IEC 61745:1998

(Main)End-face image analysis procedure for the calibration of optical fibre geometry test sets

End-face image analysis procedure for the calibration of optical fibre geometry test sets

Describes the calibration of test sets which perform end-face image analysis. This is also known as near-field or grey-scale analysis. The principles may also be applied to test sets of a different type. This standard addresses the calibration of measurements made on single-mode fibres only. This type of test set may also be used to measure multimode fibres, but the evaluation of uncertainties is not covered.

Procédure d'analyse d'image d'extrémité pour l'étalonnage de dispositifs d'essais de géométrie des fibres optiques

Describes the calibration of test sets which perform end-face image analysis. This is also known as near-field or grey-scale analysis. The principles may also be applied to test sets of a different type. This standard addresses the calibration of measurements made on single-mode fibres only. This type of test set may also be used to measure multimode fibres, but the evaluation of uncertainties is not covered.

General Information

- Status

- Published

- Publication Date

- 24-Aug-1998

- Technical Committee

- TC 86 - Fibre optics

- Drafting Committee

- WG 4 - TC 86/WG 4

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 28-Jul-2017

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61745:1998 defines a standardized procedure for the calibration of optical fibre geometry test sets that use end-face image analysis (also called near-field or grey-scale analysis). The standard is intended for calibrating instruments that measure glass geometry on single‑mode fibres and establishes requirements for calibration methods, traceability to national standards, and the evaluation and reporting of measurement uncertainty.

Key topics and technical requirements

- Scope: Calibration procedures for end-face image analysis test sets; applicable principles may be adapted for other test-set types. Measurement uncertainty evaluation for multimode fibres is outside the scope.

- Measured parameters: Cladding (reference) diameter, cladding non‑circularity, and core/cladding concentricity error.

- Instrument description: Typical geometry test sets combine an optical microscope, illumination sources, an electronic camera, digitization and computer processing to derive geometrical parameters from end-face images.

- Calibration chain & traceability:

- Definitions and use of reference standards, transfer standards, and working standards.

- Requirements for demonstrating traceability to national standards and for documenting the calibration chain.

- Calibration procedures:

- Full calibration and check calibration (re‑checks between full calibrations).

- Tests for spatial linearity and specific calibrations for concentricity and non‑circularity measurements.

- Uncertainty evaluation:

- Annex C (normative) covers calculation of uncertainties.

- Distinction between type A (statistical) and type B (non‑statistical) uncertainty components.

- Reporting of combined standard uncertainty and expanded uncertainty with a stated coverage factor (k) and confidence level.

- Documentation: Calibration records, certificates and sample certificate formats are specified.

Applications and who uses this standard

- Calibration laboratories and accredited calibration laboratories establishing traceable measurements.

- Manufacturers of geometry test sets ensuring instrument conformity and documentation of calibration factors.

- Fibre producers, R&D teams, and quality assurance groups performing geometrical characterisation of single‑mode fibres.

- Maintenance and calibration personnel performing routine check calibrations using working standards.

Related standards

- IEC 60050 (IEV - terminology)

- IEC 60027 (letter symbols)

- IEC 60417 and IEC 60617 (graphical symbols)

IEC 61745 is essential for organizations that require reliable, traceable geometry measurements of single‑mode optical fibres and need standardized procedures for calibration, uncertainty evaluation and certification. Keywords: IEC 61745, end-face image analysis, optical fibre geometry test sets, calibration, near-field analysis, grey-scale analysis, single-mode fibres, traceability, measurement uncertainty.

IEC 61745:1998 - End-face image analysis procedure for the calibration of optical fibre geometry test sets Released:8/25/1998 Isbn:2831844789

IEC 61745:1998 - End-face image analysis procedure for the calibration of optical fibre geometry test sets Released:8/25/1998 Isbn:2831856493

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 61745:1998 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "End-face image analysis procedure for the calibration of optical fibre geometry test sets". This standard covers: Describes the calibration of test sets which perform end-face image analysis. This is also known as near-field or grey-scale analysis. The principles may also be applied to test sets of a different type. This standard addresses the calibration of measurements made on single-mode fibres only. This type of test set may also be used to measure multimode fibres, but the evaluation of uncertainties is not covered.

Describes the calibration of test sets which perform end-face image analysis. This is also known as near-field or grey-scale analysis. The principles may also be applied to test sets of a different type. This standard addresses the calibration of measurements made on single-mode fibres only. This type of test set may also be used to measure multimode fibres, but the evaluation of uncertainties is not covered.

IEC 61745:1998 is classified under the following ICS (International Classification for Standards) categories: 33.180.01 - Fibre optic systems in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61745:1998 has the following relationships with other standards: It is inter standard links to IEC 61745:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61745:1998 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL

IEC

STANDARD

First edition

1998-08

End-face image analysis procedure

for the calibration of optical fibre

geometry test sets

Reference number

Numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series.

Consolidated publications

Consolidated versions of some IEC publications including amendments are

available. For example, edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the

base publication, the base publication incorporating amendment 1 and the base

publication incorporating amendments 1 and 2.

Validity of this publication

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology.

Information relating to the date of the reconfirmation of the publication is available

in the IEC catalogue.

Information on the subjects under consideration and work in progress undertaken by

the technical committee which has prepared this publication, as well as the list of

publications issued, is to be found at the following IEC sources:

• IEC web site*

• Catalogue of IEC publications

Published yearly with regular updates

(On-line catalogue)*

• IEC Bulletin

Available both at the IEC web site* and as a printed periodical

Terminology, graphical and letter symbols

For general terminology, readers are referred to IEC 60050: International

Electrotechnical Vocabulary (IEV).

For graphical symbols, and letter symbols and signs approved by the IEC for

general use, readers are referred to publications IEC 60027: Letter symbols to be

used in electrical technology, IEC 60417: Graphical symbols for use on equipment.

Index, survey and compilation of the single sheets and IEC 60617: Graphical symbols

for diagrams.

* See web site address on title page.

INTERNATIONAL

IEC

STANDARD

First edition

1998-08

End-face image analysis procedure

for the calibration of optical fibre

geometry test sets

IEC 1998 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http: //www.iec.ch

Commission Electrotechnique Internationale

PRICE CODE

V

International Electrotechnical Commission

For price, see current catalogue

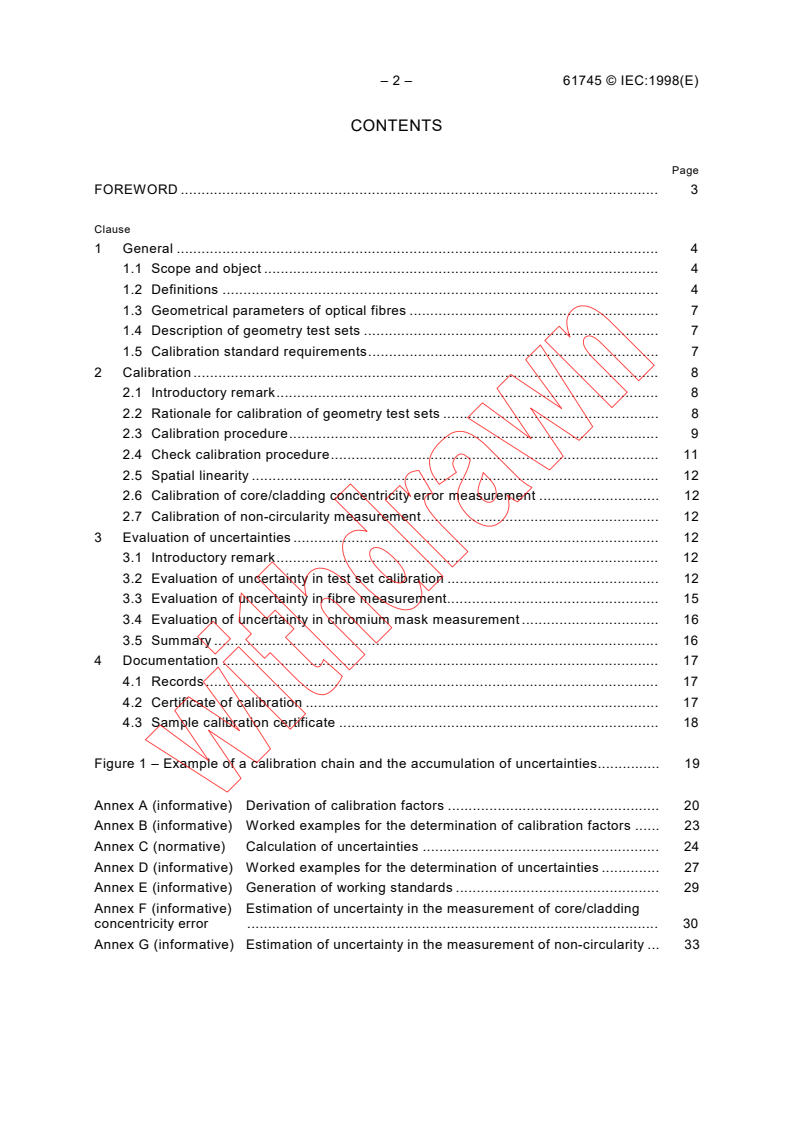

– 2 – 61745 © IEC:1998(E)

CONTENTS

Page

FOREWORD . 3

Clause

1 General . 4

1.1 Scope and object . 4

1.2 Definitions . 4

1.3 Geometrical parameters of optical fibres . 7

1.4 Description of geometry test sets . 7

1.5 Calibration standard requirements. 7

2 Calibration . 8

2.1 Introductory remark. 8

2.2 Rationale for calibration of geometry test sets . 8

2.3 Calibration procedure. 9

2.4 Check calibration procedure. 11

2.5 Spatial linearity . 12

2.6 Calibration of core/cladding concentricity error measurement . 12

2.7 Calibration of non-circularity measurement. 12

3 Evaluation of uncertainties . 12

3.1 Introductory remark. 12

3.2 Evaluation of uncertainty in test set calibration . 12

3.3 Evaluation of uncertainty in fibre measurement. 15

3.4 Evaluation of uncertainty in chromium mask measurement . 16

3.5 Summary . 16

4 Documentation . 17

4.1 Records. 17

4.2 Certificate of calibration . 17

4.3 Sample calibration certificate . 18

Figure 1 – Example of a calibration chain and the accumulation of uncertainties. 19

Annex A (informative) Derivation of calibration factors . 20

Annex B (informative) Worked examples for the determination of calibration factors . 23

Annex C (normative) Calculation of uncertainties . 24

Annex D (informative) Worked examples for the determination of uncertainties . 27

Annex E (informative) Generation of working standards . 29

Annex F (informative) Estimation of uncertainty in the measurement of core/cladding

concentricity error . 30

Annex G (informative) Estimation of uncertainty in the measurement of non-circularity . 33

61745 © IEC:1998(E) – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

__________

END-FACE IMAGE ANALYSIS PROCEDURE FOR THE CALIBRATION

OF OPTICAL FIBRE GEOMETRY TEST SETS

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International Organization

for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical reports or guides and they are accepted by the National Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61745 has been prepared by IEC technical committee 86: Fibre

optics.

The text of this standard is based on the following documents:

FDIS Report on voting

86/125/FDIS 86/134/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

Annex C forms an integral part of this standard.

Annexes A, B, D, E, F and G are for information only.

A bilingual version of this standard may be issued at a later date.

– 4 – 61745 © IEC:1998(E)

END-FACE IMAGE ANALYSIS PROCEDURE FOR THE CALIBRATION

OF OPTICAL FIBRE GEOMETRY TEST SETS

1 General

1.1 Scope and object

In the research and production environments there exists a range of test methods for

characterizing the geometry of optical fibres. Furthermore, each test method may determine

one or more of the many parameters required for complete geometrical characterization. This

International Standard describes the calibration of test sets which perform end-face image

analysis, also known as near-field or grey-scale analysis. The principles, however, may be

applied to test sets of a different type.

This standard addresses the calibration of measurements made on single-mode fibres only;

however, this type of test set may also be used to measure the geometrical parameters of the

cores of multimode fibres, but the evaluation of uncertainties associated with these

measurements is beyond the scope of this standard.

The procedures outlined are to be performed by calibration laboratories and by the

manufacturers or users of geometry test sets, for the purpose of calibrating geometry test sets

and for evaluating the uncertainties in measurements made on calibrated test sets. The

calibration of fibre coating or cable measurement test sets is not covered by this standard. The

object of this standard is to define a standard procedure for the calibration of test sets for

measuring the glass geometry of optical fibres.

1.2 Definitions

For the purpose of this International Standard, the following definitions apply.

1.2.1

accredited calibration laboratory

calibration laboratory authorised by the appropriate National Standards laboratory to issue

calibration certificates with a specified uncertainty, which demonstrate traceability to national

standards

1.2.2

artefact

any object that is measured on or used to calibrate a geometry test set. An artefact may be, for

example, an optical fibre or a chromium-on-glass pattern

1.2.3

calibration

process by which the relationship between the values indicated by the geometry test set under

calibration and the known values of the calibration standard is established. The purpose of

calibration is to bring all geometry test sets into substantial agreement with a national

standards laboratory. This may be performed either by adjustment of the geometry test set or

by documentation of a calibration factor(s) in a calibration certificate. The pertaining

environment and instrument conditions at the time of calibration are usually recorded.

Calibration includes estimation of all uncertainties.

1.2.4

calibration chain

chain of transfers from a national standard to the geometry test set through intermediate or

working standards (see figure 1)

61745 © IEC:1998(E) – 5 –

1.2.5

calibration checking

establishing that a geometry test set that has been previously calibrated but has reached its

calibration due date remains within specified uncertainty limits. If the geometry test set has

drifted outside these limits, then re-calibration is required. Otherwise, the re-checking period

can be extended for a stated period. The test set may be checked using a working standard

1.2.6

calibration standard

artefact that is calibrated against a reference standard and is used to calibrate test sets. The

artefact may be a fibre or a chromium-on-glass pattern. Proper use of a calibration standard

ensures traceability. The term includes the reference standard, the transfer standard and the

working standard(s), in descending order of metrological uncertainty

1.2.7

combined standard uncertainty

combination of a number of individual standard uncertainties.

The term "accuracy" should be avoided in this context.

In calibration reports and technical data sheets, the combined standard uncertainty in the

geometry test set measurement is reported as an overall expanded uncertainty with the

applicable confidence level, for example 95,5% or 99,7%.

1.2.8

confidence level

estimation of the probability that the true value of a measured parameter lies within a given

range (expanded uncertainty)

1.2.9

correction offset

number that is added to or subtracted from the measurement result of a test set to correct for a

known physical effect

1.2.10

coverage factor, k

factor used to calculate the expanded uncertainty U from the standard uncertainty

1.2.11

expanded uncertainty, U

range of values within which the true value of the measured parameter, at the stated

confidence level, can be expected to lie. It is also called the confidence interval and is equal to

the coverage factor k times the standard uncertainty u:

U = k ⋅ u

The measurement uncertainty of a geometry test set should be specified in the form of

expanded uncertainty.

NOTE – When the distribution of uncertainties is assumed to be normal and a large number of measurements are

made, then confidence levels of 68,3 %, 95,5 % and 99,7 % correspond to values for k of 1, 2, and 3 respectively

(see clause C.3 ).

1.2.12

geometry test set

instrument used to measure the geometrical parameters of an optical fibre. The parameters

measured will depend on the type of geometry test set

– 6 – 61745 © IEC:1998(E)

1.2.13

infant fibre

fibre whose geometry is to be measured on a calibrated geometry test set

1.2.14

instrument state

description of the measurement conditions of the geometry test set during calibration and

measurement, for instance form-fits used, data filtering schemes employed and other important

information concerning the test set such as warm-up time and date of calibration

1.2.15

national standard

standard whose measurement is traceable to fundamental quantities, such as the wavelength

of light, and which is used as the basis for fixing the value, in a country, of all other standards

of the quantity concerned

1.2.16

national standards laboratory

body or laboratory that maintains and operates the national standard

1.2.17

operating range

range of conditions under which the geometry test set is designed to perform within the stated

expanded uncertainty; for example diameter of the fibre being measured and environmental

conditions, such as temperature

1.2.18

reference standard

artefact measured at a calibration laboratory, with the measurement traceable to national

standards

1.2.19

scaling factor

ratio of the known standard values for a calibration standard to the values indicated by the

geometry test set when no correction offsets are applied

1.2.20

standard uncertainty

standard uncertainty may be evaluated either by statistical methods, termed type A evaluation,

or by other means, termed type B evaluation (see annex C for a more detailed description).

A type A evaluation of uncertainty consists of a statistical analysis of a series of measure-

ments, such as when evaluating certain random effects of measurement.

A type B evaluation of uncertainty is used when a statistical analysis is not appropriate. It

consists of an estimation of the probable sources of uncertainty, such as when evaluating

certain systematic effects of measurement.

NOTE – In order to combine standard uncertainties from different sources it is important that they all be stated at

the same confidence level. This may be achieved by use of the coverage factor k, which is determined with

reference to Student's t distribution for each individual uncertainty component.

1.2.21

traceability

ability to demonstrate, for a measurement result or a geometry test set, a calibration chain

originating from a national standard

Geometry test sets calibrated by the procedures in this standard are traceable. Direct

traceability of the measurement result to either a national standards laboratory or to an

accredited calibration laboratory needs to be demonstrated. Such traceability includes the

calibration schedules of all artefacts in the calibration chain and detailed calculations of all

61745 © IEC:1998(E) – 7 –

(cumulative) transfer uncertainties in the calibration chain. The use of a working standard alone

to compare or monitor geometry test set calibration cannot establish or re-establish traceability,

but can only extend the duration of the traceability certification if no change is found.

1.2.22

transfer standard

standard that is calibrated against a reference standard and is used for calibrating geometry

test sets

1.2.23

transfer uncertainty

estimate characterizing the uncertainty of a measurement caused by uncertainties in the

transfer process, at the given confidence level (such as changes in environmental conditions).

These uncertainties may arise from the calibration standards used as well as from the

geometry test set.

1.2.24

working standard

standard that is usually calibrated against a transfer standard or a reference standard and is

used on a routine basis to check geometry test sets

1.3 Geometrical parameters of optical fibres

It is necessary to characterize the geometrical properties of optical fibres in order to ensure

satisfactory mechanical and optical performance. The geometrical parameters measured by the

types of test sets consist of the following:

a) cladding (reference surface) diameter;

b) cladding non-circularity;

c) core/cladding concentricity error.

NOTE – Geometry measurements on a single-mode fibre are usually performed at a wavelength other than that

corresponding to single-mode operation of the fibre. It is, however, generally assumed that the value of mode-field

concentricity error of a single-mode fibre is the same as that of core/cladding concentricity error, but this is beyond

the scope of this standard.

1.4 Description of geometry test sets

End face image, or grey-scale, test sets usually comprise an optical microscope, an illumina-

tion source, an electronic image recording device, such as a camera, and a means of storing

image data for processing by digital computer. A second illumination source is usually

employed to launch light into the other end of the fibre. This enables the position of the fibre

core also to be measured. A typical measurement sequence is as follows: a cleaved fibre end

is positioned in the measurement port of the instrument and an image of the fibre end is

formed on the camera. The image of the fibre is focused, usually under automatic computer

control, digitized, and then transferred to a computer which determines the geometrical

parameters of the fibre.

The quality of the fibre end is critical in this method, and the presence of cleave damage, such

as chips or edge roughness, can seriously affect the measurement. It is thus usual to employ

data-filtering methods to reduce the sensitivity of the measured result to the presence of cleave

damage.

1.5 Calibration standard requirements

The calibration procedure detailed in this standard requires the use of traceable calibration

artefacts. These artefacts consist of a calibrated fibre end and a chromium-on-glass mask.

Their nominal dimensions are discussed in 2.3.3 and 2.5.

– 8 – 61745 © IEC:1998(E)

2 Calibration

2.1 Introductory remark

The calibration procedure comprises the following two operations.

a) The magnification, or scaling factor, of the imaging system is calibrated. This is a similar

process to conventional calibration methods for optical microscopes, except that, in this

case, a two-dimensional calibration is required.

b) A correction offset is determined. This offset is required to correct for systematic effects

such as diffraction at the fibre edge, differences between the way the calibration artefact is

calibrated and the method of measurement in the test set, and distortion of the image of the

fibre edge by camera sampling.

Worked examples for the determination of calibration factors are given in annex B.

NOTE 1 – The calibration will be valid when applied to measurements in the following way:

– the scaling factors are applied multiplicatively to the raw data from the camera, before applying form-fits and

computing the cladding diameter of the fibre under test;

– the correction offset is applied additively to the computed cladding diameter of the fibre under test.

NOTE 2 – The choice of an edge-setting criterion defining the position of the cladding edge is important and

calibration applies only to measurements using the same criterion as that used at the time of calibration.

NOTE 3 – In certain circumstances it has been found sufficient to calibrate only the scaling factor, using a fibre or

chromium-on-glass standard. This approach, however, may lead to increased uncertainties when measuring fibres

which are of significantly different diameter from the calibration standard used.

2.2 Rationale for calibration of geometry test sets

The measurement of cladding diameter is common to most types of geometry test sets, so

calibration of this parameter is very important in comparing test sets of different types. This

standard, however, details only the calibration of test sets which perform end-face image

analysis.

Basically, calibration is achieved by exposing the test set to independent geometrical

calibration standards. It is these standards that form the calibration chain and, therefore,

contribute to the transfer uncertainty.

The procedure is detailed in 2.3. The complete calibration chain is illustrated in figure 1.

Calibration of the core/cladding concentricity error and non-circularity measurement is not des-

cribed as there are no suitable standard reference materials available at the time of writing.

However, procedures enabling estimation of the uncertainties obtained in the measurement of

these parameters are given in 2.6 and 2.7 respectively.

2.2.1 Verification of calibration state

For routine verification, such as may frequently be carried out on geometry test sets in use, it is

sufficient to check (but not to reset) the state of calibration of the geometry test sets using a

working standard. The working standard may be a fibre or a chrome-on-glass mask.

A procedure for generation of a working standard is given in annex E.

The distinction between checking the state of calibration and the calibration itself must be

clearly made. While it is sufficient to establish stability of the geometry test set using the

working standard, this is not a substitute for full calibration.

The use of a working standard allows continued traceability to national standards to be

claimed, if it can be satisfactorily established that the existing instrument state, correction

61745 © IEC:1998(E) – 9 –

factors, and so on, are sufficient to provide geometry results within a specified uncertainty and

without alteration. This simply means that the geometry test set has remained stable since the

last calibration.

Continued traceability can be claimed on a calibrated test set provided that the measured

values for the working standard agree with its calibrated values within the uncertainties.

Calibration is essential in the commissioning of geometry test sets, whereas a working

standard is used for routine calibration checking.

The procedure for calibration checking is described in 2.4.

2.3 Calibration procedure

2.3.1 General advice and organization

Ensure that the environmental conditions are commensurate with the working environment as

specified by the manufacturer. Employ good metrological practices at all times.

Ensure that all calibration standards used in the calibration are calibrated according to a

documented programme with traceability to national standards laboratories or to accredited

standards laboratories. If possible maintain more than one standard on each hierarchical level

of the calibration chain, so that the performance of standards can be verified by comparisons

on the same level.

Develop a documented measurement procedure for each type of calibration performed, giving

step-by-step operating instructions and equipment to be used. Use pro-forma result sheets,

uncertainty budgets and calibration certificates (see clause 4).

Operate a quality system appropriate to the range of measurements. Ensure that there is

independent scrutiny of measurement results, intermediate calculations and calibration

certificates are prepared.

2.3.2 Test requirements

a) Perform all tests at a temperature and relative humidity that are within the manufacturer’s

specification for the test set.

b) Allow sufficient time for the geometry test set and test equipment to reach thermal

equilibrium with the environment in accordance with the manufacturer's recommendations

for the test set and the calibration standards used, before commencing the calibration

procedure.

c) Set up the geometry test set to the appropriate settings for calibration procedures, as

recommended by the manufacturer.

d) Ensure, where possible, that all accessible optical surfaces and calibration standards are

clean before measurement.

2.3.3 Calibration standard requirements

The use of calibration standards which are traceable to national standards laboratories is

mandatory. The calibration procedure requires the use of the following:

a) A fibre end with calibrated cladding diameter. The fibre should be of similar material to and

within 5,0 μm of the nominal cladding diameter of the fibres to be measured by the test set

and have a non-circularity of less than 0,5 %.

NOTE 1 – The calibrated fibre end must not be re-cleaved. This is due to variations of diameter along the length of

the fibre.

– 10 – 61745 © IEC:1998(E)

NOTE 2 – If the fibre end becomes damaged or cannot be cleaned sufficiently, it should not be used for the

purpose of calibration.

b) A calibrated measurement scale. This is a chromium-on-glass mask with a pattern,

typically, of dots, lines, circles or annuli.

For calibration checking (see 2.4), the standard may be either a fibre or a chromium-on-glass

pattern with traceable geometry values.

2.3.4 Determination of calibration factors

A derivation of the calibration factors used is given in annex A.

2.3.4.1 Scaling factor

To calibrate the scaling factor use a chromium-on-glass mask. This may comprise an array of

dots or lines, or an annular structure. The principle of calibration is to measure the distance

between graduations.

NOTE – The uniformity of the scaling factor over the field of view of the imaging system (known as spatial linearity)

will affect the uncertainty that can be transferred to measurements on fibres and also to measurements of

core/cladding concentricity error. A method for estimating spatial linearity is described in 2.5.

The scaling factors for the x and y axes of the camera are given by:

Dx

c

S = (1)

x

Dx

m

Dy

c

S = (2)

y

Dy

m

where

Dx is the measured spacing of graduations along the x-axis;

m

Dy is the measured spacing of graduations along the y-axis;

m

Dx is the calibrated spacing of graduations along the x-axis;

c

Dy is the calibrated spacing of graduations along the y-axis.

c

The procedure to measure the distance between graduations will depend on the type of chrome

mask used, as follows:

a) Regular array of dots or lines

Form an image of the array in a manner consistent with normal operation of the test set.

Measure the distances between graduations in two orthogonal directions, these being

parallel to the scan axes of the camera.

NOTE 1 – The distance over which calibration is effected should be within 5 μm of the nominal diameter of the

fibres to be measured by the test set.

NOTE 2 – It is desirable to align the axes of the array to be parallel to the scan axes of the camera. However, if

they are not so aligned, compensation for the angular misalignment needs to be applied.

b) Annulus

Form an image of the annulus in a manner consistent with normal operation of the test set.

Apply elliptical form fits to the inner and outer edges of the annulus. Determine the

measured diameters Dx and Dy along the x and y axes as follows:

m m

DDxx+

inner outer

Dx = (3)

m

61745 © IEC:1998(E) – 11 –

DDyy+

inner outer

and Dy = (4)

m

where

Dx is the measured diameter of the inner annulus along the x-axis;

inner

Dy is the measured diameter of the inner annulus along the y-axis;

inner

Dx is the measured diameter of the outer annulus along the x-axis;

outer

Dy is the measured diameter of the outer annulus along the y-axis.

outer

NOTE 1 – The diameter of the annulus should be within 5 μm of the nominal diameter of the fibres to be measured

by the test set.

NOTE 2 – If, for convenience of use, it is assumed that Dx equals Dy , any non-circularity in the annulus will

m m

affect the determination of the uncertainty in subsequent fibre non-circularity measurements, see 2.7.

Calculate the uncertainty in the determination of the scaling factors using clause 3.

2.3.4.2 Correction offset

To calibrate the correction offset a calibrated fibre is required. Form an image of the fibre end

in a manner consistent with normal operation of the test set and apply a form-fitting algorithm

to the fibre edge. Determine the correction offset O as follows:

O = D – D′ ⋅ S (5)

P,F P,F

where

D is the calibrated diameter of the fibre;

P,F

D′ is the measured diameter of the fibre (scaling factor not applied);

P,F

SS+

xy

P stands for parent, F stands for fibre and S = (mean scaling factor).

Thus D′ ⋅ S is equal to the measured diameter of the fibre, in micrometres.

P,F

Calculate the uncertainty in the determination of the correction offset using clause 3.

2.4 Check calibration procedure

This procedure is used for checking the calibration of a geometry test set. The procedure is not

used for determining calibration factors but may be used to check for test set stability since the

last calibration was performed.

As long as the geometry test set has already been calibrated and measurement of a working

standard does not reveal a geometry uncertainty greater than the permitted total uncertainty,

the claim of traceability may be extended.

a) Ensure that the test requirements given in 2.3.2 have been met.

b) Present the working standard to the geometry test set under consideration.

c) In the case where the working standard is

– a fibre: measure the mean cladding diameter;

– a chromium-on-glass mask: measure the distance between graduations.

Compare the measured values with the reference values and record any differences. It is

necessary to repeat the measurement several times to statistically reduce uncertainty in the

mean measured value.

– 12 – 61745 © IEC:1998(E)

2.5 Spatial linearity

The uncertainty in the measurement of fibres the diameter of which differs by more than 5 μm

from that of the fibre used for calibration may be estimated in one of two ways.

a) Measure a chromium-on-glass artefact at different positions within the field of view.

b) Measure the spacing between graduations of an array of lines or dots over the whole field

of view.

NOTE – In either case, the linear dimension of the artefact or the interval must be less than one-quarter of the

diameter of the calibration fibre used. If method a) is used, only a nominal calibration of the artefact is necessary. If

method b) is used, it is necessary to use an artefact that has each interval calibrated.

A variation in the scaling factor over the field of view indicates a source of uncertainty in the

calibration of the test set scaling factor. The importance of this uncertainty will depend on the

range of fibre diameters to be measured on the calibrated test set. Estimate the magnitude of

the uncertainty and add it to the total scaling factor uncertainty u , derived in 3.2.1.

S

2.6 Calibration of core/cladding concentricity error measurement

Core/cladding concentricity error is defined as the distance between the centres of the core

and cladding of a fibre.

At the time of writing there are no standard reference materials (SRM) available from standards

laboratories for direct calibration of this parameter. A procedure is given in annex F describing

how to estimate the uncertainty obtained in a concentricity error measurement.

2.7 Calibration of non-circularity measurement

Non-circularity is defined as the difference in radial distance of edge points that are

respectively furthest from and closest to the fitted centre, divided by the fitted radius. In the

case of an ellipse form-fit, non-circularity is the difference between the major and minor axes,

divided by their mean.

At the time of writing there are no standard reference materials (SRM) available from standards

laboratories for direct calibration of this parameter. A procedure is given in annex G describing

how to estimate the uncertainty obtained in a non-circularity measurement.

3 Evaluation of uncertainties

3.1 Introductory remark

In this clause, the reporting of uncertainties in the calibration of a test set and also in

subsequent measurements is discussed. The analysis is based on the statistical mathematics

given in annex C. It is important to choose a confidence level at which to calculate uncertain-

ties and use the appropriate values for the coverage factor in each calculation (see definition

1.2.11 and clause C.3).

The uncertainty of calibration of the test set is discussed in 3.2. The uncertainty in the

measurement of a fibre is discussed in 3.3. The uncertainty in the measurement of a

chromium-on-glass mask is discussed in 3.4.

Worked examples for the determination of uncertainties are given in annex D.

3.2 Evaluation of uncertainty in test set calibration

The calibration procedure (see 2.3.4) comprises two operations. First a scaling factor is

determined and then a correction offset factor is determined. Sources of uncertainty in both of

these parameters must be evaluated to estimate the calibration uncertainty of the test set.

61745 © IEC:1998(E) – 13 –

3.2.1 Uncertainty in scaling factor

The following terms are used:

S = scaling factor

D = calibrated spacing of graduations of parent chromium standard

P,C

u = uncertainty in calibration of parent chromium standard

P,C

D′ = measured spacing of graduations of parent chromium standard (raw data)

P,C

u′ = statistical uncertainty in measurement of parent chromium standard (raw data)

P,C

u = transfer uncertainty of parent chromium standard

Tr,P,C

n = number of measurements

C

where P stands for parent and C for chromium.

The determination of the scaling factor is described in 2.3.4.1 and is given in terms of two

scaling factors, one for each of the two camera axes. For the purpose of estimating the

uncertainty in the scaling factor, the two scaling factors may be combined to give the following

expression:

D

P,C

S = (6)

D′

P,C

The uncertainty u in the scaling factor consists of the calibration uncertainty u of the

S P,C

parent chromium standard, any changes u that may have occurred in the parent

Tr,P,C

chromium standard since its calibration, and the statistical uncertainty u′ in the

P,C

measurement of the parent chromium standard on the test set .

The relative uncertainty u in the scaling factor is given by:

S

uS′⋅

P, C

2 2

uu++

Tr,P,C P,C

n

C

u = (7)

S

D

P,C

3.2.1.1 Determination of u

P,C

The uncertainty u in the calibration of the parent standard may be determined from the

P,C

parent's calibration certificate or data sheet. Using the expanded uncertainty U of the

P,C

parent, calculate u as follows:

P,C

U

P,C

=

u (8)

P,C

k

where k is the coverage factor.

Determine k from the parent's calibration certificate.

3.2.1.2 Determination of u

Tr,P,C

The transfer uncertainty may be due to factors affecting the calibration of the parent chromium

standard, for example ageing, temperature-induced changes and cleanliness. Estimate the

transfer uncertainty using equation (C.2).

– 14 – 61745 © IEC:1998(E)

3.2.1.3 Determination of u′′

P,C

Determine the statistical uncertainty in measurement of the parent chromium standard using

equation (C.1).

3.2.2 Uncertainty in offset correction factor

The following terms are used:

S = scaling factor

D = calibrated diameter of parent fibre standard

P,F

u = calibration uncertainty of parent fibre standard

P,F

u′ = statistical uncertainty in measurement of parent fibre standard (raw data)

P,F

u = transfer uncertainty of parent fibre standard

Tr,P,F

n = number of measurements

F

where P stands for parent and F for fibre.

The determination of the offset correction factor is described in 2.3.4.2. The offset O is given

by:

OD=−D′ ⋅S (9)

P,F P,F

The uncertainty u in the offset factor consists of the uncertainty u in the calibration of the

O P,F

parent fibre standard, any changes u that may have occurred in the fibre standard since

Tr,P,F

its calibration and the statistical uncertainty u′ in the measurement of the parent fibre

P,F

standard on the test set.

The uncertainty u in the offset is given by:

uS′ ⋅

P,F

=+ +

uu u (10)

O

P,F Tr,P,F

n

F

NOTE – The uncertainty u in the scaling factor is not included in the derivation of equation (10). This is because

S

error in the scaling factor is compensated for in the determination of the correction offset factor, according to

equation (9). It will, however, contribute to the uncertainty in fibre diameter measurement when the diameter of the

fibre being measured is different from the diameter of the calibration fibre that was used in the determination of the

offset correction factor (see 3.3).

3.2.2.1 Determination of u

P,F

The uncertainty u of the parent may be determined from the expanded uncertainty U

P,F P,F

quoted on the parent's calibration certificate or data sheet. Express this as a standard

uncertainty u as follows:

P,F

U

P,F

u = (11)

P,F

k

where k is the coverage factor.

Determine k from the parent's calibration certificate.

61745 © IEC:1998(E) – 15 –

3.2.2.2 Determination of u

Tr,P,F

The transfer uncertainty may be due to factors affecting the calibration of the parent fibre

standard, for example ageing, temperature induced changes, and cleanliness. Estimate the

transfer uncertainty using C.2.

3.2.2.3 Determination of u′′

P,F

Determine the statistical uncertainty in measurement of the parent fibre standard using C.1.

3.3 Evaluation of uncertainty in fibre measurement

The following terms are used:

D = calibrated diameter of parent fibre standard used in offset determination

P,F

D = diameter of infant fibre (to be determined)

I,F

D′ = measured diameter of infant fibre (raw data)

I,F

u′ = statistical uncertainty in measurement of infant fibre (raw data)

I,F

u = operational uncertainty of infant fibre

Op,I,F

n = number of measurements

F

where I stands for infant and F for fibre.

The measured diameter of the infant fibre after calibration is given by:

= ′ ⋅+

DD SO (12)

I,F I,F

The uncertainty u in the measurement consists of the uncertainty u in the scaling factor, the

I,F S

uncertainty u in the offset factor and the statistical uncertainty u′ in the measurement of

O I,F

the infant fibre on the test set. Further, if the measurement depends on changes in operating

conditions from those existing at the time of calibration, these changes must be taken into

account in the form of an operational uncertainty u . Uncertainty in the determination of the

Op,I,F

scaling factor contributes to the uncertainty in the determination of the fibre diameter when

the diameter of the fibre under test is different from the diameter of the calibration fibre that

was used in the determination of the correction offset factor (see 3.2.2). This is included as the

final term in the following expression.

The uncertainty u in the measured diameter of the infant fibre is given by:

I,F

′ ⋅

uS

I,F

2 2 2 2

′

uu=+u + +(SDD⋅− ) ⋅u (13)

I,F I,F P,F

O Op,I,F S

n

F

3.3.1 Determination of u

Op,I,F

The operational uncertainty is due to operating conditions that are different from those existing

at the time of calibration, for example cleave quality, cleanliness and operating temperature.

Estimate the operational uncertainty using C.2.

3.3.2 Determination of u'

I,F

Determine the statistical uncertainty in measurement of the infant fibre using C.1.

– 16 – 61745 © IEC:1998(E)

3.4 Evaluation of uncertainty in chromium mask measurement

The following terms are used:

D = spacing of graduations of infant chromium mask (to be determined)

I,C

D′ = measured spacing of graduations of infant chromium mask (raw data)

I,C

u′ = statistical uncertainty in measurement of infant chromium mask (raw data)

I,C

u = operational uncertainty of infant chromium mask

Op,I,C

n = number of measurements

C

where I stands for infant and C for chromium.

The measured diameter of the infant chromium mask after calibration is given by:

DD= ′ ⋅S (14)

I,C I,C

The uncertainty u in the measured diameter consists of the relative uncertainty u in the

I,C S

scaling factor and the statistical uncertainty u′ in the measurement of the infant chromium

I,C

mask on the test set. Further, if the measurement depends on changes in operating conditions

from those existing at the time of calibration, these changes must be taken into account in the

form of an operational uncertainty u .

Op,I,C

The uncertainty u in the measured diameter of the infant chromium mask is:

I,C

′

uS ⋅ 2

I,C

uu=+ +Du′ ⋅ (15)

()

I,C Op,I,C I,C S

n

C

3.4.1 Determination of u

Op,I,C

The operational uncertainty is due to operating conditions that are different from those existing

at the time of calibration, for example cleave quality, cleanliness and operating temperature.

Estimate the operational uncertainty using C.2.

3.4.2 Determination of u′′

I,C

Determine the statistical uncertainty in measurement of the infant chromium mask using C.1.

3.5 Summary

The uncertainty in the calibration of the test set has been evaluated in terms of the scaling

factor uncertainty and the offset factor uncertainty, in 3.2.1 and 3.2.2 respectively.

The uncertainties in the measurement of a test fibre and a chromium-on-glass mask are

evaluated in 3.3 and 3.4 respectively.

The statement of uncertainty in the measurement on a fibre or chromium mask includes the

uncertainties of the calibration standards used to calibrate the test set, the statistical measure-

ment uncertainties and any other additional measurement uncertainties.

61745 © IEC:1998(E) – 17 –

4 Documentation

4.1 Records

Proper records shall be kept when a geometry test set is calibrated according to this pro-

cedure. These records shall include the following:

a) description of the test set and unique identification (serial number);

b) date on which the calibration was performed;

c) results obtained from the calibration process (see clause 3);

d) re-calibration interval;

e) identification of the calibration procedure followed;

f) unique identification of all calibration standards used and certification demonstrating

traceability;

g) identification of personnel performing the calibration;

h) statement of uncertainties involved in calibrating the test set and of their cumulative effect

on the uncertainties in the scaling and offset factors (see clause 3);

i) instrument state, such as threshold levels for edge point select

...

IEC 61745

Edition 1.0 1998-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

End-face image analysis procedure for the calibration of optical fibre geometry

test sets

Procédure d’analyse d’image d’extrémité pour l’étalonnage de dispositifs

d’essais de géometrie des fibres optiques

Copyright © 1998 IEC, Geneva, Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61745

Edition 1.0 1998-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

End-face image analysis procedure for the calibration of optical fibre geometry

test sets

Procédure d’analyse d’image d’extrémité pour l’étalonnage de dispositifs

d’essais de géometrie des fibres optiques

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

V

CODE PRIX

ICS 33.180.01 ISBN 2-8318-5649-3

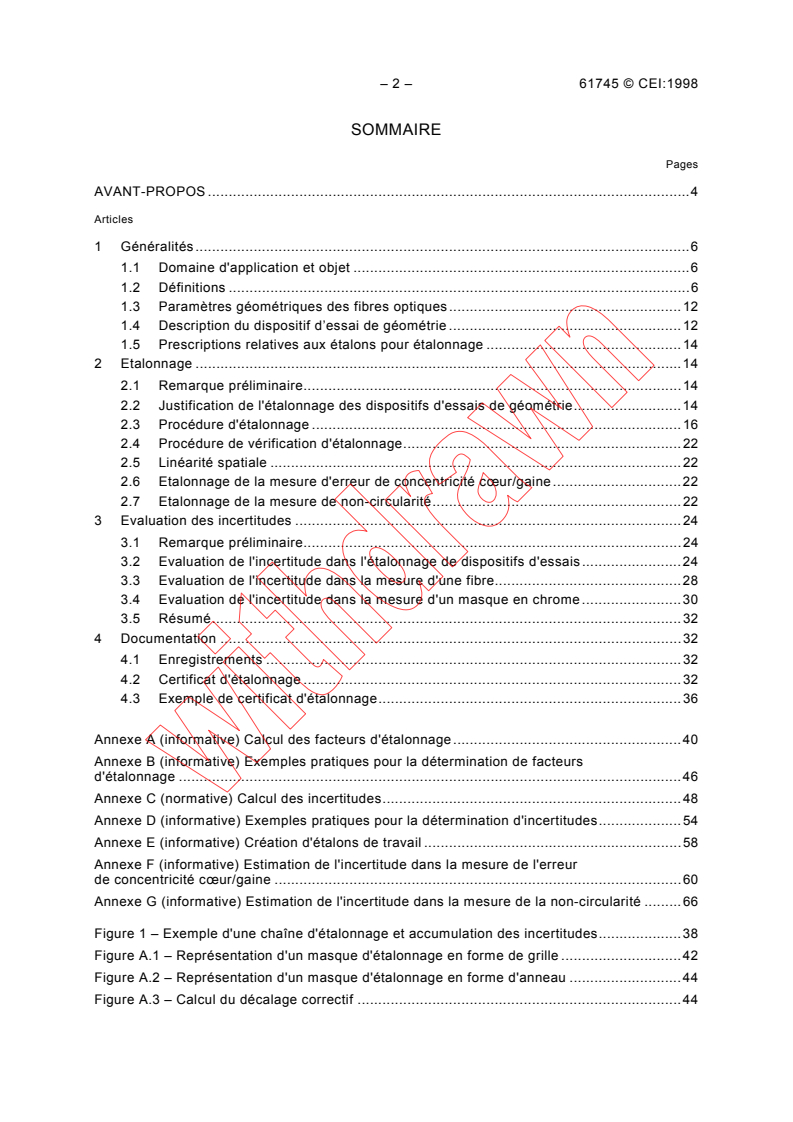

– 2 – 61745 © CEI:1998

SOMMAIRE

Pages

AVANT-PROPOS .4

Articles

1 Généralités.6

1.1 Domaine d'application et objet .6

1.2 Définitions.6

1.3 Paramètres géométriques des fibres optiques.12

1.4 Description du dispositif d’essai de géométrie .12

1.5 Prescriptions relatives aux étalons pour étalonnage .14

2 Etalonnage.14

2.1 Remarque préliminaire.14

2.2 Justification de l'étalonnage des dispositifs d'essais de géométrie.14

2.3 Procédure d'étalonnage .16

2.4 Procédure de vérification d'étalonnage.22

2.5 Linéarité spatiale .22

2.6 Etalonnage de la mesure d'erreur de concentricité cœur/gaine.22

2.7 Etalonnage de la mesure de non-circularité.22

3 Evaluation des incertitudes .24

3.1 Remarque préliminaire.24

3.2 Evaluation de l'incertitude dans l'étalonnage de dispositifs d'essais.24

3.3 Evaluation de l'incertitude dans la mesure d'une fibre.28

3.4 Evaluation de l'incertitude dans la mesure d'un masque en chrome.30

3.5 Résumé.32

4 Documentation.32

4.1 Enregistrements.32

4.2 Certificat d'étalonnage .32

4.3 Exemple de certificat d'étalonnage.36

Annexe A (informative) Calcul des facteurs d'étalonnage.40

Annexe B (informative) Exemples pratiques pour la détermination de facteurs

d'étalonnage .46

Annexe C (normative) Calcul des incertitudes.48

Annexe D (informative) Exemples pratiques pour la détermination d'incertitudes.54

Annexe E (informative) Création d'étalons de travail .58

Annexe F (informative) Estimation de l'incertitude dans la mesure de l'erreur

de concentricité cœur/gaine .60

Annexe G (informative) Estimation de l'incertitude dans la mesure de la non-circularité .66

Figure 1 – Exemple d'une chaîne d'étalonnage et accumulation des incertitudes.38

Figure A.1 – Représentation d'un masque d'étalonnage en forme de grille .42

Figure A.2 – Représentation d'un masque d'étalonnage en forme d'anneau .44

Figure A.3 – Calcul du décalage correctif .44

61745 © IEC:1998 – 3 –

CONTENTS

Page

FOREWORD.5

Clause

1 General.7

1.1 Scope and object.7

1.2 Definitions.7

1.3 Geometrical parameters of optical fibres .13

1.4 Description of geometry test sets .13

1.5 Calibration standard requirements .15

2 Calibration .15

2.1 Introductory remark.15

2.2 Rationale for calibration of geometry test sets .15

2.3 Calibration procedure .17

2.4 Check calibration procedure .23

2.5 Spatial linearity.23

2.6 Calibration of core/cladding concentricity error measurement .23

2.7 Calibration of non-circularity measurement.23

3 Evaluation of uncertainties .25

3.1 Introductory remark.25

3.2 Evaluation of uncertainty in test set calibration .25

3.3 Evaluation of uncertainty in fibre measurement .29

3.4 Evaluation of uncertainty in chromium mask measurement.31

3.5 Summary.33

4 Documentation.33

4.1 Records.33

4.2 Certificate of calibration .33

4.3 Sample calibration certificate .37

Annex A (informative) Derivation of calibration factors .41

Annex B (informative) Worked examples for the determination of calibration factors .47

Annex C (normative) Calculation of uncertainties.49

Annex D (informative) Worked examples for the determination of uncertainties.55

Annex E (informative) Generation of working standards .59

Annex F (informative) Estimation of uncertainty in the measurement of core/cladding

concentricity error .61

Annex G (informative) Estimation of uncertainty in the measurement of non-circularity.67

Figure 1 – Example of a calibration chain and the accumulation of uncertainties .39

Figure A.1 – Representation of a grid calibration mask .43

Figure A.2 – Representation of an annulus calibration mask .45

Figure A.3 – Derivation of correction offset.45

– 4 – 61745 © CEI:1998

COMMISSION ELECTROTECHNIQUE INTERNATIONALE

__________

PROCÉDURE D'ANALYSE D'IMAGE D’EXTRÉMITÉ POUR L'ÉTALONNAGE

DE DISPOSITIFS D'ESSAIS DE GÉOMÉTRIE DES FIBRES OPTIQUES

AVANT-PROPOS

1) La CEI (Commission Électrotechnique Internationale) est une organisation mondiale de normalisation composée

de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a pour objet de

favoriser la coopération internationale pour toutes les questions de normalisation dans les domaines de

l'électricité et de l'électronique. A cet effet, la CEI, entre autres activités, publie des Normes internationales.

Leur élaboration est confiée à des comités d'études, aux travaux desquels tout Comité national intéressé par le

sujet traité peut participer. Les organisations internationales, gouvernementales et non gouvernementales, en

liaison avec la CEI, participent également aux travaux. La CEI collabore étroitement avec l'Organisation

Internationale de Normalisation (ISO), selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux intéressés

sont représentés dans chaque comité d’études.

3) Les documents produits se présentent sous la forme de recommandations internationales. Ils sont publiés

comme normes, spécifications techniques, rapports techniques ou guides et agréés comme tels par les Comités

nationaux.

4) Dans le but d'encourager l'unification internationale, les Comités nationaux de la CEI s'engagent à appliquer de

façon transparente, dans toute la mesure possible, les Normes internationales de la CEI dans leurs normes

nationales et régionales. Toute divergence entre la norme de la CEI et la norme nationale ou régionale

correspondante doit être indiquée en termes clairs dans cette dernière.

5) La CEI n’a fixé aucune procédure concernant le marquage comme indication d’approbation et sa responsabilité

n’est pas engagée quand un matériel est déclaré conforme à l’une de ses normes.

6) L’attention est attirée sur le fait que certains des éléments de la présente Norme internationale peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 61745 a été établie par le comité d'études 86 de la CEI: Fibres

optiques.

La présente version bilingue, publiée en 2001-03, correspond à la version anglaise.

Le texte anglais de cette norme est basé sur les documents 86/125/FDIS et 86/134/RVD. Le

rapport de vote 86/134/RVD donne toute information sur le vote ayant abouti à l’approbation de

cette norme.

La version française de cette norme n’a pas été soumise au vote.

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 3.

L'annexe C fait partie intégrante de la présente norme.

Les annexes A, B, D, E, F et G ne sont fournies qu'à titre d'information.

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant 2005. A cette

date, la publication sera

• reconduite;

• supprimée;

• remplacée par une édition révisée, ou

• amendée.

61745 © IEC:1998 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

__________

END-FACE IMAGE ANALYSIS PROCEDURE FOR THE CALIBRATION

OF OPTICAL FIBRE GEOMETRY TEST SETS

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International Organization

for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61745 has been prepared by IEC technical committee 86: Fibre

optics.

This bilingual version, published in 2001-03, corresponds to the English version.

The text of this standard is based on the following documents:

FDIS Report on voting

86/125/FDIS 86/134/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

Annex C forms an integral part of this standard.

Annexes A, B, D, E, F and G are for information only.

The committee has decided that the contents of this publication will remain unchanged

until 2005. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 6 – 61745 © CEI:1998

PROCÉDURE D'ANALYSE D'IMAGE D’EXTRÉMITÉ POUR L'ÉTALONNAGE

DE DISPOSITIFS D'ESSAIS DE GÉOMÉTRIE DES FIBRES OPTIQUES

1 Généralités

1.1 Domaine d'application et objet

Dans les environnements de la recherche et de la production, il existe une gamme de

méthodes d'essais pour caractériser la géométrie des fibres optiques. En outre, chaque

méthode d'essai peut déterminer un ou plusieurs paramètres permettant une caractérisation

complète de la géométrie. La présente Norme internationale décrit l'étalonnage de dispositifs

d'essais qui effectuent une analyse d'image d’extrémité, également appelée «analyse de

champ proche» ou «analyse d'échelle de gris». Les principes peuvent toutefois être appliqués

à des dispositifs d'essais d'un type différent.

La présente norme traite de l'étalonnage des mesures effectuées uniquement sur des fibres

optiques unimodales; cependant, ce type de dispositif d’essai peut être également utilisé pour

mesurer les paramètres géométriques de cœurs de fibres multimodales, mais l'évaluation des

incertitudes associées à ces mesures ne s'inscrit pas dans le domaine d’application de la

présente norme.

Les procédures indiquées sont à utiliser par des laboratoires d'étalonnage et par les fabricants

ou utilisateurs de dispositifs d'essais de géométrie, à des fins d'étalonnage de dispositifs

d’essais de géométrie et à des fins d'évaluation des incertitudes des mesures effectuées sur

des dispositifs d'essais étalonnés. La présente norme ne couvre pas l'étalonnage de dispositifs

d’essais pour le revêtement primaire de la fibre ou pour la mesure du câble.

La présente norme a pour objet de définir une procédure normale pour l'étalonnage de

dispositifs d'essais afin de mesurer la géométrie du verre des fibres optiques.

1.2 Définitions

Pour les besoins de la présente Norme internationale, les définitions suivantes s'appliquent.

1.2.1

laboratoire d'étalonnage agréé

laboratoire d'étalonnage autorisé par le laboratoire national de normalisation approprié à

émettre des certificats d'étalonnage avec une incertitude spécifiée qui démontrent la traçabilité

à des étalons nationaux

1.2.2

artefact

tout objet mesuré sur un dispositif d’essai de géométrie ou utilisé pour étalonner un dispositif

d’essai de géométrie. Il peut s'agir, par exemple, d'une fibre optique ou d'un motif en chrome

sur verre

1.2.3

étalonnage

procédé établissant la relation existant entre les valeurs indiquées par le dispositif d’essai de

géométrie en cours d'étalonnage et les valeurs connues de l'étalon pour étalonnage.

L'étalonnage a pour objet d’inscrire tous les dispositifs d'essais de géométrie dans un accord

substantiel avec un laboratoire national de normalisation. Ce résultat peut être obtenu par le

réglage du dispositif d’essai de géométrie ou par la documentation du ou des facteurs d'étalon-

nage dans un certificat d'étalonnage. L'environnement et les conditions des instruments au

moment de l'étalonnage sont habituellement enregistrés. L'étalonnage comprend l'estimation

de toutes les incertitudes

61745 © IEC:1998 – 7 –

END-FACE IMAGE ANALYSIS PROCEDURE FOR THE CALIBRATION

OF OPTICAL FIBRE GEOMETRY TEST SETS

1 General

1.1 Scope and object

In the research and production environments there exists a range of test methods for

characterizing the geometry of optical fibres. Furthermore, each test method may determine

one or more of the many parameters required for complete geometrical characterization. This

International Standard describes the calibration of test sets which perform end-face image

analysis, also known as near-field or grey-scale analysis. The principles, however, may be

applied to test sets of a different type.

This standard addresses the calibration of measurements made on single-mode fibres only;

however, this type of test set may also be used to measure the geometrical parameters of the

cores of multimode fibres, but the evaluation of uncertainties associated with these

measurements is beyond the scope of this standard.

The procedures outlined are to be performed by calibration laboratories and by the

manufacturers or users of geometry test sets, for the purpose of calibrating geometry test sets

and for evaluating the uncertainties in measurements made on calibrated test sets. The

calibration of fibre coating or cable measurement test sets is not covered by this standard.

The object of this standard is to define a standard procedure for the calibration of test sets for

measuring the glass geometry of optical fibres.

1.2 Definitions

For the purpose of this International Standard, the following definitions apply.

1.2.1

accredited calibration laboratory

calibration laboratory authorised by the appropriate National Standards laboratory to issue

calibration certificates with a specified uncertainty, which demonstrate traceability to national

standards

1.2.2

artefact

any object that is measured on or used to calibrate a geometry test set. An artefact may be, for

example, an optical fibre or a chromium-on-glass pattern

1.2.3

calibration

process by which the relationship between the values indicated by the geometry test set under

calibration and the known values of the calibration standard is established. The purpose of

calibration is to bring all geometry test sets into substantial agreement with a national

standards laboratory. This may be performed either by adjustment of the geometry test set or

by documentation of a calibration factor(s) in a calibration certificate. The pertaining

environment and instrument conditions at the time of calibration are usually recorded.

Calibration includes estimation of all uncertainties.

– 8 – 61745 © CEI:1998

1.2.4

chaîne d'étalonnage

chaîne de transferts, d'un étalon national au dispositif d’essai de géométrie, réalisés par des

étalons intermédiaires ou des étalons de travail (se reporter à la figure 1)

1.2.5

vérification d'étalonnage

détermination qu'un dispositif d’essai de géométrie précédemment étalonné mais ayant atteint

sa date limite d'étalonnage demeure dans les limites d'incertitude spécifiées. Si le dispositif

d’essai de géométrie a dérivé hors de ces limites, un réétalonnage est nécessaire. Autrement,

la période de revérification peut être prolongée d’une période déclarée. Le dispositif d’essai

peut être contrôlé à l'aide d'un étalon de travail

1.2.6

étalon pour étalonnage

artefact étalonné par rapport à un étalon de référence et utilisé pour étalonner des dispositifs

d'essais. Il peut s'agir d'une fibre optique ou d'un motif en chrome sur verre. L'usage correct

d'un étalon pour étalonnage garantit la traçabilité. Le terme comprend l'étalon de référence,

l'étalon de transfert et l'étalon ou les étalons de travail, dans l'ordre décroissant de l'incertitude

métrologique

1.2.7

incertitude type combinée

combinaison de plusieurs incertitudes types individuelles.

Il convient d'éviter le terme «exactitude» dans ce contexte.

Dans les rapports d'étalonnage et les fiches techniques, l'incertitude type combinée dans la

mesure des dispositifs d'essais de géométrie est rapportée comme une incertitude étendue

globale, avec le niveau de confiance applicable, par exemple 95,5 % ou 99,7 %

1.2.8

niveau de confiance

estimation de la probabilité que la valeur vraie d'un paramètre mesuré s’inscrit dans les limites

d’une plage donnée (incertitude étendue)

1.2.9

décalage correctif

nombre ajouté ou soustrait au résultat de la mesure d'un dispositif d’essai afin de corriger un

effet physique connu

1.2.10

facteur de couverture, k

facteur utilisé pour calculer l'incertitude étendue U à partir de l'incertitude type

1.2.11

incertitude étendue, U

étendue de valeurs à l’intérieur de laquelle la valeur vraie du paramètre mesuré, au niveau de

confiance déclaré, est supposée se trouver. Elle est également appelée «intervalle de confiance»

et est égale au produit du facteur de couverture k par l'incertitude type u:

U = k ⋅ u

Il convient de spécifier sous la forme d'incertitude étendue l'incertitude de mesure d'un

dispositif d’essai de géométrie.

NOTE Lorsque la distribution des incertitudes est supposée normale et qu'on effectue un grand nombre de

mesures, les niveaux de confiance à 68,3 %, 95,5 % et 99,7 % correspondent respectivement à des valeurs pour k

de 1, 2, et 3 (voir l'article C.3).

61745 © IEC:1998 – 9 –

1.2.4

calibration chain

chain of transfers from a national standard to the geometry test set through intermediate or

working standards (see figure 1)

1.2.5

calibration checking

establishing that a geometry test set that has been previously calibrated but has reached its

calibration due date remains within specified uncertainty limits. If the geometry test set has