IEC 63171-6:2021

(Main)Connectors for electrical and electronic equipment - Part 6: Detail specification for 2-way and 4-way (data/power), shielded, free and fixed connectors for power and data transmission with frequencies up to 600 MHz

Connectors for electrical and electronic equipment - Part 6: Detail specification for 2-way and 4-way (data/power), shielded, free and fixed connectors for power and data transmission with frequencies up to 600 MHz

IEC 63171-6:2021 covers 2-way and 4-way (data/power), shielded, free and fixed connectors for data transmission with frequencies up to 600 MHz and specifies the common dimensions, mechanical, electrical and transmission characteristics and environmental requirements as well as test specifications. This second edition cancels and replaces the first edition published in 2020. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) Mating conditions changed, see Figure 2, Figure 4, Figure 13, Figure 15, Figure 19 and Figure 21. b) Voltage proof requirement added, 2 250 V DC, see 5.7.2. c) Mechanical shock requirement added, see 5.7.6 (the requirement itself already was specified indirectly by Ed1 due to the specification of the test EP3 of Table 14 which is still identical to Ed1). d) Styles added, 6P-M8CI and 6J-M8CI, see Table 1.

General Information

- Status

- Published

- Publication Date

- 27-Oct-2021

- Technical Committee

- SC 48B - Electrical connectors

- Current Stage

- PPUB - Publication issued

- Start Date

- 28-Oct-2021

- Completion Date

- 22-Oct-2021

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 63171-6:2021 is an International Electrotechnical Commission (IEC) standard that defines detailed specifications for shielded 2-way and 4-way data/power connectors (free and fixed) intended for combined power and data transmission at frequencies up to 600 MHz. The second edition (2021) updates mating conditions, adds a voltage proof requirement (2 250 V DC), introduces a mechanical shock requirement and two new styles (6P‑M8CI and 6J‑M8CI). The standard specifies common dimensions, mechanical and electrical characteristics, transmission requirements, environmental ratings and test procedures.

Key topics and requirements

- Connector types and styles: Defines multiple mechanical styles including M8 and M12 variants and specific 2‑way and 4‑way configurations; includes overall and mating dimensions and pin assignments.

- Electrical characteristics: Requirements for voltage rating, voltage proof (2 250 V DC), current‑carrying capacity, contact and shield resistance, insulation resistance, and impedance.

- Transmission performance: Specifications and test methods for insertion loss, return loss, propagation delay, transfer impedance, coupling attenuation, and alien NEXT/FEXT metrics up to 600 MHz.

- Mechanical requirements: Insertion/withdrawal forces, polarization, vibration and mechanical shock resistance (new explicit shock requirement), mating conditions, and durability (number of mating cycles).

- Environmental and safety: Climatic category classification, IP degree of protection, clearance and creepage distances and derating diagrams for data and power pins.

- Test specifications: Detailed test schedules and groups (basic and full test schedules), mounting arrangements for specimens, and standardized test procedures for electrical, mechanical and environmental verification.

Applications and users

IEC 63171-6 is intended for:

- Connector manufacturers designing shielded data/power 2‑way and 4‑way solutions (M8/M12 and other styles).

- OEMs and equipment designers building industrial automation, robotics, sensors, fieldbus and PoDL/PoE-like systems that require combined power and data over compact connectors.

- Test laboratories and compliance engineers performing type and routine testing to IEC requirements (electrical, mechanical, environmental and RF transmission).

- System integrators and procurement teams evaluating connector compatibility, performance up to 600 MHz, and environmental suitability.

Practical benefits include consistent mechanical interoperability, verified signal integrity (insertion/return loss and crosstalk controls), robust power delivery, and harmonized test methods for reliable, field‑grade connector selection.

Related standards

- Other parts of the IEC 63171 series cover alternative connector variants and higher‑level system considerations. Users should consult the complete IEC catalogue for related connector and electrotechnical standards.

IEC 63171-6:2021 - Connectors for electrical and electronic equipment - Part 6: Detail specification for 2-way and 4-way (data/power), shielded, free and fixed connectors for power and data transmission with frequencies up to 600 MHz

Frequently Asked Questions

IEC 63171-6:2021 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Connectors for electrical and electronic equipment - Part 6: Detail specification for 2-way and 4-way (data/power), shielded, free and fixed connectors for power and data transmission with frequencies up to 600 MHz". This standard covers: IEC 63171-6:2021 covers 2-way and 4-way (data/power), shielded, free and fixed connectors for data transmission with frequencies up to 600 MHz and specifies the common dimensions, mechanical, electrical and transmission characteristics and environmental requirements as well as test specifications. This second edition cancels and replaces the first edition published in 2020. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) Mating conditions changed, see Figure 2, Figure 4, Figure 13, Figure 15, Figure 19 and Figure 21. b) Voltage proof requirement added, 2 250 V DC, see 5.7.2. c) Mechanical shock requirement added, see 5.7.6 (the requirement itself already was specified indirectly by Ed1 due to the specification of the test EP3 of Table 14 which is still identical to Ed1). d) Styles added, 6P-M8CI and 6J-M8CI, see Table 1.

IEC 63171-6:2021 covers 2-way and 4-way (data/power), shielded, free and fixed connectors for data transmission with frequencies up to 600 MHz and specifies the common dimensions, mechanical, electrical and transmission characteristics and environmental requirements as well as test specifications. This second edition cancels and replaces the first edition published in 2020. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) Mating conditions changed, see Figure 2, Figure 4, Figure 13, Figure 15, Figure 19 and Figure 21. b) Voltage proof requirement added, 2 250 V DC, see 5.7.2. c) Mechanical shock requirement added, see 5.7.6 (the requirement itself already was specified indirectly by Ed1 due to the specification of the test EP3 of Table 14 which is still identical to Ed1). d) Styles added, 6P-M8CI and 6J-M8CI, see Table 1.

IEC 63171-6:2021 is classified under the following ICS (International Classification for Standards) categories: 31.220.10 - Plug-and-socket devices. Connectors. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 63171-6:2021 has the following relationships with other standards: It is inter standard links to IEC 63171-6:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 63171-6:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 63171-6 ®

Edition 2.0 2021-10

INTERNATIONAL

STANDARD

Connectors for electrical and electronic equipment –

Part 6: Detail specification for 2-way and 4-way (data/power), shielded, free and

fixed connectors for power and data transmission with frequencies up to

600 MHz

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 63171-6 ®

Edition 2.0 2021-10

INTERNATIONAL

STANDARD

Connectors for electrical and electronic equipment –

Part 6: Detail specification for 2-way and 4-way (data/power), shielded, free and

fixed connectors for power and data transmission with frequencies up to

600 MHz

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.220.10 ISBN 978-2-8322-1030-7

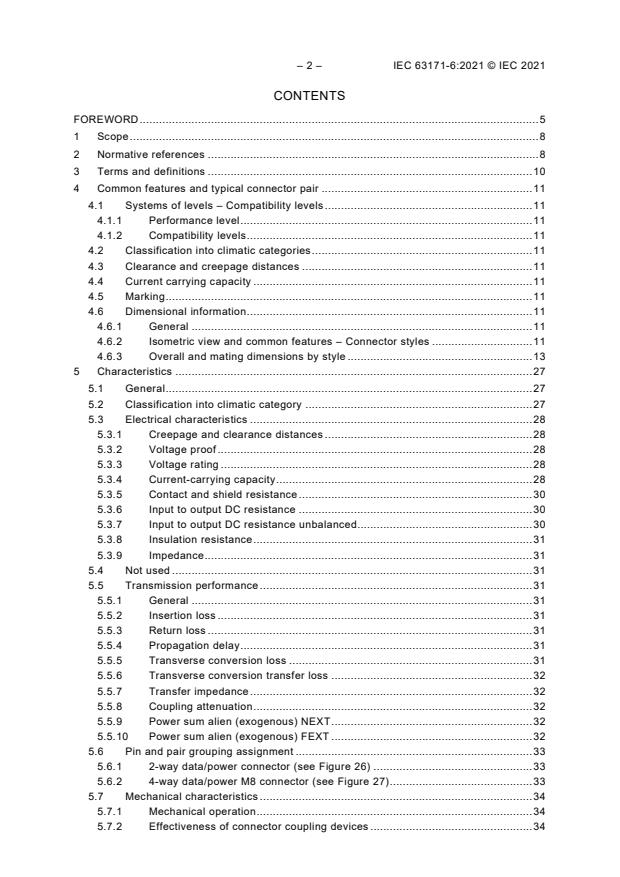

– 2 – IEC 63171-6:2021 © IEC 2021

CONTENTS

FOREWORD . 5

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 10

4 Common features and typical connector pair . 11

4.1 Systems of levels – Compatibility levels . 11

4.1.1 Performance level . 11

4.1.2 Compatibility levels . 11

4.2 Classification into climatic categories . 11

4.3 Clearance and creepage distances . 11

4.4 Current carrying capacity . 11

4.5 Marking . 11

4.6 Dimensional information . 11

4.6.1 General . 11

4.6.2 Isometric view and common features – Connector styles . 11

4.6.3 Overall and mating dimensions by style . 13

5 Characteristics . 27

5.1 General . 27

5.2 Classification into climatic category . 27

5.3 Electrical characteristics . 28

5.3.1 Creepage and clearance distances . 28

5.3.2 Voltage proof . 28

5.3.3 Voltage rating . 28

5.3.4 Current-carrying capacity . 28

5.3.5 Contact and shield resistance . 30

5.3.6 Input to output DC resistance . 30

5.3.7 Input to output DC resistance unbalanced. 30

5.3.8 Insulation resistance . 31

5.3.9 Impedance . 31

5.4 Not used . 31

5.5 Transmission performance . 31

5.5.1 General . 31

5.5.2 Insertion loss . 31

5.5.3 Return loss . 31

5.5.4 Propagation delay . 31

5.5.5 Transverse conversion loss . 31

5.5.6 Transverse conversion transfer loss . 32

5.5.7 Transfer impedance . 32

5.5.8 Coupling attenuation . 32

5.5.9 Power sum alien (exogenous) NEXT . 32

5.5.10 Power sum alien (exogenous) FEXT . 32

5.6 Pin and pair grouping assignment . 33

5.6.1 2-way data/power connector (see Figure 26) . 33

5.6.2 4-way data/power M8 connector (see Figure 27) . 33

5.7 Mechanical characteristics . 34

5.7.1 Mechanical operation . 34

5.7.2 Effectiveness of connector coupling devices . 34

5.7.3 Insertion and withdrawal forces . 35

5.7.4 Polarizing method . 35

5.7.5 Vibration resistance . 35

5.7.6 Mechanical shock resistance . 35

5.7.7 IP degree of protection . 36

6 Tests and test schedule . 36

6.1 General . 36

6.2 Test procedures and measuring methods . 36

6.3 Mounting of specimens . 36

6.3.1 General . 36

6.3.2 Arrangement for contact resistance measurement . 37

6.3.3 Arrangement for dynamic stress tests . 37

6.3.4 Wiring of specimens . 38

6.4 Test schedules . 38

6.4.1 Basic (minimum) test schedule . 38

6.4.2 Full test schedule . 38

Bibliography . 48

Figure 1 – Style 2J-L, overall dimensions . 13

Figure 2 – Style 2J-L, mating dimensions . 14

Figure 3 – Style 2P-L, overall dimensions . 15

Figure 4 – Style 2P-L, mating dimensions . 16

Figure 5 – Style 6J-S8, overall dimensions . 17

Figure 6 – Style 6J-S8, mating dimensions . 17

Figure 7 – Style 6P-S8, overall dimensions . 18

Figure 8 – Styles 6J-P8 or 6J-M8, overall dimensions . 19

Figure 9 – Style 6J-P8, size 8 push pull jack, mating dimensions . 19

Figure 10 – Style 6J-M8, M8 thread jack, mating dimensions . 20

Figure 11 – Styles 6P-P8, overall dimensions . 21

Figure 12 – Style 6P-M8, overall dimensions, field attachable version (top), non field

attachable version (bottom). 21

Figure 13 – Style 6P-M8, mating dimensions . 22

Figure 14 – Styles 6J-P12, 6J-M12, 6J-C12, overall dimensions . 22

Figure 15 –Styles 6J-C12, 6J-P12 and 6J-M12, mating dimensions . 23

Figure 16 – Style 6P-M12, overall dimensions. 24

Figure 17 – Style 6P-P12, overall dimensions . 24

Figure 18 – Style 6J-M8C, overall dimensions. 25

Figure 19 – Styles 6J-M8C, 6P-M8CI, mating dimensions . 25

Figure 20 – Style 6J-M8CI, overall dimensions. 26

Figure 21 – Styles 6J-M8CI, 6P-M8C, mating dimensions . 26

Figure 22 – Style 6P-M8C, overall dimensions . 27

Figure 23 – Style 6P-M8CI, overall dimensions . 27

Figure 24 – Derating diagram for the Ø 0,5 mm data pins of the 2-way and 4-way

connectors . 29

Figure 25 – Derating diagram for the Ø 1 mm power pins of the 4-way connector . 30

Figure 26 – Connector pin assignment for 2-way free connector, front view . 33

– 4 – IEC 63171-6:2021 © IEC 2021

Figure 27 – Connector pin assignment for 4-way M8 connector, front view. 33

Figure 28 – Contact resistance arrangement . 37

Figure 29 – Arrangement for vibration and mechanical shock tests . 38

Table 1 – Connector styles . 12

Table 2 – Geometrical position of planes . 23

Table 3 – Climatic category. 28

Table 4 – Current ratings of connectors . 29

Table 5 – 2-way connector signal pin assignment . 33

Table 6 – 4-way M8 connector signal pin assignment . 34

Table 7 – Preferred values for the number of mating cycles . 34

Table 8 – Preferred values for the pull-out force . 35

Table 9 – Test group P . 39

Table 10 – Test group AP . 39

Table 11 – Test group BP . 41

Table 12 – Test group CP . 43

Table 13 – Test group DP . 44

Table 14 – Test group EP . 45

Table 15 – Test group FP . 46

Table 16 – Test group GP . 47

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

CONNECTORS FOR ELECTRICAL AND ELECTRONIC EQUIPMENT –

Part 6: Detail specification for 2-way and 4-way (data/power),

shielded, free and fixed connectors for power and data

transmission with frequencies up to 600 MHz

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This International Standard IEC 63171-6 has been prepared by subcommittee 48B: Electrical

connectors, of IEC technical committee 48: Electrical connectors and mechanical structures for

electrical and electronic equipment.

This second edition cancels and replaces the first edition published in 2020. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Mating conditions changed, see Figure 2, Figure 4, Figure 13, Figure 15, Figure 19 and

Figure 21.

b) Voltage proof requirement added, 2 250 V DC, see 5.7.2.

c) Mechanical shock requirement added, see 5.7.6 (the requirement itself already was

specified indirectly by Ed1 due to the specification of the test EP3 of Table 14 which is still

identical to Ed1).

– 6 – IEC 63171-6:2021 © IEC 2021

d) Styles added, 6P-M8CI and 6J-M8CI, see Table 1.

The text of this International Standard is based on the following documents:

FDIS Report on voting

48B/2907/FDIS 48B/2917/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 63171 series, published under the general title Connectors for

electrical and electronic equipment, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IEC SC 48B – Electrical connectors IEC 63171-6 Ed. 2

Specification available from: IEC General secretariat or from the

addresses shown on the inside cover.

DETAIL SPECIFICATION in accordance with IEC 61076-1

2-way data

IP20, latch locking

2-way data

IP65/IP67, snap-in locking

2-way data

IP65/IP67, push-pull locking

-+

2-way data

IP65/IP67, M8 screw locking

2-way data

IP65/IP67, M12 screw locking or

push-pull locking (or both)

4-way (2 power + 2 data)

IP65/IP67, M8 screw locking

– 8 – IEC 63171-6:2021 © IEC 2021

CONNECTORS FOR ELECTRICAL AND ELECTRONIC EQUIPMENT –

Part 6: Detail specification for 2-way and 4-way (data/power),

shielded, free and fixed connectors for power and data

transmission with frequencies up to 600 MHz

1 Scope

This document covers 2-way and 4-way (data/power), shielded, free and fixed connectors for

data transmission with frequencies up to 600 MHz and specifies the common dimensions,

mechanical, electrical and transmission characteristics and environmental requirements as well

as test specifications.

NOTE 1 This 63171-6 document is not fully harmonized with the content and structure of IEC 63171. There are

several specifications in both documents which are overlapping. In any case the provisions within this document

prevail.

NOTE 2 The connectors are intended to be used for single-pair Ethernet (SPE) according to the following IEEE

Standards: 10BaseT1 (IEEE 802.3cg), 100Base-T1 (IEEE 802.3bw), 1000Base-T1 (IEEE 802.3bp), and optionally

with Power over Data line (PoDL) power supply according to IEEE 802.3bu.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60050-581, International Electrotechnical Vocabulary (IEV) – Part 581: Electromechanical

components for electronic equipment

IEC 60068-1, Environmental testing – Part 1: General and guidance

IEC 60068-2-14, Environmental testing – Part 2-14: Tests – Test N: Change of temperature

IEC 60068-2-38, Environmental testing – Part 2-38: Tests – Test Z/AD: Composite

temperature/humidity cyclic test

IEC 60352 (all parts), Solderless connections

IEC 60512-1, Connectors for electrical and electronic equipment – Tests and measurements –

Part 1: Generic specification

IEC 60512-1-1, Connectors for electronic equipment – Tests and measurements – Part 1-1:

General examination – Test 1a: Visual examination

IEC 60512-1-2, Connectors for electronic equipment – Tests and measurements – Part 1-2:

General examination – Test 1b: Examination of dimension and mass

IEC 60512-2-1, Connectors for electronic equipment – Tests and measurements – Part 2-1:

Electrical continuity and contact resistance tests – Test 2a: Contact resistance – Millivolt level

method

IEC 60512-2-5, Connectors for electronic equipment – Tests and measurements – Part 2-5:

Electrical continuity and contact resistance tests – Test 2e: Contact disturbance

IEC 60512-3-1, Connectors for electronic equipment – Tests and measurements – Part 3-1:

Insulation tests – Test 3a: Insulation resistance

IEC 60512-4-1, Connectors for electronic equipment – Tests and measurements – Part 4-1:

Voltage stress tests – Test 4a: Voltage proof

IEC 60512-5-2, Connectors for electronic equipment – Tests and measurements – Part 5-2:

Current-carrying capacity tests – Test 5b: Current-temperature derating

IEC 60512-6-3, Connectors for electronic equipment – Tests and measurements – Part 6-3:

Dynamic stress tests – Test 6c: Shock

IEC 60512-6-4, Connectors for electronic equipment – Tests and measurements – Part 6-4:

Dynamic stress tests – Test 6d: Vibration (sinusoidal)

IEC 60512-9-1, Connectors for electronic equipment – Tests and measurements – Part 9-1:

Endurance tests – Test 9a: Mechanical operation

IEC 60512-9-2, Connectors for electronic equipment – Tests and measurements – Part 9-2:

Endurance tests – Test 9b: Electrical load and temperature

IEC 60512-11-3, Connectors for electronic equipment – Tests and measurements – Part 11-3:

Climatic tests – Test 11c: Damp heat, steady state

IEC 60512-11-4, Connectors for electronic equipment – Tests and measurements – Part 11-4:

Climatic tests – Test 11d: Rapid change of temperature

IEC 60512-11-7, Connectors for electronic equipment – Tests and measurements – Part 11-7:

Climatic tests – Test 11g: Flowing mixed gas corrosion test

IEC 60512-11-9, Connectors for electronic equipment – Tests and measurements – Part 11-9:

Climatic tests – Test 11i: Dry heat

IEC 60512-11-10, Connectors for electronic equipment – Tests and measurements – Part 11-9:

Climatic tests – Test 11j: Cold

IEC 60512-11-12, Connectors for electronic equipment – Tests and measurements –

Part 11-12: Climatic tests – Test 11m: Damp heat, cyclic

IEC 60512-13-2, Connectors for electronic equipment – Tests and measurements – Part 13-2:

Mechanical operation tests – Test 13b: Insertion and withdrawal forces

IEC 60512-13-5, Connectors for electronic equipment – Tests and measurements – Part 13-5:

Mechanical operation tests – Test 13e: Polarizing and keying method

IEC 60512-15-6, Connectors for electronic equipment – Tests and measurements – Part 15-6:

Connector tests (mechanical) – Test 15f: Effectiveness of connector coupling devices

IEC 60512-25-7, Connectors for electronic equipment – Tests and measurements – Part 25-7:

Test 25g – Impedance, reflection coefficient, and voltage standing wave ratio (VSWR)

IEC 60512-25-9, Connectors for electrical equipment – Tests and measurements – Part 25-9:

Signal integrity tests – Test 25i: Alien crosstalk

– 10 – IEC 63171-6:2021 © IEC 2021

IEC 60512-26-100, Connectors for electronic equipment – Tests and measurements –

Part 26-100: Measurement setup, test and reference arrangements and measurements for

connectors according to IEC 60603-7 – Tests 26a to 26g

IEC 60512-28-100, Connectors for electrical and electronic equipment – Tests and

measurements – Part 28-100: Signal integrity tests up to 2 000 MHz – Tests 28a to 28g

IEC 60529, Degrees of protection provided by enclosures (IP code)

IEC 60603-7:2020, Connectors for electronic equipment – Part 7: Detail specification for 8-way,

unshielded, free and fixed connectors

IEC 60664-1, Insulation coordination for equipment within low-voltage systems – Part 1:

Principles, requirements and tests

IEC 61076-1:2006, Connectors for electronic equipment – Product requirements – Part 1:

Generic specification

IEC 61076-2-010, Connectors for electrical and electronic equipment – Product requirements –

Part 2-010: Circular connectors – Detail specification for connectors with outer or inner push-

pull locking mechanism, based on mating interfaces according to IEC 61076-2-101,

IEC 61076-2-109, IEC 61076-2-111 and IEC 61076-2-113

IEC 61076-2-101: Connectors for electronic equipment – Product requirements – Part 2-101:

Circular connectors – Detail specification for M12 connectors with screw-locking

IEC 61076-3, Connectors for electronic equipment – Product requirements – Part 3:

Rectangular connectors – Sectional specification

IEC 61156 (all parts), Multicore and symmetrical pair/quad cables for digital communications

IEC 61984, Connectors – Safety requirements and tests

IEC 62153-4-15, Metallic communication cable test methods – Part 4-15: Electromagnetic

compatibility (EMC) – Test method for measuring transfer impedance and screening attenuation

– or coupling attenuation with triaxial cell

IEC 63171:2021, Connectors for electrical and electronic equipment – Shielded or unshielded

free and fixed connectors for balanced single-pair data transmission with current-carrying

capacity – General requirements and tests

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-581,

IEC 61076-1, IEC 61076-3 and IEC 60512-1 apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

4 Common features and typical connector pair

4.1 Systems of levels – Compatibility levels

4.1.1 Performance level

Connectors according to this document are classified by mating performance level (MPL). See

5.7.1 for details.

4.1.2 Compatibility levels

Compatibility levels are according to IEC 61076-1

a) Intermateability

Intermateability as defined in Clause B.3 of IEC 61076-1:2006 standardizes only dimensions

of electrical and mechanical interfaces. Intermateability shall be ensured by application of

the “Go” and “No-Go” gauge requirements in the standards that may be referenced, and

adherence to the dimensional requirements within.

b) Interoperability

Interoperability as defined in Clause B.5 of IEC 61076-1:2006 shall be assured by

compliance with the specified interface dimensions and by compliance with the requirements

in 5.2 through 5.7 proven by the respective testing sequences in Clause 6.

4.2 Classification into climatic categories

See 5.2.

4.3 Clearance and creepage distances

See 5.3.1.

4.4 Current carrying capacity

See 5.3.4

4.5 Marking

The marking of the connector and the packaging shall be in accordance with 2.7 of

IEC 61076-12006.

4.6 Dimensional information

4.6.1 General

Drawings are shown in the first angle projection. The shape of connectors may deviate from

those shapes given in the following figures as long as the specified dimensions are not

influenced. Coordination dimensions are dimensions without tolerances which indicate the

boundary or centre-line references in order to allow for (modular) arrangement.

4.6.2 Isometric view and common features – Connector styles

Table 1 shows an overview of connector styles specified in this document.

– 12 – IEC 63171-6:2021 © IEC 2021

Table 1 – Connector styles

Style Description Figures

Picture

2P-L Figure 3

PLUG – Free 2-way IP20

connector with male

Figure 4

contacts, latch locking

2J-L Figure 1

JACK – Fixed 2-way IP20

connector with female

Figure 2

contacts, latch locking,

intended for PCB mounting

6P-S8 Figure 7

6J-S8 Figure 5

JACK – Fixed 2-way

IP65/IP67 connector with

Figure 6

female contacts, size 8,

snap-in locking, intended

for single hole mounting.

6P-P8 Figure 11

PLUG – Free 2-way

IP65/IP67 connector with

Figure 8

male contacts, size 8, push

pull locking

6J-P8 Figure 8

Figure 9

6P-M8 Figure 12

PLUG – Free 2-way

IP65/IP67 connector with

Figure 13

male contacts, size 8, M8-

screw locking

6J-M8 Figure 8

JACK – Fixed 2-way

IP65/IP67 connector with

Figure 10

female contacts, size 8, M8

thread locking, intended for

single hole mounting.

6P-P12

Figure 14

PLUG – Free 2-way

IP65/IP67 connector with

Figure 17

male contacts, size 12,

push pull locking

6P-M12 Figure 16

PLUG – Free 2-way

IP65/IP67 connector with

male contacts, size 12,

M12 thread locking

6J-P12 Figure 14

JACK – Fixed 2-way

IP65/IP67 connector with

Figure 15

female contacts, size 12,

push pull locking, intended

for single hole mounting

6J-M12 Figure 14

JACK – Identical to 6J-P12

but with M12 thread locking

Figure 15

instead of push pull,

intended for single hole

mounting

6J-C12 Figure 14

JACK – Combination of

6J-P12 and 6J-M12: With

Figure 15

both, M12 thread and push

pull locking, intended for

single hole mounting

Style Description Figures

Picture

6P-M8C Figure 21

PLUG – Free 4-way

IP65/IP67 connector with

Figure 22

male contacts, size 8, M8

thread locking

Figure 18

6J-M8C Figure 18

JACK – Fixed 4-way

IP65/IP67connector with

Figure 19

female contacts, size 8, M8

thread locking, intended for

single hole mounting

6P-M8CI Figure 19

PLUG – Free 4-way

IP65/IP67 connector with

Figure 23

female contacts, “inverse

style”, size 8, M8 thread

locking

6J-M8CI Figure 20

JACK – Fixed 4-way

IP65/IP67connector with

Figure 21

male contacts, “inverse

style”, size 8, M8 thread

locking, intended for single

hole mounting

The terms PLUG and JACK are used only for easier reading since they are widely used.

The designation “size 8” and “size 12” indicates roughly the diameter of the jack in millimetres.

The pictures are only intended to give an idea of the components, the visible details are not binding.

4.6.3 Overall and mating dimensions by style

4.6.3.1 2-way connectors

4.6.3.1.1 Styles 2J-L and 2P-L

4.6.3.1.1.1 Style 2J-L, jack

Figure 1 shows the overall dimensions of fixed 2-way IP20 connector with female contacts, latch

locking, intended for PCB mounting. Figure 2 shows its mating dimensions.

Dimensions in millimetres

Figure 1 – Style 2J-L, overall dimensions

NOTE The PCB is shown only for illustration purposes.

– 14 – IEC 63171-6:2021 © IEC 2021

Dimensions in millimetres

Figure 2 – Style 2J-L, mating dimensions

4.6.3.1.1.2 Style 2P-L, plug

Figure 3 shows the overall dimensions of the free, 2-way IP20 connector with male contacts,

latch locking. Figure 4 shows its mating dimensions.

Dimensions in millimetres

Figure 3 – Style 2P-L, overall dimensions

– 16 – IEC 63171-6:2021 © IEC 2021

Dimensions in millimetres

Figure 4 – Style 2P-L, mating dimensions

4.6.3.1.2 Styles 6J-S8 and 6P-S8,

4.6.3.1.2.1 Size 8 snap-in jack, 6J-S8

Figure 5 shows the overall dimensions of fixed 2-way IP65/IP67 connector with male contacts,

size 8, snap-in locking, intended for single hole mounting. Figure 6 shows its mating

dimensions.

Dimensions in millimetres

Figure 5 – Style 6J-S8, overall dimensions

NOTE For this style no axial overall dimensions are specified besides those which are concluded from by the mating

dimensions in Figure 6.

Dimensions in millimetres

Figure 6 – Style 6J-S8, mating dimensions

Figure 2 applies respectively.

– 18 – IEC 63171-6:2021 © IEC 2021

4.6.3.1.2.2 Size 8 snap-in plug, 6P-S8

Figure 7 shows the overall dimensions of free 2-way IP65/IP67 connector with male contacts,

size 8, snap-in locking.

NOTE Besides Figure 4 for this style there are no additional mating dimensions specified.

Dimensions in millimetres

NOTE Side views: Short, field attachable version (top) and longer, non field attachable version (middle).

Figure 7 – Style 6P-S8, overall dimensions

4.6.3.1.3 Styles 6J-P8, 6J-M8, 6P-P8 and 6P-M8

4.6.3.1.3.1 Size 8 push pull jack, 6J-P8 and M8 thread jack, 6J-M8

Figure 8 shows the overall dimensions of fixed IP65/IP67 connector with female contacts and

push pull or M8 thread locking, intended for single hole mounting. Figure 9 shows the mating

dimensions of the push pull jack, 6J-P8. Figure 10 shows the mating dimensions of the M8

thread jack, 6P-M8.

Dimensions in millimetres

Figure 8 – Styles 6J-P8 or 6J-M8, overall dimensions

NOTE For this style no axial overall dimensions are specified besides those which are concluded from by the mating

dimensions.

Dimensions in millimetres

Figure 9 – Style 6J-P8, size 8 push pull jack, mating dimensions

– 20 – IEC 63171-6:2021 © IEC 2021

Figure 2 applies respectively.

Dimensions in millimetres

Figure 10 – Style 6J-M8, M8 thread jack, mating dimensions

Figure 2 applies respectively.

4.6.3.1.3.2 Size 8 push pull plug, 6P-P8

Figure 11 shows the overall dimensions of free IP65/IP67 connector with male contacts and

push pull locking.

NOTE Besides Figure 4 for this style, there are no additional mating dimensions specified.

Dimensions in millimetres

Figure 11 – Styles 6P-P8, overall dimensions

Figure 4 applies respectively.

4.6.3.1.3.3 M8 thread plug, 6P-M8

Figure 12 shows the overall dimensions of the free IP65/IP67 connector with male contacts and

M8 thread locking. Figure 13 shows its mating dimensions.

Dimensions in millimetres

Figure 12 – Style 6P-M8, overall dimensions, field attachable version (top),

non field attachable version (bottom)

– 22 – IEC 63171-6:2021 © IEC 2021

Dimensions in millimetres

Figure 13 – Style 6P-M8, mating dimensions

Figure 4 applies respectively.

4.6.3.1.4 Styles 6J-P12, 6J-M12, 6J-C12, 6P-P12, 6P-M12

4.6.3.1.4.1 Size 12 jacks, 6J-P12, 6J-M12, 6J-C12

Figure 14 shows the overall dimensions of fixed 2-way IP65/IP67 fixed connector with female

contacts, size 12, various locking mechanisms intended for single hole mounting.

NOTE For these styles no axial overall dimensions are specified besides those which are concluded from the mating

dimensions.

Dimensions in millimetres

Figure 14 – Styles 6J-P12, 6J-M12, 6J-C12, overall dimensions

The three different styles of size 12 jacks have many common mating dimensions. Thus, the

mating dimensions of all three styles are laid down within one drawing shown in Figure 15.

Dimensions in millimetres

Figure 15 –Styles 6J-C12, 6J-P12 and 6J-M12, mating dimensions

With the 6J-P12 style the M12 thread is omitted, with the 6J-M12 style the circumferential

groove (detail X) is omitted.

Figure 2 applies respectively.

Dimensions for the thread and push pull locking given by IEC 61076-2-101 and IEC 61076-

2-010 apply respectively. The corresponding axial position references, dimensions A and B, are

given in Table 2.

Table 2 – Geometrical position of planes

Style/Locking Referenced standard Designation of plane Position of plane in

in referenced standard referenced standard

with respect to plane

C in Figure 15

6J-P12/Push Pull Locking 61076-2-010 Engage-plane type 1 Dimension A: 3,1+-0,4

6J-M12/Screw locking 61076-2-101 Sealing plane Dimension B: 5,8+-0,5

4.6.3.1.4.2 Styles 6P-M12, 6P-P12

Figure 16 shows the overall dimensions of the free 2-way IP65/IP67 connector with male

contacts, size 12, M12 locking. Figure 17 shows the overall dimensions of the free 2-way

connector with male contacts, size 12, push pull locking.

– 24 – IEC 63171-6:2021 © IEC 2021

Dimensions in millimetres

Figure 16 – Style 6P-M12, overall dimensions

Dimensions in millimetres

Figure 17 – Style 6P-P12, overall dimensions

Figure 4 applies respectively.

4.6.3.2 4-way connectors

4.6.3.2.1 Style 6J-M8C

Figure 18 shows the overall dimensions of the fixed 4-way IP65/IP67 connector with female

contacts, size 8, M8 thread locking, intended for single hole mounting (rear mounting).

Figure 19 shows its mating dimensions.

Dimensions in millimetres

Figure 18 – Style 6J-M8C, overall dimensions

Dimensions in millimetres

Figure 19 – Styles 6J-M8C, 6P-M8CI, mating dimensions

4.6.3.2.2 Style 6J-M8CI

Figure 20 shows the overall dimensions of the fixed 4-way IP65/IP67 connector with male

contacts, “inverse style”, size 8, M8 thread locking, intended for single hole mounting (rear

mounting). The mating dimensions are shown in Figure 21 and are identical to those of style

6P-M8C.

– 26 – IEC 63171-6:2021 © IEC 2021

Dimensions in millimetres

Figure 20 – Style 6J-M8CI, overall dimensions

Dimensions in millimetres

Figure 21 – Styles 6J-M8CI, 6P-M8C, mating dimensions

4.6.3.2.3 Style 6P-M8C

Figure 22 shows the overall dimensions of the free 4-way IP65/IP67 connector with male

contacts, size 8, M8 thread locking. The mating dimensions are shown in Figure 21 and are

identical to those of style 6J-M8CI.

Dimensions in millimetres

Figure 22 – Style 6P-M8C, overall dimensions

4.6.3.2.4 Style 6P-M8CI

Figure 23 shows the overall dimensions of the free 4-way IP65/IP67 connector with female

contacts, “inverse style”, size 8, M8 thread locking. The mating dimensions are shown in

Figure 19 and are identical to those of style 6J-M8C.

Dimensions in millimetres

Figure 23 – Style 6P-M8CI, overall dimensions

5 Characteristics

5.1 General

Compliance to the test schedules shall ensure the reliability of all performance parameters,

over the range of operating climatic conditions given in this document. Stable and compliant

contact resistance is a good indication of the stability of transmission performance.

NOTE With respect to the environmental rating scheme defined by ISO/IEC 11801-1:2017, 6.2.2 (MICE classes)

components according to this document are of higher rating than M1, mechanical. The rating with respect to ingress,

chemical and electromagnetical follows the scheme of IEC 61984 and IEC 61076 series and is not comparable to the

MICE classification of ISO/IEC 11801-1.

5.2 Classification into climatic category

The lowest and highest temperatures and the duration of the damp-heat steady-state test

should be selected from the preferred values st

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...