IEC TR 61094-10:2022

(Main)Electroacoustics - Measurement microphones - Part 10: Absolute pressure calibration of microphones at low frequencies using calculable pistonphones

Electroacoustics - Measurement microphones - Part 10: Absolute pressure calibration of microphones at low frequencies using calculable pistonphones

IEC TR 61904-10:2022

- is applicable to laboratory standard microphones meeting the requirements of IEC 61094-1 and other types of measurement microphones,

- describes one possible absolute method for determining the complex pressure sensitivity, based on a device capable of generating a known sound pressure, especially at low frequencies, and

- provides a reproducible and accurate basis for the measurement of sound pressure at low frequencies.

All quantities are expressed in SI units.

General Information

- Status

- Published

- Publication Date

- 03-Aug-2022

- Technical Committee

- TC 29 - Electroacoustics

- Drafting Committee

- WG 5 - TC 29/WG 5

- Current Stage

- PPUB - Publication issued

- Start Date

- 04-Aug-2022

- Completion Date

- 26-Aug-2022

Overview

IEC TR 61094-10:2022 - "Electroacoustics - Measurement microphones - Part 10: Absolute pressure calibration of microphones at low frequencies using calculable pistonphones" - describes an absolute calibration method for measurement microphones using a calculable pistonphone. The technical report is applicable to laboratory standard microphones (per IEC 61094-1) and other measurement microphones, and provides a reproducible, SI‑unit based basis for determining complex pressure sensitivity at low frequencies without reliance on a secondary microphone.

Key topics and technical requirements

- Principle: Calibration is based on generating a known sound pressure in a sealed cavity (coupler) driven by a piston with a calculable volume velocity. The microphone’s pressure sensitivity M is obtained from the measured output voltage and the calculated sound pressure.

- Acoustic transfer impedance (ZT): The sound pressure at the microphone diaphragm is derived from the cavity’s acoustic transfer impedance and the piston’s displacement/volume velocity.

- Piston displacement measurement: Rigid piston frontal area and displacement are measured (e.g., laser interferometry or other displacement techniques) to determine volume velocity.

- Corrections and limits: The report includes heat‑conduction corrections, operating frequency range considerations, and guidance on ensuring uniform pressure distribution within the cavity.

- Environmental reference conditions: Reference conditions are defined (23.0 °C, 101.325 kPa, 50 % RH) and all quantities are expressed in SI units.

- Influencing factors: Treatment of factors that affect pressure sensitivity such as polarizing voltage, shield configuration, static pressure, temperature, humidity, vibration and distortion.

- Uncertainty analysis: Framework for calibration uncertainty components, example uncertainty budgets, and combined/expanded uncertainties (informative Annex B).

- Design examples: Informative Annex A provides example pistonphone designs (including laser pistonphones) to aid implementation.

Applications and who uses it

- National metrology institutes (NMIs) and calibration laboratories performing absolute pressure calibration of measurement and laboratory standard microphones at low frequencies.

- Acoustic calibration labs needing a primary or absolute method alternative to reciprocity techniques (IEC 61094-2).

- Manufacturers of measurement microphones and pistonphones designing calibration hardware and validating low‑frequency microphone performance.

- Acoustics engineers and quality assurance teams requiring traceable, reproducible low‑frequency microphone sensitivity data for sound measurement systems.

Related standards

- IEC 61094-1: Specifications for laboratory standard microphones

- IEC 61094-2: Primary pressure calibration by the reciprocity technique (related calibration method)

Keywords: IEC TR 61094-10:2022, absolute pressure calibration, calculable pistonphone, measurement microphones, low-frequency calibration, acoustic transfer impedance, microphone sensitivity, calibration uncertainty.

Get Certified

Connect with accredited certification bodies for this standard

BSMI (Bureau of Standards, Metrology and Inspection)

Taiwan's standards and inspection authority.

Sponsored listings

Frequently Asked Questions

IEC TR 61094-10:2022 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Electroacoustics - Measurement microphones - Part 10: Absolute pressure calibration of microphones at low frequencies using calculable pistonphones". This standard covers: IEC TR 61904-10:2022 - is applicable to laboratory standard microphones meeting the requirements of IEC 61094-1 and other types of measurement microphones, - describes one possible absolute method for determining the complex pressure sensitivity, based on a device capable of generating a known sound pressure, especially at low frequencies, and - provides a reproducible and accurate basis for the measurement of sound pressure at low frequencies. All quantities are expressed in SI units.

IEC TR 61904-10:2022 - is applicable to laboratory standard microphones meeting the requirements of IEC 61094-1 and other types of measurement microphones, - describes one possible absolute method for determining the complex pressure sensitivity, based on a device capable of generating a known sound pressure, especially at low frequencies, and - provides a reproducible and accurate basis for the measurement of sound pressure at low frequencies. All quantities are expressed in SI units.

IEC TR 61094-10:2022 is classified under the following ICS (International Classification for Standards) categories: 17.140.50 - Electroacoustics. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 61094-10:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TR 61094-10 ®

Edition 1.0 2022-08

TECHNICAL

REPORT

colour

inside

Electroacoustics – Measurement microphones –

Part 10: Absolute pressure calibration of microphones at low frequencies using

calculable pistonphones

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 19 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TR 61094-10 ®

Edition 1.0 2022-08

TECHNICAL

REPORT

colour

inside

Electroacoustics – Measurement microphones –

Part 10: Absolute pressure calibration of microphones at low frequencies using

calculable pistonphones

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 17.140.50 ISBN 978-2-8322-4374-9

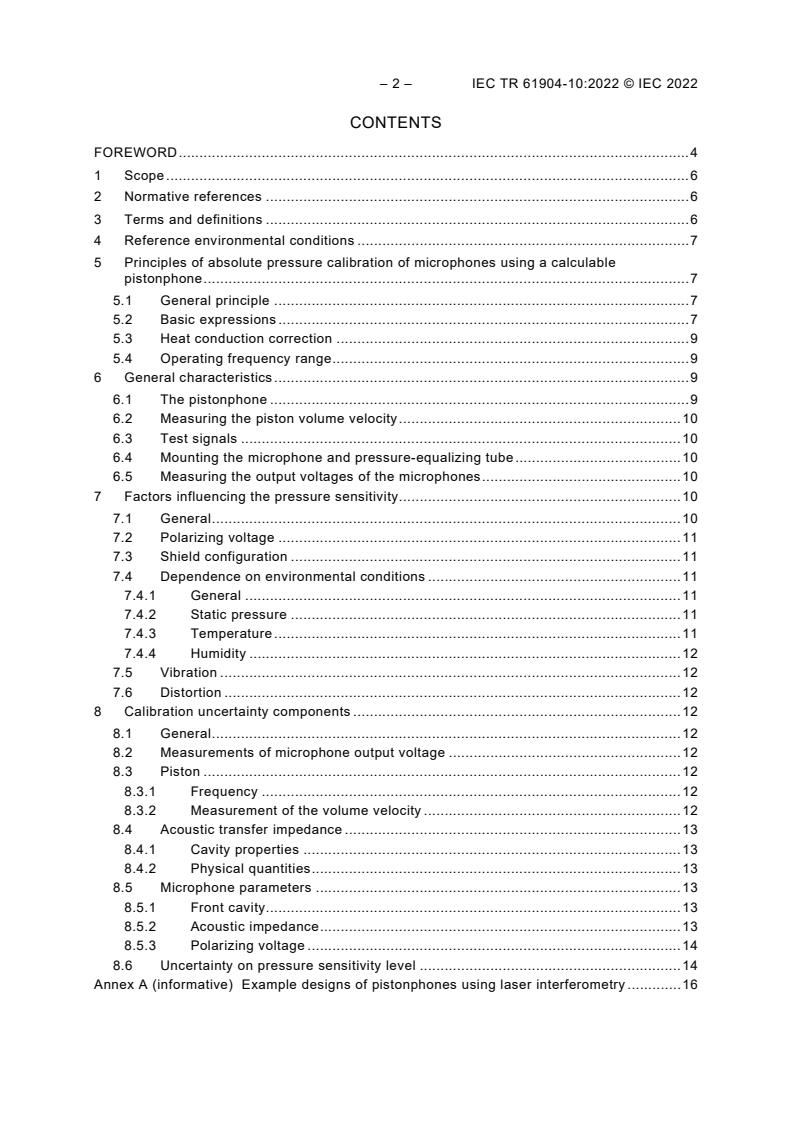

– 2 – IEC TR 61904-10:2022 © IEC 2022

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Reference environmental conditions . 7

5 Principles of absolute pressure calibration of microphones using a calculable

pistonphone . 7

5.1 General principle . 7

5.2 Basic expressions . 7

5.3 Heat conduction correction . 9

5.4 Operating frequency range . 9

6 General characteristics . 9

6.1 The pistonphone . 9

6.2 Measuring the piston volume velocity . 10

6.3 Test signals . 10

6.4 Mounting the microphone and pressure-equalizing tube . 10

6.5 Measuring the output voltages of the microphones . 10

7 Factors influencing the pressure sensitivity. 10

7.1 General . 10

7.2 Polarizing voltage . 11

7.3 Shield configuration . 11

7.4 Dependence on environmental conditions . 11

7.4.1 General . 11

7.4.2 Static pressure . 11

7.4.3 Temperature . 11

7.4.4 Humidity . 12

7.5 Vibration . 12

7.6 Distortion . 12

8 Calibration uncertainty components . 12

8.1 General . 12

8.2 Measurements of microphone output voltage . 12

8.3 Piston . 12

8.3.1 Frequency . 12

8.3.2 Measurement of the volume velocity . 12

8.4 Acoustic transfer impedance . 13

8.4.1 Cavity properties . 13

8.4.2 Physical quantities . 13

8.5 Microphone parameters . 13

8.5.1 Front cavity. 13

8.5.2 Acoustic impedance . 13

8.5.3 Polarizing voltage . 14

8.6 Uncertainty on pressure sensitivity level . 14

Annex A (informative) Example designs of pistonphones using laser interferometry . 16

IEC TR 61904-10:2022 © IEC 2022 – 3 –

Annex B (informative) Measurement uncertainties . 18

B.1 General . 18

B.2 Example of a typical uncertainty analysis . 18

B.2.1 General . 18

B.2.2 Uncertainty budget . 18

B.2.3 Combined and expanded uncertainties . 19

Bibliography . 20

Figure 1 – Equivalent circuit for evaluating the sound pressure over the exposed

surface of the diaphragm of the microphone . 8

Figure A.1 – Schematic cross-section of a laser pistonphone . 16

Figure A.2 – Example of laser pistonphone . 17

Figure A.3 – Example of laser pistonphone . 17

Table 1 – Uncertainty components . 14

Table B.1 – Example of uncertainty budget at 1 Hz . 19

– 4 – IEC TR 61904-10:2022 © IEC 2022

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTROACOUSTICS –

MEASUREMENT MICROPHONES –

Part 10: Absolute pressure calibration of microphones

at low frequencies using calculable pistonphones

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC TR 61094-10 has been prepared by IEC technical committee 29: Electroacoustics. It is a

Technical Report.

The text of this Technical Report is based on the following documents:

Draft Report on voting

29/1113/DTR 29/1124/RVDTR

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this Technical Report is English.

IEC TR 61904-10:2022 © IEC 2022 – 5 –

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 61094 series, published under the general title Electroacoustics –

Measurement microphones, can be found on the IEC website.

Future documents in this series will carry the new general title as cited above. Titles of existing

documents in this series will be updated at the time of the next edition.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

– 6 – IEC TR 61904-10:2022 © IEC 2022

ELECTROACOUSTICS –

MEASUREMENT MICROPHONES –

Part 10: Absolute pressure calibration of microphones

at low frequencies using calculable pistonphones

1 Scope

This part of IEC 61094

• is applicable to laboratory standard microphones meeting the requirements of IEC 61094-1

and other types of measurement microphones,

• describes one possible absolute method for determining the complex pressure sensitivity,

based on a device capable of generating a known sound pressure, especially at low

frequencies, and

• provides a reproducible and accurate basis for the measurement of sound pressure at low

frequencies.

All quantities are expressed in SI units.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 61094-1:2000, Measurement microphones – Part 1: Specifications for laboratory standard

microphones

IEC 61094-2:2009, Electroacoustics – Measurement microphones – Part 2: Primary method for

pressure calibration of laboratory standard microphones by the reciprocity technique

IEC 61094-2:2009/AMD1:2022

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 61094-1 and

IEC 61094-2 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

pistonphone

device in which sound pressure is generated in a fixed sealed volume of air, by the motion of

one or more pistons creating a well-defined volume velocity

IEC TR 61904-10:2022 © IEC 2022 – 7 –

3.2

calculable pistonphone

pistonphone where the generated sound pressure can be calculated from physical principles

4 Reference environmental conditions

The reference environmental conditions are the following:

• temperature 23,0 °C;

• static pressure 101,325 kPa;

• relative humidity 50 %.

5 Principles of absolute pressure calibration of microphones using a

calculable pistonphone

5.1 General principle

The microphone to be calibrated is exposed to a known or calculable sound pressure produced

within the sealed cavity (or coupler) of a pistonphone, without the need for a prior measurement

with another microphone. The dimensions of the cavity are constrained to allow the assumption

to be made that the sound pressure is uniformly distributed within.

A sound generator consisting of a sealed cavity (or coupler) of known volume that is driven by

a piston or similar mechanism capable of producing a known volume velocity (e.g. an

electrodynamic loudspeaker) has the potential to generate a known sound pressure. If the

piston is assumed to be rigid and of known frontal area, laser interferometry or other

displacement measurement techniques can be used to determine the piston displacement and

thereby derive the volume displacement.

The pressure sensitivity M of the microphone is then determined directly from its open-circuit

p

output voltage U and the applied sound pressure p .

m,0 m

U

m0,

M =

(1)

p

p

m

Alternatively, a microphone system comprising of a microphone, a preamplifier and optionally

and amplifier stage, can be calibrated by the same principle, except that the system output

voltage replaces the open-circuit output voltage of the microphone in Formula (1).

5.2 Basic expressions

The generated sound pressure p that is applied to the diaphragm of the microphone is

m

calculated from an evaluation of the acoustic transfer impedance Z of the cavity and a

T

measurement of the piston displacement 𝛿𝛿𝛿𝛿.

The acoustic transfer impedance is the constant of proportionality between the sound pressure

at the microphone diaphragm and the volume velocity driving the cavity. In the case of a

sinusoidally driven rigid piston, the volume velocity is given by the product of the piston area

S , the piston displacement and a factor jω, where ω is the angular frequency:

p

pjω Sδx⋅Z

(2)

m pT

=

– 8 – IEC TR 61904-10:2022 © IEC 2022

If the piston is not rigid, calculation of the volume velocity requires the surface integral of

displacement to be determined, for example with scanning interferometry.

The acoustic transfer impedance can be calculated when the cavity has a simple geometry

enabling its volume, V to be determined. When the characteristic cavity dimensions are

significantly smaller than the acoustic wavelength, λ (typically when V λ ), then the sound

pressure can be assumed to be uniformly distributed within the cavity. Then, assuming adiabatic

compression and expansion of the gas and that the cavity is perfectly sealed, the acoustic

impedance of the cavity Z is κ P /(jωV), where κ is the ratio of specific heats for air and P is

c s s

the static pressure inside the cavity. From the equivalent circuit in Figure 1, Z is then given by:

T

V

1 11 V

e,m

= += jω +

(3)

Z ZZ κP κP

T C m S r S,r

where

V is the equivalent volume of microphone to be calibrated;

e,m

κ and κ are the ratio of the specific heats at measurement conditions and at reference

r

conditions respectively;

P is the reference static pressure.

s,r

Values for κ and κ in humid air can be determined from formulas given in IEC 61094-2:2009,

r

Annex F.

Key

𝜔𝜔 angular frequency

S piston surface area

p

δx piston displacement

q and q volume velocities

m

Z and Z acoustic impedances of the cavity and microphone respectively

c m

p sound pressure acting on the microphone

m

Figure 1 – Equivalent circuit for evaluating the sound pressure over

the exposed surface of the diaphragm of the microphone

At higher frequencies, where the wavelength can no longer be considered sufficiently large

compared to the cavity dimensions, the evaluation of Z generally becomes more complicated

T

and requires the specific geometry of the cavity to be accounted for. The onset of such

behaviour is generally considered to be the upper frequency limit for the operation of the

pistonphone within the scope of this document.

IEC TR 61904-10:2022 © IEC 2022 – 9 –

5.3 Heat conduction correction

The evaluation of Z in Formula (3) assumes adiabatic conditions in the cavity. However, in

T

practice, the influence of heat conduction at the walls of the cavity causes increasing departure

from purely adiabatic conditions as the frequency is reduced, especially for small cavities.

At frequencies where the sound pressure can be considered to be uniformly distributed within

the cavity and under the assumption that the walls remain at a constant temperature, the

influence of the heat conduction losses can be calculated and expressed in terms of a complex

correction factor ΔH to the geometrical volume V in Formula (3). The formulation for the

influence of the heat conduction losses and expressions for a correction factor ΔH, when the

cavity shape is a perfect right circular cylinder, are given in IEC 61094-2:2009 and

IEC 61094-2:2009/AMD1:2022.

5.4 Operating frequency range

The upper frequency limit of operation is likely to be determined by the onset of sound pressure

non-uniformity. This is normally assessed by modelling the sound field within the pistonphone

cavity. The model can be used to determine a correction to account for the non-uniform sound

pressure distribution for the specific cavity geometry, but a point will be reached where the

magnitude of this correction, and therefore the associated uncertainty, becomes unacceptable.

Each cavity geometry will require individual treatment, but an upper frequency limit of around

200 Hz is typically possible when characteristic dimensions are no greater than 60 mm.

It is also possible that the volume velocity source determines the upper frequency of operation.

As the frequency increases, a gr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...