with them.

Compliance is checked by the following tests.

The motorized cleaning head is subjected to an impact test as described in IEC 60068-2-75,

the value of the impact being 2 J. The motorized cleaning head is rigidly supported and

three blows are applied to every point of the enclosure that is likely to be weak.

It is then subjected to the free fall test procedure 1 of IEC 60068-2-32. It is dropped 4 000

times from a height of 100 mm onto a steel plate having a thickness of not less than 15 mm. It

is dropped

– 1 000 times on its right side;

– 1 000 times on its left side;

– 1 000 times on its front face;

– 1 000 times on its cleaning surface.

The motorized cleaning head is then subjected to the test described in 14.2.7 of IEC 60529,

the water containing approximately 1 % NaCl.

The motorized cleaning head shall then withstand the electric strength test of 16.3, the

voltage being applied between the live parts and the solution, and inspection shall show that

there is no trace of saline solution on insulation which could result in a reduction of

clearances and creepage distances below the values specified in Clause 29.

NOTE The test is not carried out on motorized cleaning heads of class III construction having a working

voltage up to 24 V.

– 8 – 60335-2-72 Amend. 1 IEC:2005(E)

16 Leakage current and electric strength

Replace the existing text by the following:

This clause of Part 1 is applicable except as follows.

16.3 Addition:

Current-carrying hoses, except for their electrical connections, are immersed for 1 h in water

containing approximately 1 % NaCl, at a temperature of 20 °C ± 5 °C. While the hose is still

immersed, a voltage of 2 000 V is applied for 5 min between each conductor and all the other

conductors connected together. A voltage of 3 000 V is then applied for 1 min between all the

conductors and the saline solution.

19 Abnormal operation

19.7 Add the following new paragraph:

Motorized cleaning heads are tested with the rotating brush or similar device locked for 30 s.

20 Stability and mechanical hazards

20.1 Add the following note:

NOTE 101 Motorized cleaning heads are not subjected to this test.

20.102.4 Add the following new paragraph:

Pedals shall be arranged so that they can be operated without risk of confusion. Their surface

shall be slip-resistant and easy to clean.

20.108 Add to the existing text the following new paragraphs:

Ride-on machines shall have an acoustic warning device controlled by the driver. If they are

fitted with hazardous exposed moving brushes, they shall also have a yellow pulsating or

rotating light. it shall not be possible to inadvertently disconnect these warning devices.

Compliance is checked by inspection and by manual test.

21 Mechanical strength

Add the following new subclauses:

21.102 Current-carrying hoses shall be resistant to crushing.

Compliance is checked by the following test.

The hose is placed between two parallel steel plates each having a length of 100 mm, a width

of 50 mm and the edges of the longer sides rounded with a radius of 1 mm. The axis of the

hose is positioned at right angles to the longer sides of the plates. The plates are placed at a

distance of approximately 350 mm from one end of the hose.

60335-2-72 Amend. 1 IEC:2005(E) – 9 –

The steel plates are pressed t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...